Patents

Literature

31results about How to "Realize simultaneous movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

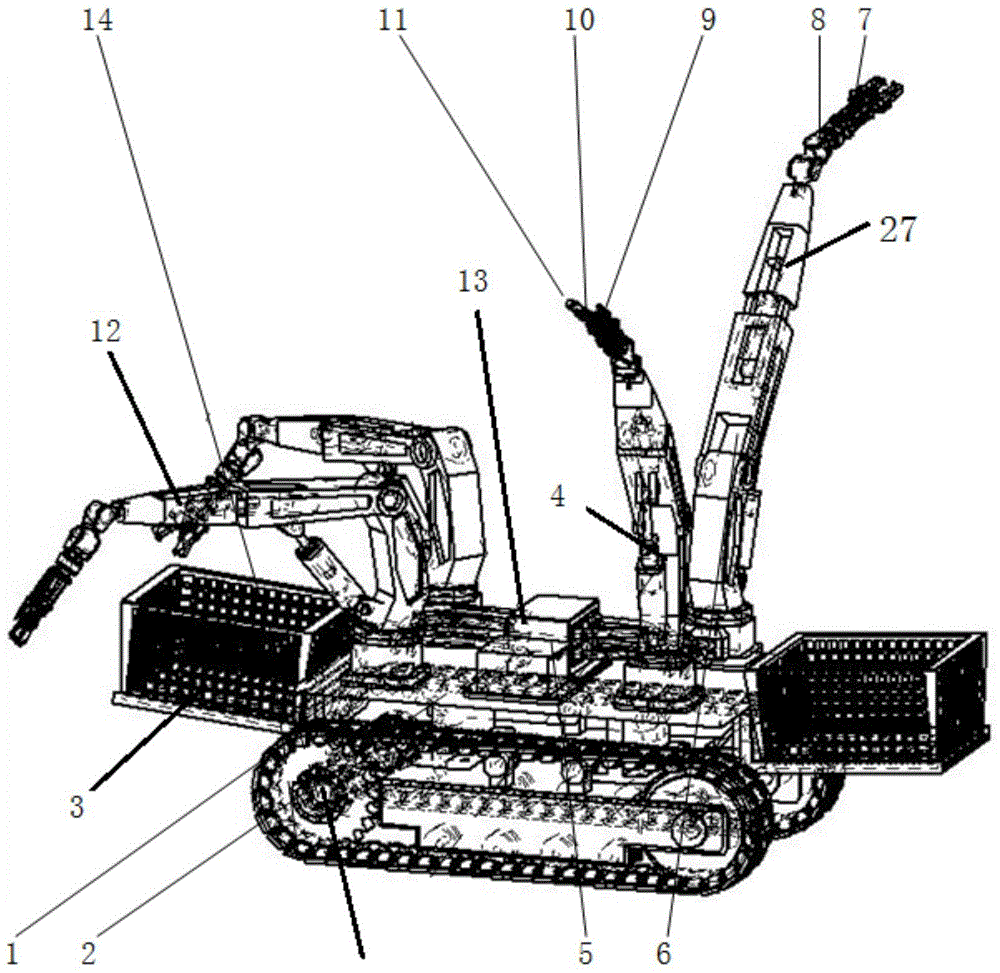

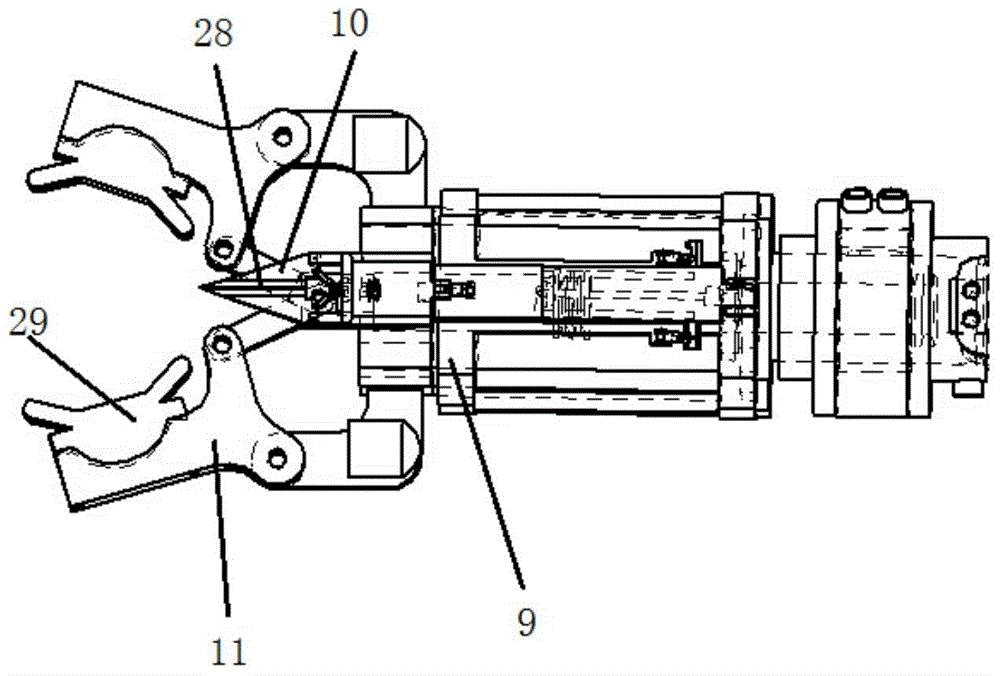

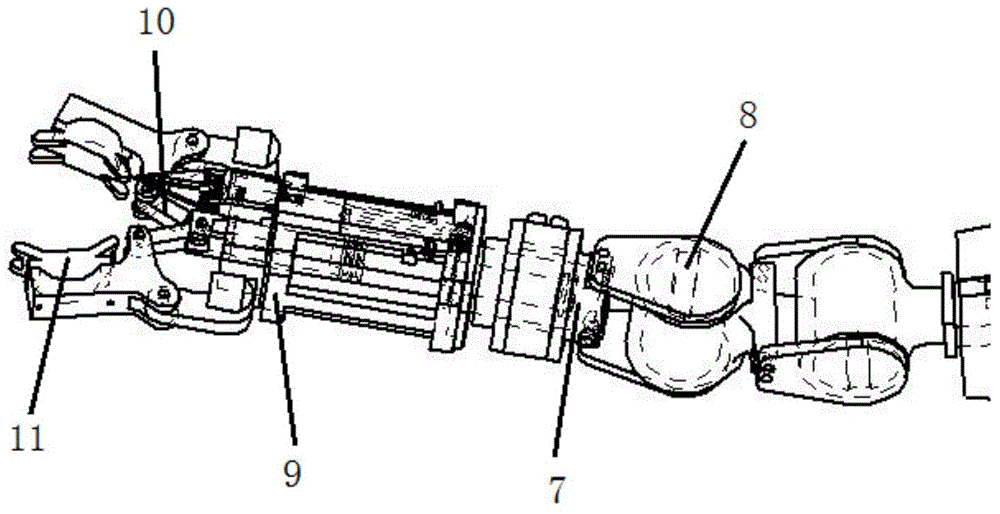

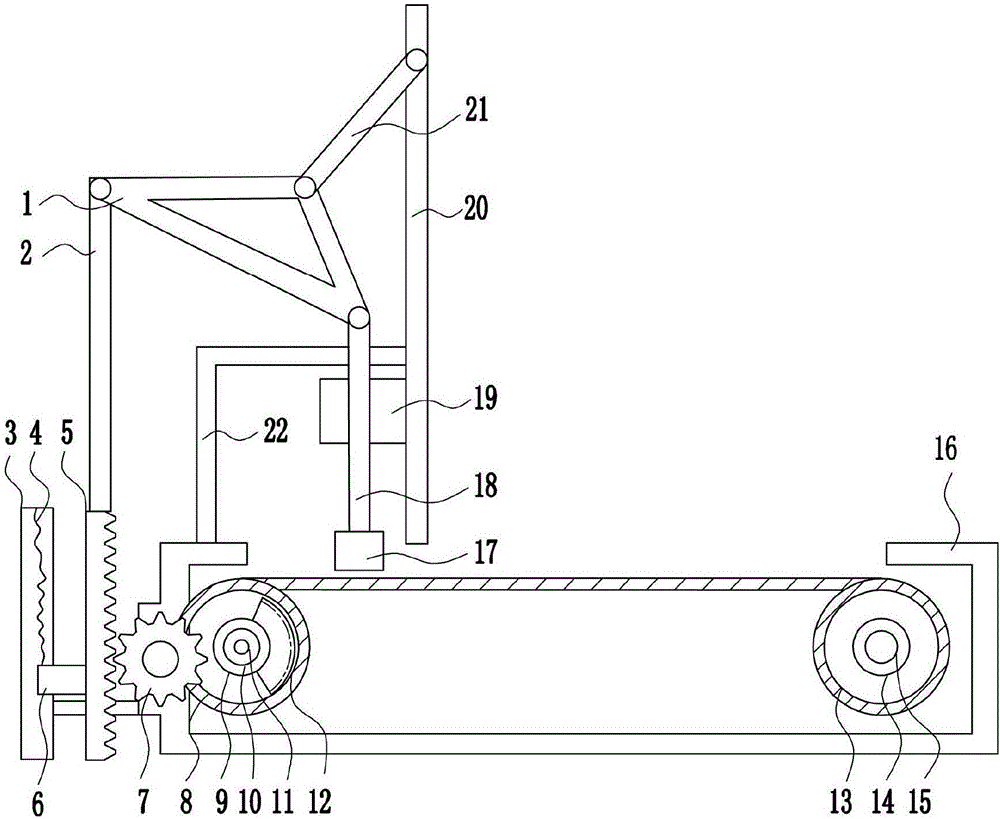

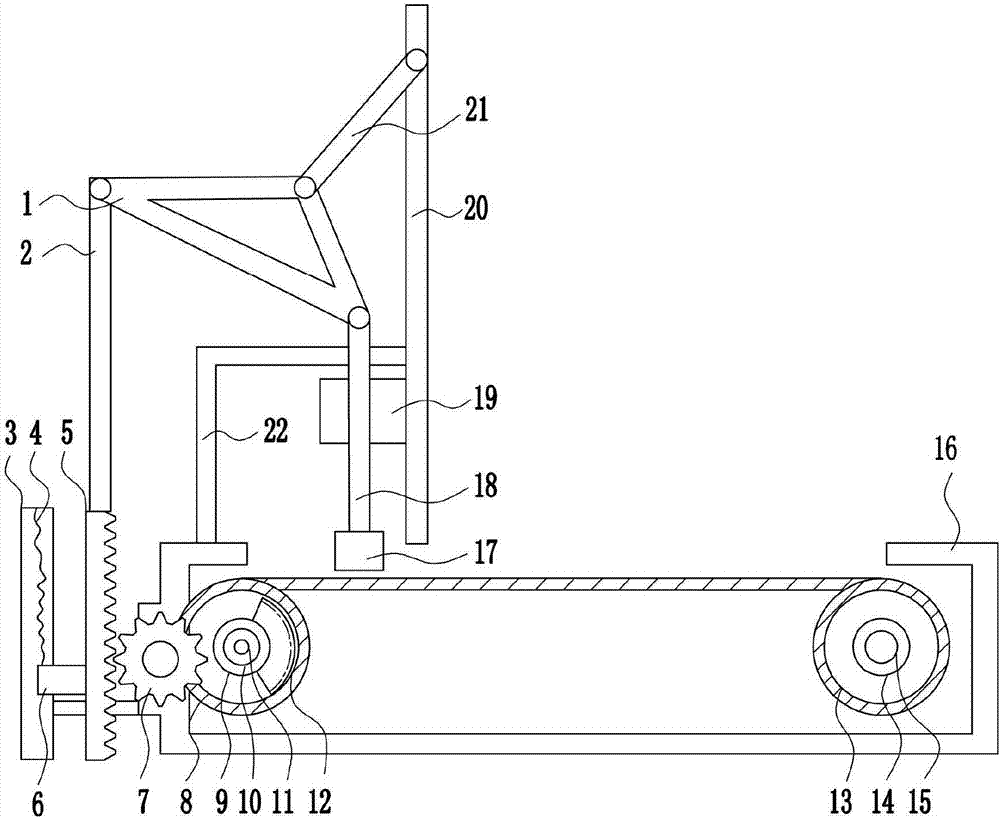

Vegetable and fruit picking robot and control method thereof

InactiveCN105027834ARealize simultaneous movementAccurate identificationPicking devicesRobotic armControl theory

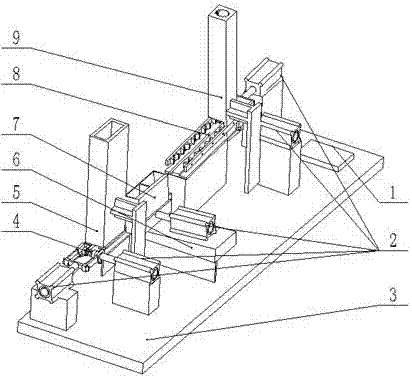

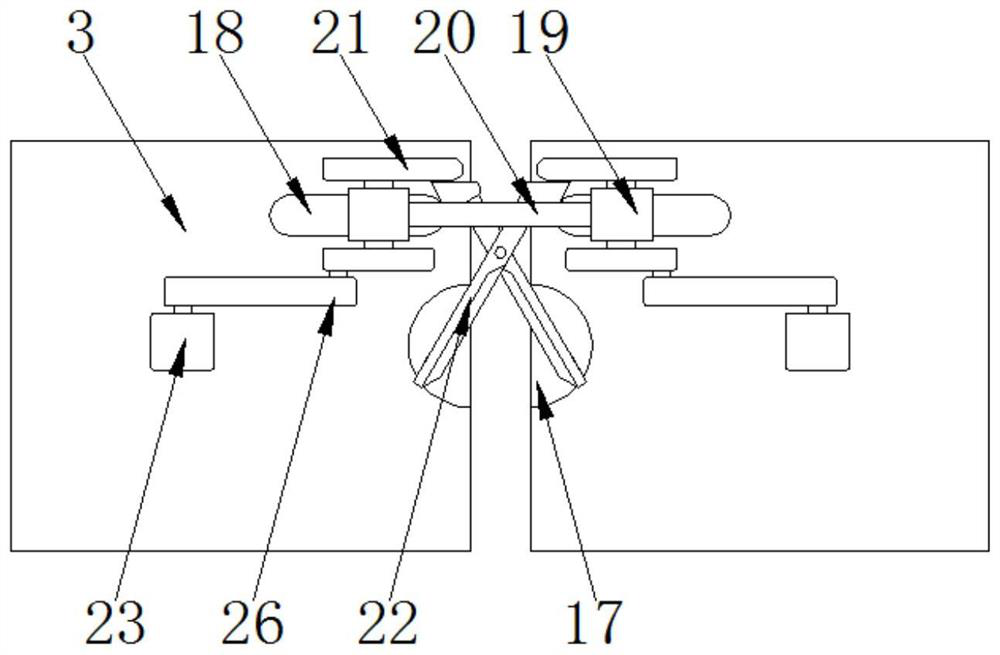

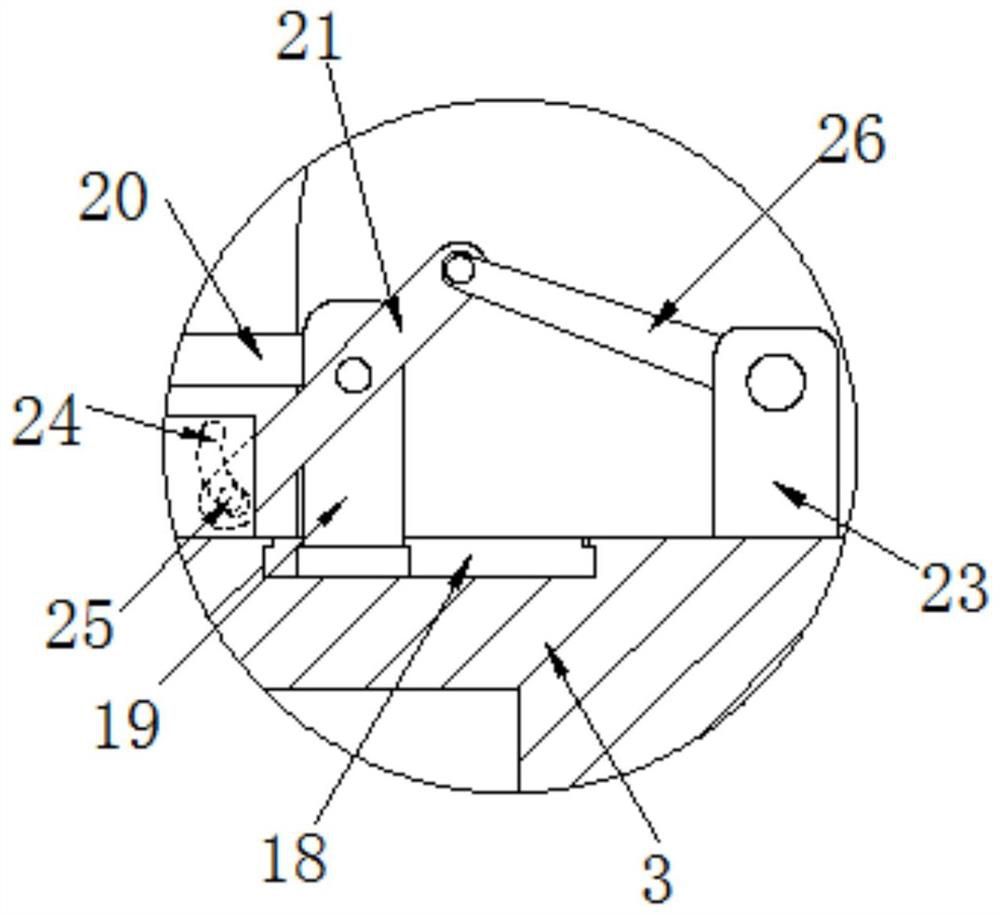

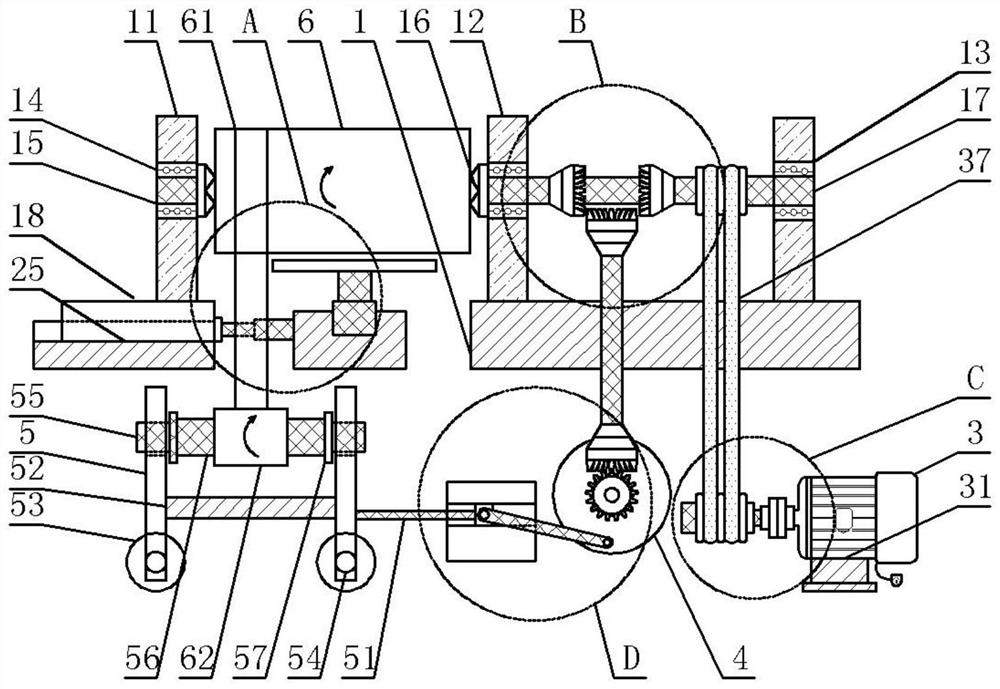

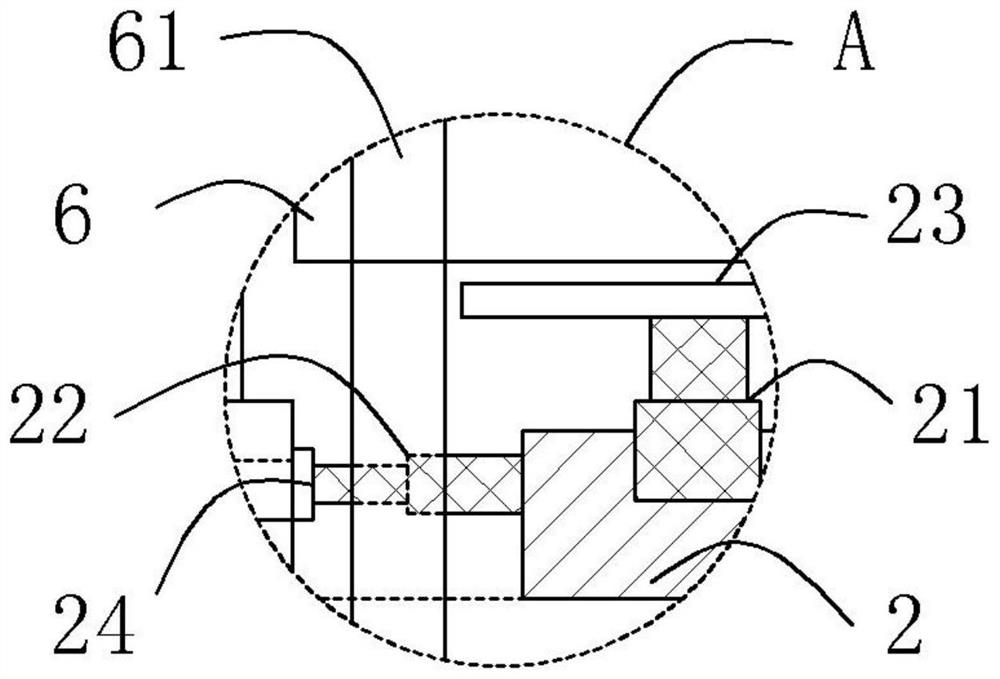

The invention discloses a vegetable and fruit picking robot and a control method thereof. The vegetable and fruit picking robot comprises a walking mechanism. A base is arranged on the walking mechanism. Storage baskets are arranged at the front and rear ends of the base respectively. An execution mechanism, a recognition system, a first driving mechanism, a second driving mechanism and a controller are arranged on the base. The controller is connected with the recognition system, the first driving mechanism and the second driving mechanism through wires. Both fruits on trees and plant fruits at low positions can be picked, and therefore the picking object range is wide; the crawler-type walking mechanism drives a plurality of mechanical arms to work at the same time, and therefore the picking efficiency is high; a small arm is flexible and continuous in movement, the stretching range of the mechanical arms is wide, and therefore the vegetable and fruit picking robot can adapt to various operating environments; the multi-sensor function and the digital imaging technology are adopted, and therefore the fruits can be accurately recognized and positioned; clamping force is controlled through sensor detection, and therefore the fruits are prevented from being damaged.

Owner:平顶山工业职业技术学院

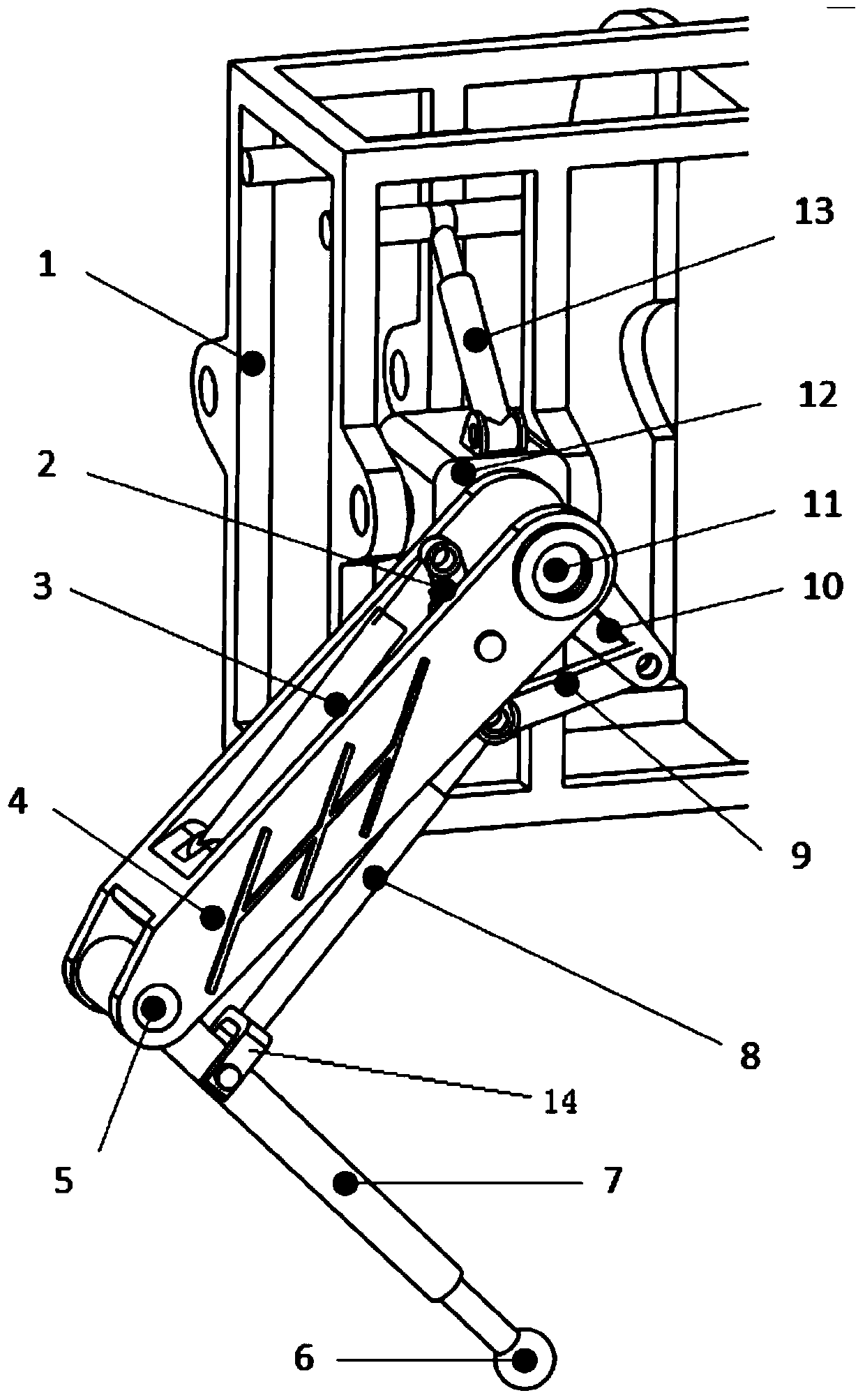

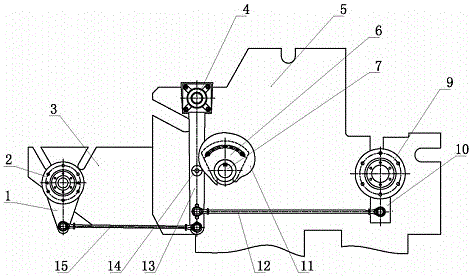

Leg linkage mechanism of quadruped robot

InactiveCN103802909AEasy to solve driving displacementMove fastVehiclesThighPhysical medicine and rehabilitation

The invention relates to a leg linkage mechanism of a quadruped robot. The leg linkage mechanism is characterized in that a thigh assembly, a shank assembly and a hip driver are included, the thigh assembly, the shank assembly and the hip driver are connected respectively through connecting rods to from the leg linkage mechanism of the robot, and the connecting rods comprise a thigh swing connecting rod, a shank swing connecting rod and a hip swing connecting rod; the thigh assembly comprises thighs and a thigh driving oil cylinder 3, one end of the thigh swing connecting rod is in pin joint with the thigh driving oil cylinder, the other end of the thigh swing connecting rod is respectively in pin joint with the shank swing connecting rod and the hip swing connecting rod, the other end of the shank swing connecting rod is connected with the shank assembly, and the other end of the hip swing connecting rod is connected with the hip driver. The leg linkage mechanism has the advantages that under the condition that only two leg drivers are arranged, leg motions of tetrapods in the natural world can be simulated, in the lying-down and standing-up process, thigh drivers in the thighs can synchronously extend or contract, feet are driven to move up and down, and the motion interference phenomenon does not exist between the legs.

