Two-dimensional precise angle trimmer for the second crystal of double-crystal monochromator

A technology of twin-crystal monochromator and fine-tuning device, which is applied in the mechanical field, and can solve problems such as inability to realize rotation and fine-tuning, and failure to meet the working requirements of the second crystal of the double-crystal monochromator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

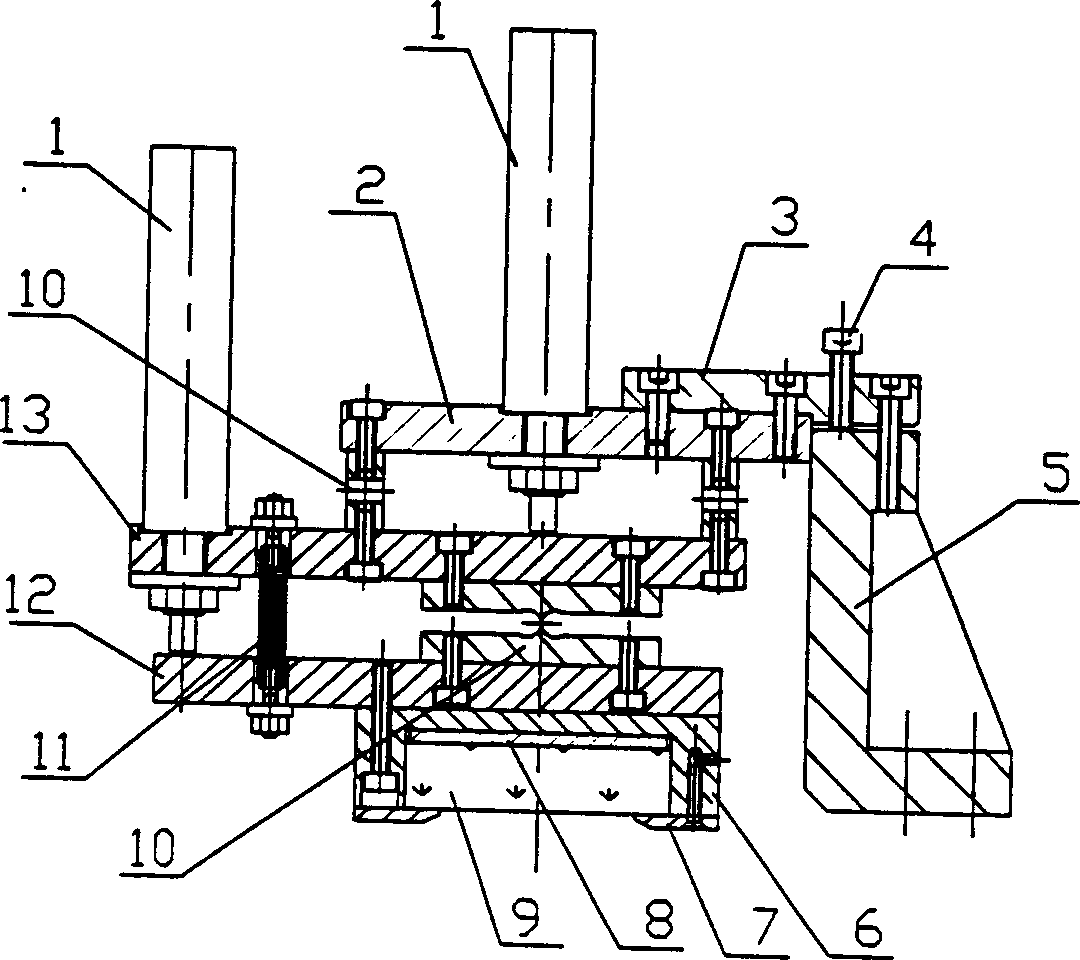

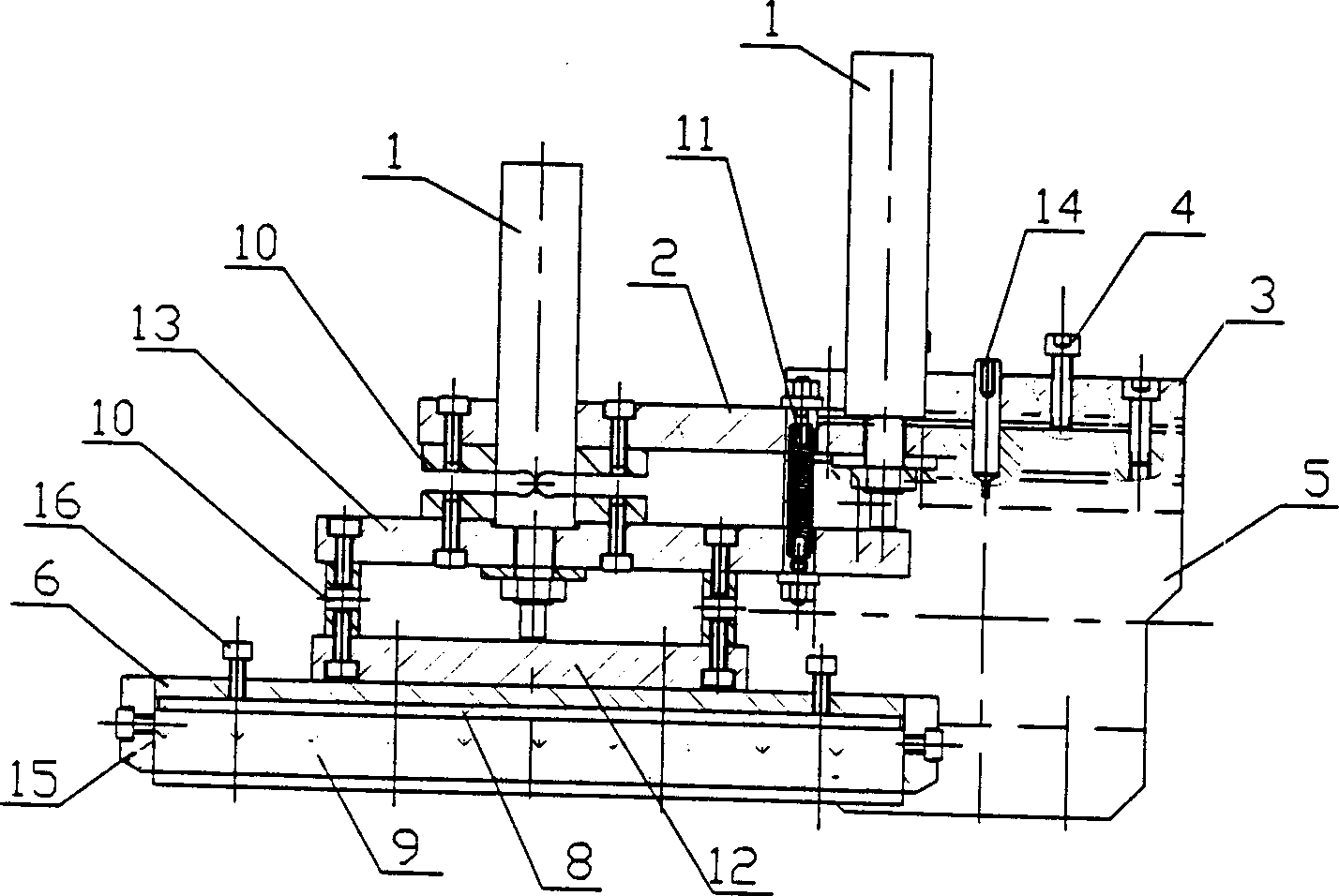

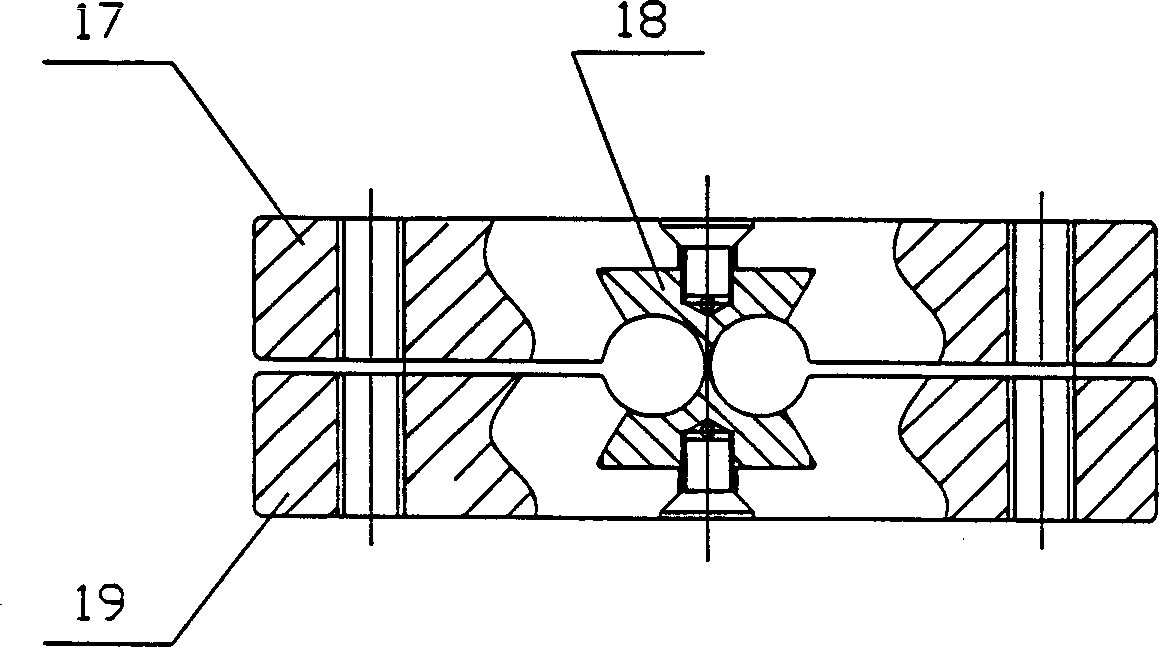

[0012] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention mainly includes: 2 linear stepper motors 1 with encoders, upper support plate 2, positioning plate 3, adjustment screws 4, 16, frame 5, crystal frame 6, crystal pressing plate 7, adjustment plate 8 , the second crystal 9, 4 sets of flexible hinge assemblies 10, 2 sets of tension spring assemblies 11, the lower support plate 12, the middle support plate 13, the positioning pin 14, the crystal lateral pressure plate 15, and its connection mode is: the upper support plate 2 After connecting with the positioning plate 3 with screws, and then connecting with the frame 5 with screws, after matching the drill pin holes, use the positioning pin 14 for positioning, and the two adjusting screws 4 are located in the screw holes of the positioning plate 3, with the encoder After the head screw of the linear stepper motor 1 is inserted into the mounting hole of the upper bracket plate 2, tighten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com