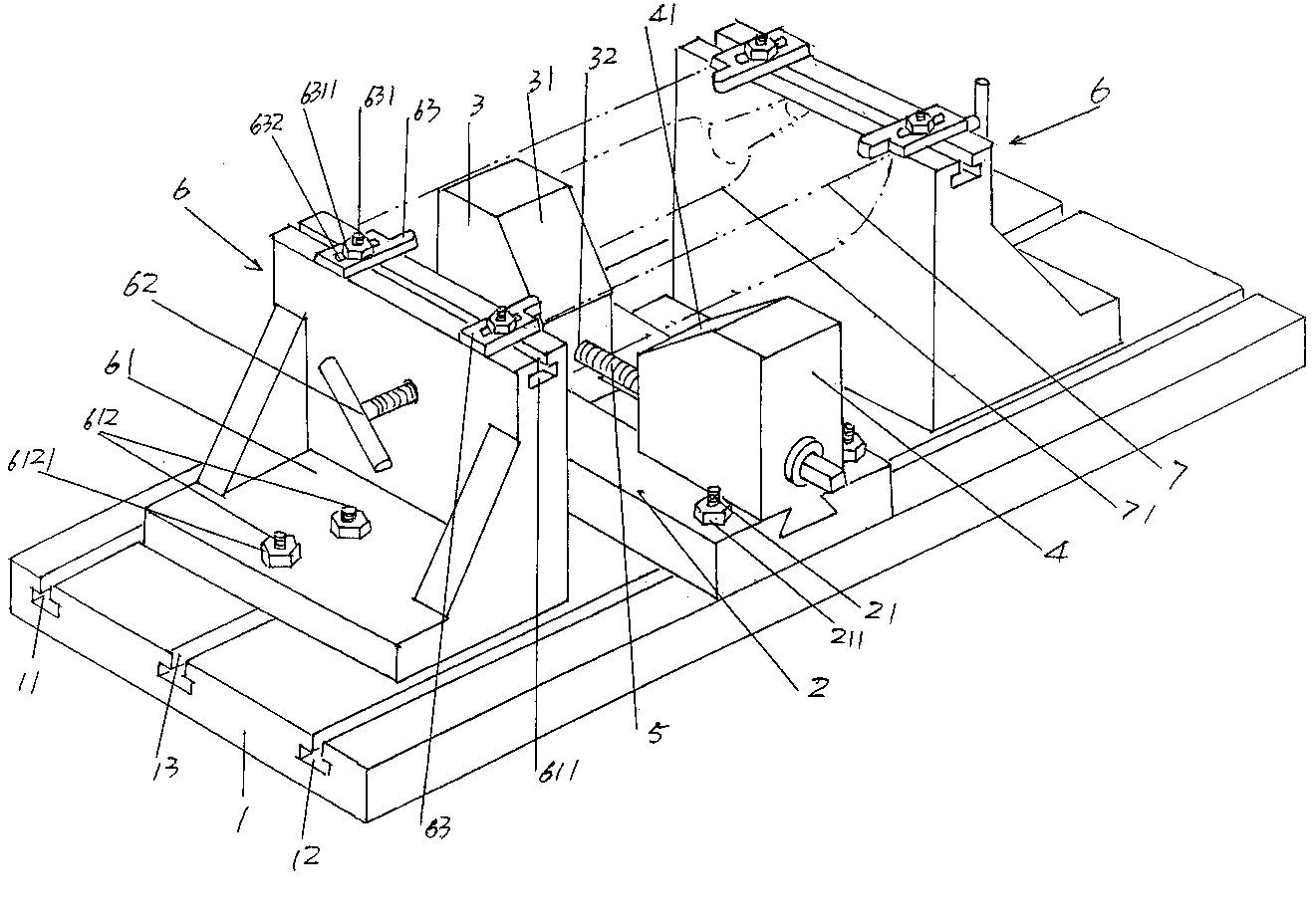

Work fixture for machining inner cavities and joint closing surfaces of glass molds

A glass mold and tooling fixture technology, applied in the field of tooling fixtures, can solve the problems of difficult manufacturing, lack of mold lifting function, high operating intensity, etc., and achieve the effect of simple overall structure, good clamping effect, and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to enable examiners of the Patent Office, especially the public, to more clearly understand the technical essence and beneficial effects of the present invention, the applicant will describe in detail in the form of examples below, but the description of the examples is not intended to describe the solution of the present invention. As a limitation, any equivalent transformations made according to the concept of the present invention that are merely formal rather than substantive should be regarded as the technical solution scope of the present invention.

[0017] See figure 1 , A base plate 1 is given. Since the base plate 1 is fixed to a machining center such as a CNC machine tool in use, it can be called a machine tool rail plate. Under normal circumstances, the base plate 1 is the worktable of the machine tool . When the base plate 1 is in use (that is, as shown in the figure), the surface facing the upper side is provided with first, The second adjustment g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com