Owner:MILITARY TRANSPORTATION UNIV PLA

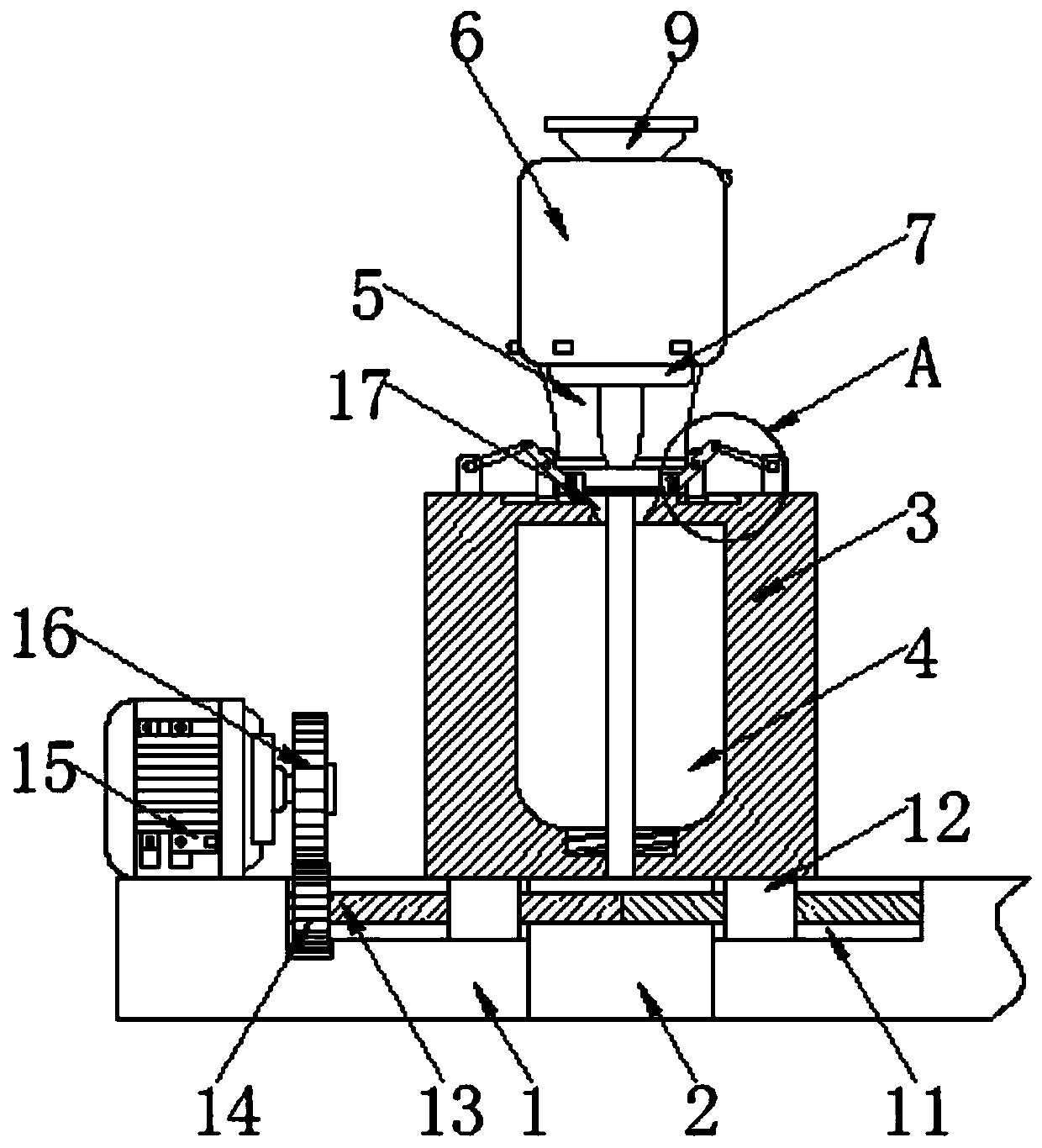

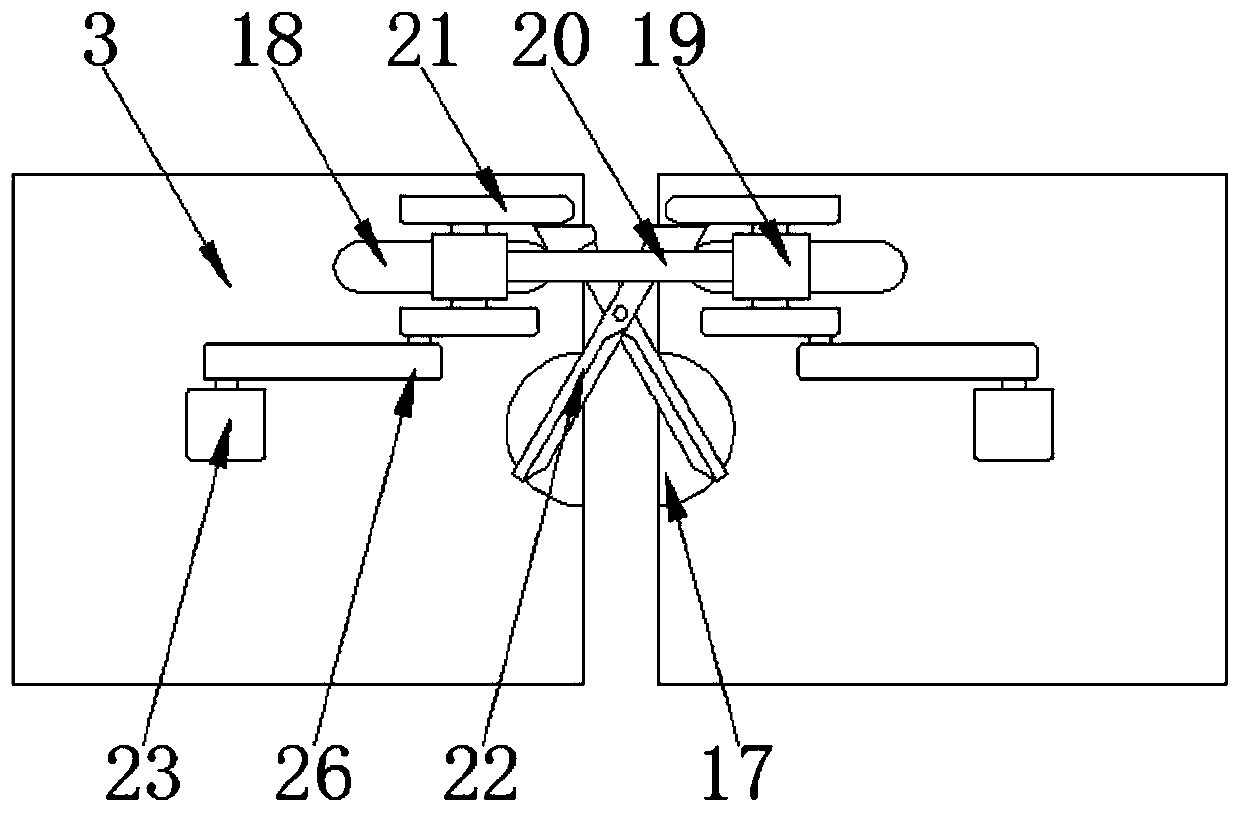

Blow molding equipment for blow molded container

The invention discloses blow molding equipment for a blow molded container, and relates to the technical field of the blow molding equipment. The blow molding equipment comprises a working table, a collecting hole is formed in the top of the working table, container molds are movably connected on the two sides of the top of the working table, appearance grooves are formed in the opposite sides ofthe two container molds, and a supporting frame is fixedly connected to the back face of the working table. According to the blow molding equipment for the blow molded container, second sliding grooves are formed in the tops of the container molds, so that when the two container molds move towards the sides away from each other, the positions of the second sliding blocks are not changed due to thefact that the two second sliding blocks are connected through a fixing rod, at the moment, swinging rods drive rotating rods to rotate, so that the sides, away from each other, of two sleeve blocks are moved, then the sharp sides of two blades can make contact with each other, through the structure, redundant materials can be cut off to fall off along with the container, and the redundant materials are prevented from falling into the appearance grooves.

Owner:宏全食品包装清新有限公司

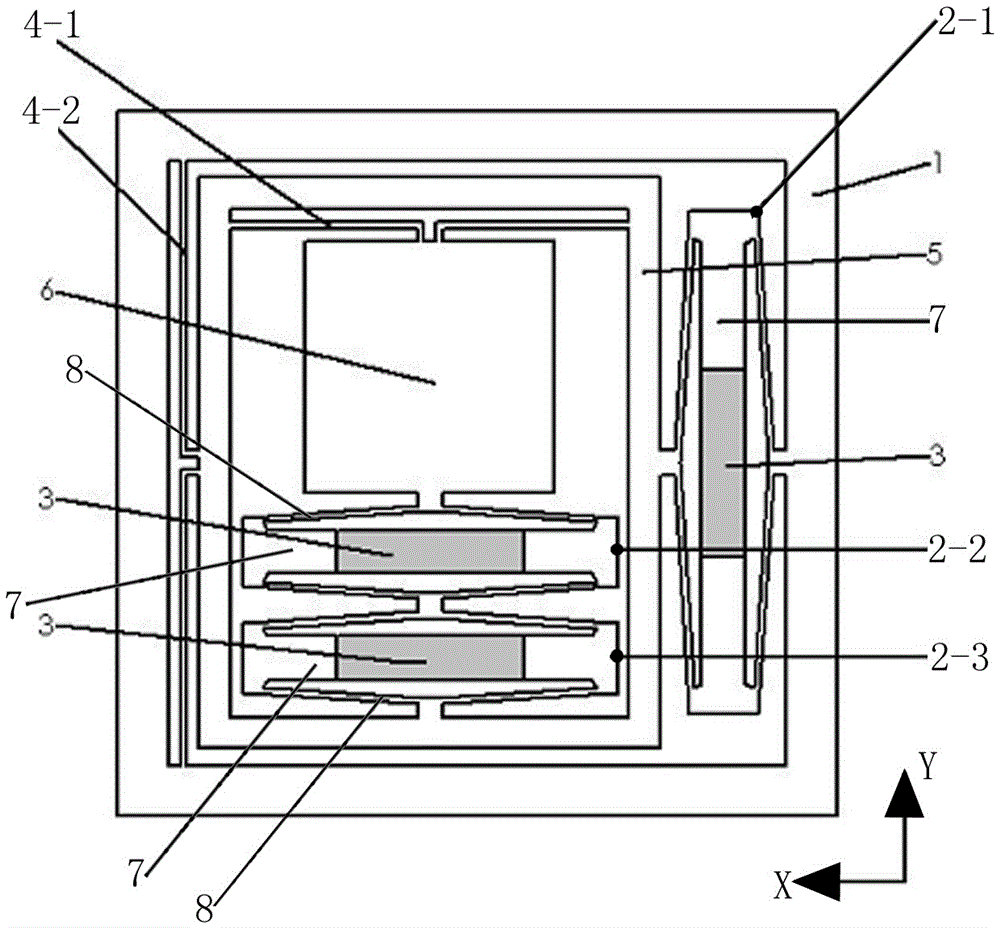

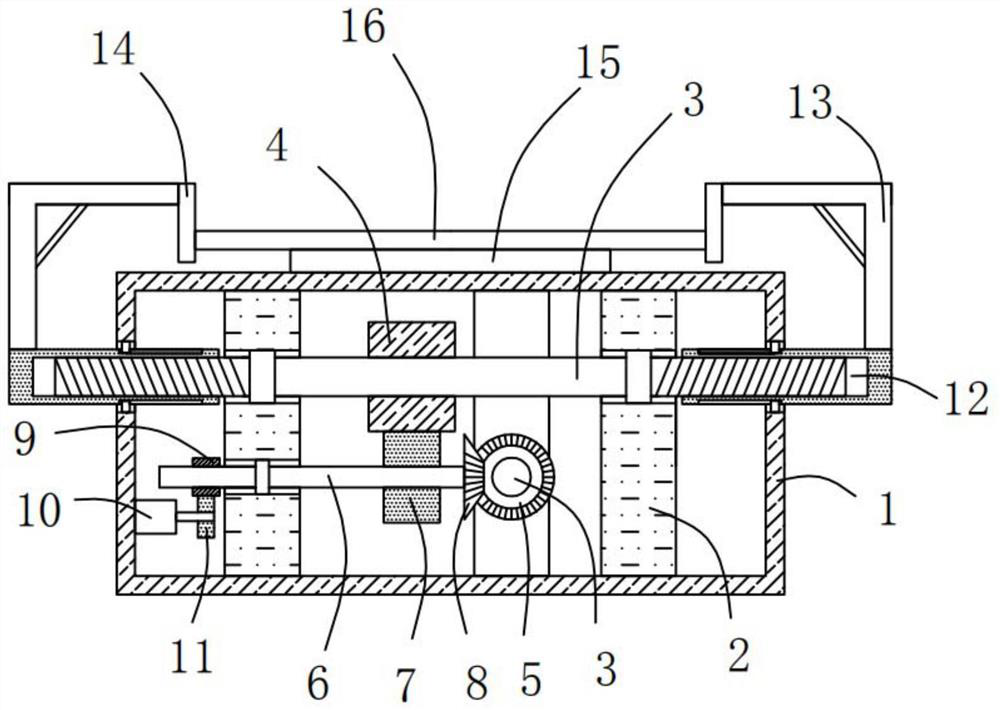

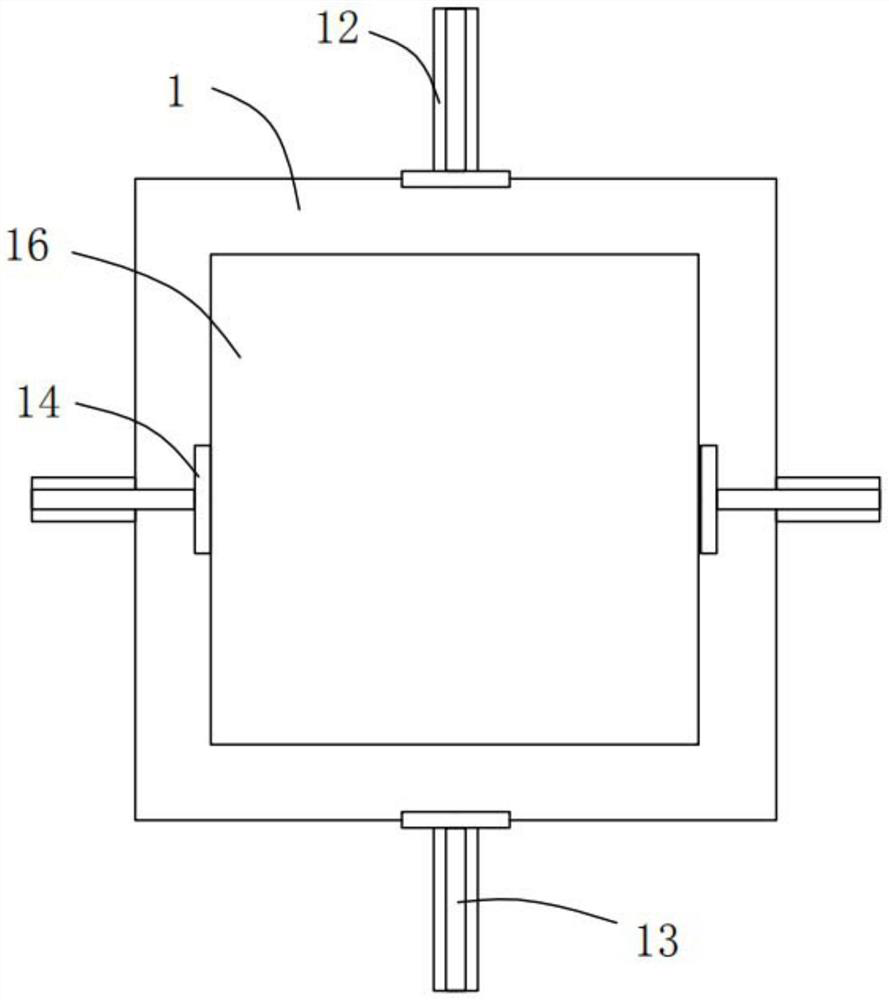

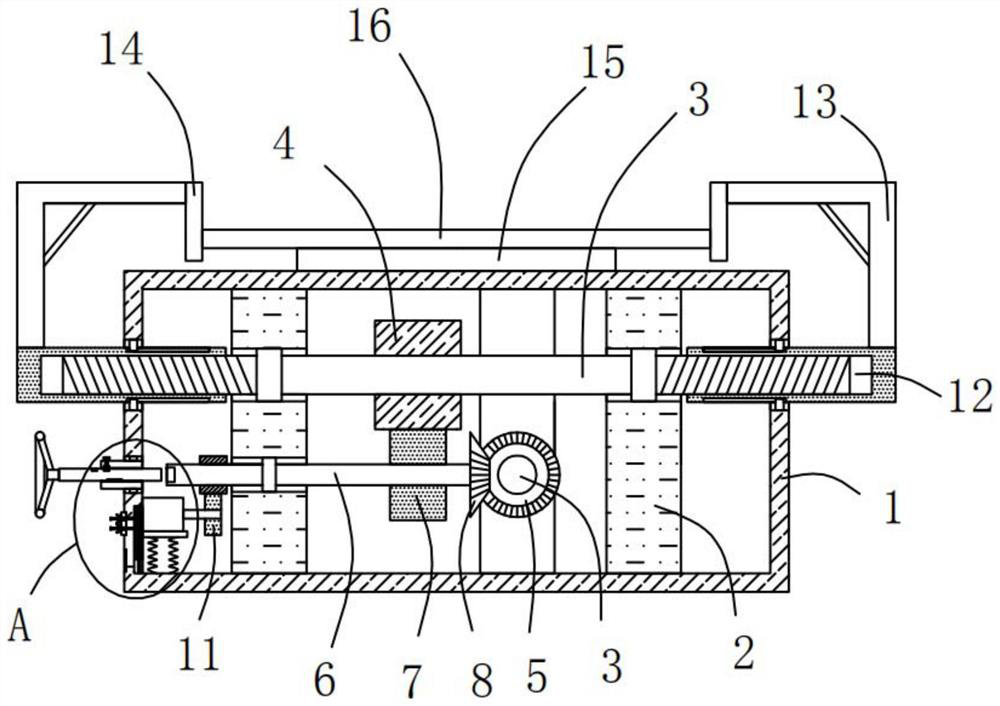

Piezoelectric driving large-stroke no-coupling two-dimensional precise micro locating platform

InactiveCN106373617ASolve the problem of small output displacementImprove working precisionInstrumental componentsIndependent motionImage resolution

Disclosed is a piezoelectric driving large-stroke no-coupling two-dimensional precise micro locating platform. The piezoelectric driving large-stroke no-coupling two-dimensional precise micro locating platform is characterize in that the platform comprises an outer layer support seat, a rhombus displacement magnifying mechanism, a piezoelectric ceramic actuator, symmetrical long arm hinges, an inner layer base plate and a workbench; and compared with the prior art, the platform has the advantages that 1, X-direction and Y-direction independent motion can be achieved, and X-direction and Y-direction simultaneous motion can also be achieved; 2, the maximum displacement output quantities in the X direction and the Y direction are close; 3, displacement quantity can be increased, coupling is eliminated, and error is reduced; and 4, the platform has the advantages that mechanical friction, delaying and clearance are avoided, lubrication is not needed, heat and noise are not produced, and the motion resolution is high.

Owner:SHENYANG POLYTECHNIC UNIV

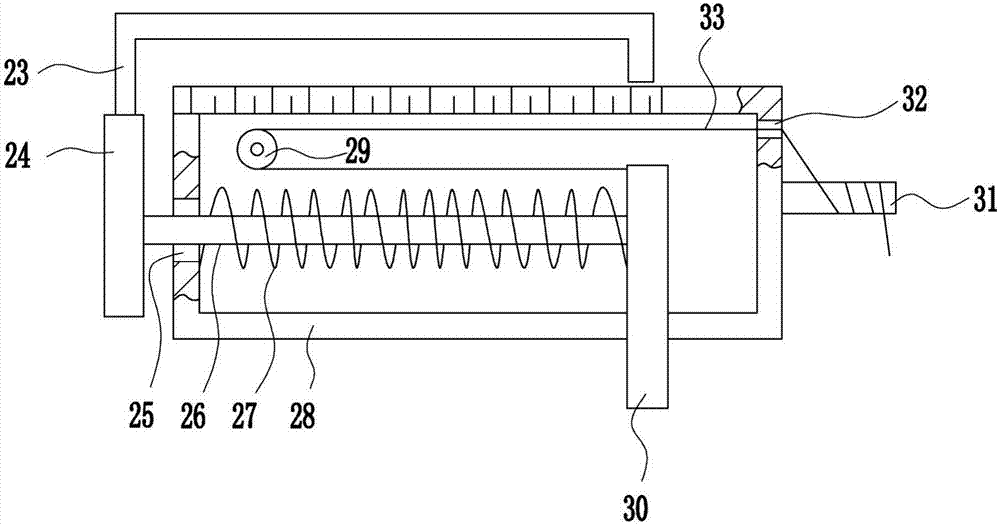

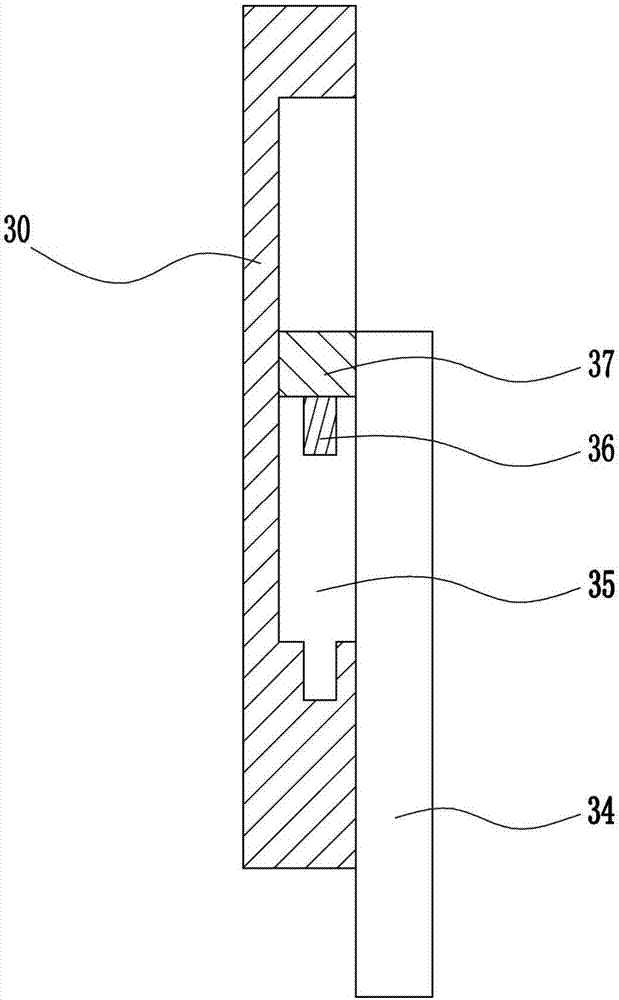

Aluminum foil fixed width cutting device for pharmaceutical packaging

InactiveCN106584546APlay the role of reinforcementImprove securityMetal working apparatusInterference fitCoupling

The invention relates to a cutting device, in particular to an aluminum foil fixed width cutting device for pharmaceutical packaging. The technical problem to be solved is to provide an aluminum foil fixed width cutting device which is used for pharmaceutical packaging and is capable of controlling the cutting width conveniently and small in cutting friction. To solve the technical problem, the aluminum foil fixed width cutting device for pharmaceutical packaging comprises a tripod, a first connecting rod, a sliding rail, a first spring, a rack, a sliding block, a first gear, a sector gear, a gear motor, a first rotary rod, a first roller and the like. An output shaft of the gear motor is connected with the first rotary rod through a coupling, the first rotary rod is in interference fit connection with the sector gear and the first roller sequentially from front to rear. The aluminum foil fixed width cutting device achieves the effects that the cutting precision is high, the cutting width can be controlled flexibly and the time and labor are saved during cutting when the aluminum foil fixed width cutting work is conducted

