Magneto-rheological damper

A magneto-rheological damper and damping cylinder technology, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of large axial size, imperfection, and structural oscillation of the piston, and achieve increased The limit speed of the piston, good fail-safe ability, and the effect of preventing settlement and hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

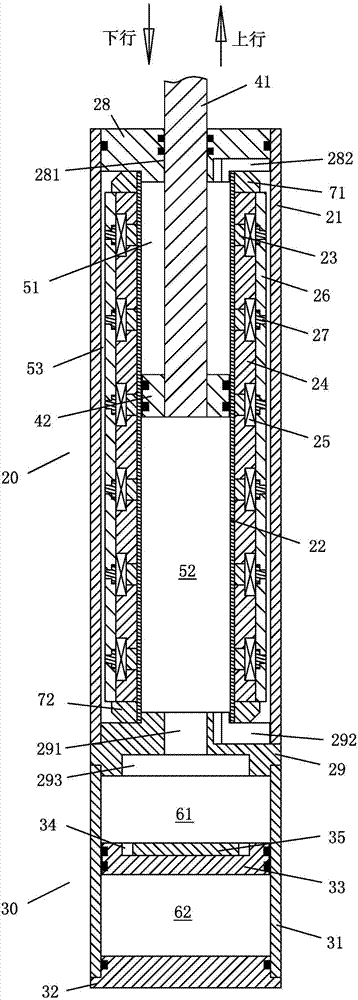

[0053] Such as figure 2 As shown, the magnetorheological damper of the present invention includes a damping cylinder 20, and a compensation cylinder 30 is connected to the bottom of the damping cylinder 20, wherein the damping cylinder 20 adopts a single rod double barrel structure, and the damping cylinder 20 includes a magnetically conductive outer cylinder 21 , The outer cylinder 21 is made of carbon steel or alloy steel pipe with good strength and magnetic conductivity, and a certain wall thickness is required to form the magnetic field line loop. The wall thickness must be determined by considering the magnetic flux and structural strength factors. A non-magnetic inner cylinder 22 is provided. The inner cylinder 22 is made of stainless steel or other non-magnetic pipe with better strength, and the wall thickness is required to be determined by considering the structural strength. The outer wall of the inner cylinder 22 is alternately sheathed A yoke ring 24 and a permanent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com