Three DOF micro-positioning workbench for nano-imprint lithography system

A photolithography system and nano-imprinting technology, applied in the field of micro-operating systems, can solve the problems of uneven distribution of imprinting force, limitation of processing accuracy and quality, easy stretching and deformation of silica gel, etc., to achieve micro-feed and precise positioning, Eliminate nonlinear, compact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

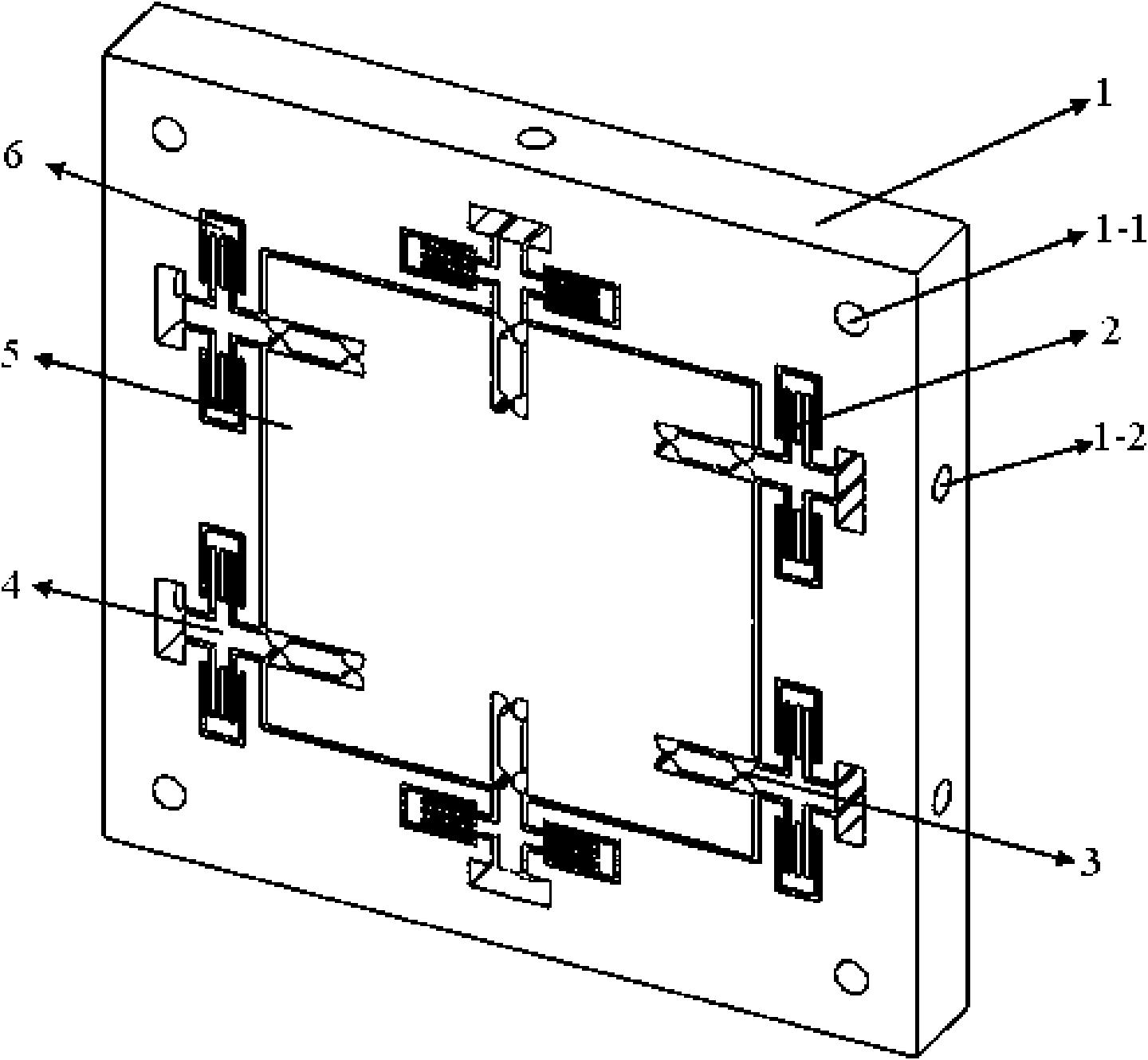

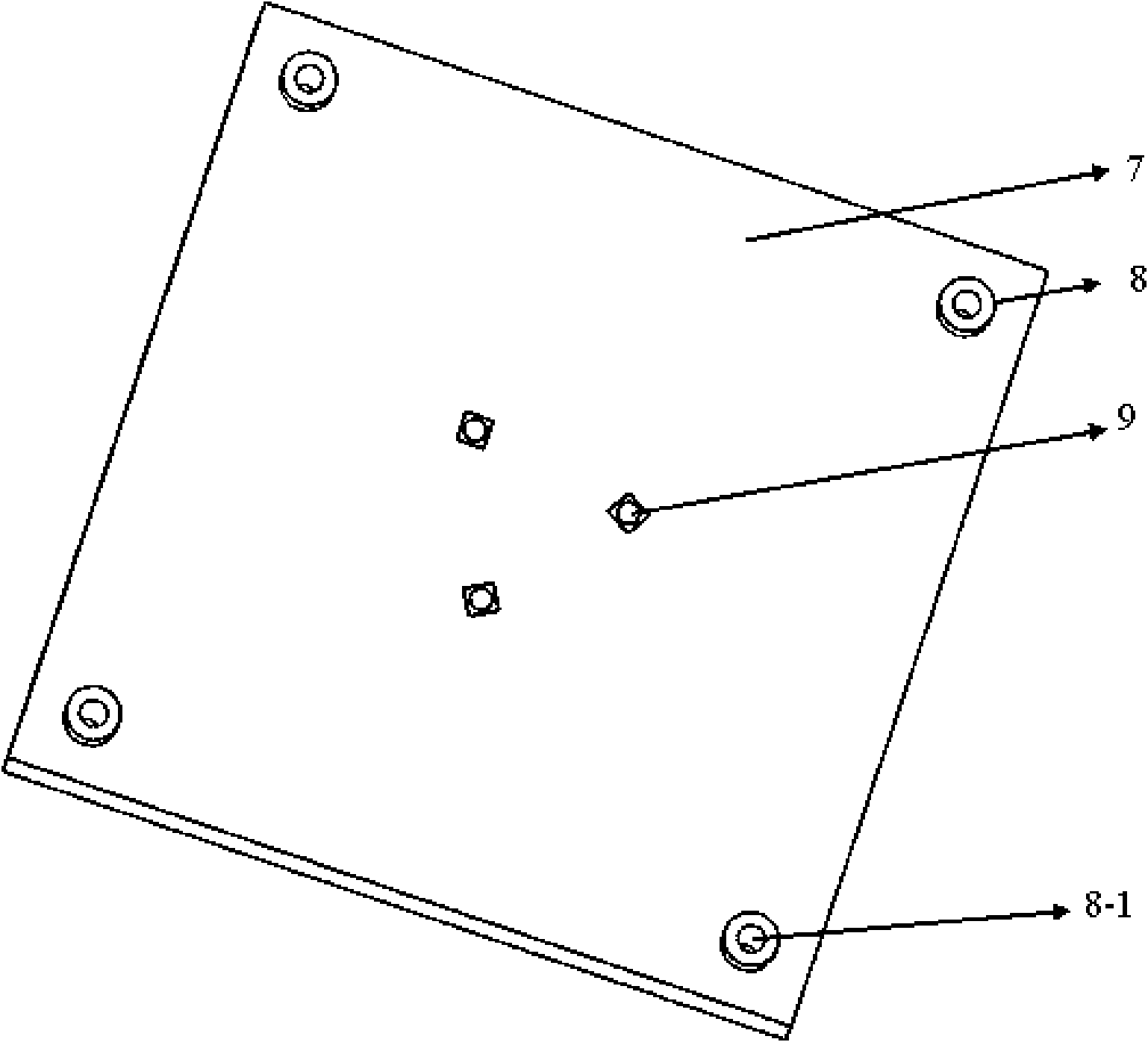

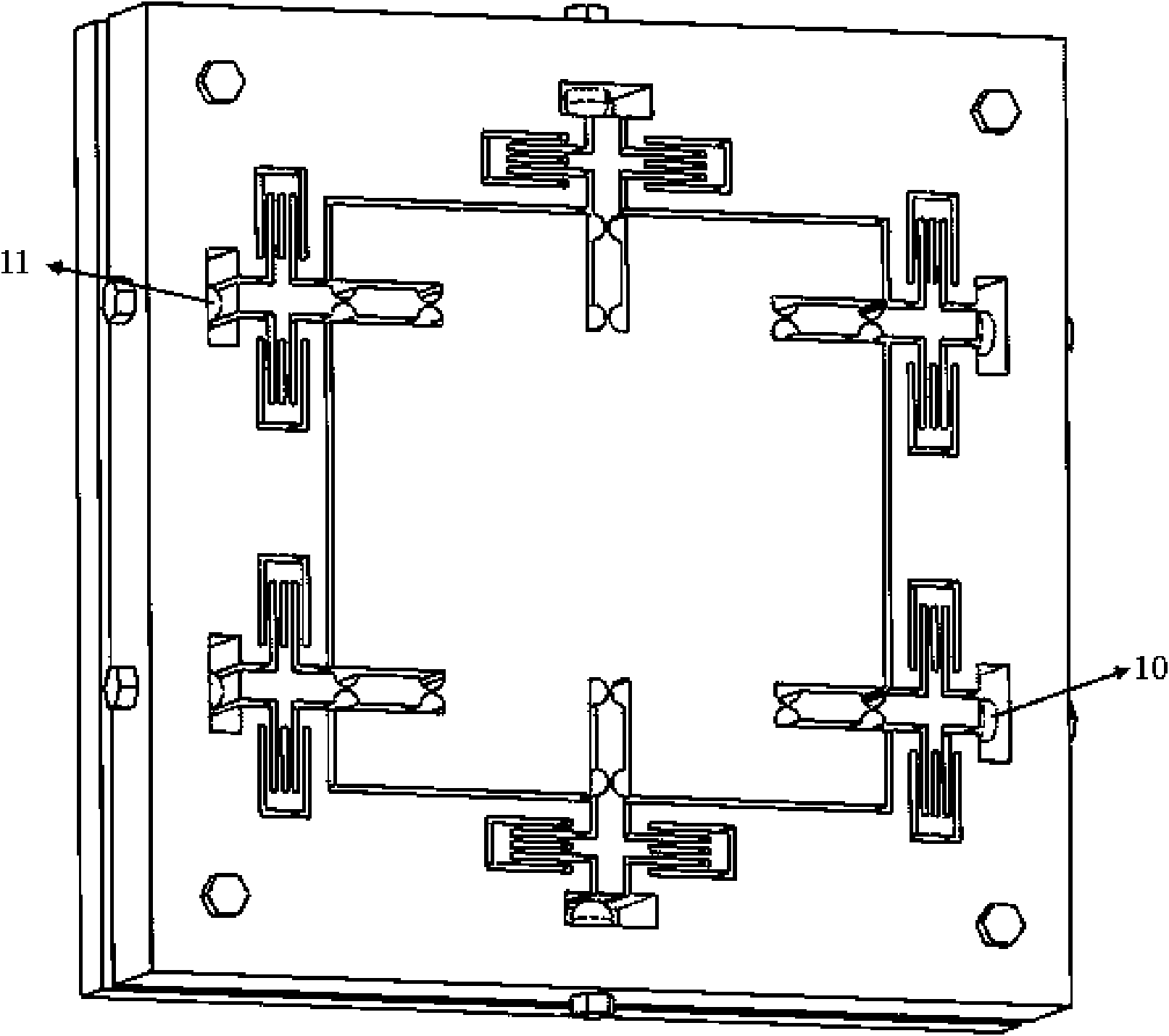

[0020] See Figure 1~4 , a three-degree-of-freedom micro-positioning stage for nanoimprint lithography systems. This workbench comprises rigid support 7 and the base 1 that is connected on the top of described rigid support 7, is connected with a moving platform 5 that its cross section is rectangular by six flexible branch chains in the middle of described base, and it also It includes six piezoelectric ceramic drivers 10, each of which is equipped with a ball joint 11 on the top, through which the spherical joint 11 contacts with the rigid moving block 4 in a small-area Hertz contact manner, the piezoelectric ceramic driver 10 is placed horizontally, and the tails are respectively passed through the holes 1 -2 threaded on base 1. Such as Figure 4 As shown (the hat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com