Owner:广州市必盈体育有限责任公司 +1

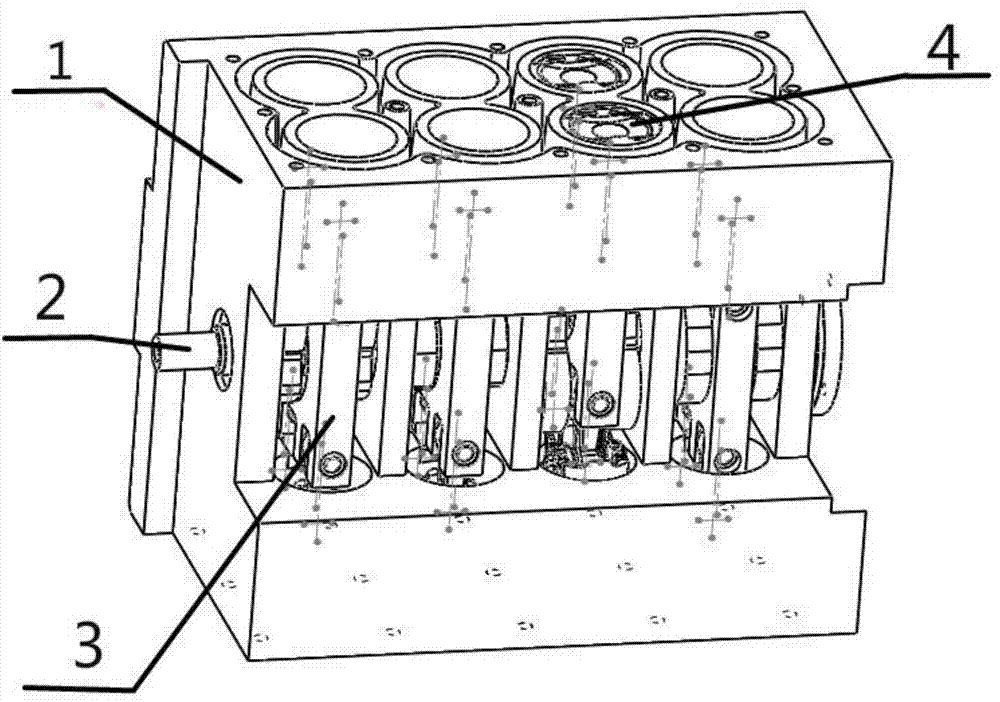

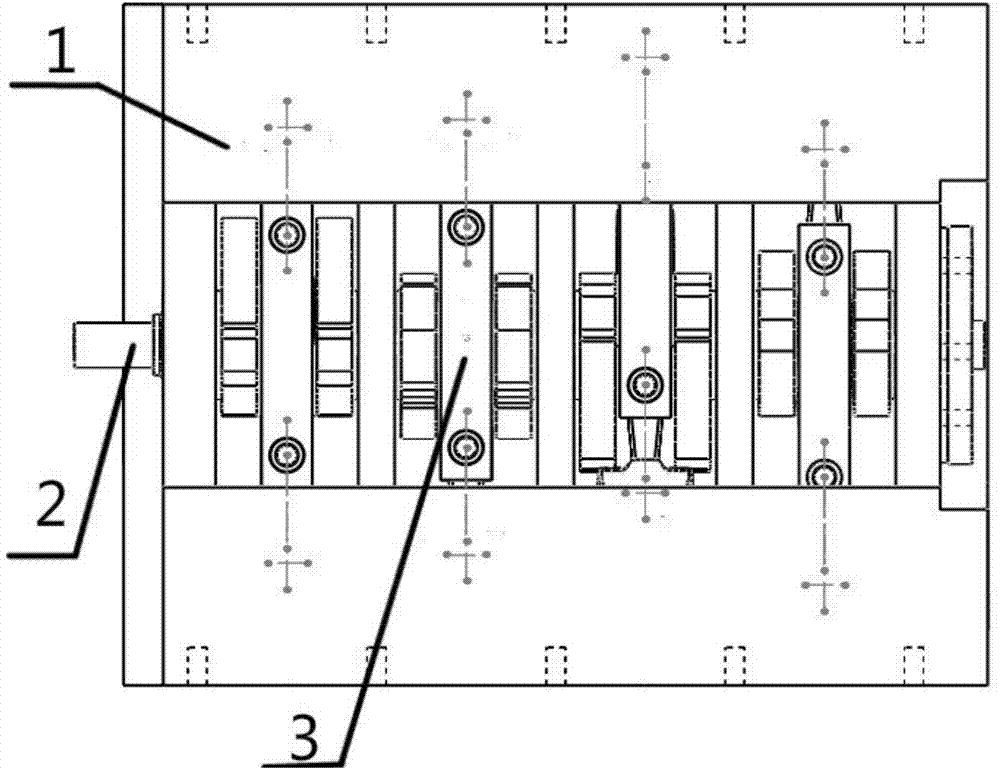

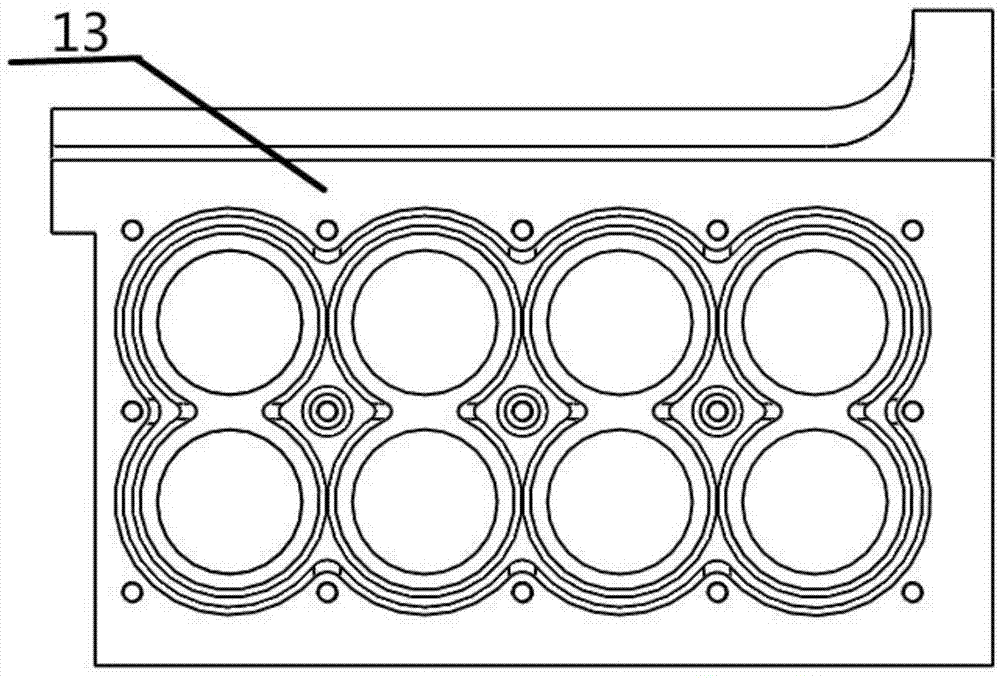

Horizontally-opposed matrix engine

InactiveCN104500221AImprove work efficiencyRealize simultaneous movementMachines/enginesCircular discAviation

The invention relates to the fields of internal combustion engines, air compressors, ships, aviation, spinningequipment and the like, in particular to a horizontally-opposed matrix engine. The horizontally-opposed matrix engine comprises a crankshaft box body, a crankshaft, a circular gap crank, pistons and cylinder bodies, wherein the cylinder bodies are arranged in arrays; the pistons are symmetrically arranged at the two ends of each cylinder body; the pistons are connected through piston pins, piston connecting rods, crank pins and a crank; the circular gap crank is embedded into the crank; the circular gap crank is a circular disc, and a crank throw groove is formed in the circular gap crank; the central axis of the circular gap crank is perpendicular to that of the cylinder body; the crankshaft is fixed to the crankshaft box body; the central axis of the crankshaft is perpendicular to the moving direction of the pistons; the circular gap crank sleeves the crankshaft through the crank throw groove; a lubricating oil channel is formed in the crank and used for lubricating the circular gap crank and the crank. According to the horizontally-opposed matrix engine, the pistons are assembled on the crank and can simultaneously move in a stroke for applying work, so that the working efficiency of the engine is improved.

Owner:SHAANXI JUZHEN POWER TECH CO LTD

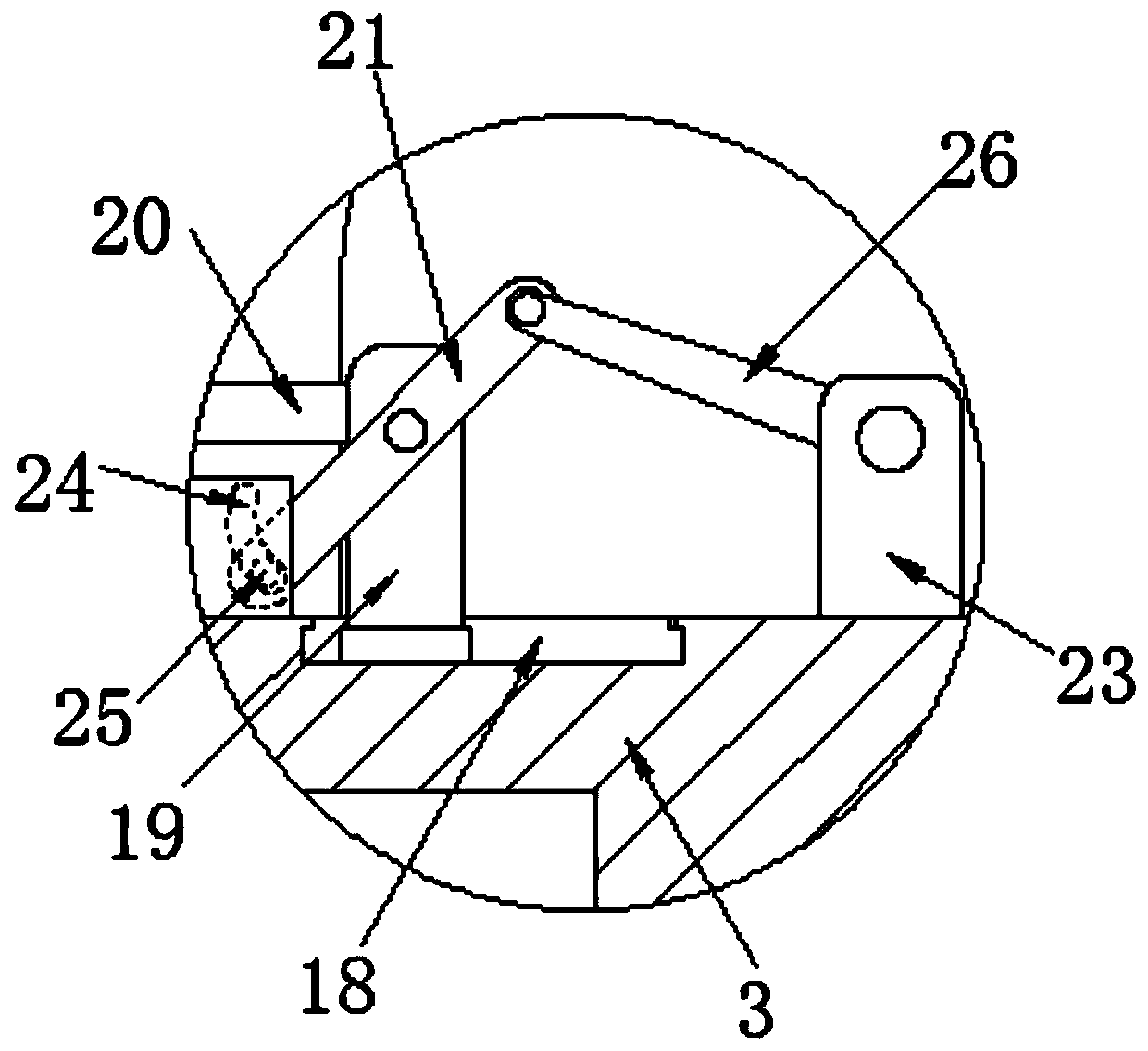

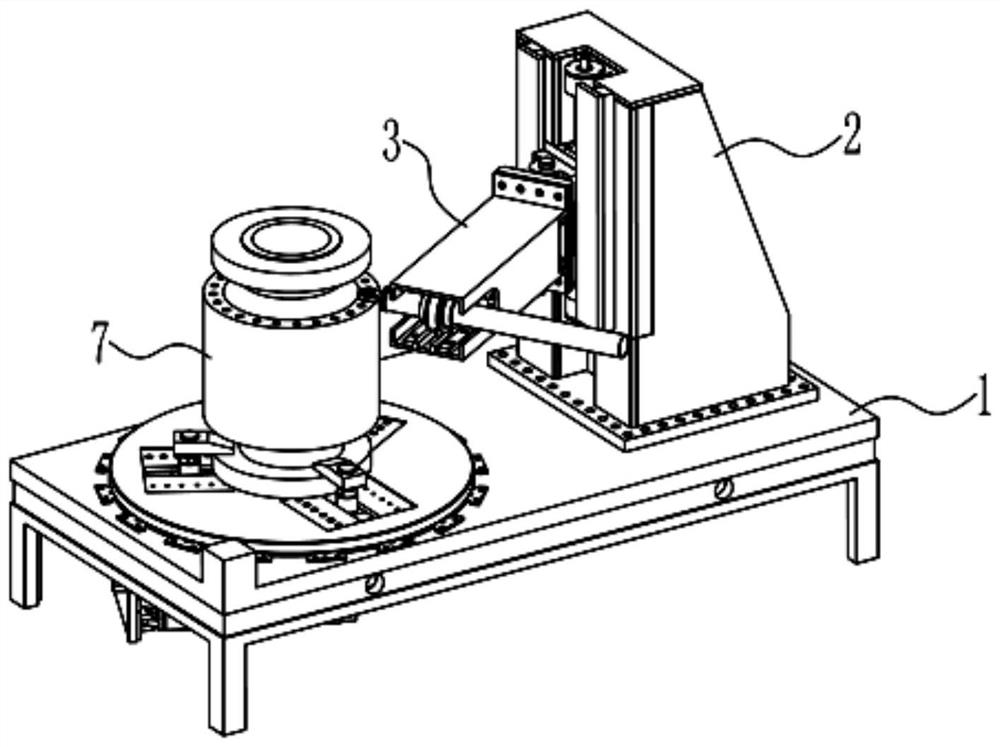

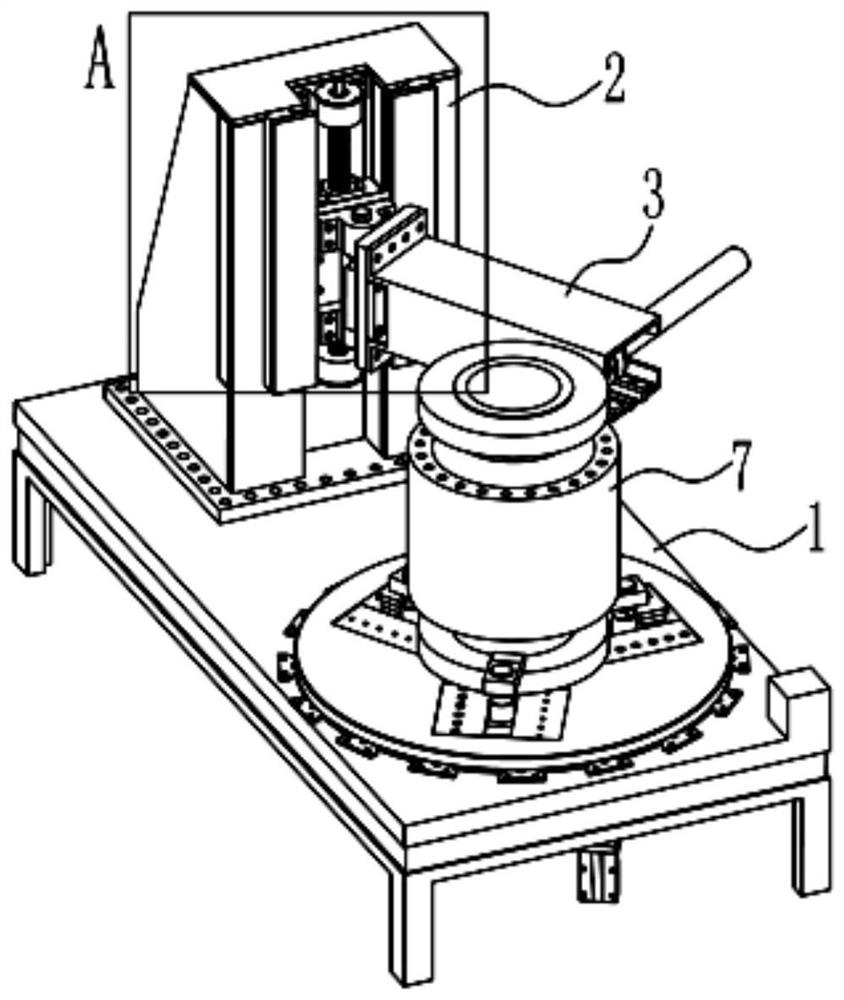

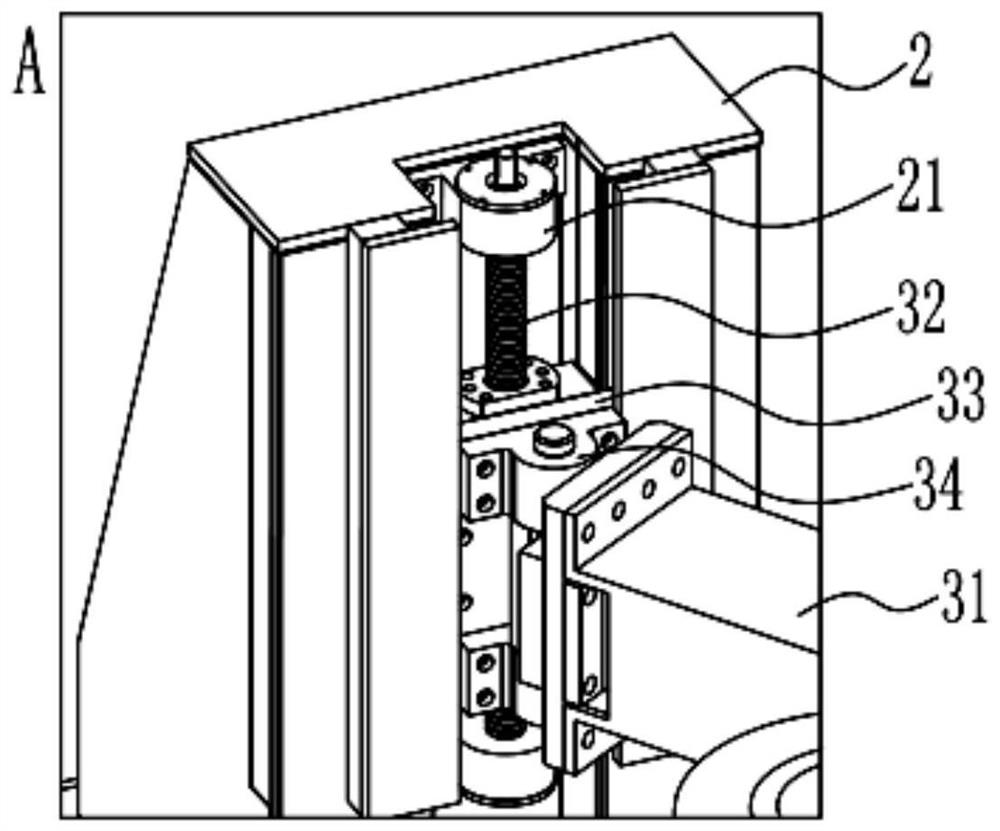

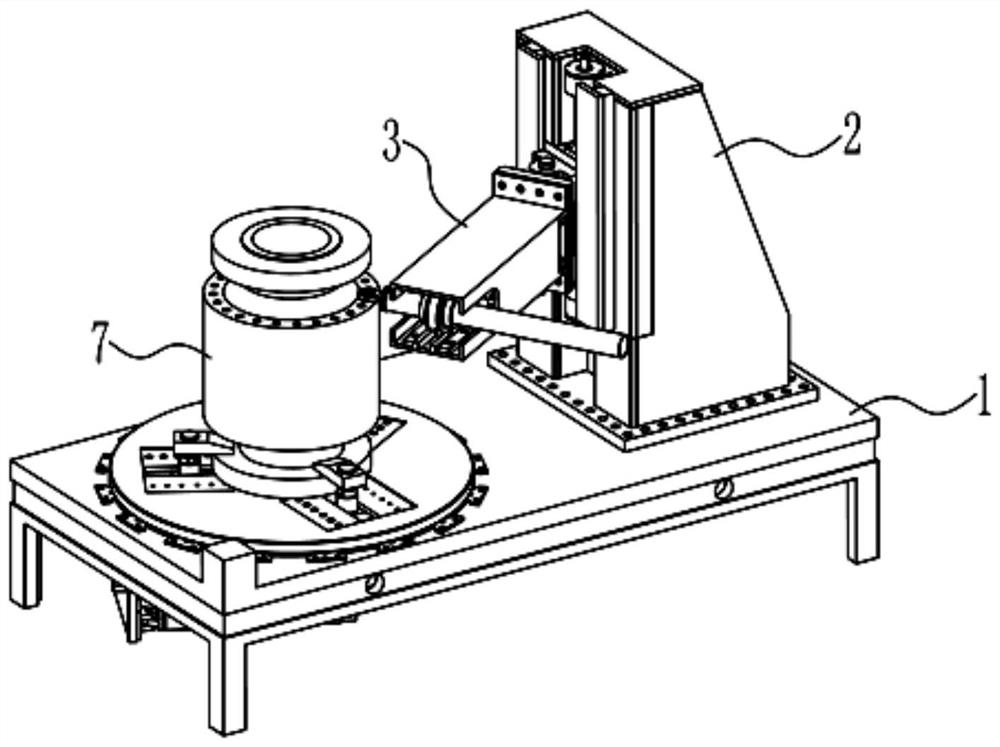

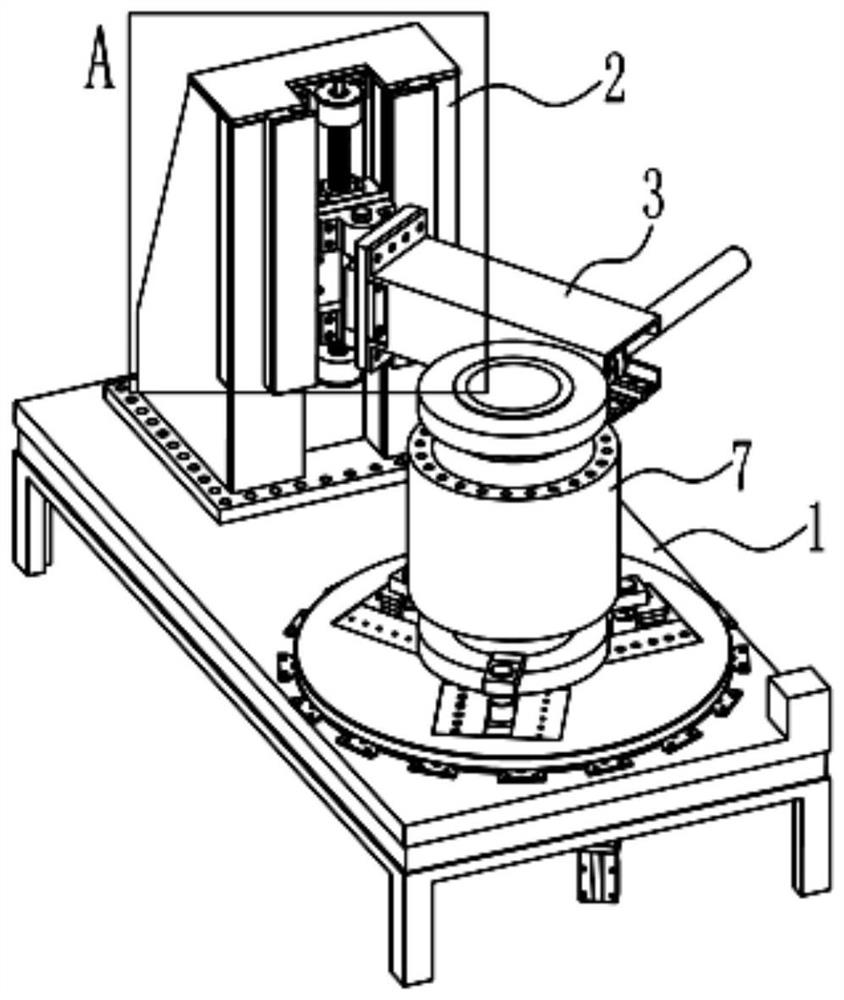

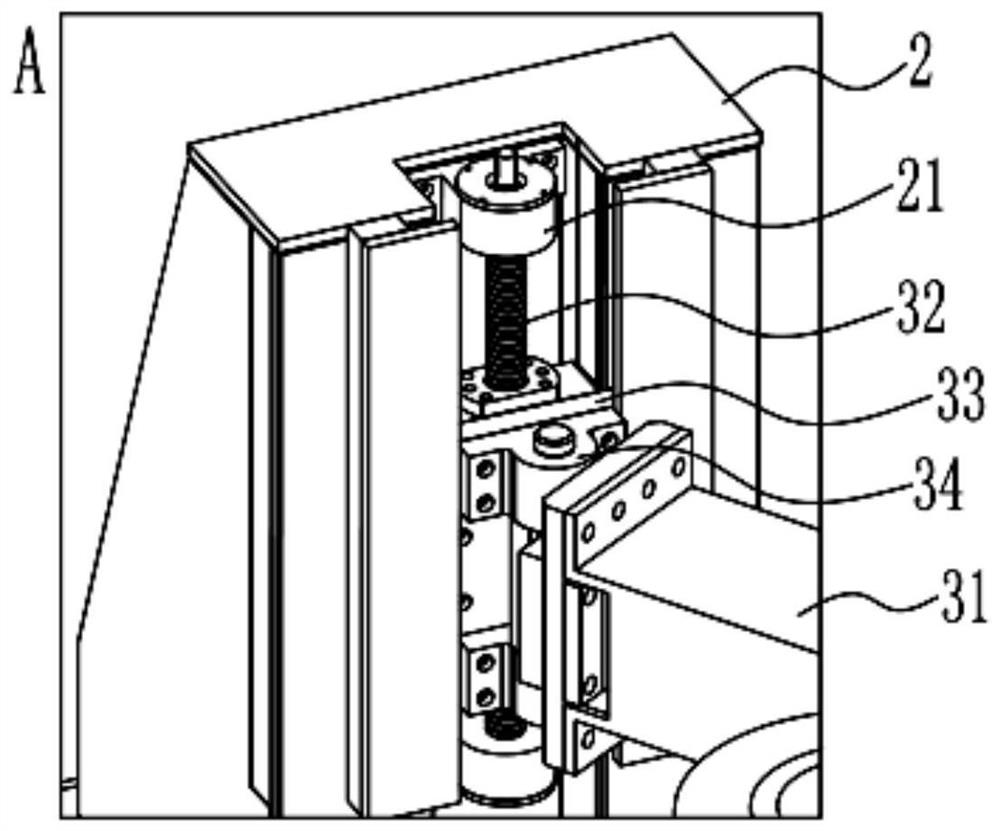

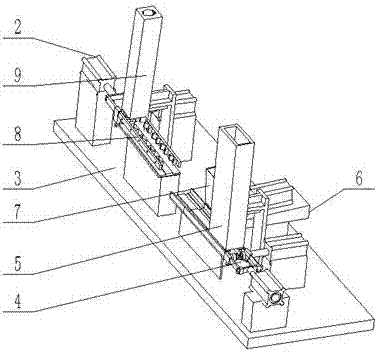

Dismounting and tightening equipment for valve connecting bolt

ActiveCN112828574ARealize simultaneous movementAchieve the purpose of turningMetal working apparatusHydraulic cylinderEngineering

The invention discloses dismounting and tightening equipment for a valve connecting bolt. The dismounting and tightening equipment comprises a workbench, a stand column, a movable connecting arm, a solid wrench connecting device, a rotating device, and a pressing device. The stand column and the rotating device are installed on the workbench. The movable connecting arm is connected with the stand column and the solid wrench connecting device. The pressing device is installed on the rotating device; a valve is arranged on the rotating device; and the rotating device enables the valve to rotate in the axial direction of the rotating device. The movable connecting arm comprises a shell, a lead screw, a sliding block, a hinge lug, and a first hydraulic cylinder. Two ends of the lead screw are rotationally connected with the stand column; the sliding block is in threaded connection with the lead screw; one surface, far away from the lead screw, of the sliding block is fixedly connected with the hinge lug; a first hydraulic cylinder is installed in the shell; and a piston rod of the first hydraulic cylinder is connected with the solid wrench connecting device. According to the dismounting and tightening equipment for the valve connecting bolt, aiming at the conditions that the positions of connecting bolts of many valves are narrow and the space is limited, the bolts can be automatically tightened and disassembled, and the device can be suitable for valves of different specifications.

