Two-translational-motion precision positioning working table for nano-imprint photoetching system

A photolithography system and precise positioning technology, applied in the field of micro-operating systems, can solve the problems of uneven distribution of imprinting force, limitation of processing accuracy and quality, and easy stretching and deformation of silicone, so as to achieve micro-feeding and precise positioning, eliminating Nonlinear, assembly-free effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments, structures, features, and effects provided by the present invention are described in detail below with reference to the drawings and preferred embodiments.

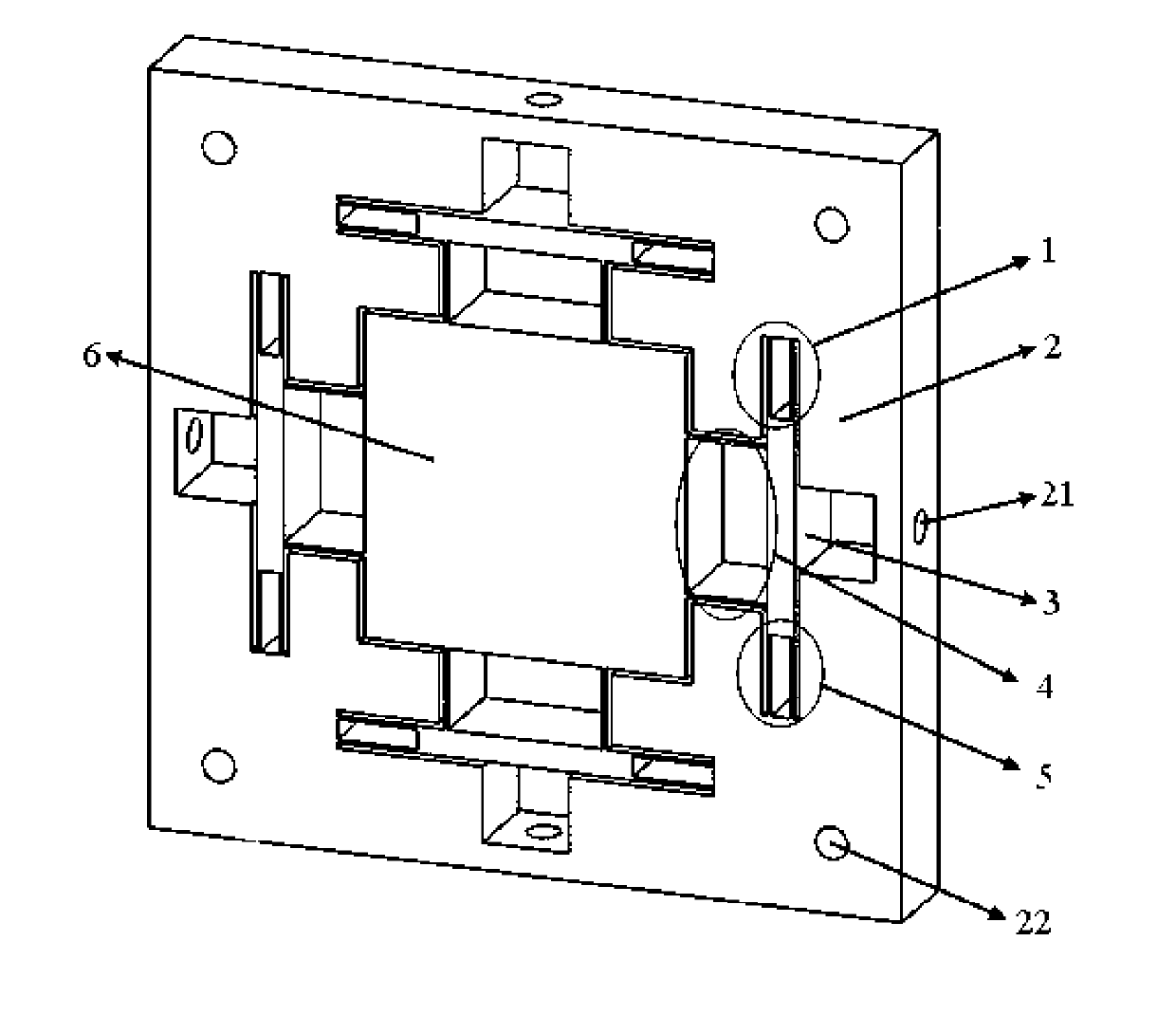

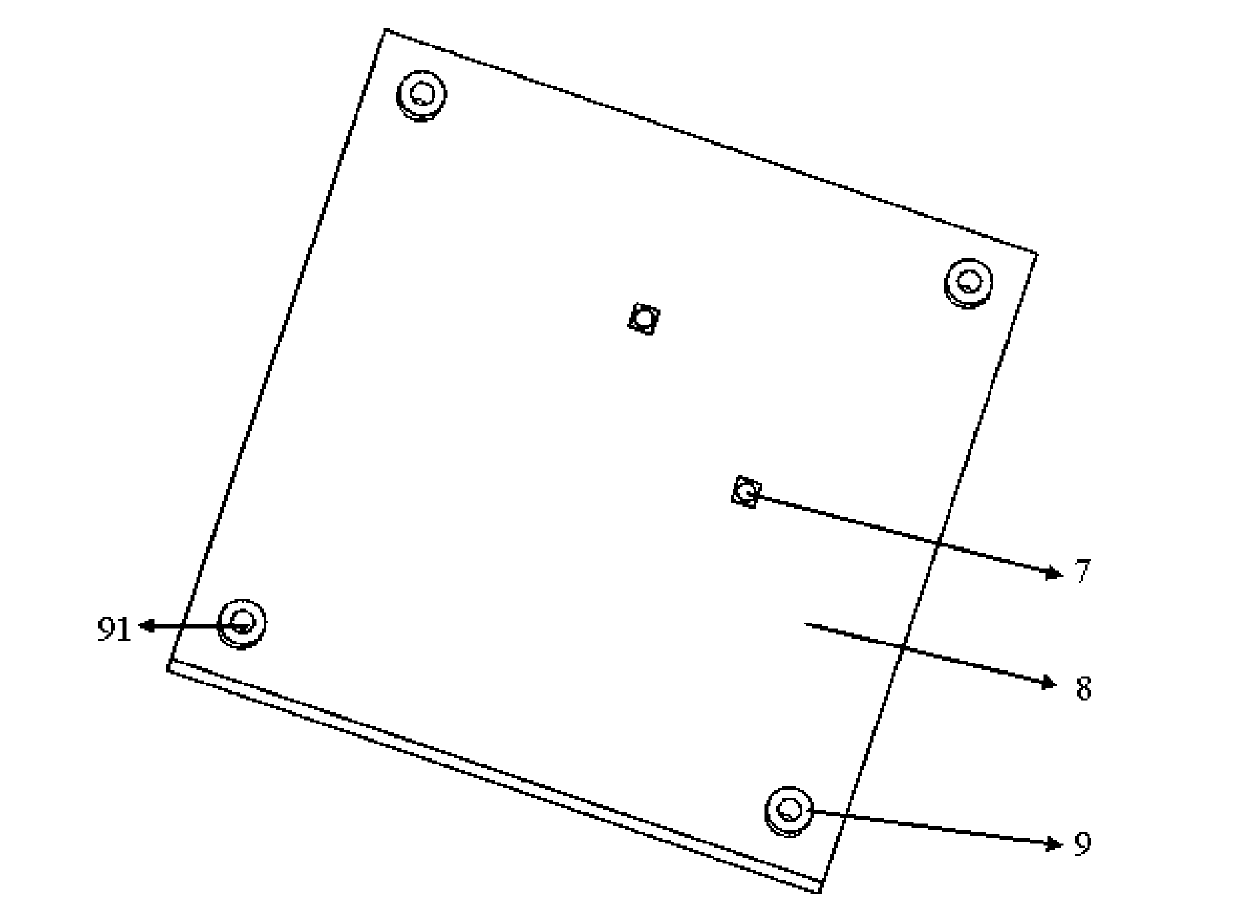

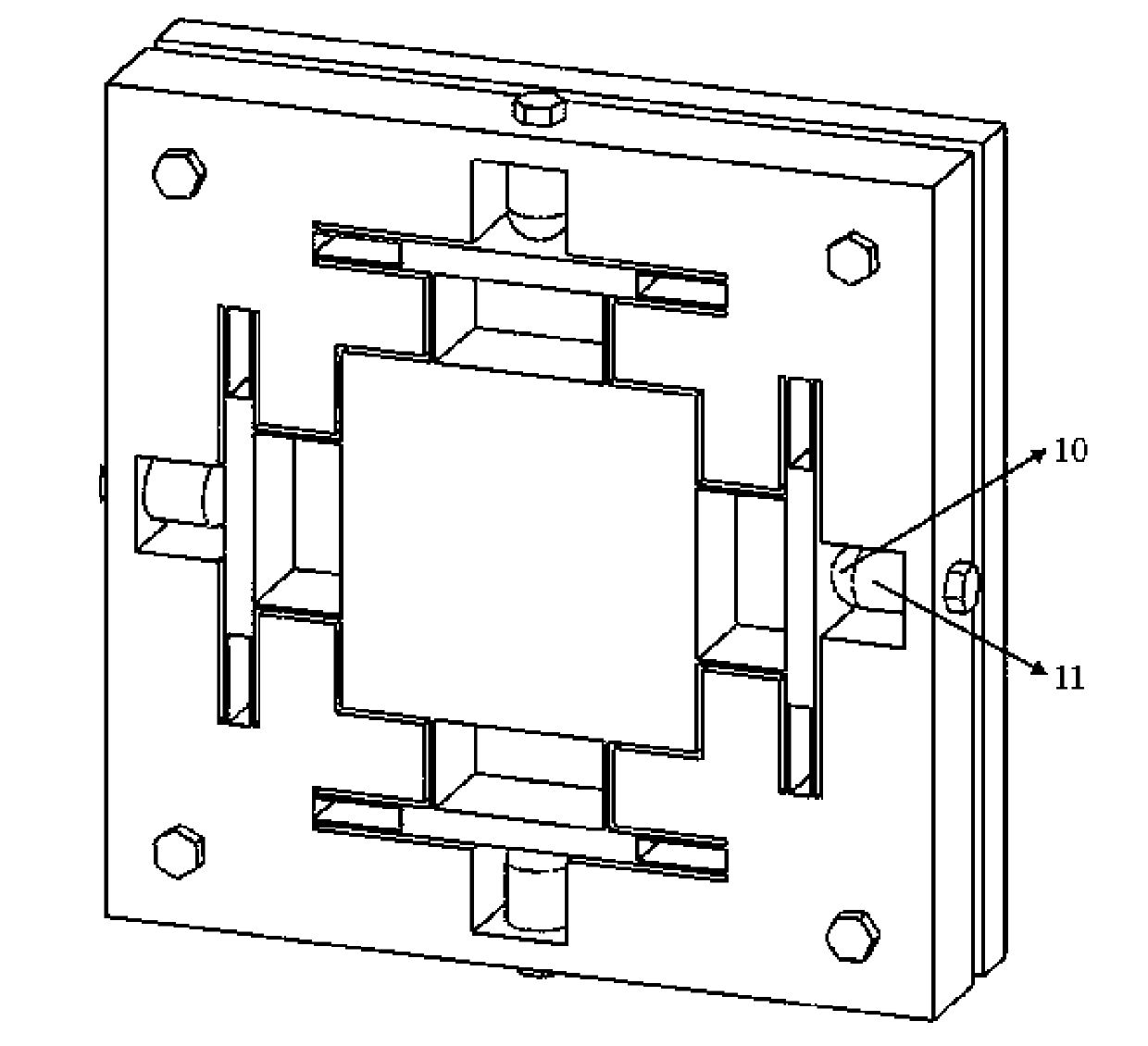

[0020] See Figure 1~4 , A two-translation precision positioning table for nanoimprint lithography system. This workbench ( image 3 ) There are four piezoelectric ceramic actuators 11, and a spherical joint 10 is installed on the top. The spherical joint 10 contacts the moving block 3 in a small area Hertz contact mode. The piezoelectric ceramic actuator 11 is placed horizontally. In order to avoid piezoelectric ceramics and The driving link of the flexible mechanism is separated during the working process, and the tail of the piezoelectric ceramic driver 11 is screwed on the base 2 through the holes 21, and installed between the driving link of the flexible mechanism and the base in an interference assembly manner to achieve pretension. The two translational precision positioning workbench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com