Six-degree-of-freedom series-connected robot with target positioning

A robot and degree-of-freedom technology, used in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of low motion accuracy, large duty angle, difficult control, etc., and achieve high motion resolution, small duty angle, Control easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

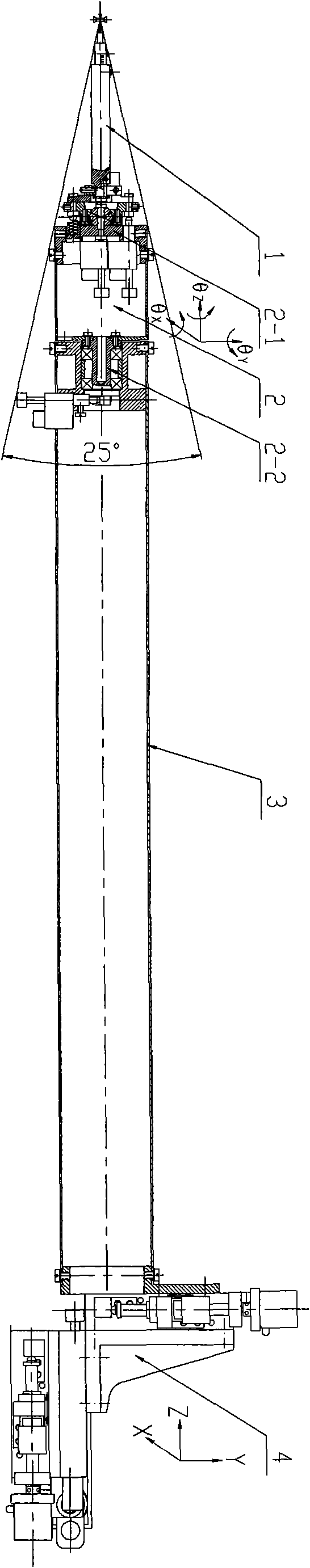

[0022] Example 1: Reference figure 1 The six-degree-of-freedom tandem robot for target positioning is composed of a rapid target-changing mechanism 1, a three-dimensional rotating robot 2, an intermediate connecting sleeve 3, and a three-dimensional translation table 4. The quick target changing mechanism 1 is connected to the front end of the three-dimensional rotating robot 2 by screws, the three-dimensional rotating robot 2 is fixed at the front end of the intermediate connecting sleeve 3, and the rear end of the intermediate connecting sleeve 3 is fixed on the three-dimensional translation workbench 4 Front end.

Embodiment 2

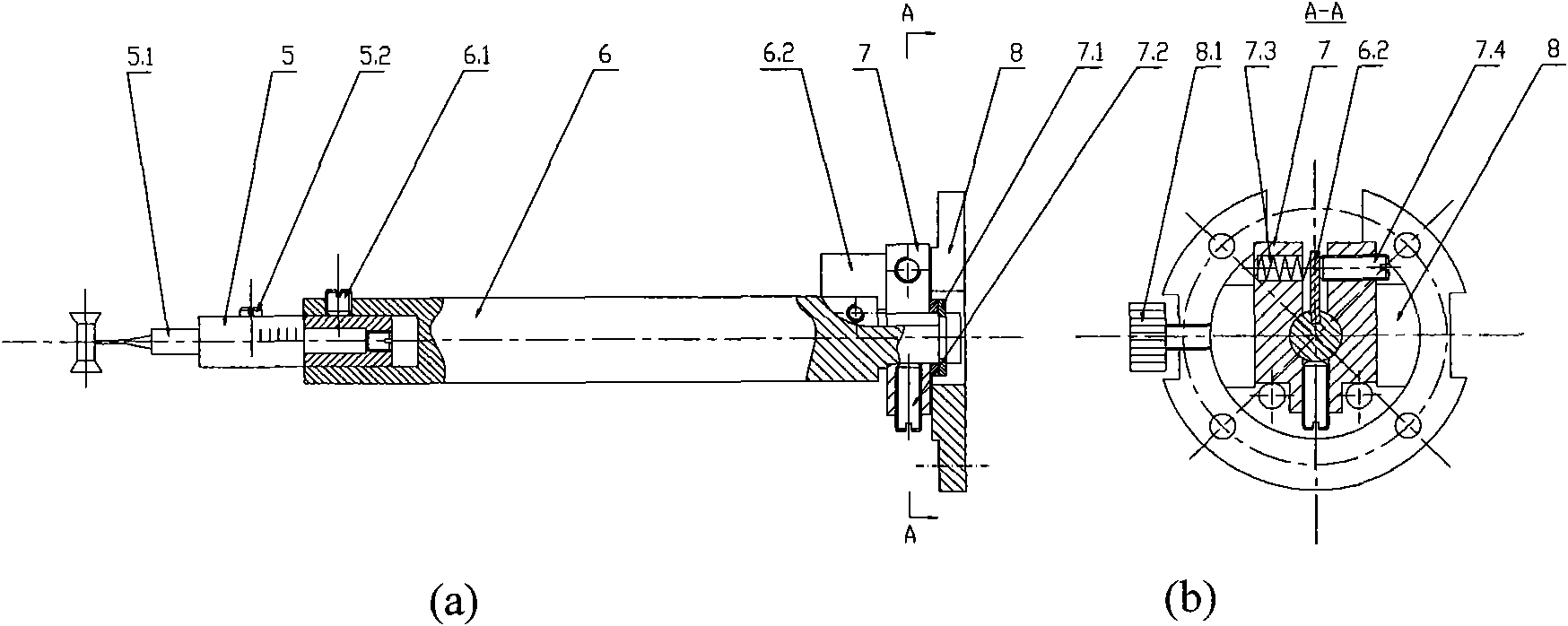

[0023] The second embodiment: This embodiment is basically the same as the first embodiment, and the special features are as follows: Reference figure 2 The aforementioned quick target changing mechanism 1 is composed of a target sleeve 5, a target support rod 6, a V-shaped block 7, and a dovetail disc 8. The experimental target 5.1 is fixed in the hole of the target sleeve 5 by the set screw 5.2; the target sleeve 5 is engraved with equal intervals of engraved lines to adjust the axial position of the experimental target, and is fixed to the target support rod by the set screw 6.1 In the hole of 6; the target support rod 6 is axially fixed on the V-shaped block 7 through the right end of the stop ring 7.1, the right end of the target support rod 6 is embedded in the stop piece 6.2, adjust the set screw 7.4 to push the stop piece 6.2, in the spring 7.3 Under the action, the target support rod 6 can be rotated around its own axis to adjust the radial position of the experimental...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com