Owner:CHONGQING JIUHUAN MACHINERY & ELECTRIC CO LTD

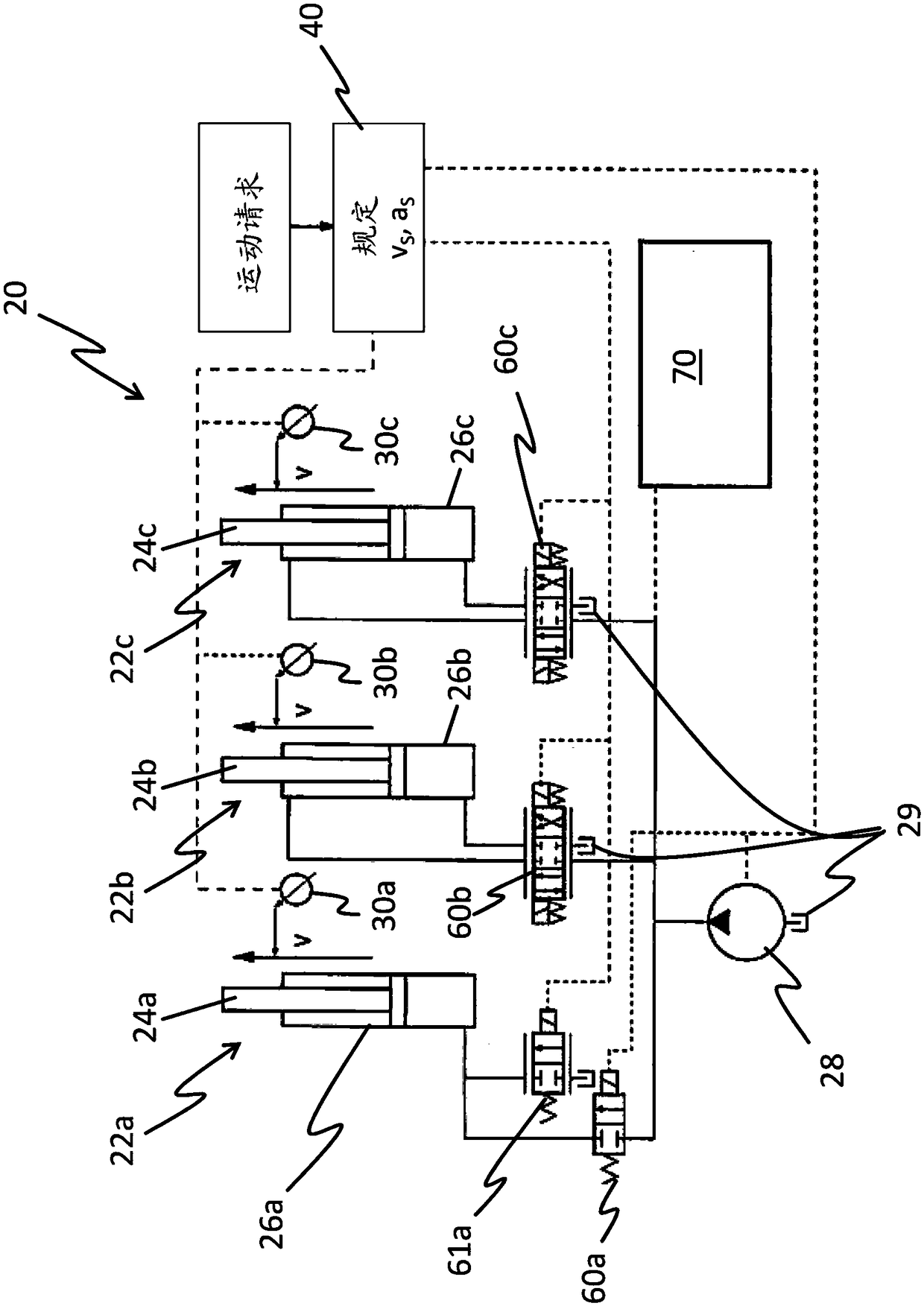

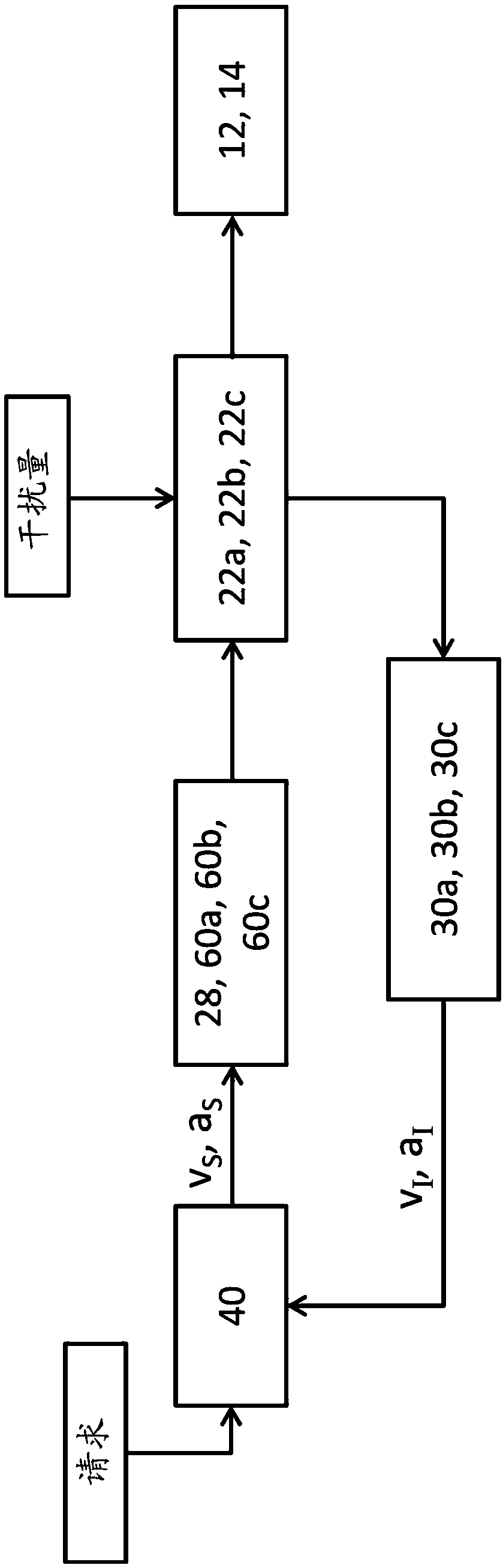

Industrial truck having a control unit for regulating the movement of a hydraulic cylinder, and method for controlling the same

PendingCN108217541ARealize simultaneous movementSimple structureServomotorsServometer circuitsHydraulic cylinderEngineering

An industrial truck comprises a lift frame having a load part for carrying a load and a hydraulic system including at least one hydraulic cylinder having a piston rod disposed within a cylindrical housing, and a hydraulic power unit. At least one sensor is configured to determine at least one of: (i) an actual speed of the piston rod of the at least one hydraulic cylinder, and (ii) an actual acceleration of the piston rod of the at least one hydraulic cylinder. Furthermore, a control unit is configured to: (i) receive at least one of a target speed of the piston rod and a target acceleration of the piston rod, (ii) determine at least one of a speed control deviation value from the target speed, and an acceleration control deviation value from the target acceleration, and, (iii) regulate atleast one of the actual speed of the piston rod based on the actual speed control deviation value and the actual acceleration of the piston rod based on the actual acceleration control deviation value.

Owner:JUNGHEINRICH AG

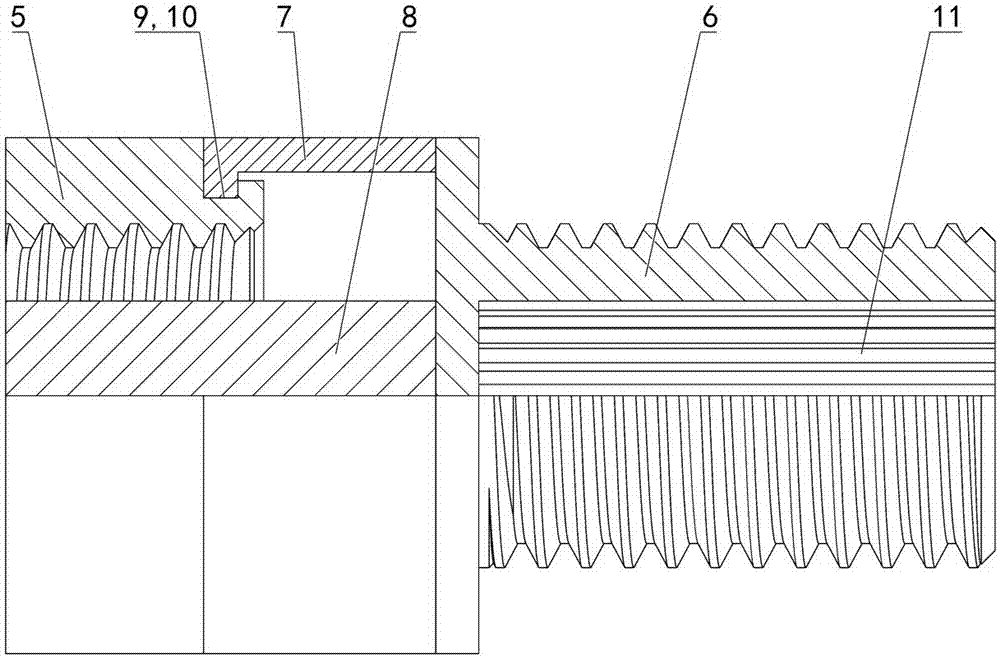

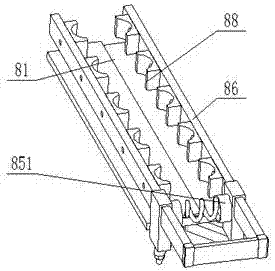

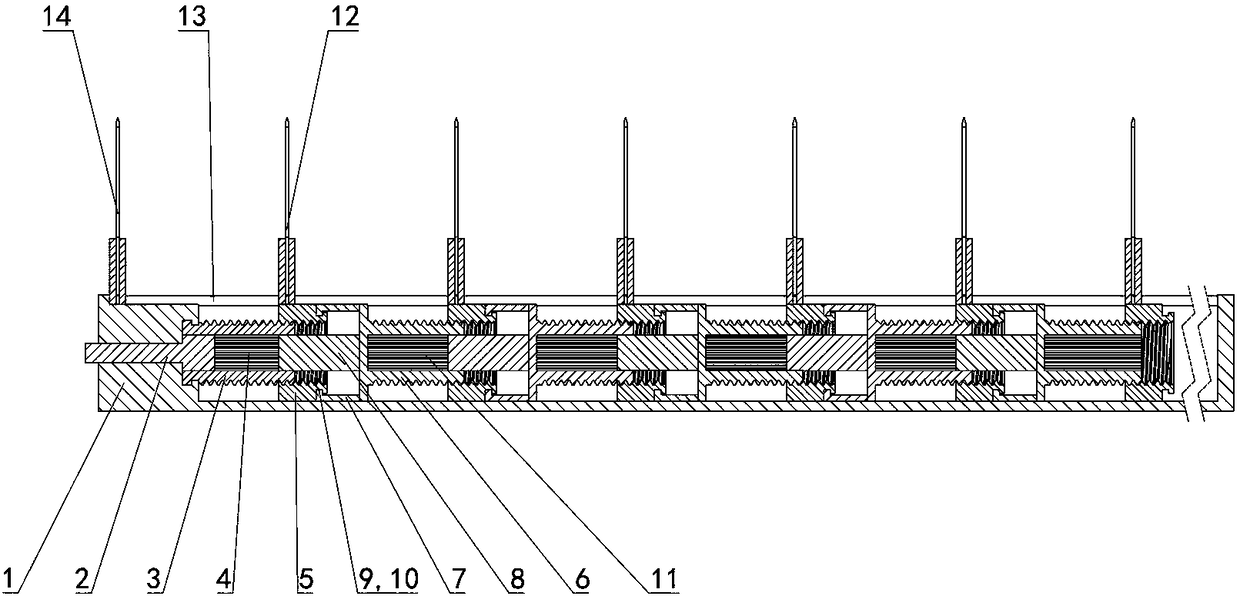

Isometric adjusting device for slitting tool equipment

InactiveCN107297780ARealize simultaneous movementKeep relative moving distance in real timeMetal working apparatusFixed frameEngineering

The invention relates to an isometric adjusting device for slitting tool equipment. The isometric adjusting device comprises a fixing frame with a cylindrical cavity, a rotating shaft is mounted at the left end of the fixing frame, a cylinder in the cavity is mounted on the fixing frame, and the rotating shaft and the cylinder are in spline connection. The right side of the cylinder is provided with a plurality of tool rest units in the cavity. Each tool rest unit comprises a nut, a bolt, a ferrule and a spline shaft, wherein the nut is capable of sliding in the cavity, the outer peripheral surface of the nut is provided with a peripheral groove, the left end of the ferrule is provided with an inner peripheral boss in the peripheral groove, the left end of the bolt is connected with the right end of the ferrule and the right end of the spline shaft, and the right end of the bolt is provided with a spline hole. The nut in each tool rest unit is screwed to the bolt in the adjacent tool rest unit, the spline shaft in each tool rest unit is meshed with the spline hole in the adjacent tool rest unit, the nut in the tool rest unit adjacent to the cylinder is in threaded connection with the cylinder, and the spline shaft in the tool rest unit adjacent to the cylinder is meshed with a spline through hole.

