Method for straight line motor automatic door vector control based on linear Hall sensor

A linear motor and linear Hall technology, applied in vector control systems, motor generator control, AC motor control, etc., can solve the requirements of unsuitable working environment and low cost, unsuitable for large-stroke operation of automatic doors, and measurement feedback components Expensive and other issues, to achieve high system stability and reliability, easy to implement algorithms, and reduce hardware costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

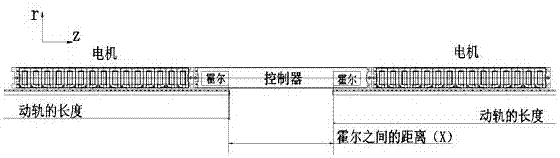

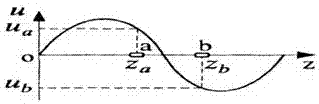

[0023] See figure 1 , the linear motor automatic door driver adopting the inventive method includes two linear motors, a controller located in the middle of the two linear motors, a permanent magnet moving rail (not shown) driven by the linear motors, and the controller includes two linear motors with a difference of 90°. Hall sensor and a DSP chip that receives the linear Hall sensor voltage signal and performs calculations. The driver uses a 40 series linear motor with a rated power of 100w. The main chip of the driver uses DSP33EP512, and the linear Hall model is AH3503. In addition to the 90-degree difference between the linear Hall sensor and the moving track magnet, the gap between it and the moving track magnet should be between 1.5mm and 3mm.

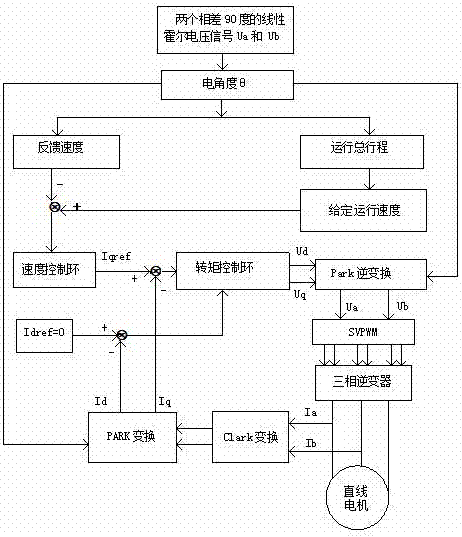

[0024] See figure 2 , the method for the linear motor automatic door vector control based on the linear Hall sensor provided by the present invention includes: detecting the back electromotive force of the linear motor throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com