Hybrid type dynamic pressure gas journal bearing

A radial bearing and hybrid technology, applied in sliding contact bearings, rotating bearings, bearings, etc., can solve problems such as insufficient load capacity, insufficient impact resistance, and inability to achieve high-speed operation, and achieve high impact resistance. The effect of capacity and load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

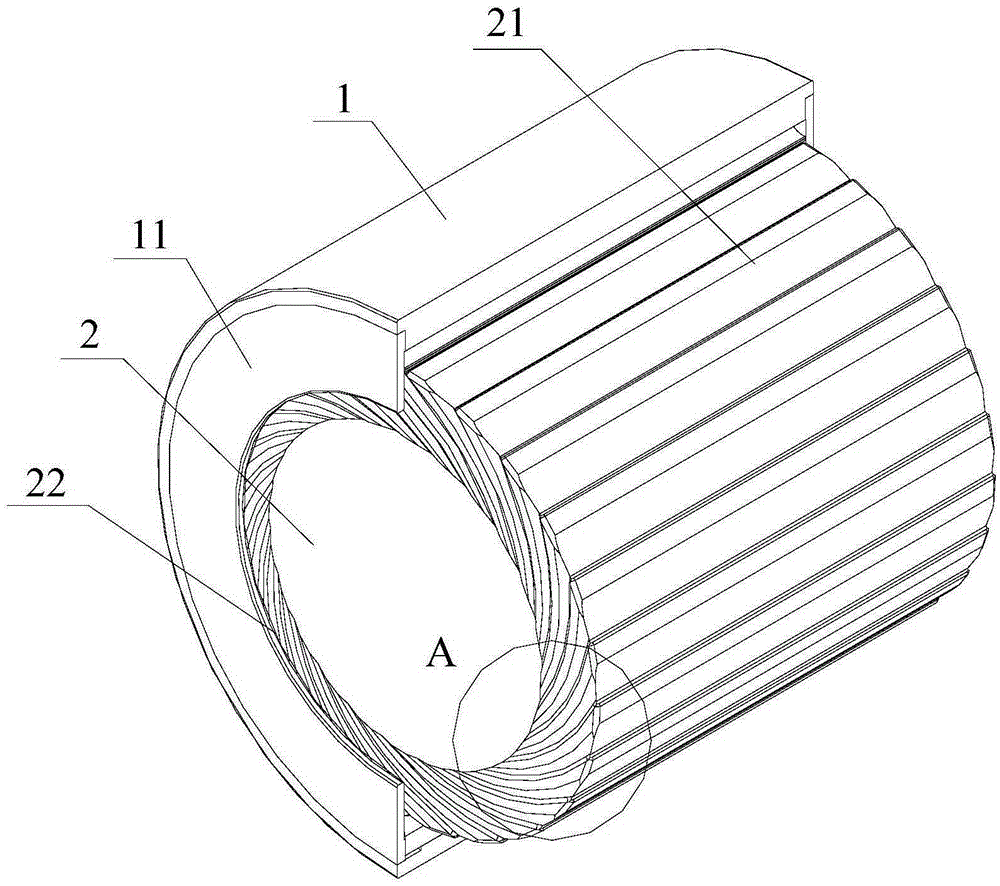

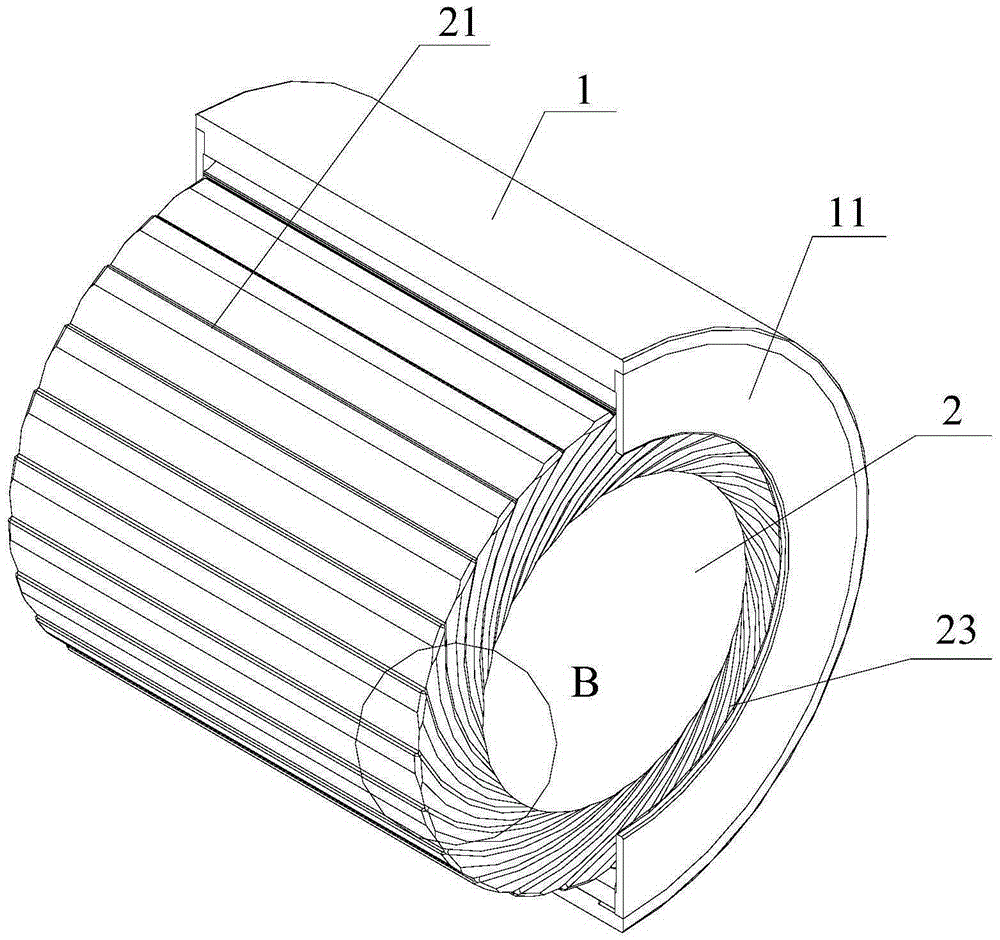

[0042] like figure 1 and image 3 Shown: a hybrid dynamic pressure gas radial bearing provided in this embodiment includes: a bearing outer sleeve 1 and a bearing inner sleeve 2, the outer circumferential surface and the left and right end surfaces of the bearing inner sleeve 2 have regular shapes. The grooves (21, 22 and 23 in the figure, the grooves in this embodiment are all in the shape of an impeller), and the grooves 22 on the left end face and the grooves 23 on the right end face form mirror symmetry.

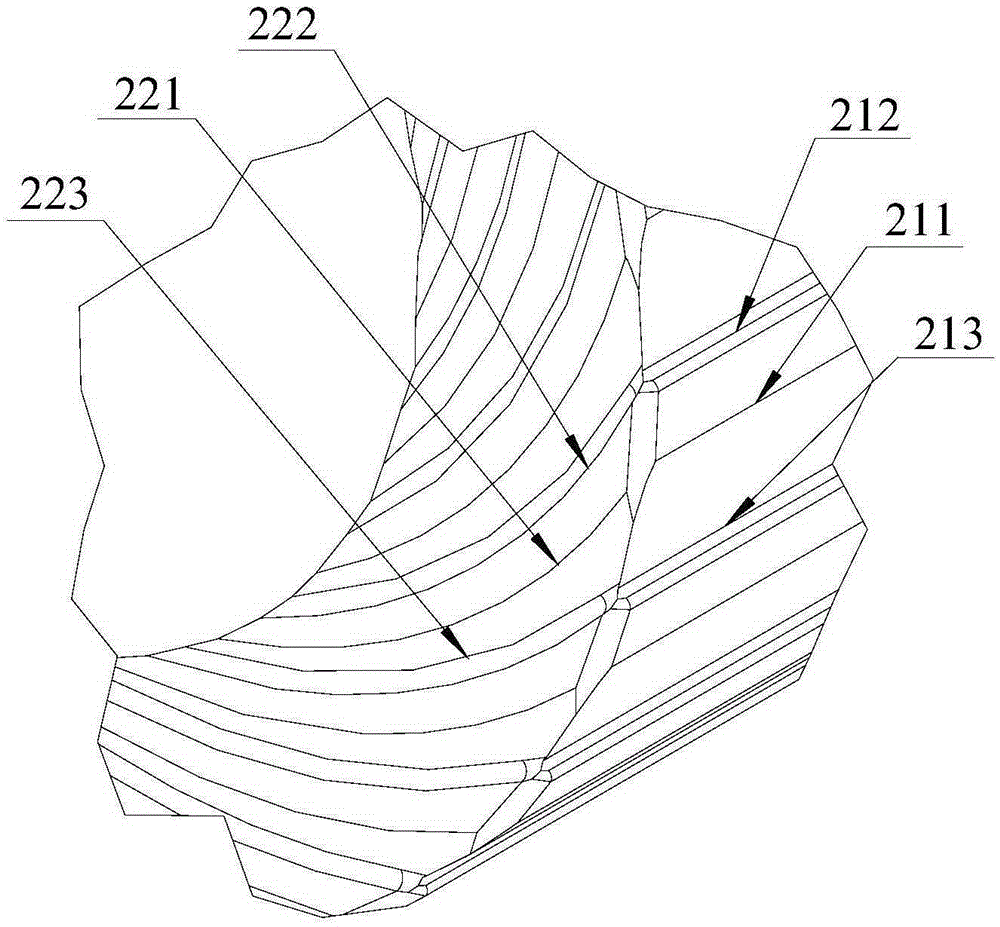

[0043] combine Figure 1 to Figure 4 Shown: the axial contour line of the groove pattern 21 on the outer circumferential surface of the bearing inner sleeve 2 and the radial contour lines of the groove pattern (22 and 23) on the left and right end faces form a one-to-one correspondence and intersect with each other That is: the axial high-order line 211 in the groove pattern 21 on the outer circumferential surface corresponds to the radial high-order line (221 and 231)...

Embodiment 2

[0051] like Figure 8 As shown, the difference between a hybrid dynamic pressure gas radial bearing provided in this embodiment and Embodiment 1 is only that the foil-type elastic member 3 is composed of a corrugated foil 31 and a flat foil 32, and the corrugated foil 31 is composed of a The top end of the arc-shaped protrusion 311 is in contact with the inner circumferential wall of the bearing housing 1 , and the transition bottom edge 312 between the wave arches of the corrugated foil 31 is in contact with the flat foil 32 .

[0052] Figure 9 A schematic diagram of the structure of the corrugated foil 31 is shown.

Embodiment 3

[0054] like Figure 10 and 11 As shown, the difference between the hybrid dynamic pressure gas radial bearing provided in this embodiment and the embodiment 1 is only that the foil elastic member 3 is composed of a flat foil 32 and a flat foil 33 provided with a through hole 331 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com