Owner:GUANGXI BAISE XINGHE ALUMINUM

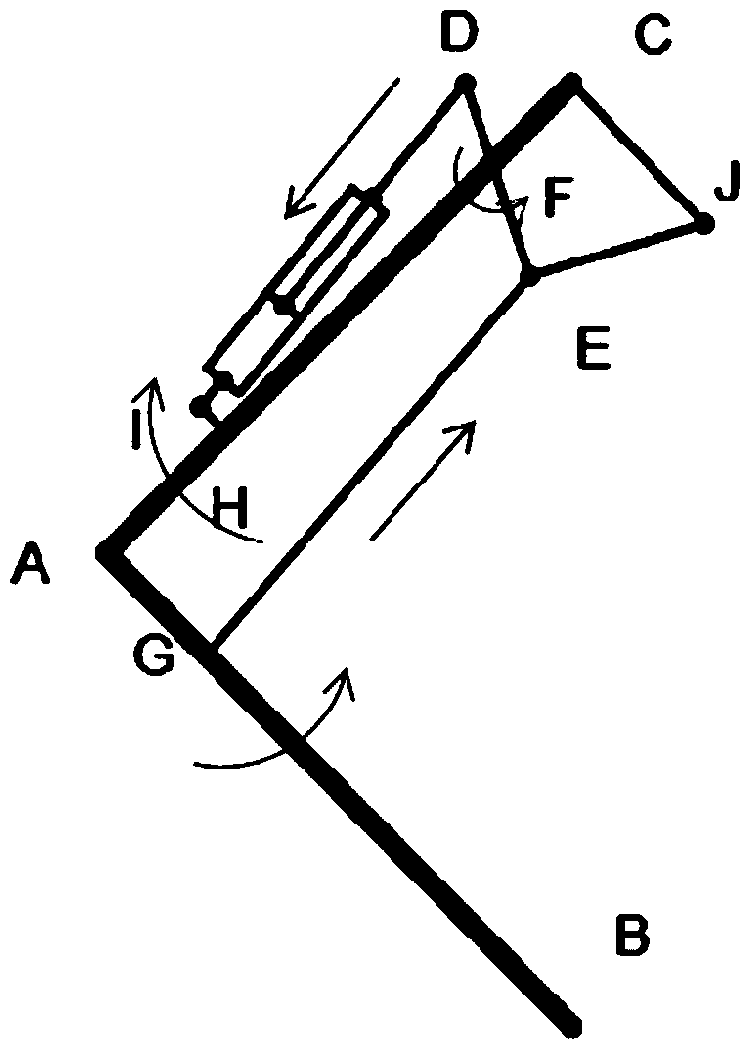

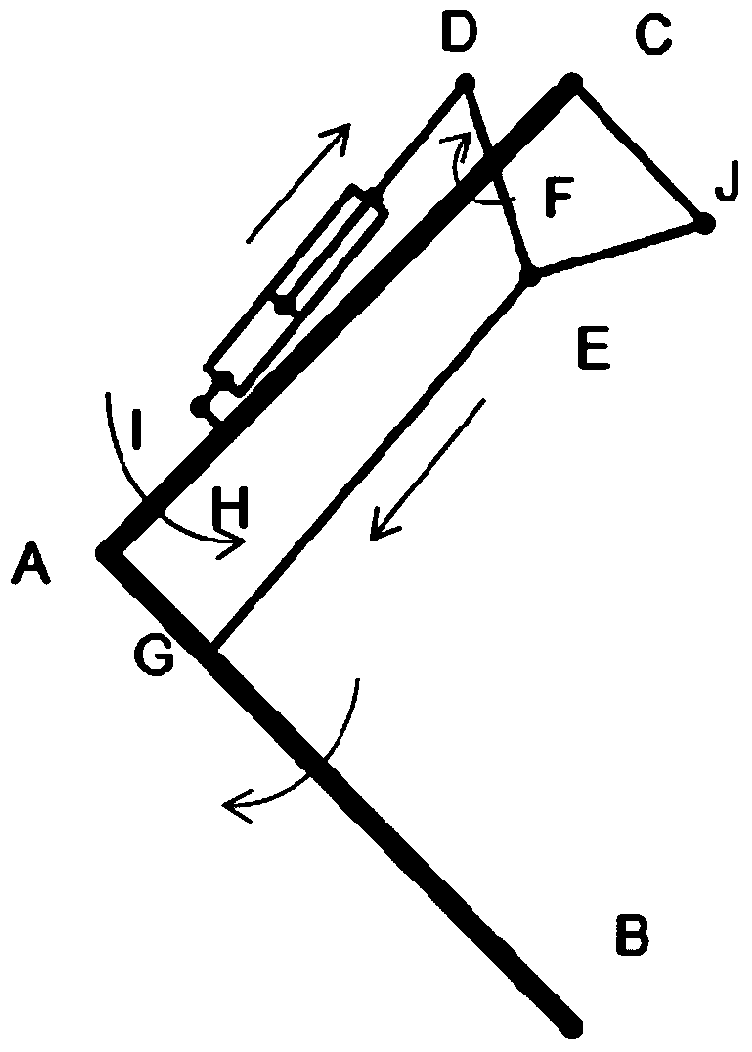

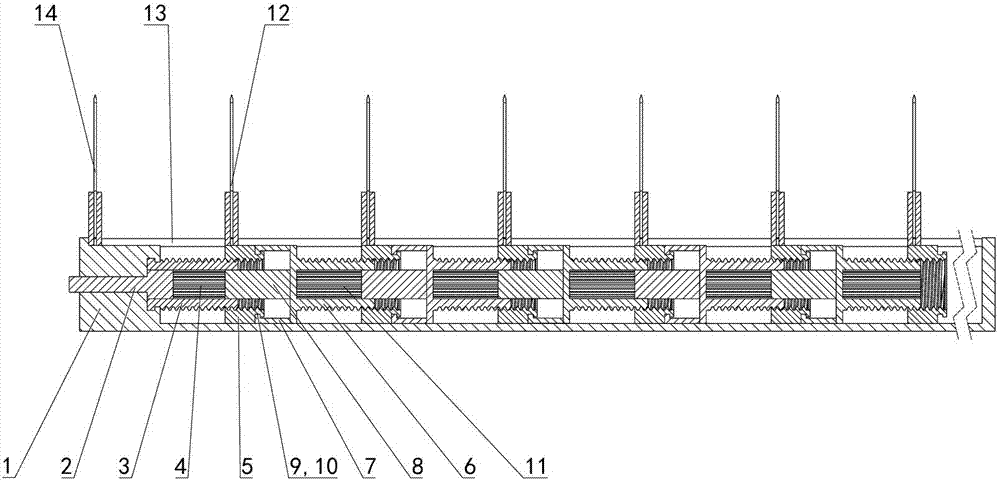

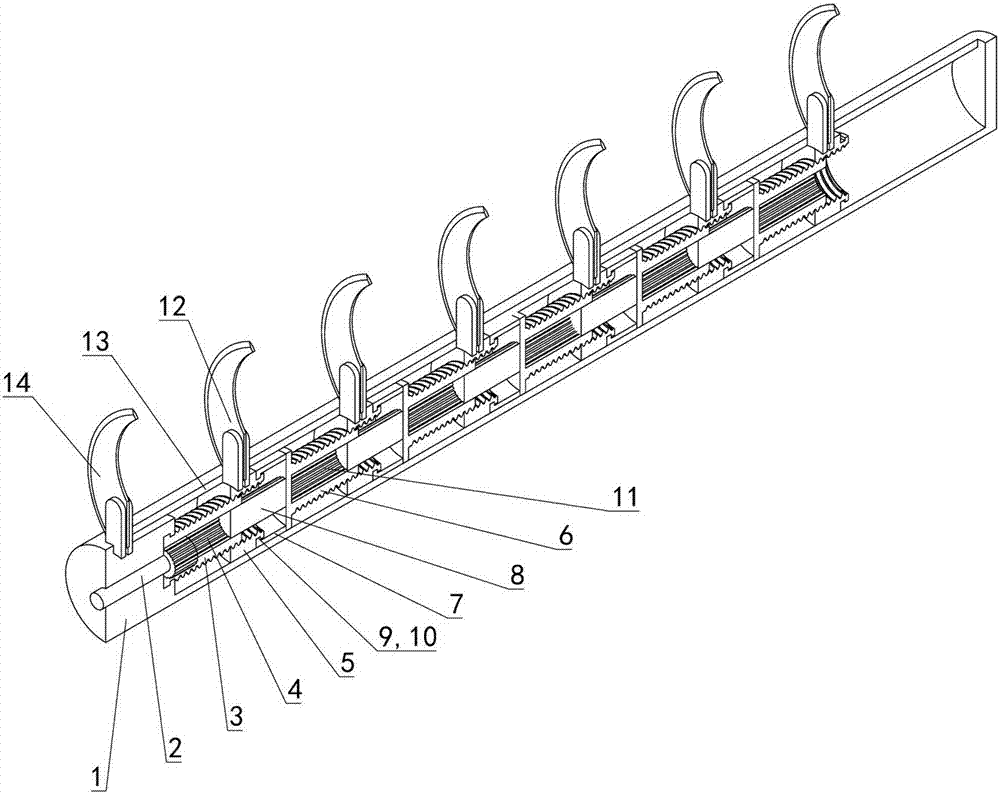

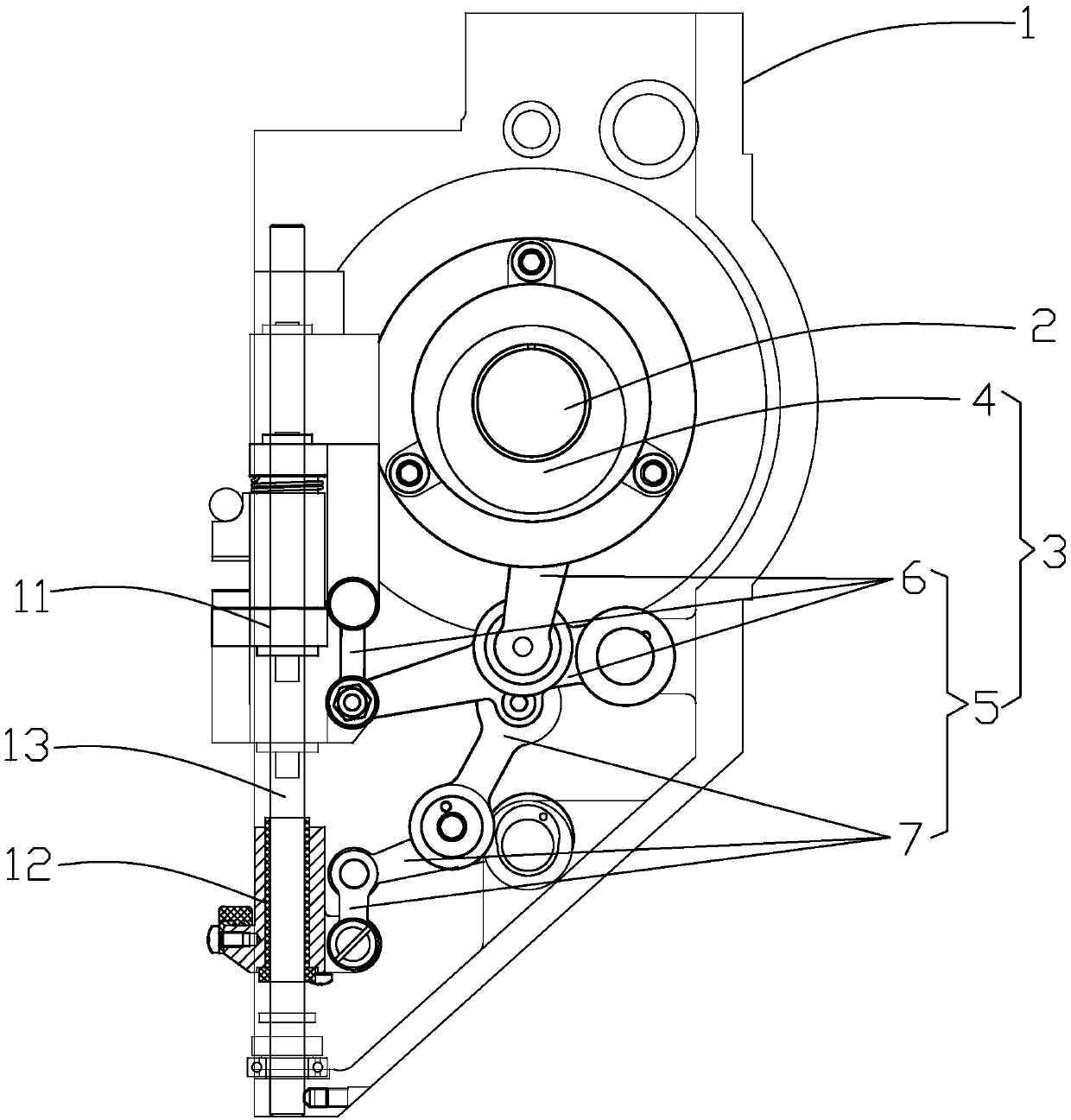

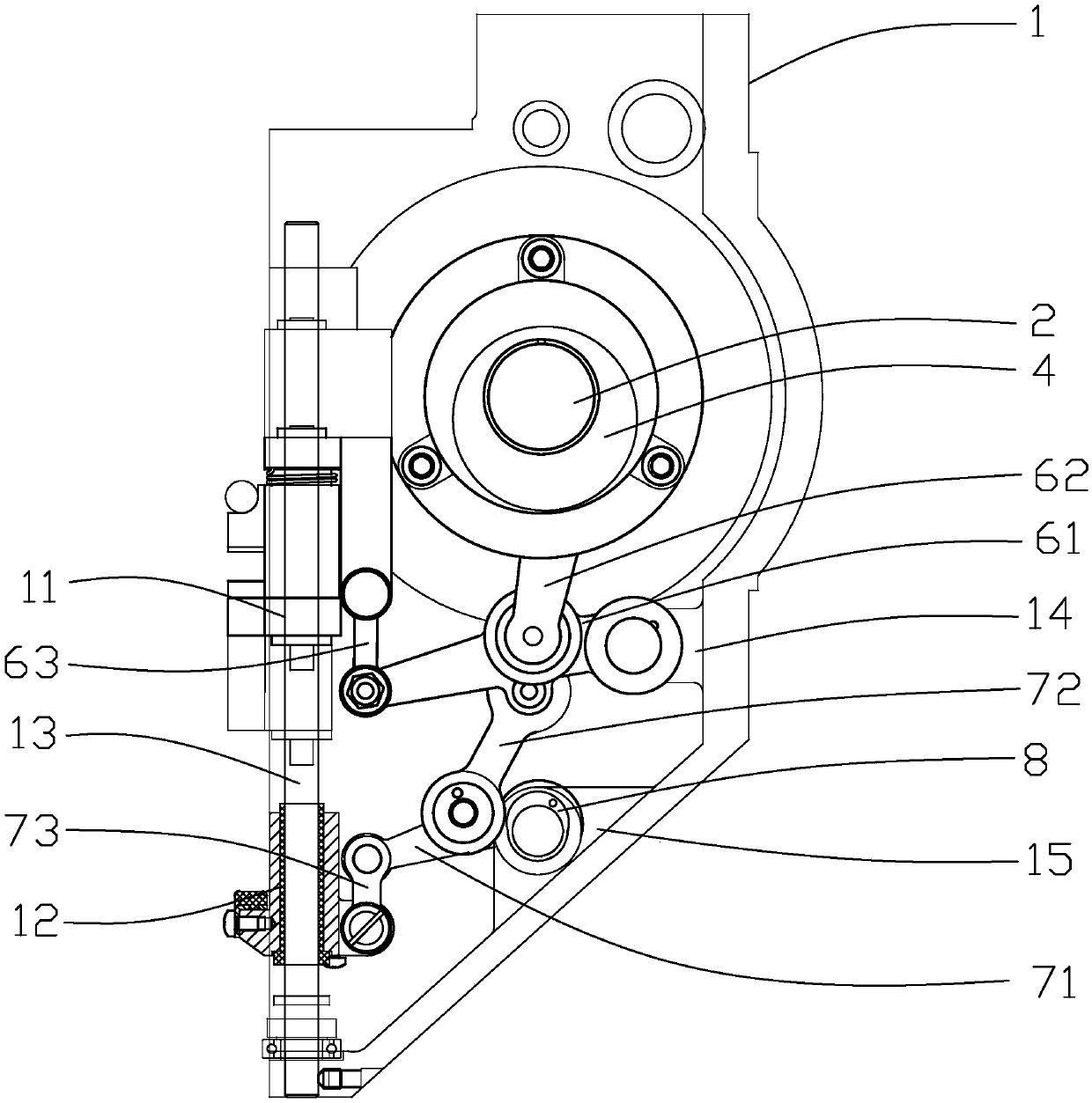

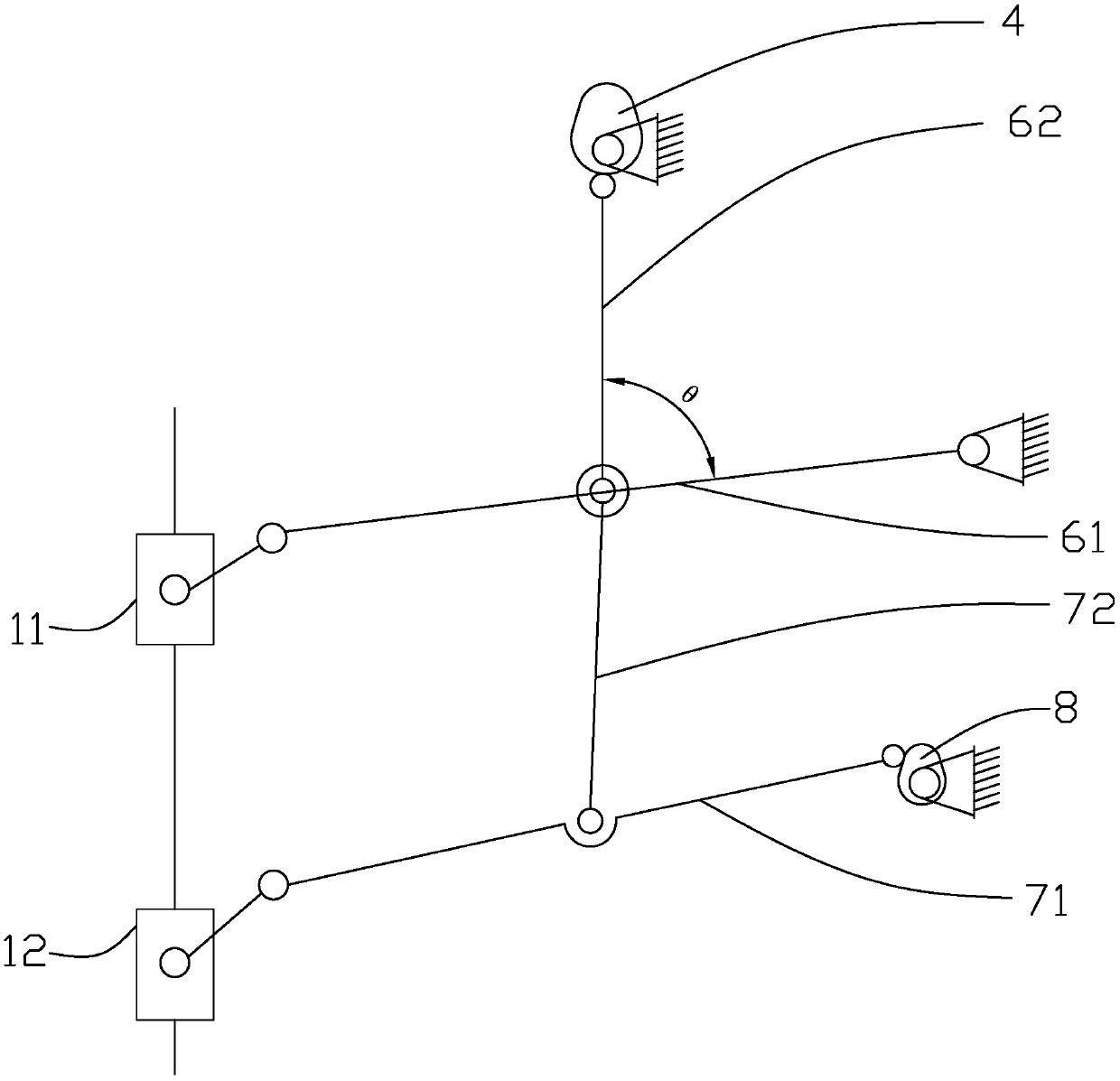

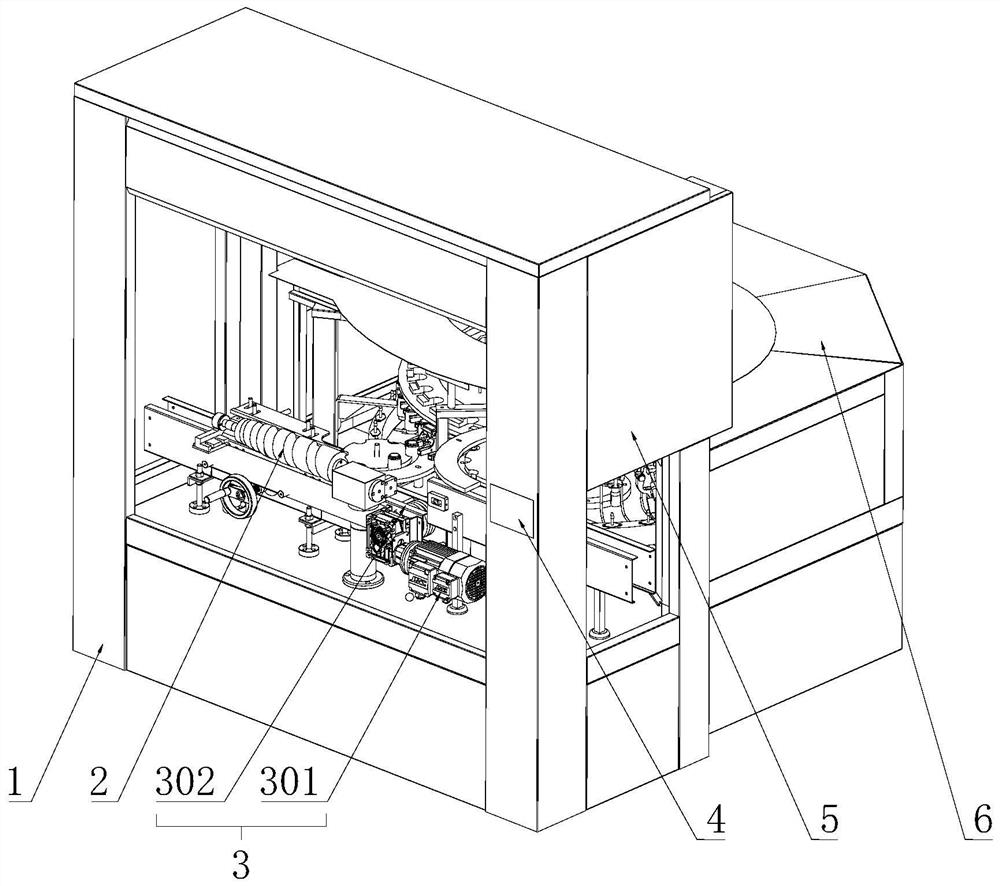

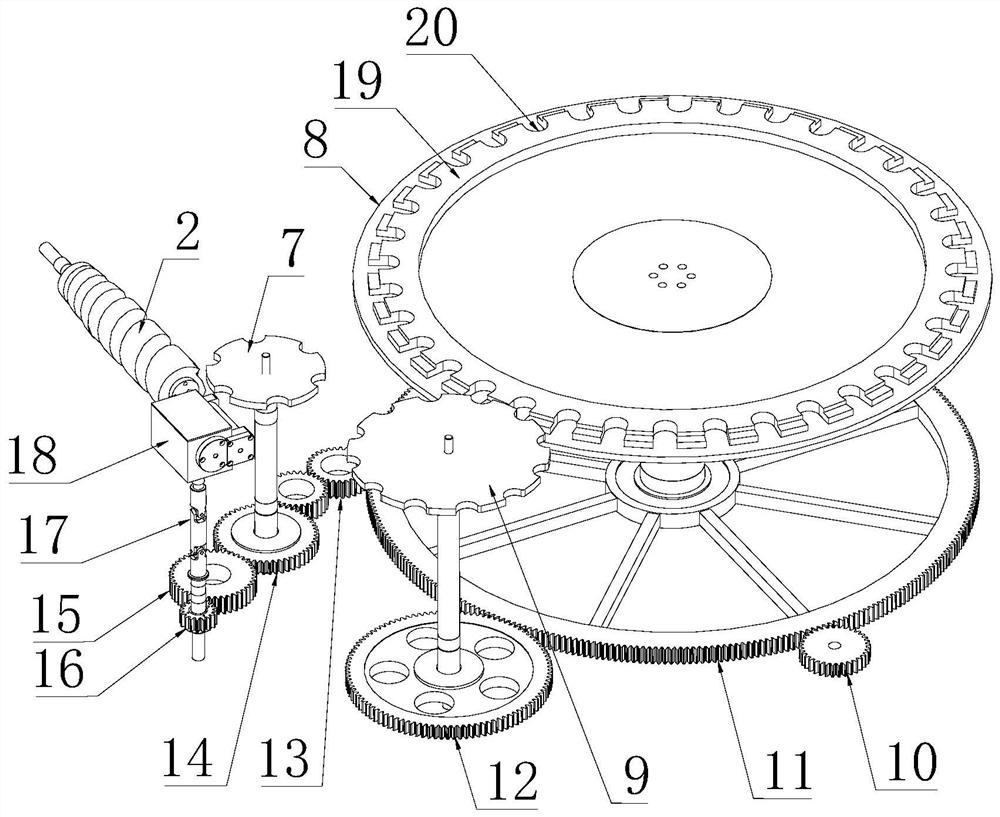

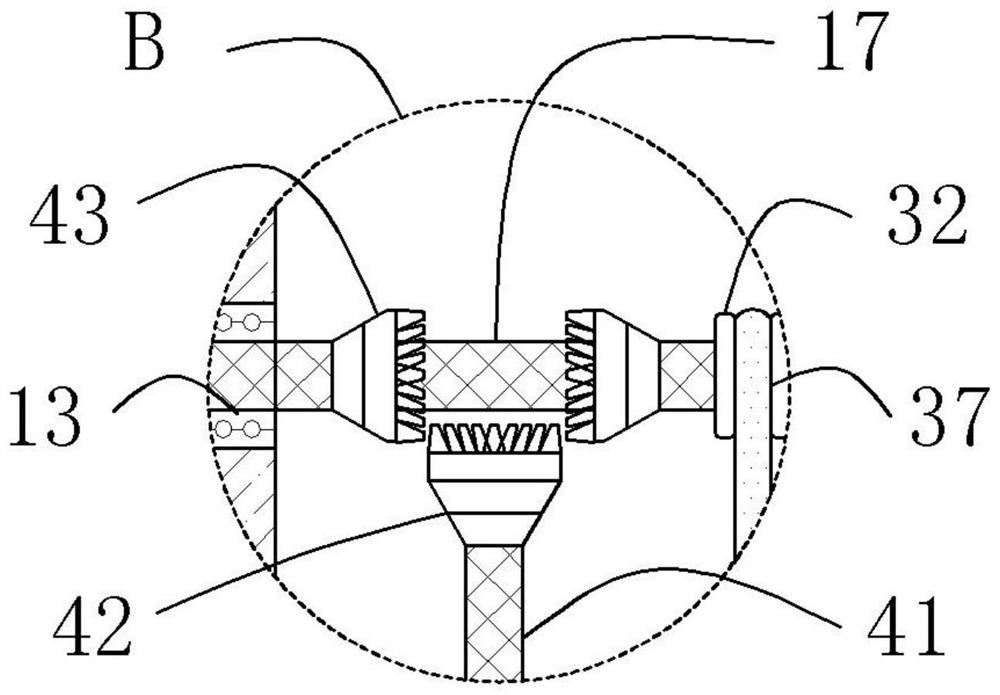

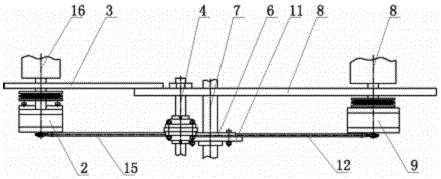

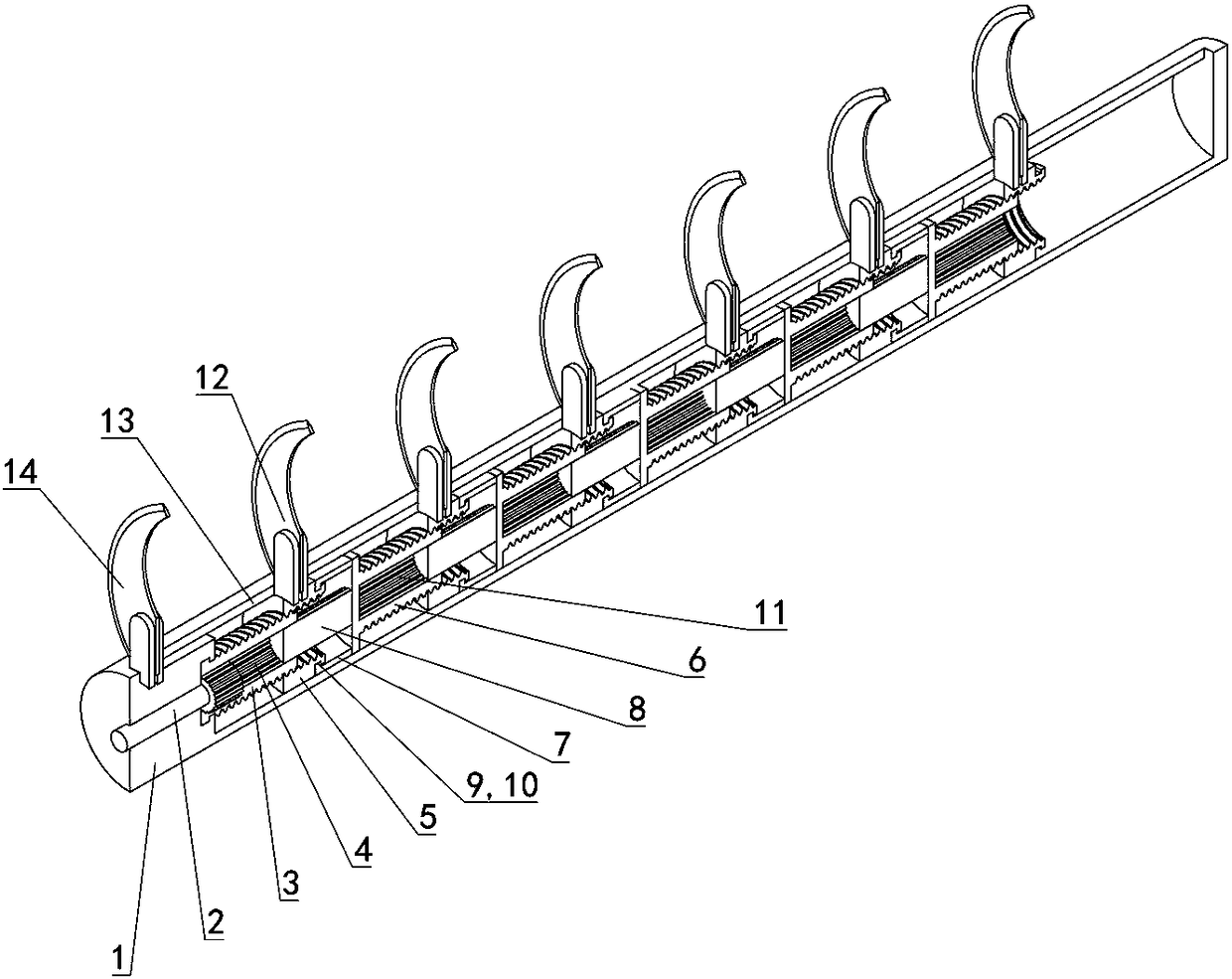

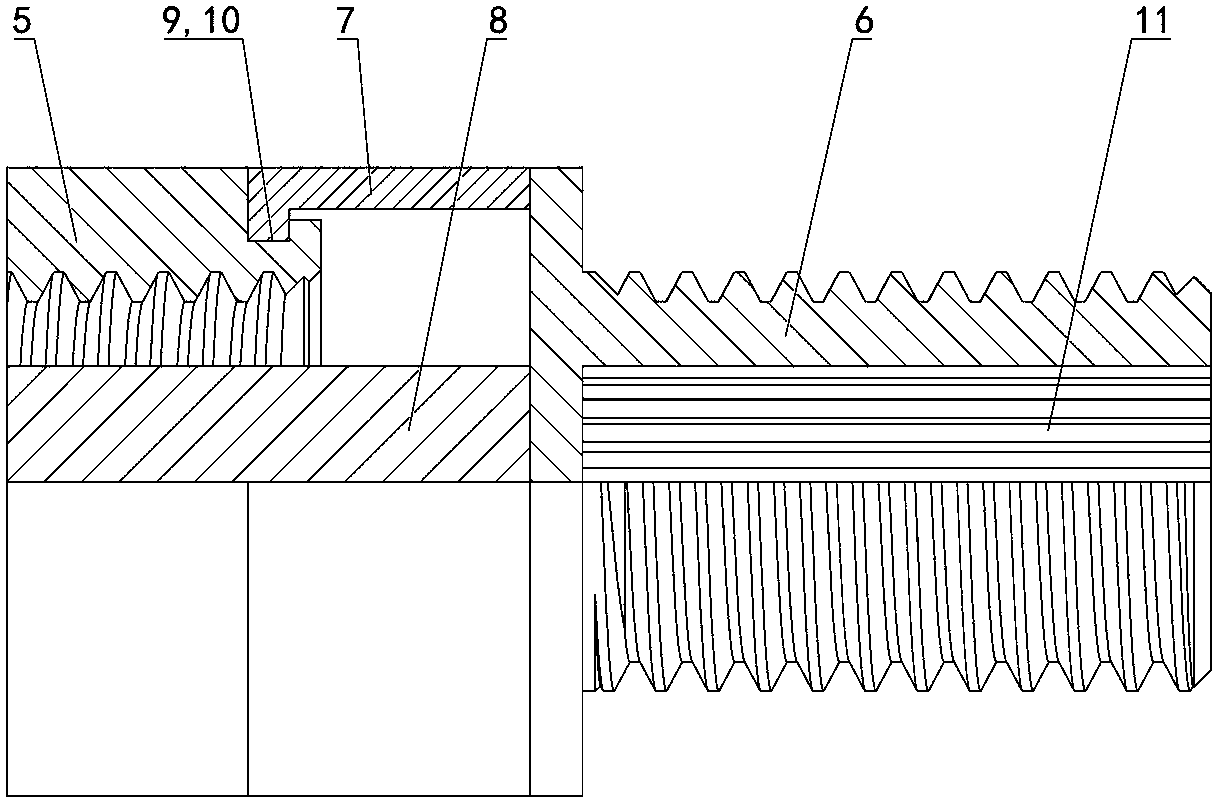

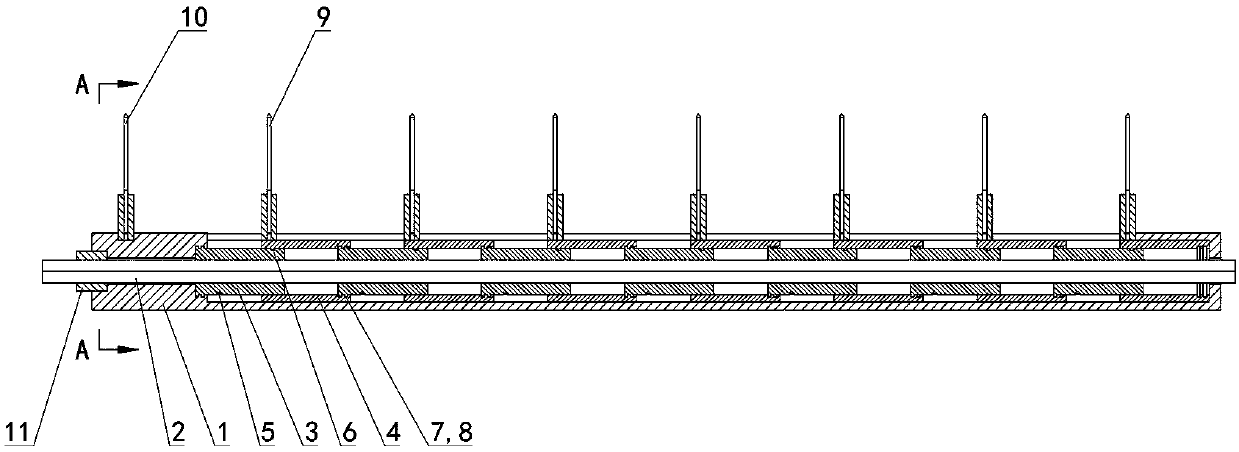

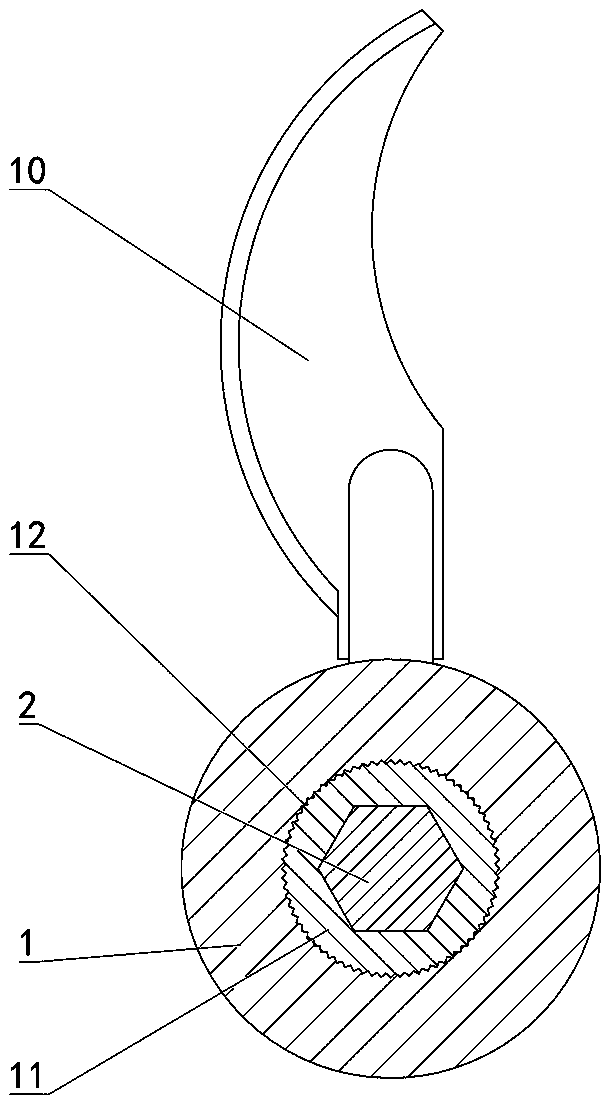

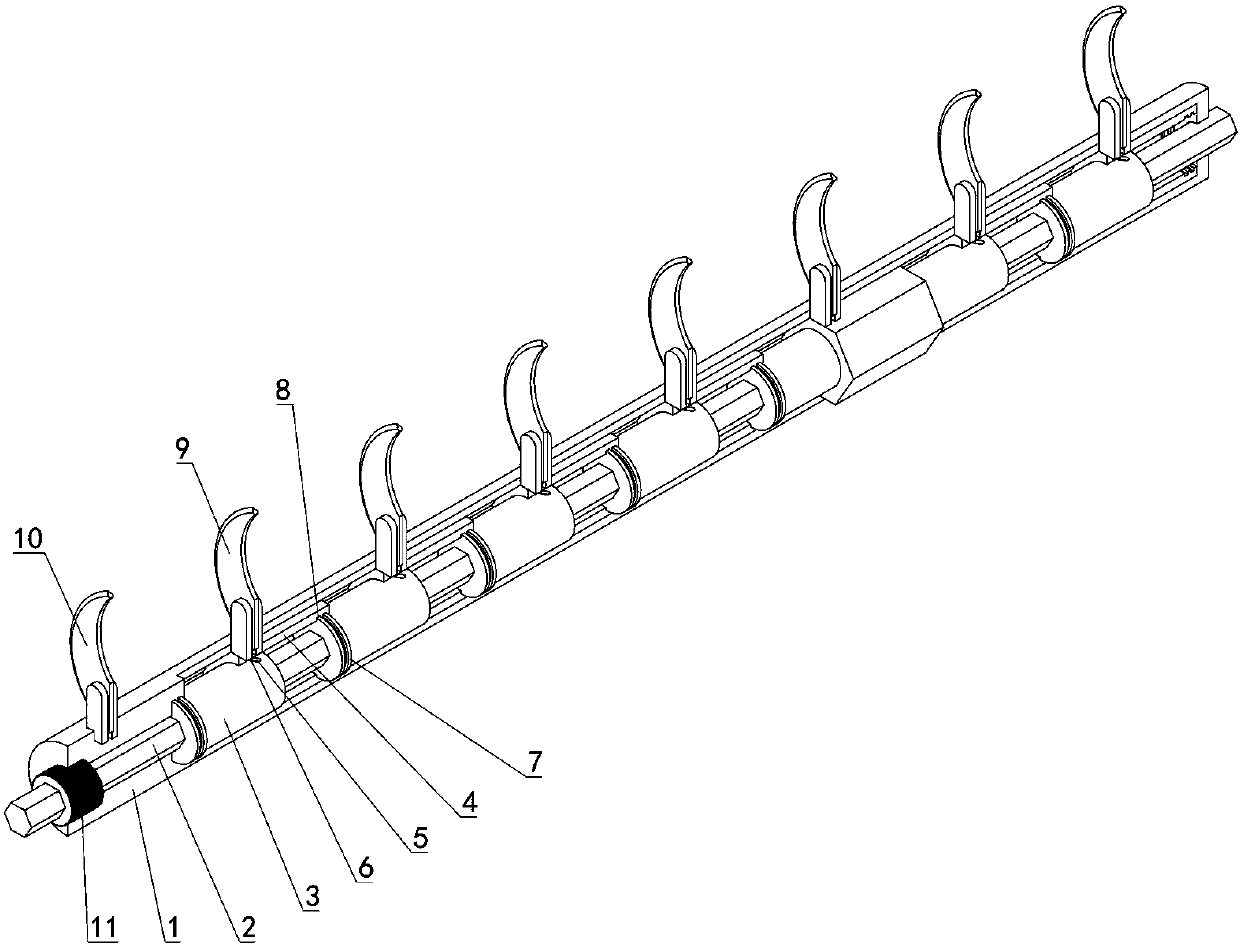

Needle rod-pressure pin driving device applied to computer embroidering machine

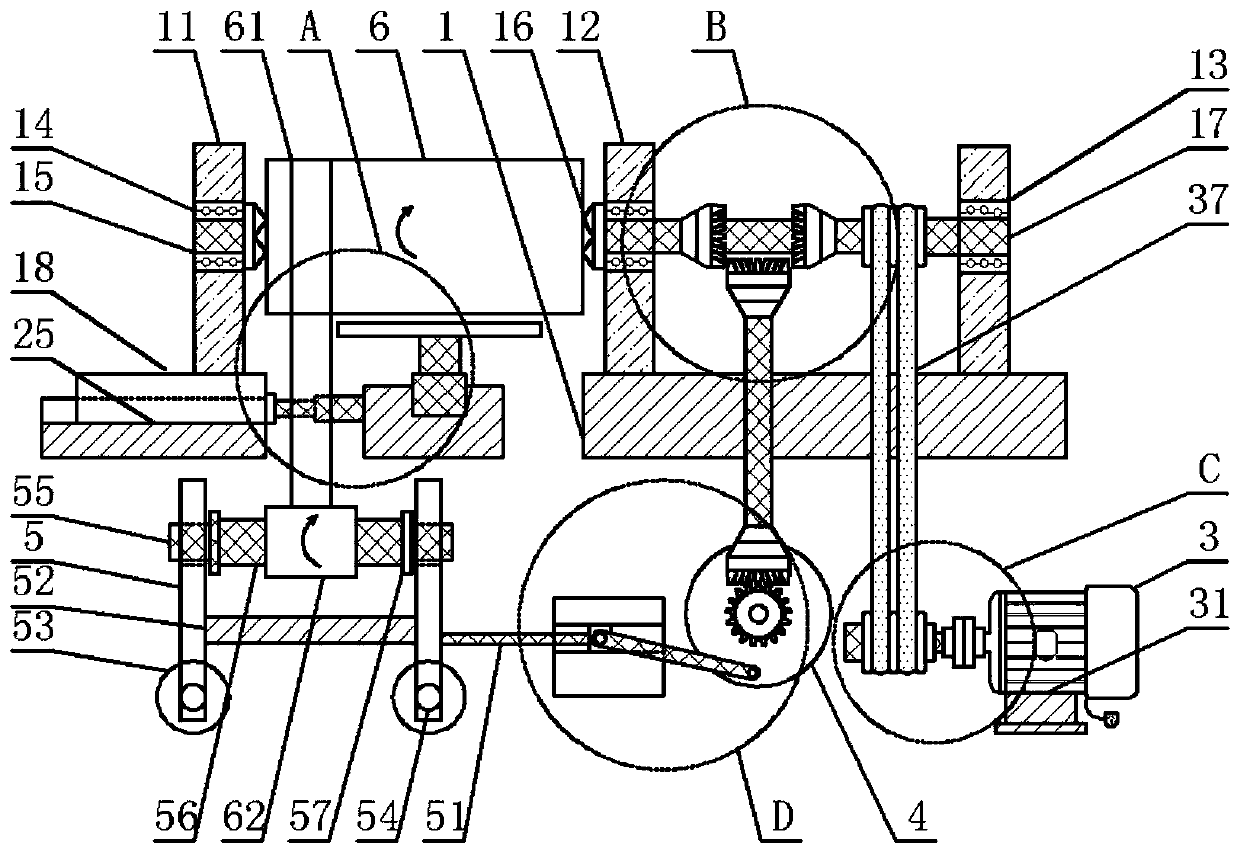

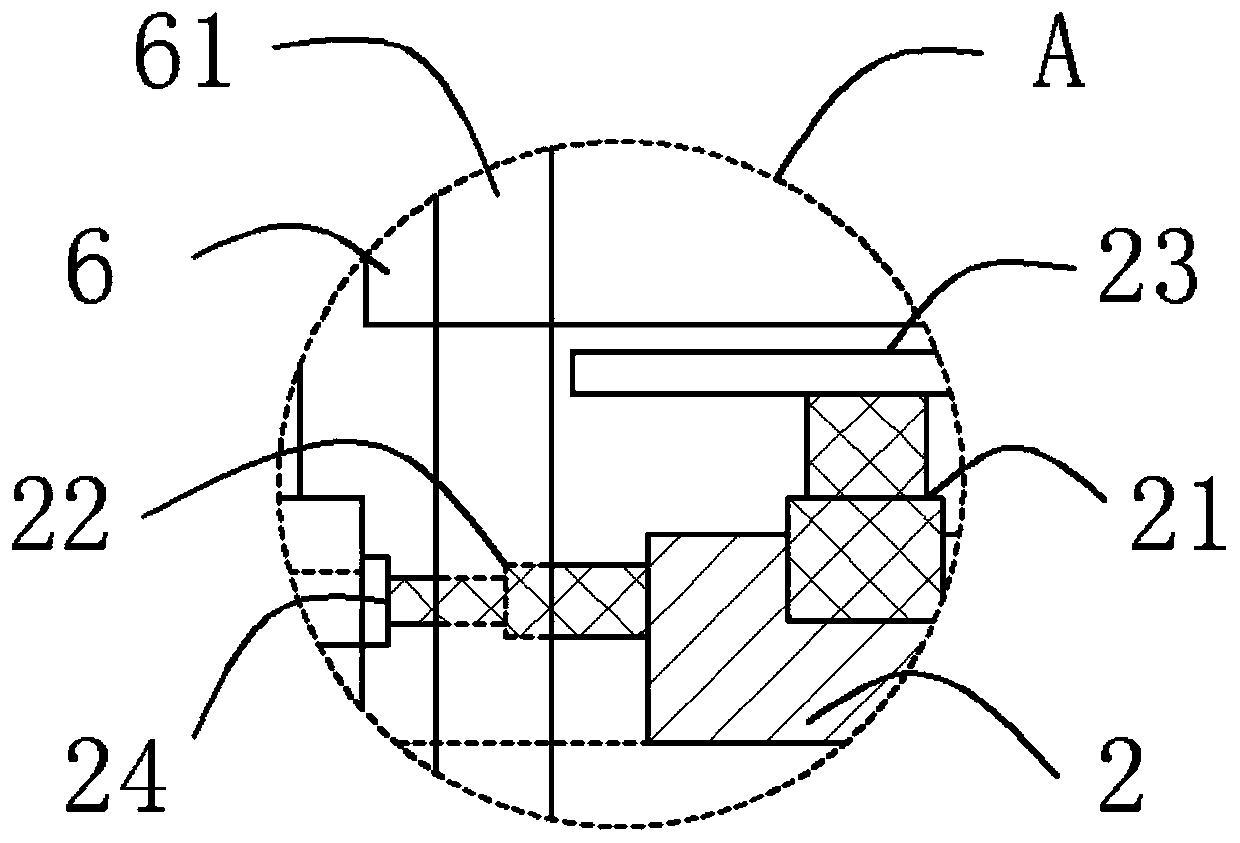

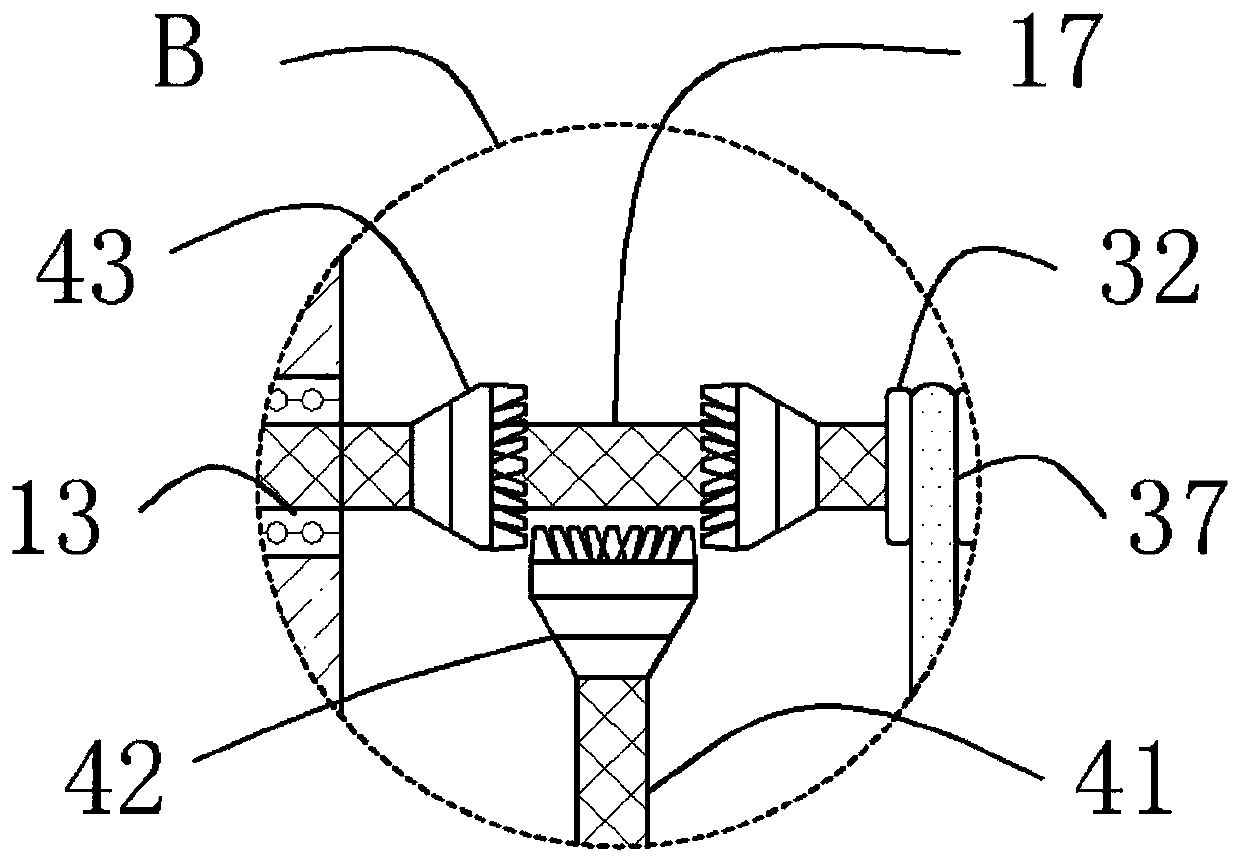

ActiveCN108950915AMovement speed is adjustableBig impactEmbroidering machines apparatusEngineeringMotion space

The invention relates to a needle rod-pressure pin driving device applied to a computer embroidering machine. The device comprises a shell and is characterized in that a driving mains shaft is arranged on the shell, wherein a driving mechanism is arranged on the driving main shaft and comprises a driving cam and a linkage mechanism, the driving cam is mounted on the driving main shaft, the linkagemechanism is connected with the driving cam and comprises a needle rod linkage mechanism and a pressure pin linkage mechanism, the needle rod linkage mechanism is used for driving a needle rod to move, and the pressure pin linkage mechanism is used for driving the pressure pin to move; the driving cam is connected with the needle rod linkage mechanism, and the pressure pin linkage mechanism is connected with the needle rod linkage mechanism; and a guide rail is further arranged on the shell, and the needle rod and the pressure pin are movably mounted on the guide rail through the driving mechanism. According to the needle rod-pressure pin driving