Secondary bearing with electromagnetic speed regulation in interelectrode

An electromagnetic drive and bearing technology, applied in rotating bearings, rolling contact bearings, bearings, etc., can solve the problem of no correlation between inner and outer ring speeds, and achieve the effect of no mechanical impact, small moment of inertia, and reduced relative speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

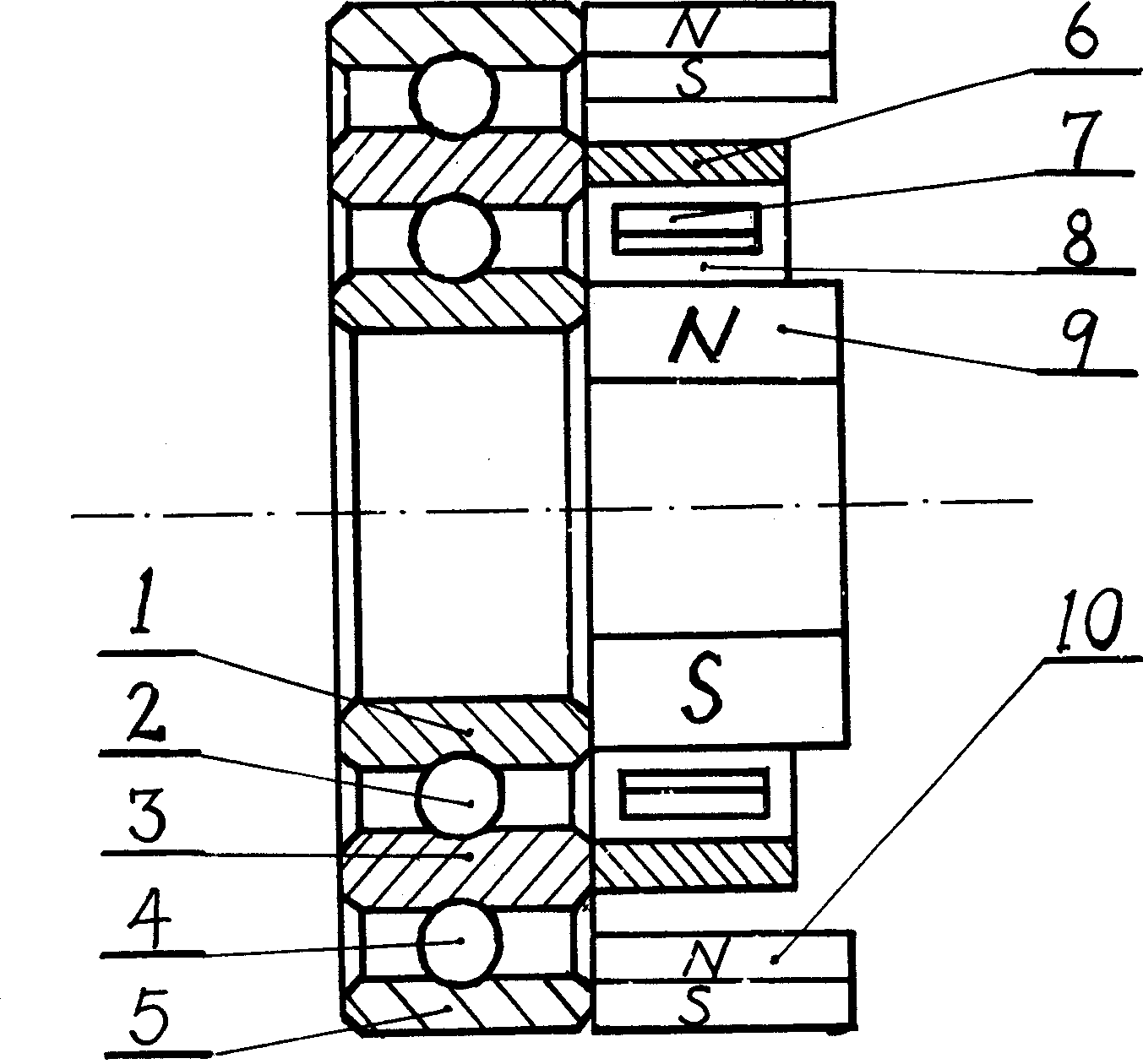

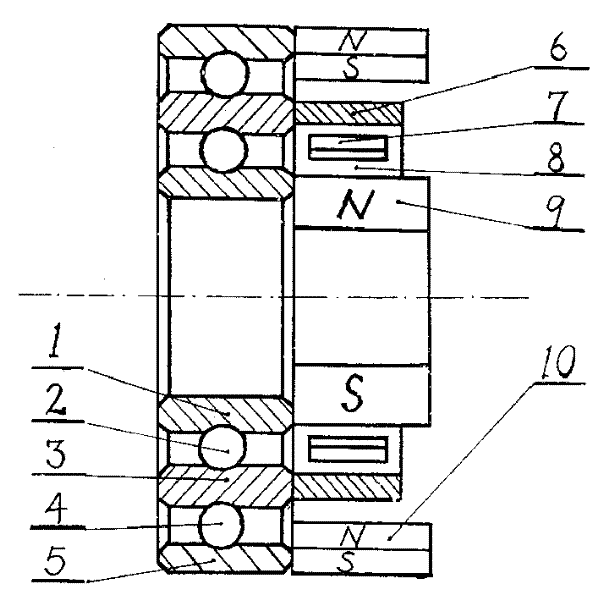

[0020] Please refer to the attached figure 1 .

[0021] Inner ring 1, balls 2, intermediate ring 3, balls 4, and outer ring 5 together form a two-stage radial ball bearing (cage diagram omitted). A permanent magnet 9 is fixedly installed on the right side of the inner ring 1 as an inner stator, so that the direction of the main magnetic pole of the magnet 9 is perpendicular to the axis of the bearing and intersects. On the right side of the middle ring 3, that is, on the same side as the inner stator, a consolidated cage-shaped hollow bronze ring 6 can be installed as a rotor. On the right side of the outer ring 5, a permanent magnet 10 is fixedly installed as an outer stator, so that the direction of the main magnetic pole of the magnet 10 is perpendicular to the axis of the bearing and intersects. Make the magnetic induction intensity of the inner and outer stators at the rotor place equal. Then the inner stator permanent magnet 9, the outer stator permanent magnet 10 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com