Trolley limiting buffer device of bridge crane

An overhead crane and buffer device technology, applied in the field of trolley spare parts, can solve the problems of increased cost, unstable goods, loss of vehicle gear and buffer, and achieve the effects of speeding up the limit speed, saving man-hours and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

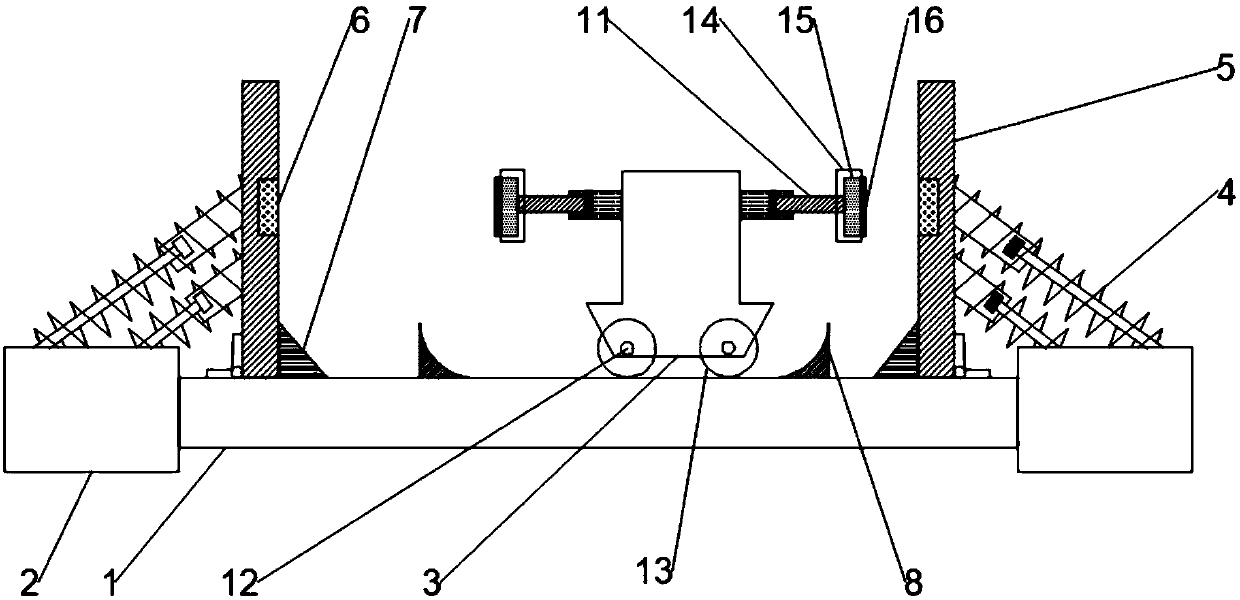

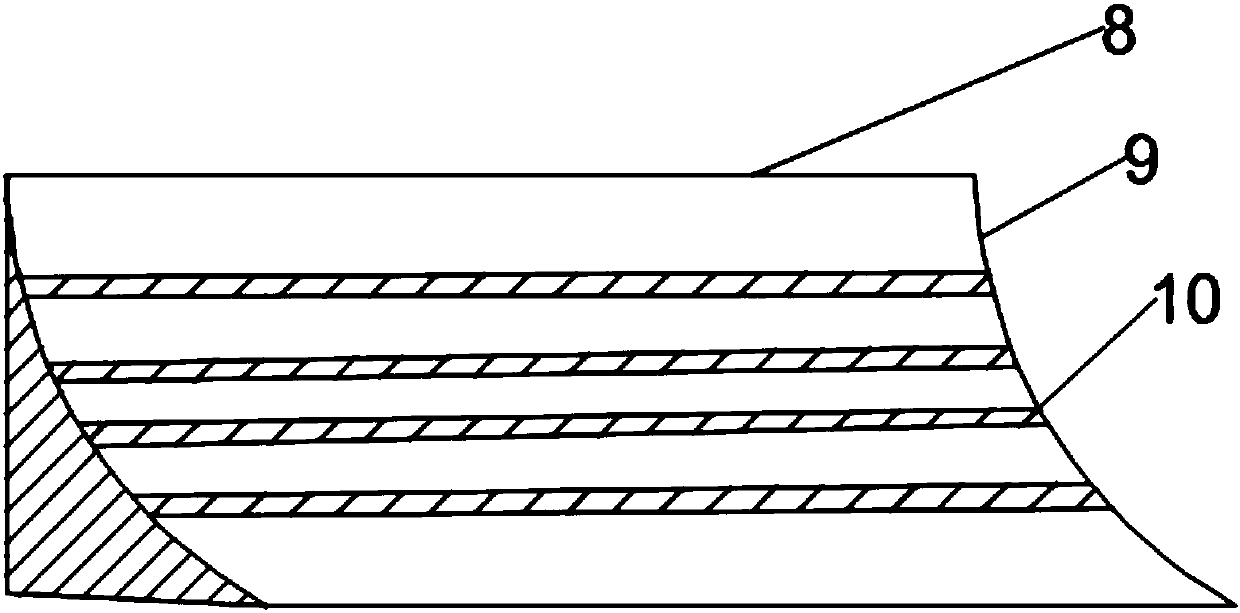

[0025] Such as figure 1 As shown, the present invention provides a trolley limit buffer device for a bridge crane, including a trolley track 1, which allows the trolley to translate left and right on the beam, and the two ends of the trolley track 1 are fixedly installed with end beams 2, and the end beams The beam 2 is perpendicular to the trolley track 1, the trolley track 1 is provided with a trolley frame 3, the left and right sides of the trolley frame 3 are fixed with hydraulic rods 11, and the top surface of the end beam 2 passes through the shock absorber 4 Connected with a gear 5, the shock absorber 4 is installed obliquely and is a rod-shaped shock absorber 4, the number of the shock absorber 4 can be selected according to the size of the collision force, and the shock absorber 4 adopts a hydraulic shock absorber or Spring shock absorbers and hydraulic shock absorbers have a better cushioning effect than spring shock absorbers, but the cost of spring shock absorbers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com