device, the simultaneous movement of the needle rod and the pressure pin is realized; the driving mechanism is simple and practical, and drivingmechanisms required by the needle rod and the pressure pin are combined together, so that the arranged mechanical parts are reduced, meanwhile, the motion space required by the operation of the driving mechanism is reduced, and the production cost is effectively lowered.

Owner:陈启聪

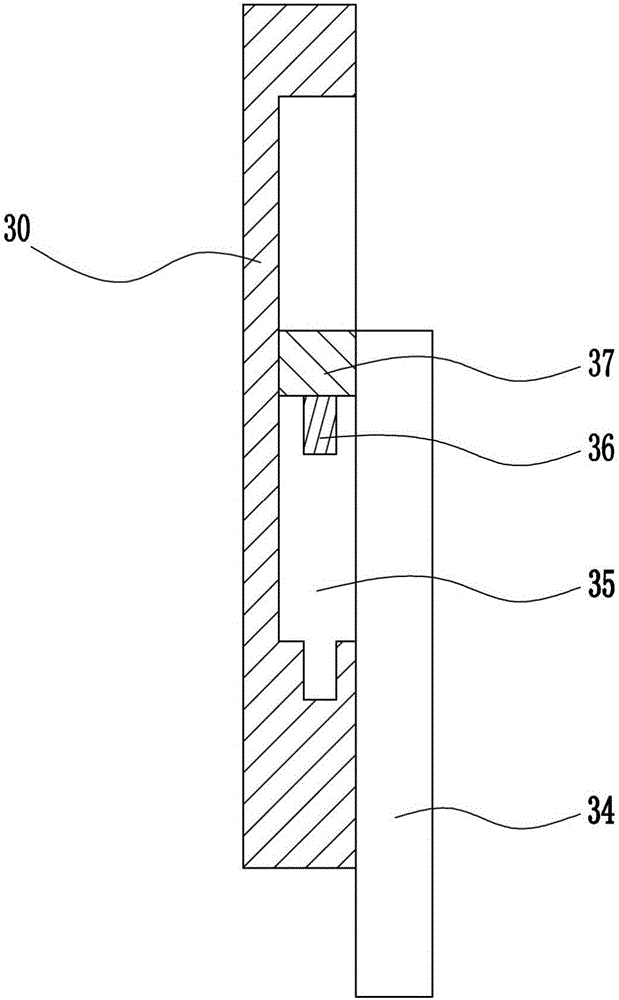

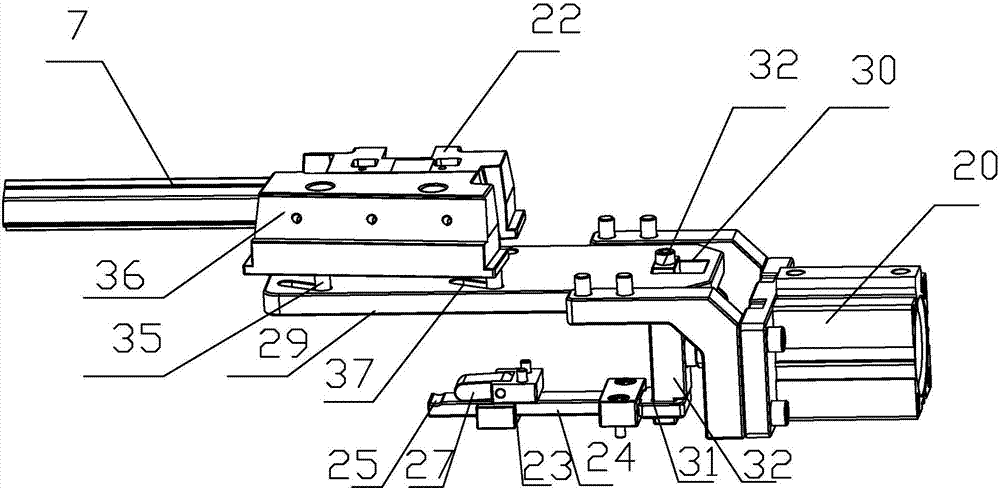

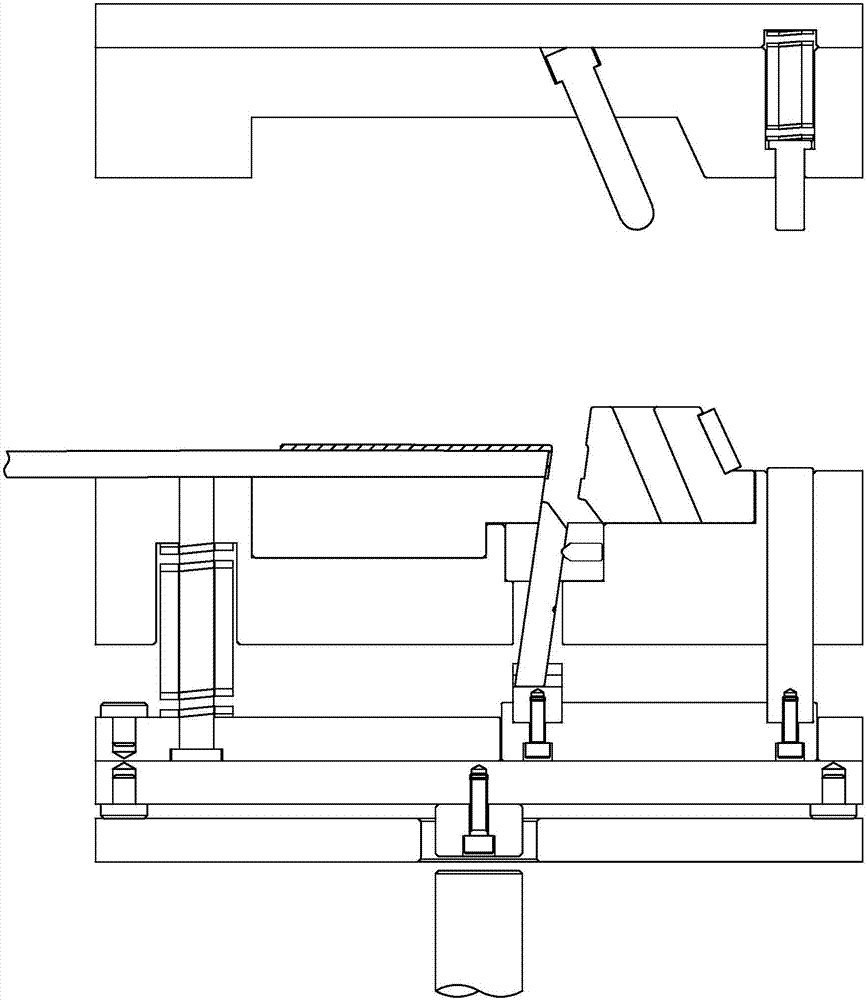

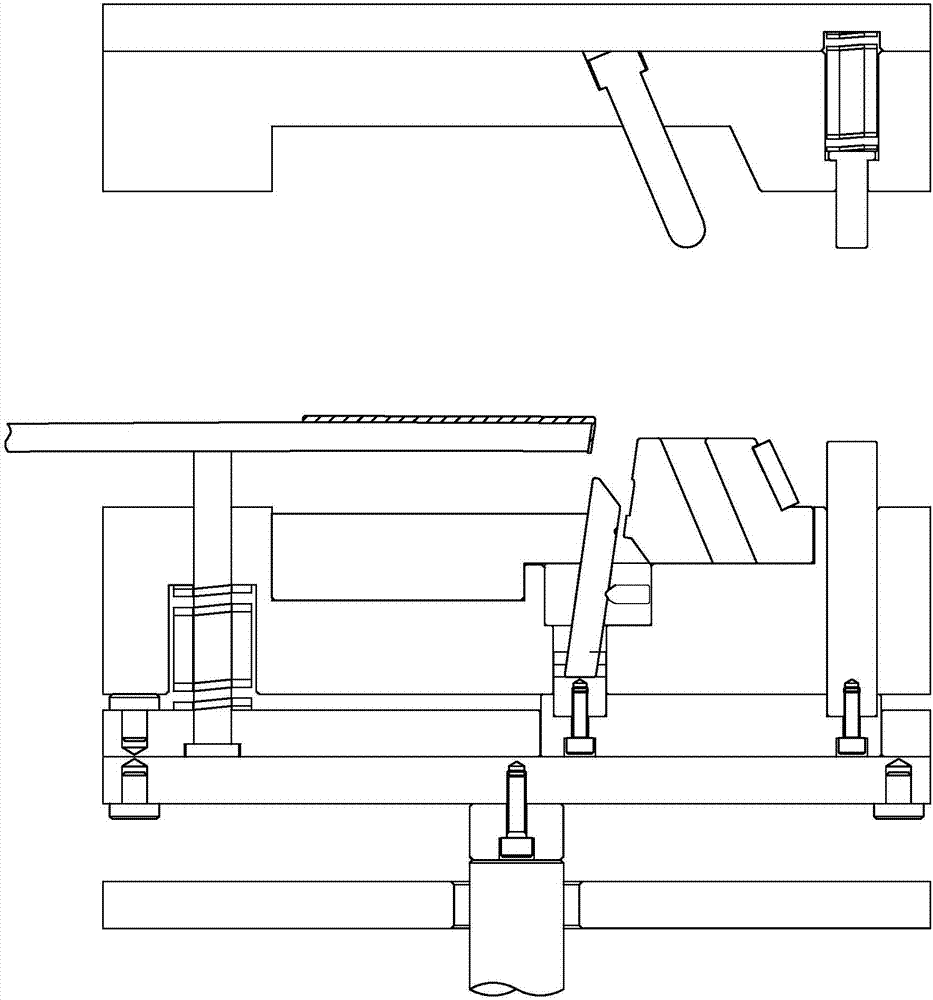

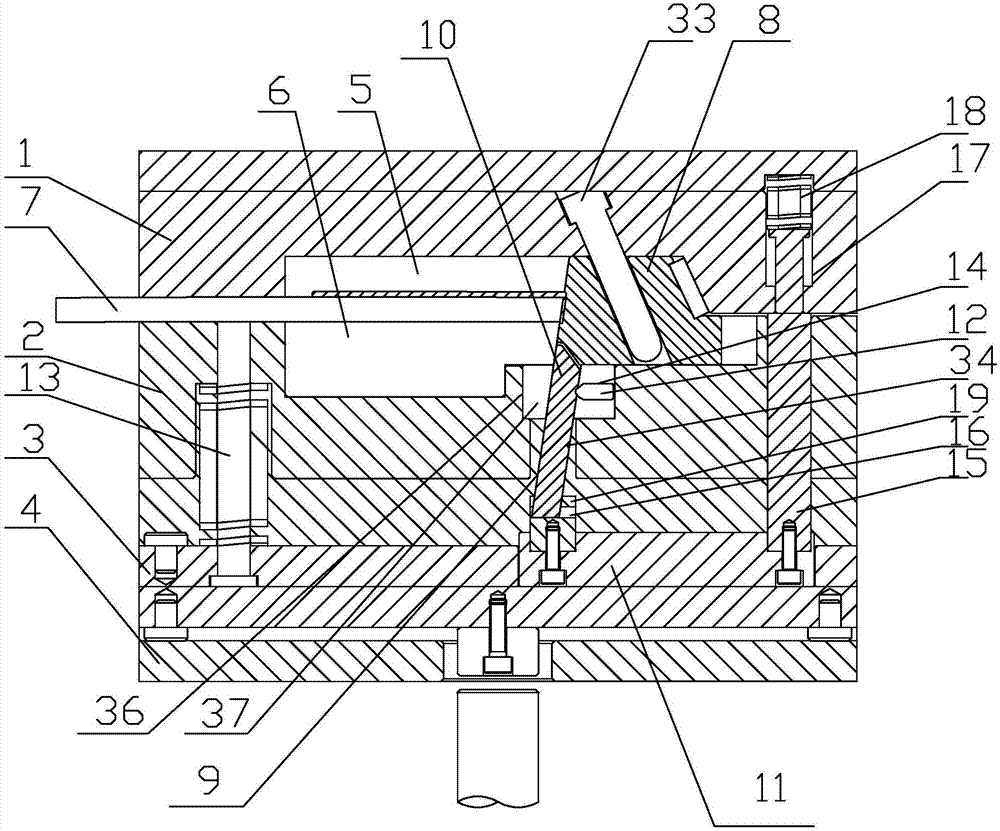

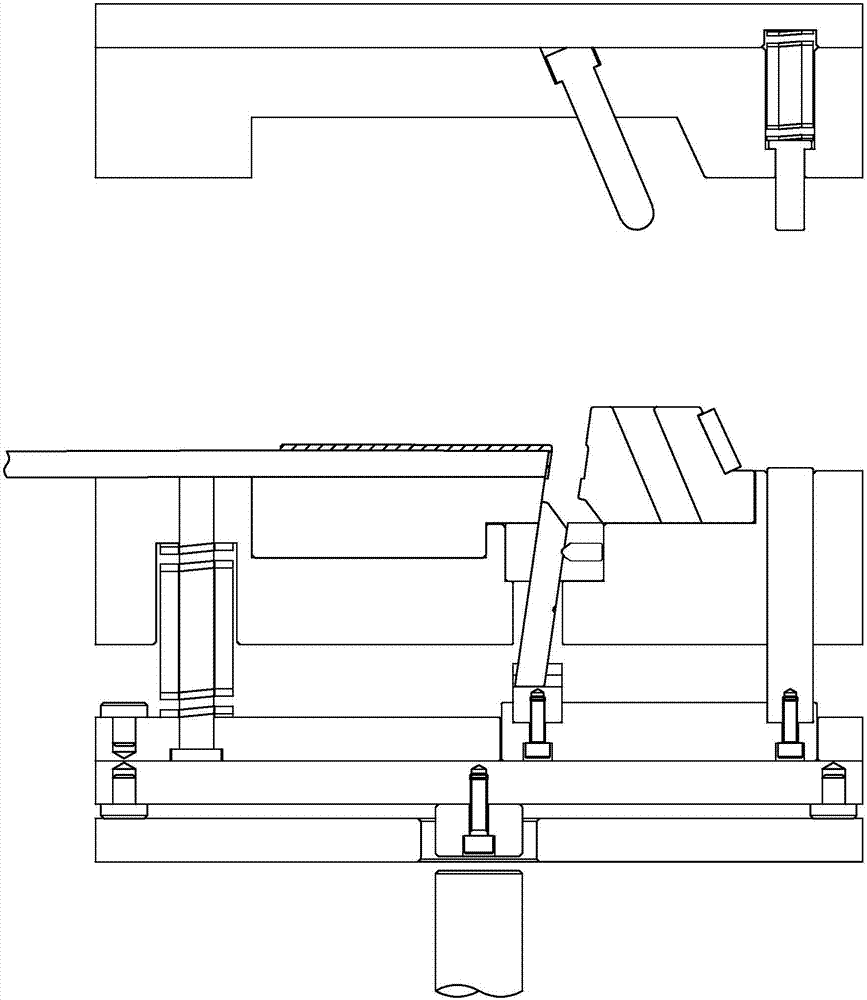

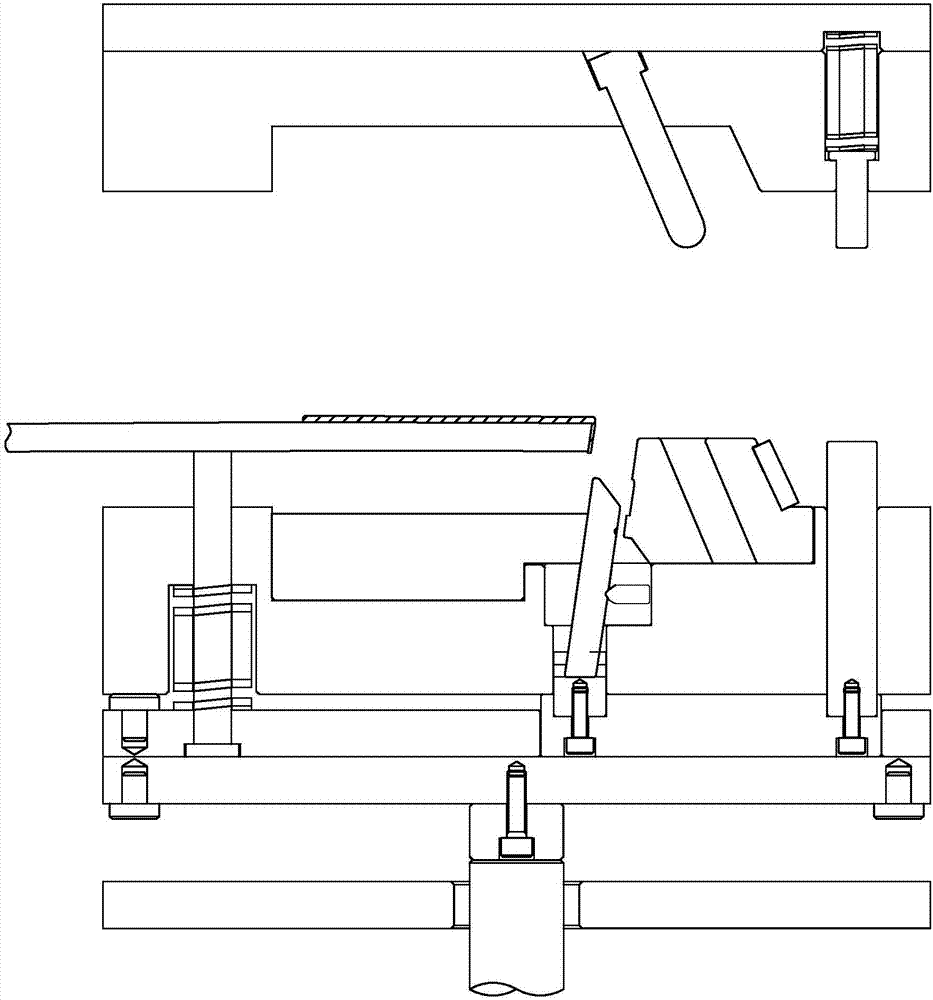

Injection mold for embedding of automobile sealing strip insert

PendingCN107160630AImprove securityNo personal injuryDomestic articlesComposite materialSafety coefficient

The invention discloses an injection mold for embedding of an automobile sealing strip insert. The injection mold comprises an upper mold plate (1), a lower mold plate (2), an ejection plate (3), a base plate (4) and a sealing strip (7). The ejection plate (3) is located on the base plate (4). The lower mold plate (2) is located between the upper mold plate (1) and the ejection plate (3). An upper mold plate (5) is arranged below the upper mold plate (1). A lower mold plate (6) is arranged above the lower mold plate (2). The lower mold plate (2) is provided with an oblique slide block (8) used for forming the rubber coating part of the front end face of the sealing strip (7), a slide block (22) used for forming the rubber coating part of the inner side face of the sealing strip (7) and a mobile slide block (36) positioning the outer side face of the front end of the sealing strip (7). The upper mold plate (1) is provided with an oblique guide column (33) slidably matched with the oblique slide block (8). By adoption of the injection mold for embedding of the automobile sealing strip insert, personal injury cannot be caused, so that the safety coefficient is high.

