Manufacturing method of water lubricated bearing taking hard rubber as liner

A technology of water-lubricated bearings and hard rubber, which is applied in the field of bearing manufacturing and can solve the problems that high-hardness rubber is not suitable for water-lubricated bearings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The silicone rubber with a hardness of 65 shore D was kneaded at room temperature for 10 min with a double-roll mill to obtain a sheet material with a thickness of 3 mm and a width of 15 mm;

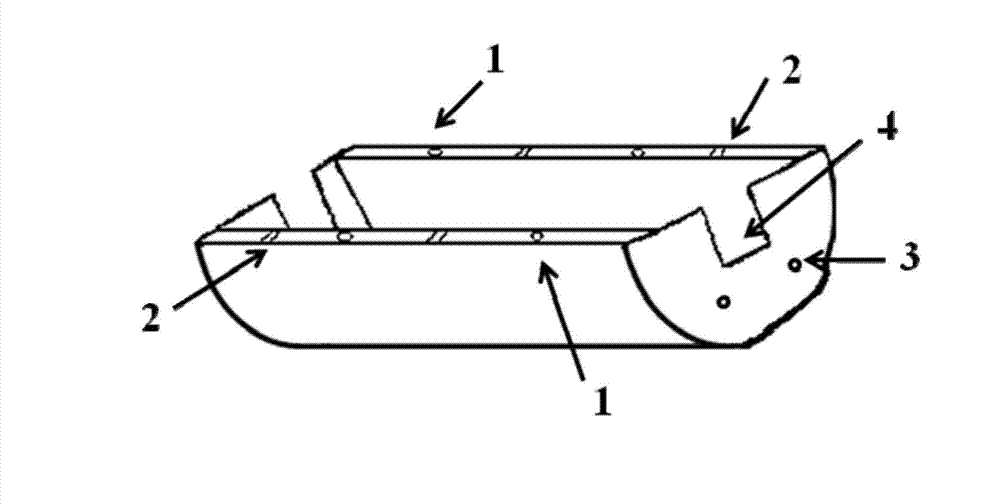

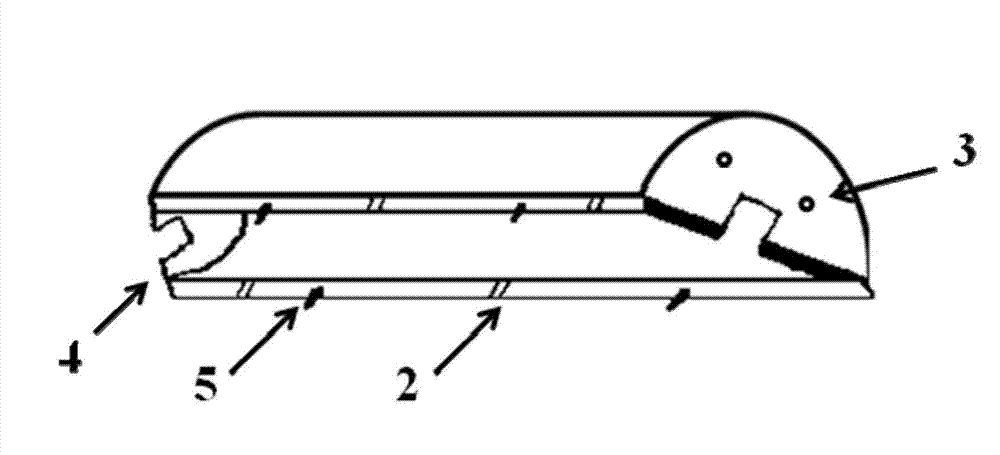

[0036] Coat the core of the mold, the base of the mold and the upper cover of the mold with silicone oil release agent, preheat for 40 minutes at 165 °C, wrap the above-mentioned silicone rubber tightly around the core of the mold, and place it on the base of the mold , cover the upper cover of the mold, the guide post 5 and the screw hole 1 match each other, the gas in the cavity is discharged through the vent hole 2, the excess compounded rubber is extruded out of the mold through the discharge port 3, and fixed through the gap 4 Shaft core, then put the mold into the vulcanizer, vulcanize at 180°C and 10 MPa pressure for 60 minutes, open the mold, take out the shaft core, demould, and get the blank product of water-lubricated bearing bush;

[0037]The blank product of the above...

Embodiment 2

[0039] The acrylonitrile-butadiene rubber that hardness is 60 shore D utilizes double roller open mill to knead 10 min at normal temperature, obtains 3 mm thickness, the sheet material of 15 mm width;

[0040] Coat the core of the mold, the base of the mold and the upper cover of the mold with silicone oil, preheat for 40 minutes at 120 °C, wind the nitrile rubber after mixing tightly on the core of the mold, place it on the base of the mold, cover it On the upper mold cover, the guide post 5 and the screw hole 1 match each other, the gas in the cavity is discharged through the vent hole 2, the excess compound rubber is extruded out of the mold through the discharge port 3, and the shaft core is fixed through the gap 4 , then put the mold into the vulcanizer, vulcanize at 120°C and 10 MPa pressure for 130 minutes, open the mold, take out the shaft core, demould, and obtain the blank product of the water-lubricated bearing bush;

[0041] The above-mentioned water-lubricated bea...

Embodiment 3

[0043] The fluororubber with a hardness of 62 shore D was kneaded at room temperature for 10 min with a double-roller open mill to obtain a sheet material with a thickness of 3 mm and a width of 15 mm;

[0044] Coat the core of the mold shaft, the base of the mold and the upper cover of the mold with silicone oil, preheat for 40 minutes at 180 °C, wrap the above mixed fluororubber tightly around the core of the mold, place it on the base of the mold, and cover it The upper cover of the mold, the guide post 5 and the screw hole 1 match each other, the gas in the cavity is discharged through the vent hole 2, the excess compounded rubber is extruded out of the mold through the discharge port 3, and the shaft core is fixed through the gap 4, Then put the mold into the vulcanizer, vulcanize at 165°C and 10 MPa pressure for 20 minutes, open the mold, take out the shaft core, demould, and obtain the blank product of the water-lubricated bearing bush;

[0045] The above-mentioned wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com