Piezoelectric driving large-stroke no-coupling two-dimensional precise micro locating platform

A micro-positioning platform, piezoelectric drive technology, applied in the parts, instruments and other directions of the instrument, can solve the problem of small stroke, and achieve the effect of not needing lubrication, eliminating coupling, and increasing displacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

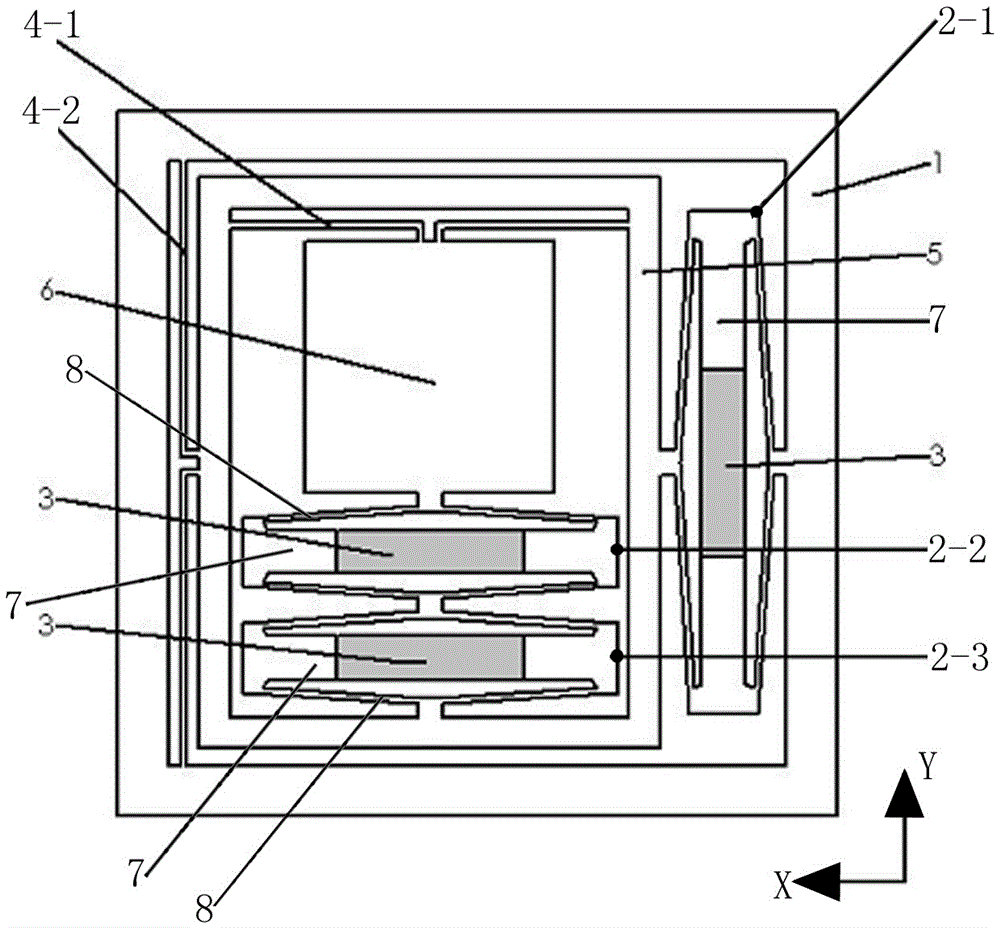

[0022] As shown in the figure, the present invention provides a piezoelectric-driven large-stroke non-coupling two-dimensional precision micro-positioning platform, which includes an outer support 1, a diamond-shaped displacement amplification mechanism, a piezoelectric ceramic driver, a symmetrical long-arm hinge, an inner layer Substrate 5 and workbench 6; workbench 6 is nested on the inner substrate 5, one end of the workbench 6 in the Y direction is connected to the inner substrate 5 through a Y-direction symmetrical long-arm hinge 4-1, and the other end of the workbench 6 in the Y direction The inner substrate 5 is connected through the Y-direction diamond-shaped displacement amplification mechanism; the inner substrate 5 is nested on the outer support 1, and one end of the inner substrate 5 in the X direction is connected to the outer support 1 through the X-direction long-arm hinge 4-2 , the other end of the X-direction of the inner substrate 5 is connected to the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com