Owner:NINGHAI HESHI PLASTIC CO LTD

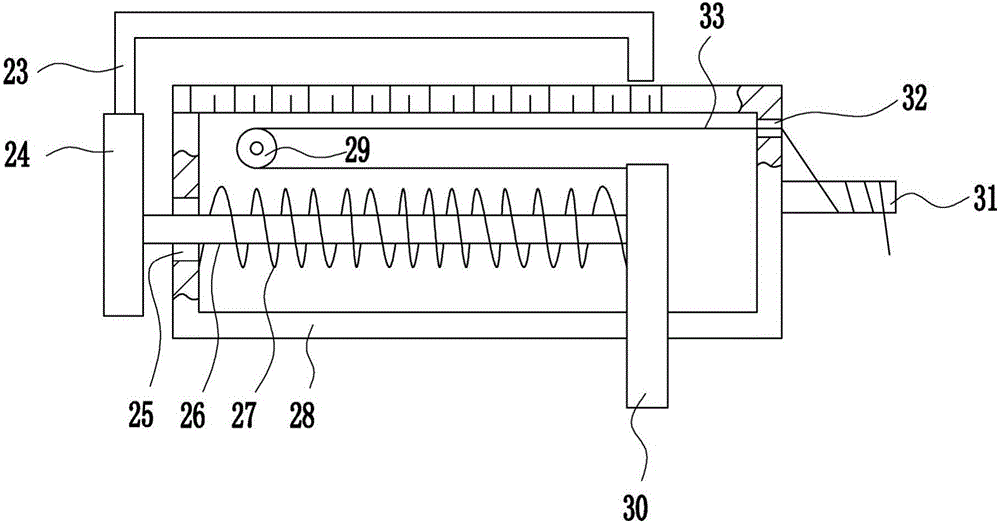

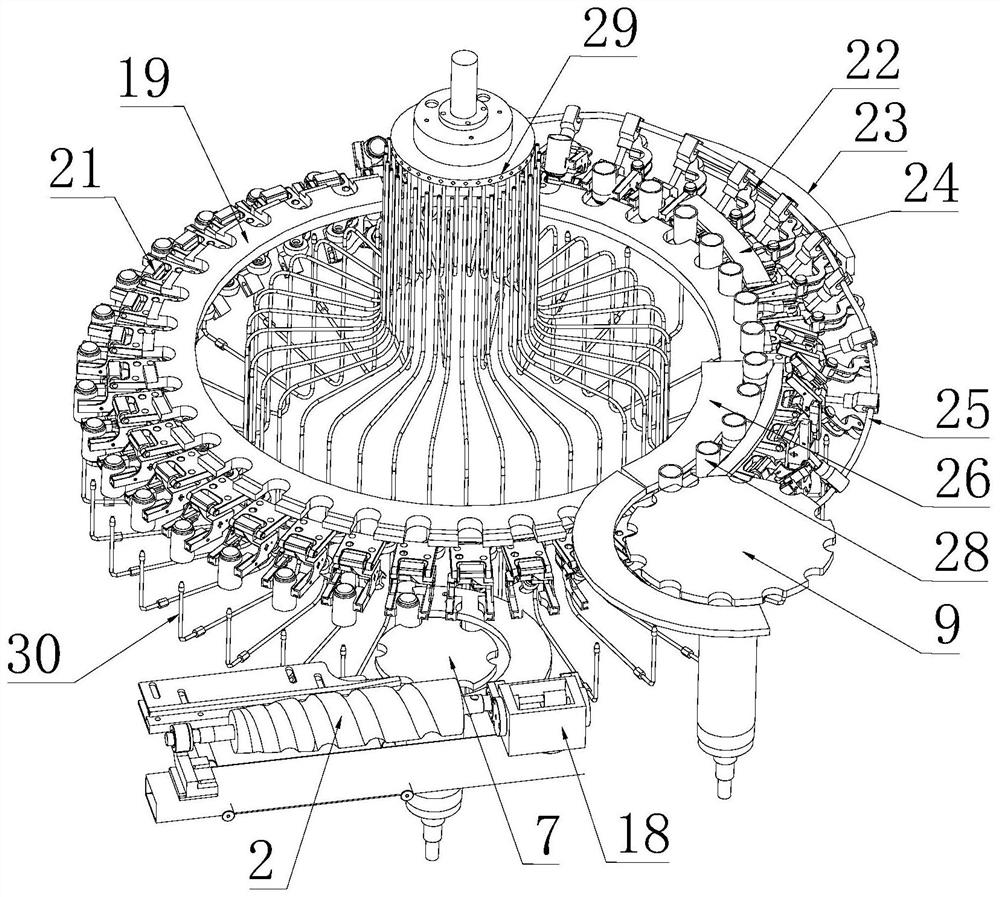

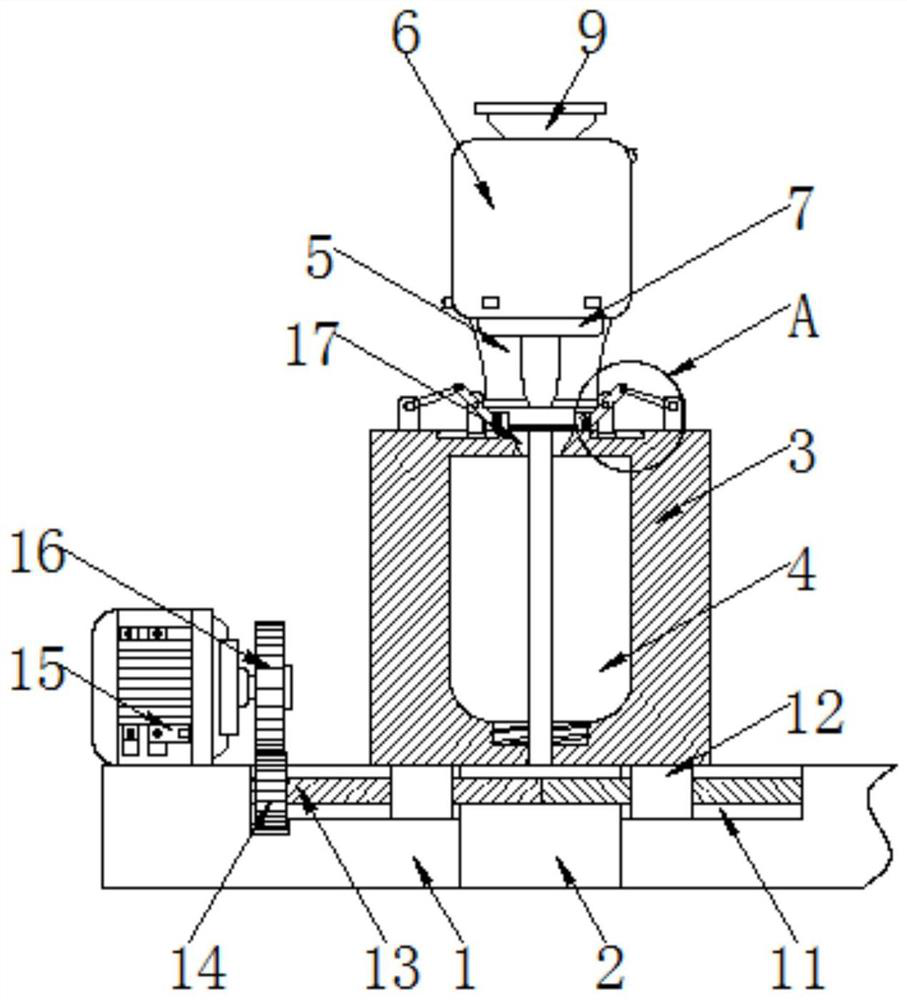

Bottle washing machine for large-diameter bottle

PendingCN114505313AStable center of gravityAvoid the phenomenon of pouring bottlesPlastic recyclingHollow article cleaningGravity centerWash bottle

The invention discloses a bottle washing machine for a large-diameter bottle, relates to the technical field of bottle washing machines, and solves the technical problems that an existing bottle washing machine is prone to bottle falling, and the washing efficiency is affected. Comprising a machine body, a bottle feeding conveying device, a bottle separating auger, a bottle feeding driving plate, a bottle washing mechanism, a bottle discharging driving plate and the like, the bottle separating auger is connected with the bottle feeding conveying device to feed bottles into the bottle feeding driving plate, the bottle feeding driving plate is arranged at the bottle feeding end of the bottle washing mechanism, and the bottle discharging driving plate is arranged at the bottle discharging end of the bottle washing mechanism. The bottle washing mechanism comprises a rotary table, bottle clamps and a washing mechanism, a conveying drive plate is fixed to the rotary table, a circle of bottle clamps are arranged on the edge of the rotary table, the bottle clamps are connected with the overturning guide rail in a sliding mode, and a separation guide guardrail and a return guide guardrail are further arranged above the rotary table; bottles are fed in an inverted buckling mode, the bottle cleaning device is particularly suitable for cleaning large-diameter bottles, the gravity center of the bottles is more stable, the phenomenon of bottle falling is avoided, the working procedure is simple, the automation degree is higher, and the cleaning efficiency is high.

Owner:LUZHOU JIANGXU MACHINERY MFG

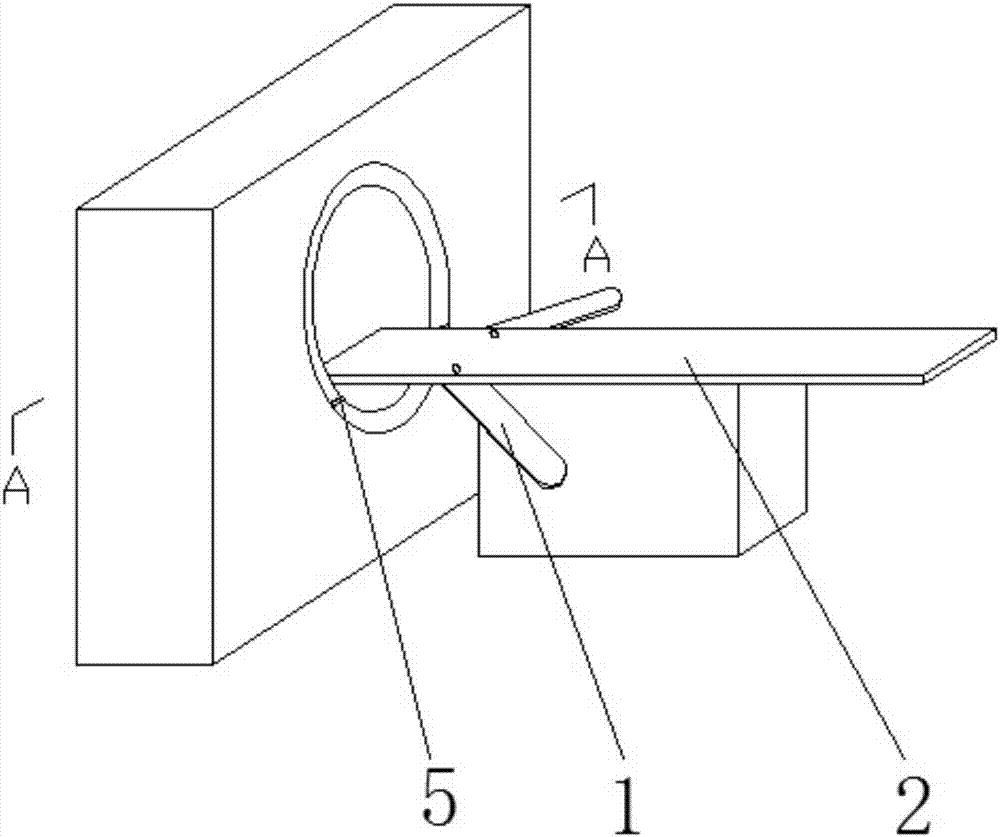

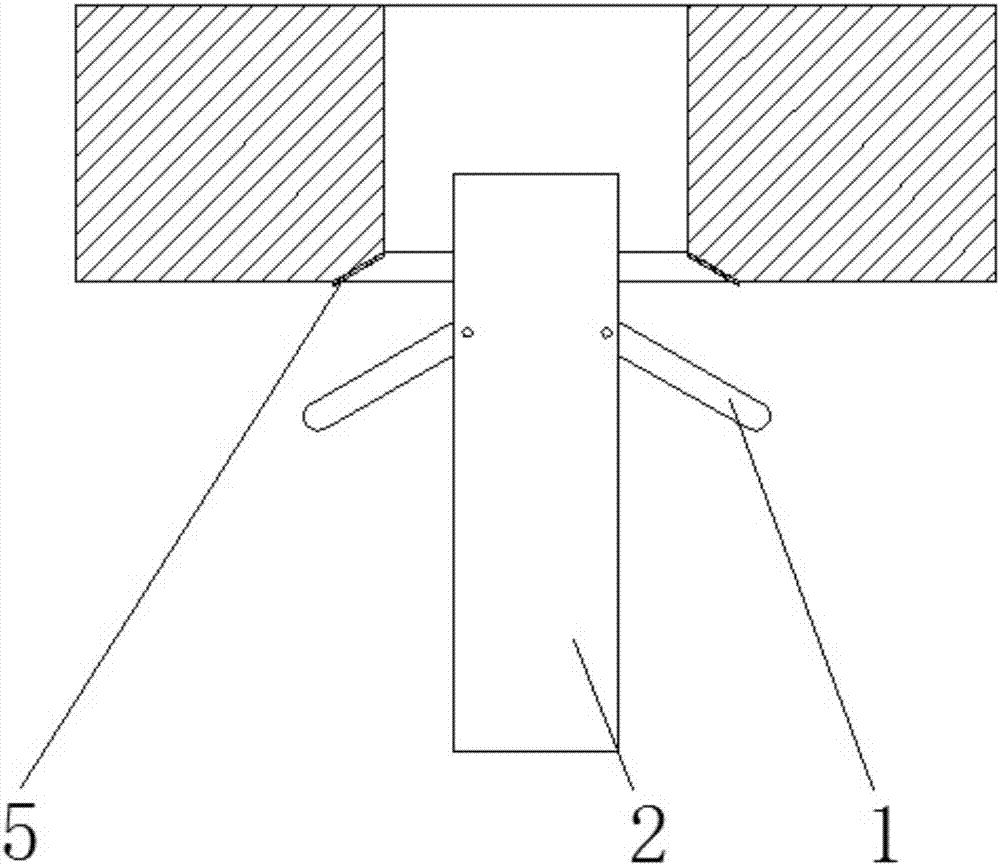

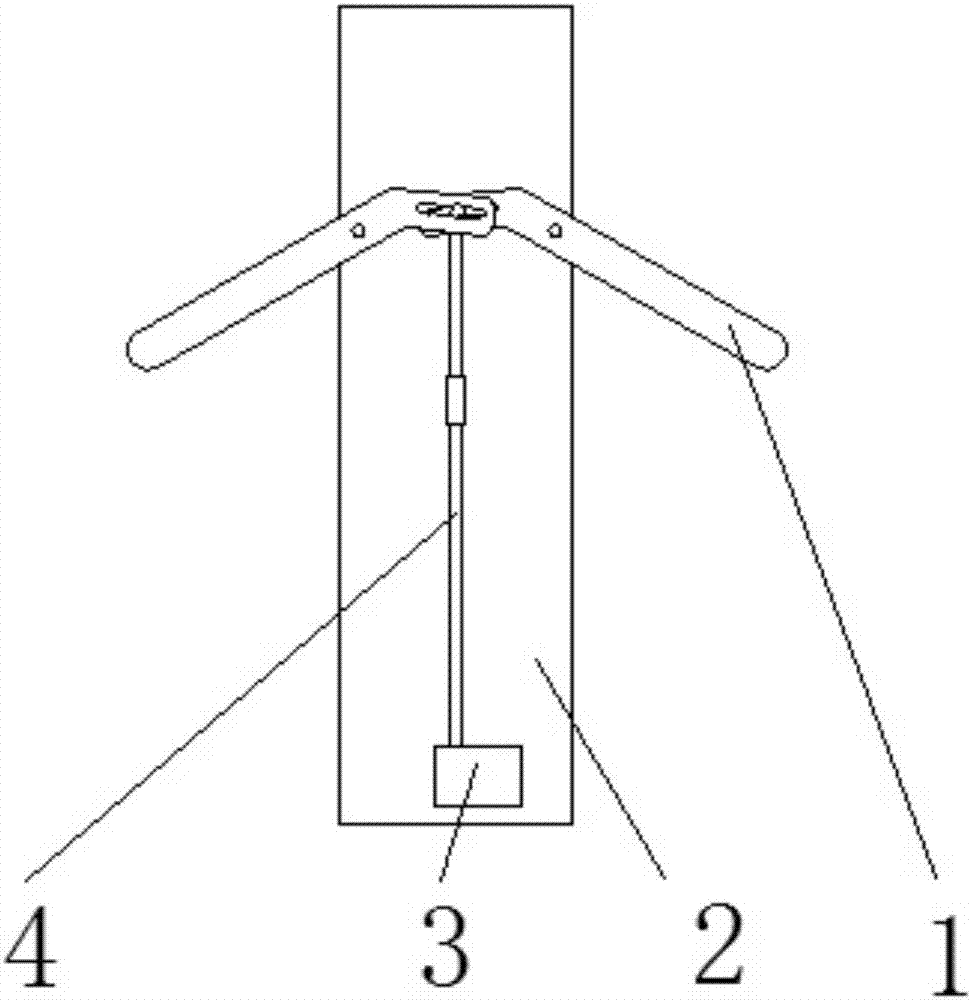

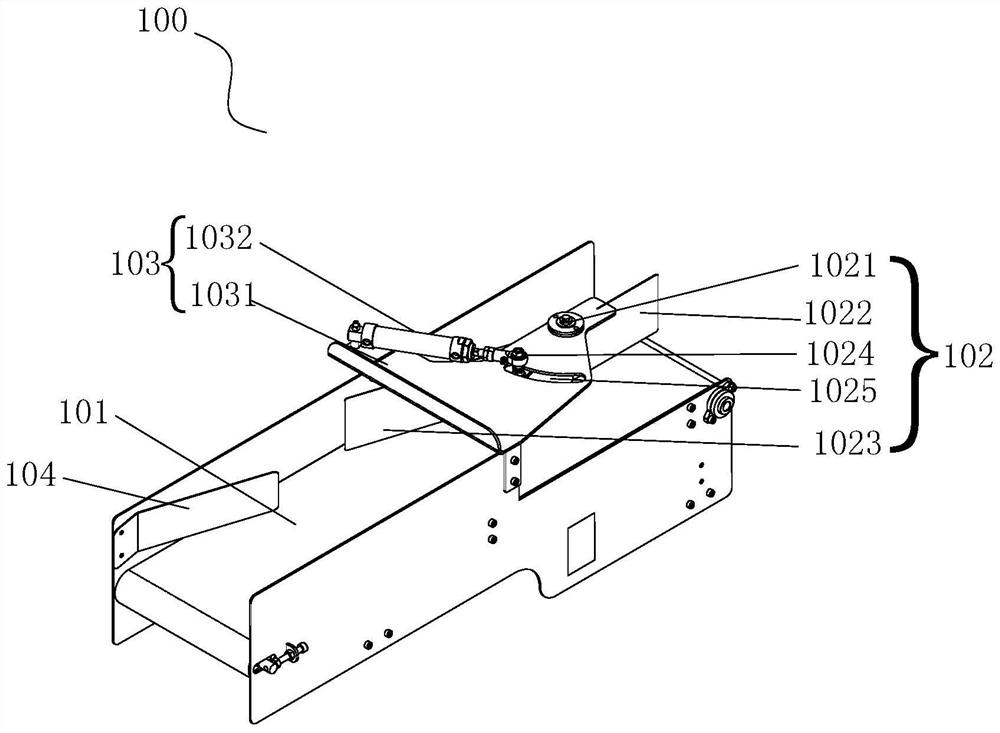

CT arm separation bracket system and control method thereof

ActiveCN106963411AImprove scan detection qualityAvoid interferencePatient positioning for diagnosticsComputerised tomographsMedicineApparatus instruments

The invention discloses a CT arm separation bracket system and a control method thereof, and belongs to the field of medical instruments. The system comprises an arm bracket, a power source, a transmission mechanism, a controller, a distance sensor. The arm bracket is connected with a mobile bed board of a CT machine in a hinged mode. The power source is connected with the arm bracket through the transmission mechanism. The distance sensor is installed on the front side of the arm bracket or at the scanning entrance of the CT machine. The distance sensor and the power source are respectively connected with the controller. The system and the method have the advantages that the patient's arm can be kept away from the trunk as far as possible so as to improve the quality of the scanning detection; the system is safe and reliable, and convenient to use.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Injection moulding die used for automotive sealing strip

PendingCN107053581AGuaranteed accuracyReduce mistakesDomestic articlesInjection mouldingMechanical engineering

The invention discloses an injection moulding die used for an automotive sealing strip. The injection moulding die comprises an upper die plate (1), a lower die plate (2), an ejection plate (3), a base plate (4) and a sealing strip (7), wherein the ejection plate (3) is located on the base plate (4); the lower die plate (2) is located between the upper die plate (1) and the ejection plate (3); an upper mandrel (5) is arranged below the upper die plate (1); a lower mandrel (6) is arranged above the lower die plate (2); an oblique sliding block (8) used for moulding the front end surface rubber coating part of the sealing strip (7) and a sliding block (22) used for moulding the front end inner side surface rubber coating part of the sealing strip (7) are arranged on the lower die plate (2); and an oblique guide post (33) which is in sliding match with the oblique sliding block (8) is arranged on the upper die plate (1). The injection moulding die used for the automotive sealing strip has the beneficial effects that punching tolerance can be effectively eradicated, so that the yield is high, and cost is low.

Owner:NINGHAI HESHI PLASTIC CO LTD

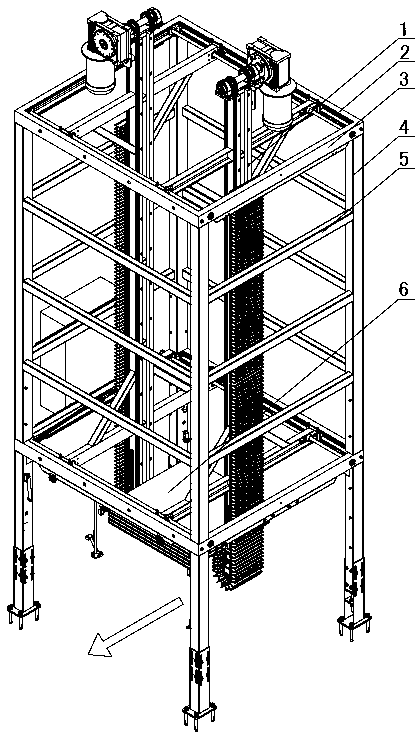

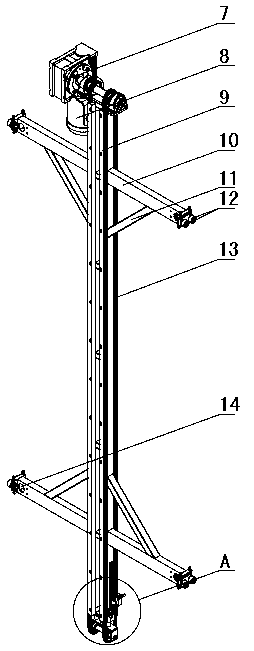

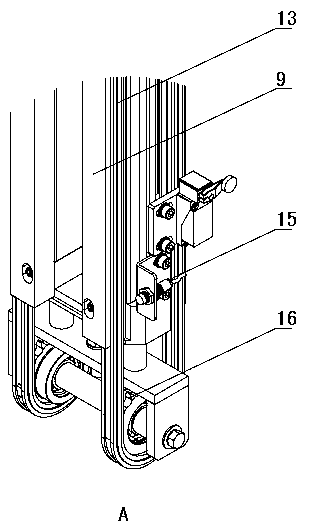

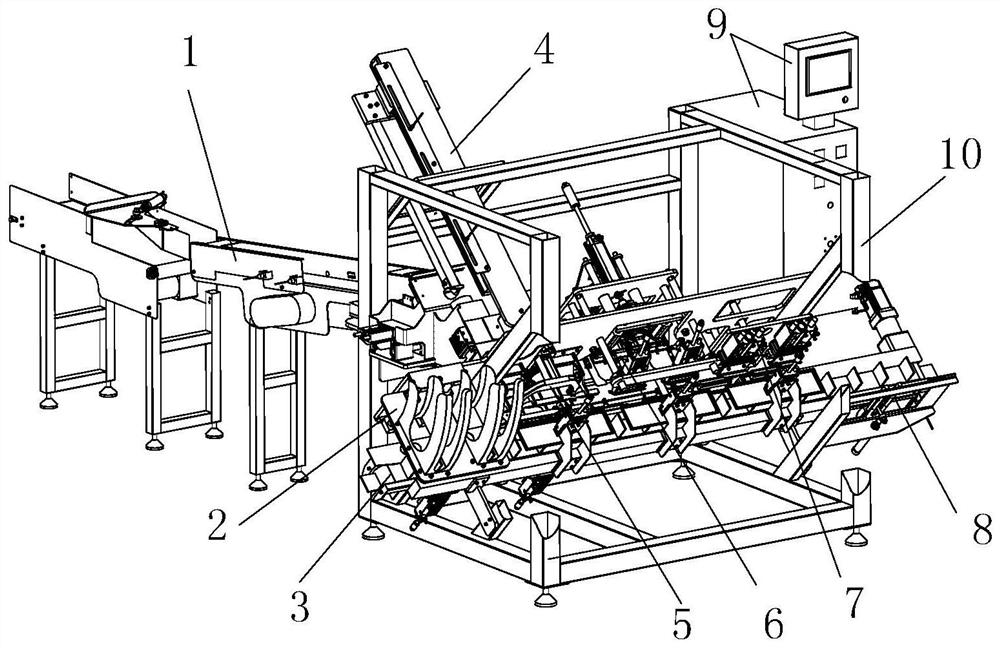

A tile lifting method for a tile temporary storage warehouse of a tile packaging line

The invention discloses a ceramic tile temporary tile storage warehouse of a ceramic tile packaging assembly line and a ceramic tile lifting method, and belongs to the field of ceramic tile packaging equipment. The warehouse is characterized by comprising a tile storage warehouse main frame, two ceramic tile lifting devices (1) are vertically arranged in the tile storage warehouse main frame, power units are arranged in the ceramic tile lifting devices (1), and drive chain lifting units vertically arranged on the ceramic tile lifting devices (1) to run, ceramic tile bearing and supporting mechanisms are arranged on the chain lifting units, ceramic tile bearing and supporting mechanisms on the ceramic tile lifting devices (1) are oppositely arranged and carry out bearing and supporting from two sides of ceramic tiles (6), and lifting or falling of the ceramic tiles (6) is achieved. According to the ceramic tile temporary tile storage warehouse of the ceramic tile packaging assembly line, detained ceramic tiles can be automatically borne, supported and lifted, large-amount detaining of the ceramic tiles in the packaging link can be effectively prevented, and in-order operation of production is ensured.

Owner:山东爱而生智能科技有限公司

A valve connecting bolt dismantling and tightening equipment

ActiveCN112828574BRealize simultaneous movementAchieve the purpose of turningMetal working apparatusHydraulic cylinderEngineering

The invention discloses a valve connecting bolt dismantling and tightening device, comprising a worktable, a column, a movable connecting arm, a wrench connecting device, a rotating device and a pressing device; a column and a rotating device are installed on the working platform, and the movable connecting arm and the column It is connected with a dead wrench connecting device; a pressing device is installed on the rotating device, a valve is arranged on the rotating device, and the rotating device enables the valve to rotate along its axis. The movable connecting arm includes a casing, a lead screw, a slide block, a hinge ear and a first hydraulic cylinder; both ends of the lead screw are rotatably connected with the upright column; the slide block is threadedly connected with the lead screw, and the side of the slide block far from the lead screw is fixed with the hinge ear connection; a first hydraulic cylinder is installed in the casing, and the piston rod of the first hydraulic cylinder is connected with a dead wrench connecting device. The present invention can automatically tighten and remove the bolts in the case that the position of the connecting bolts of many valves is narrow and the space is limited, and can be suitable for valves of different specifications.

Owner:CHONGQING JIUHUAN MACHINERY & ELECTRIC CO LTD

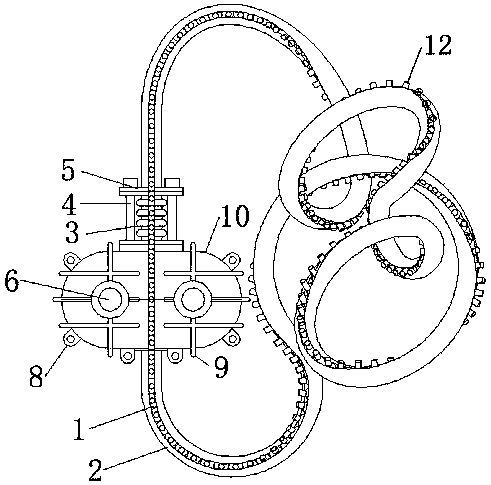

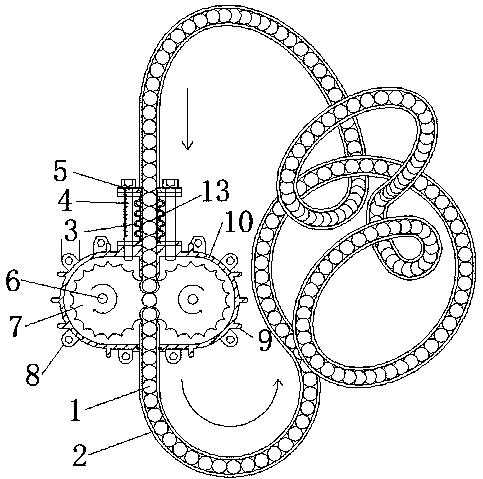

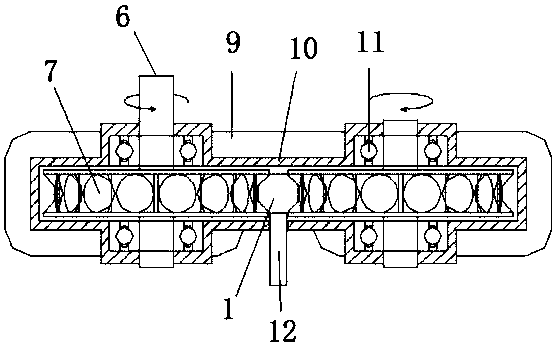

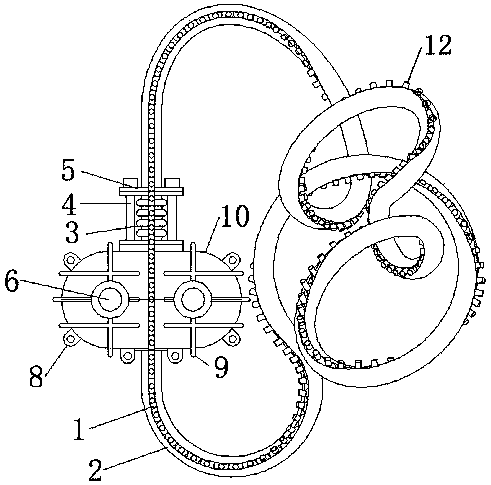

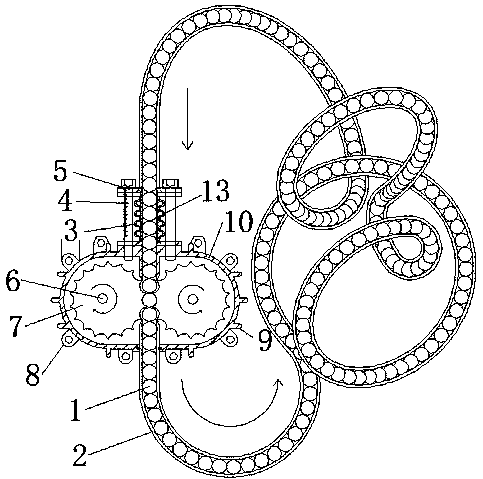

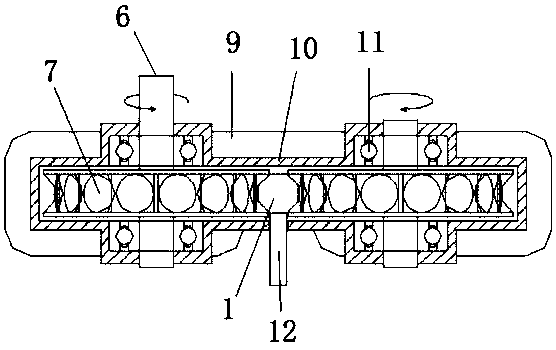

Ball push transmission device

ActiveCN108662104ARealize simultaneous movementEasy to replaceFriction gearingsMaintainabilityExpansion joint

The invention provides a ball push transmission device, and belongs to the field of mechanical transmission devices. The ball push transmission device comprises balls, an open pipeline, a corrugated pipe expansion joint, a machine shell, shaft rods, ball gap wheels, a shell, bearings, ball handles and a socket and spigot expansion pipe. The open pipeline is in a fixed S-shaped curve and is connected with the corrugated pipe expansion joint and the shell. The balls and the ball handles are combined into a whole, and the balls are arranged in the open pipeline. A gap with the size equal to the size of each ball is reserved between the two ball gap wheels. When the ball gap wheels rotate, each ball can be pushed into the open pipeline, each poked ball pushes the other ball, the balls drive the ball handles, and therefore running of the ball handles is achieved. The ball push transmission device has the advantages that the structure is simple, the universality is high, and various series of products and various styles of ball handles can be designed. Multi-mode combination is conducted through the combination of the task content in the purchasing process, and the requirements of different working conditions are met. The storage and release performance, the coordination performance, the stability and the maintainability are good.

Owner:陈刚

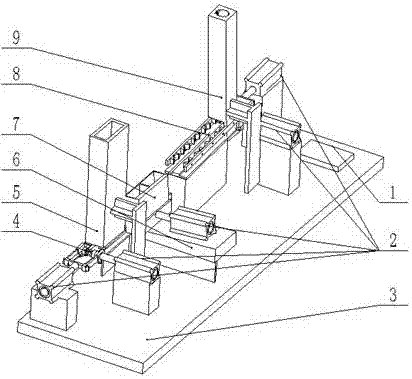

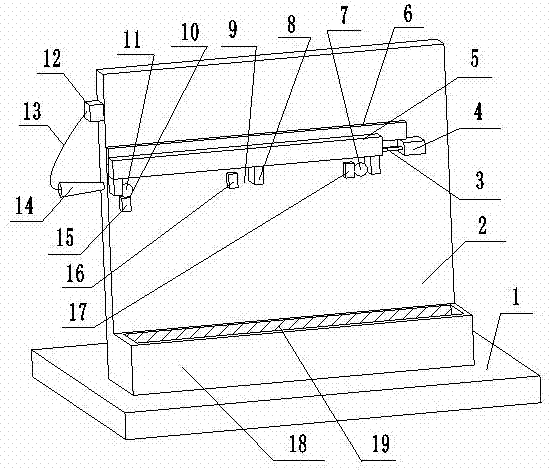

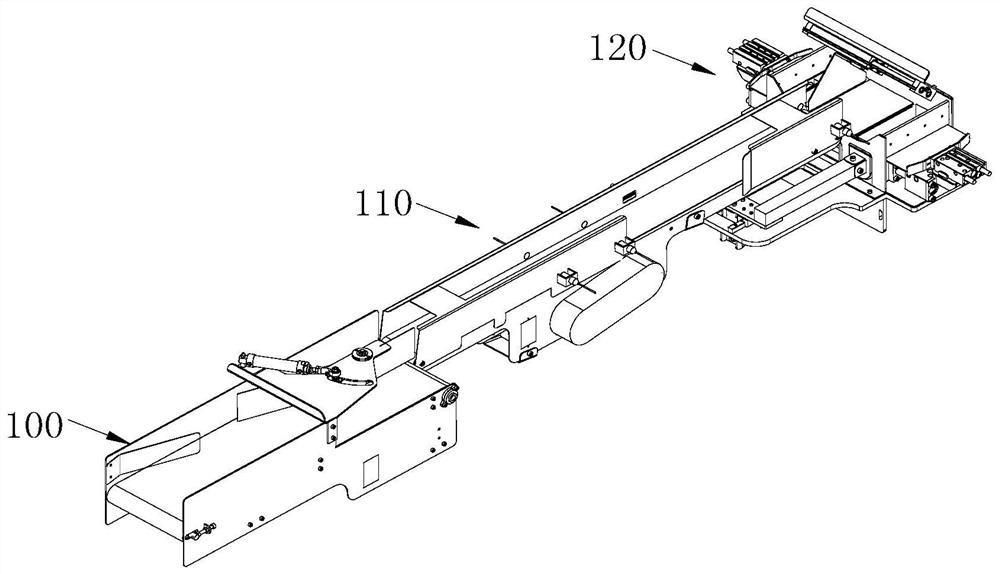

Automatic propelling device for medical slice preparation clamp

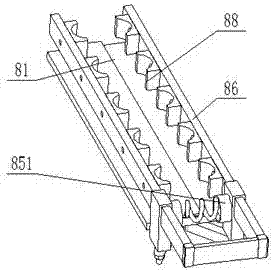

InactiveCN107378474ARealize automatic feedingRealize simultaneous movementAssembly machinesMetal working apparatusArm movingPush pull

An automatic propulsion device for medical film-making clips, which belongs to the field of medical machinery, is composed of a convex plate, a slider, a connecting rod, a stepped slider, a clamp arm and a push-pull plate, and is characterized in that the clamp arm is placed On the convex plate, the push-pull plate is installed on two clamp arms, and the clamp arm moves along the push-pull plate, and the two step-shaped sliders are installed on the two clamp arms, and the convex plate under the There is a chute, the slider is placed in the chute, the slider is connected with the stepped slider through two connecting rods, and the clamp arm is stepped. The benefit of this invention is that the The device can realize the automatic feeding of the film-making clamp cylinder. The clamp arm is stepped, which can hold the base and prevent the base from falling under pressure during assembly. Through the slider and the connecting rod, the two clamp arms can move at the same time .

Owner:柴传程

Clamping device for PCB production

PendingCN112399714AAchieve simultaneous rotationRealize simultaneous movementPrinted circuit manufactureGear wheelEngineering

The invention provides a clamping device for PCB production. The clamping device for PCB production comprises a supporting box; four supporting blocks which are all fixedly mounted in the supporting box; two rotating rods which are rotationally connected with two corresponding supporting blocks respectively; a first gear which is fixedly arranged on the outer side of one of the rotating rods in asleeving mode; a first bevel gear which is fixedly arranged on the outer side of the other rotating rod in a sleeving mode; a driving rod installed on the corresponding supporting block in a rotatingmode; and a second gear which is fixedly arranged on the outer side of the driving rod in a sleeving mode, wherein the second gear is engaged with the first gear. The clamping device for PCB production has the advantages of being convenient to use and capable of conveniently processing the four sides of a PCB.

Owner:AOSHIKANG TECH CO LTD

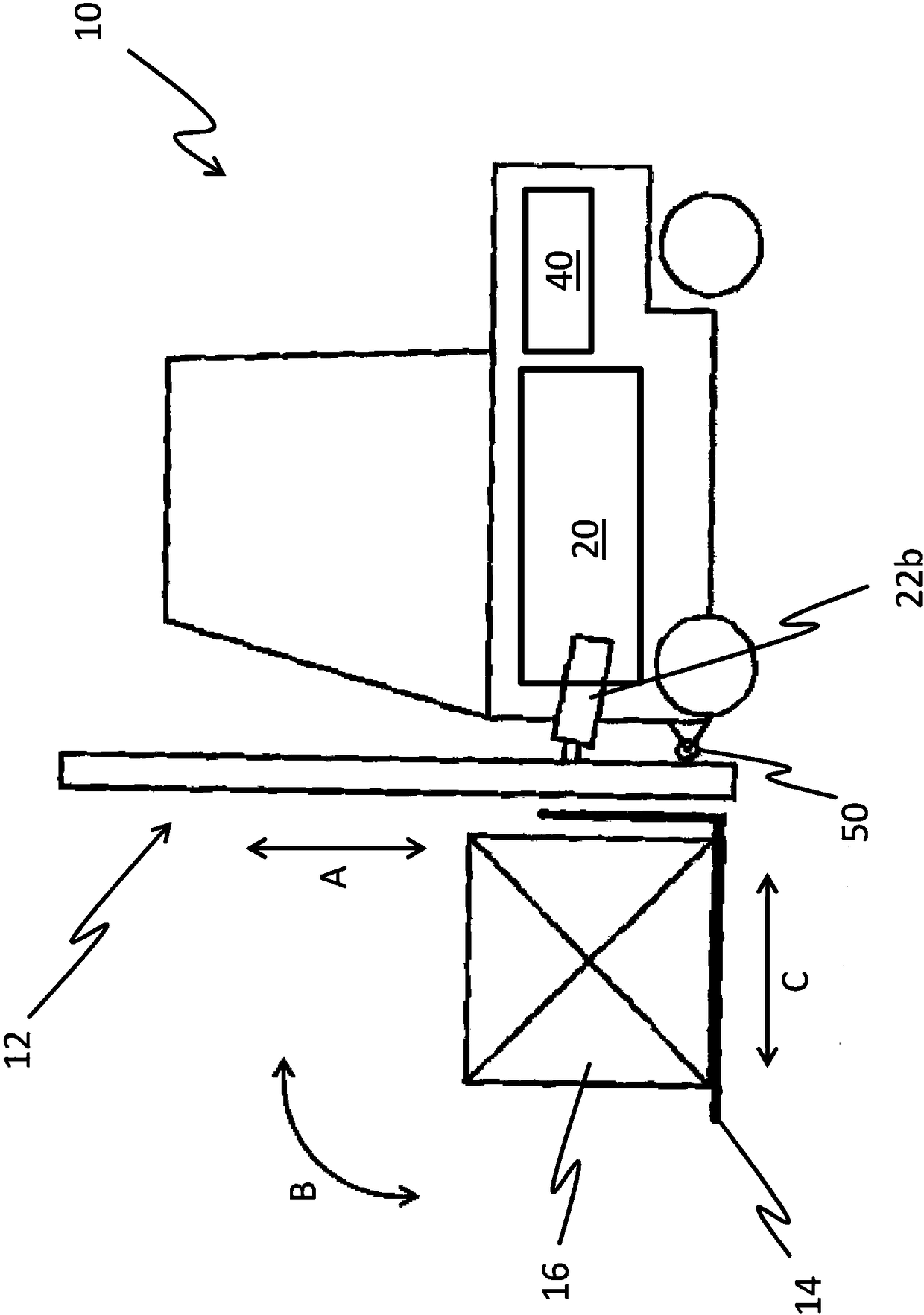

Experimental device for verifying collision of horizontal projectile motion and free fall in sky

The invention relates to an experimental device for verifying the collision of horizontal projectile motion and free fall in the sky, and the device comprises a substrate, a vertical plate, and a power drive unit. The vertical plate is located on the substrate, and the vertical plate is provided with a plurality of supporting apparatuses. A clamping bar and a clamping groove are disposed above the supporting apparatuses, and the clamping groove can move left and right along the clamping bar. The clamping groove is provided with clamping board matched with the supporting apparatuses. One horizontal projectile platform and a plurality of moving bayonets are formed between the supporting apparatuses and the clamping board. The horizontal projectile platform is provided with a horizontal projectile steel ball which is used for verifying the horizontal projectile motion. The moving bayonets are provided with falling steel balls which are used for verifying the motion of free fall. The power drive unit is disposed in front of the clamping groove, and the power drive unit drives the clamping groove to move, thereby achieving the simultaneous moving of the horizontal projectile steel ball and the falling steel balls. The device provided by the invention can verify that the component motion of the horizontal projectile steel ball in the vertical direction is the motion of free fall after the horizontal projectile steel ball leaves a track. The device is simple in structure, is convenient to operate and use, and is vivid and visual in demonstration.

Owner:柯胜

Automatic propelling device for medical slice preparation clamp assembly

InactiveCN107378428ARealize automatic feedingRealize simultaneous movementMetal working apparatusPush pullSlice preparation

An automatic propulsion device for a medical film-making clamp assembly, which belongs to the field of medical machinery, is composed of a convex plate, a small slider, a connecting rod, a large slider, a clamp arm, a push-pull plate and a fixing block, and is characterized in that: the clamp arm Placed on the convex plate, the push-pull plate is installed on the two clamp arms, the clamp arm moves along the push-pull plate, two large sliders are installed on the two clamp arms, there is a chute under the convex plate, and the small slider is placed on the In the chute, the small slider is connected with the big slider through two connecting rods, the fixed block is arranged on the two clamp arms, and there are round holes on the fixed block. The advantage of this invention is that the device can realize the For the automatic feeding of the cylinder, the fixed block is arc-shaped and has a round hole, which can fix the film-making clamp cylinder; through the slider and the connecting rod, the simultaneous movement of the two clamp arms can be realized.

Owner:柴传程

Blow molding equipment for blow molding containers

The invention discloses a blow molding equipment for blow molding containers, comprising a workbench, the top of the workbench is provided with collecting holes, both sides of the workbench top are movably connected with container molds, two Outline grooves are opened on the opposite sides of the container mold, and a support frame is fixedly connected to the back of the workbench. The invention relates to the technical field of blow molding equipment. The blow molding equipment used for blow molding containers, by setting the second sliding groove on the top of the container mold, when the two container molds move to the side relatively far away, since the two second sliding blocks are connected by the fixed rod , so the position of the second sliding block remains unchanged. At this time, the swinging rod drives the rotating rod to rotate, thereby moving the side of the two socket blocks that is relatively far away, so that the sharp sides of the two blades can be contacted. Through this structure, the Cut off the excess material and drop it with the container, avoiding falling into the inside of the profile groove.

Owner:宏全食品包装清新有限公司

A combined silage coating machine and its application method

ActiveCN111296081BSatisfy coating operationRealize simultaneous movementBalingSlide plateConveyor belt

The invention discloses a combined silage coating machine and its use method, which comprises a bottom plate, a telescopic mechanism, a belt transmission mechanism, a connecting rod assembly, and a moving part. Axis; the left side of the bottom plate is equipped with a telescopic mechanism, the left end of the hydraulic horizontal cylinder in the telescopic mechanism is connected with a sliding piece, and the top surface of the sliding plate on the sliding piece is provided with a bracket plate; the horizontal axis rotates synchronously with the driving shaft on the belt transmission mechanism through the transmission belt , the upper part of the left section of the horizontal axis is provided with a pair of bevel gears, and the bottom of the pair of bevel gears is engaged with the first bevel gear on the connecting rod assembly; the connecting rod assembly is fixedly connected with the moving part, and the roller on the moving part is sleeved With film sleeve. The invention is more convenient and fast for film introduction and coating, can adapt to various shapes of straw bales, has high quality of coating, and can realize the coating operation of straw bales of various shapes.

Owner:朱德文

A push ball transmission device

ActiveCN108662104BRealize simultaneous movementEasy to replaceFriction gearingsMaintainabilityEngineering

A rolling-ball conveying device comprises balls (1), an open pipe (2), a corrugated pipe expansion joint (3), a machine housing (4), a shaft rod (6), ball accommodating wheels (7), a casing (10), a bearing (11), a ball handle (12), and a spigot-and-socket retractable pipe (13). The open pipe (2) has a fixed serpentine curve, and is connected to the corrugated pipe expansion joint (3) and the casing (10). The ball (1) and the ball handle (12) are integrated together. The ball (1) is disposed in the open pipe (2). A space of the size of the ball (1) is provided between the two ball accommodating wheels (7). When the ball accommodating wheels (7) rotate, the ball (1) is pushed into the open pipe (2), and the pushed ball (1) pushes another ball (1), and drives the ball handle (12), thereby enabling operation of the ball handle (12). The rolling-ball conveying device has a simple structure, is versatile, can be designed into multiple series of products, and can have multiple types of ball handles. On purchasing the invention, a user can determine a combination of multiple modes according to a task so as to meet requirements of different operation conditions. The invention has good retractability, compatibility, stability, and maintainability.

Owner:陈刚

Grid rolling device

The invention relates to a net rolling device. It is characterized in that: a short pillar is fixedly installed perpendicular to the inner wall, the upper end of the swing rod is rotatably connected with the short pillar, and the lower end of the swing rod is provided with two hinge points, one of which is rolled back through the push rod one. The rotating arm of the net clutch is connected, and the other hinge point is connected with the rotating arm of the main winding net clutch through the push rod two; the side of the swing rod is provided with a cam mechanism to drive the swing rod to swing. Compared with the prior art, the beneficial effect of the present invention is that: the device simultaneously drives the main winding clutch and the rear winding clutch through the swing rod, so that the main winding roller and the rear winding roller move at the same time, and the movement steps are consistent. It can ensure the tension of the roll net is stable, the roll net does not slip, its structure is simple, and it is reliable to use.

Owner:XINCHANG COUNTY ZHUOYUAN TEXTILE CO LTD

Shaping mechanism

A shaping mechanism comprises a first bag opening shaping unit; the first bag opening shaping unit comprises a transverse shaping assembly; the transverse shaping assembly comprises four-connecting-rod units formed by connecting first rotating rods, fixing bases, second rotating rods and transverse shaping supporting plates end to end; two groups of four-connecting-rod units are in mirror symmetryand located on the same plane; the transverse shaping supporting plates of the two groups of four-connecting-rod units extend oppositely to form an integrated structure; the fixing bases extend downwards and are fixedly connected with transverse shaping plates; the plate surfaces of the transverse shaping plates and the four-connecting-rod units are also located on the same plane; the first rotating rods extend upwards to form extending arms; a transverse shaping drive is arranged between the two groups of extending arms of the groups of two four-connecting-rod units; and the two power ends of the transverse shaping drive are hinged to the corresponding extending arms respectively. When the two transverse shaping plates act oppositely, the entering depth can be automatically adjusted according to the size of resistance applied to the two sides of a packaging bag to ensure that the optimal shaping effect is achieved.

Owner:HEFEI CHERISHING PACK TECH

A fixed-width cutting device for aluminum foil for pharmaceutical packaging

InactiveCN106584546BAchieve rise and fallRealize simultaneous movementMetal working apparatusInterference fitCoupling

The invention relates to a cutting device, in particular to an aluminum foil fixed width cutting device for pharmaceutical packaging. The technical problem to be solved is to provide an aluminum foil fixed width cutting device which is used for pharmaceutical packaging and is capable of controlling the cutting width conveniently and small in cutting friction. To solve the technical problem, the aluminum foil fixed width cutting device for pharmaceutical packaging comprises a tripod, a first connecting rod, a sliding rail, a first spring, a rack, a sliding block, a first gear, a sector gear, a gear motor, a first rotary rod, a first roller and the like. An output shaft of the gear motor is connected with the first rotary rod through a coupling, the first rotary rod is in interference fit connection with the sector gear and the first roller sequentially from front to rear. The aluminum foil fixed width cutting device achieves the effects that the cutting precision is high, the cutting width can be controlled flexibly and the time and labor are saved during cutting when the aluminum foil fixed width cutting work is conducted

Owner:广州市必盈体育有限责任公司 +1

Combined high-efficiency silage coating machine and use method thereof

ActiveCN111296081ASatisfy coating operationRealize simultaneous movementBalingDrive shaftTransmission belt

The invention discloses a combined high-efficiency silage coating machine and a use method thereof. The silage coating machine comprises a bottom plate, a telescopic mechanism, a belt transmission mechanism, a connecting rod assembly and a moving part, a vertical plate is arranged on the top face of the bottom plate, and a transverse shaft is transversely arranged on the vertical plate; a telescopic mechanism is arranged on the left side of the bottom plate, a sliding part is connected to the left end face of a hydraulic transverse cylinder in the telescopic mechanism, and a support plate is arranged on the top face of a sliding plate on the sliding part. The transverse shaft and a driving shaft on the belt transmission mechanism synchronously rotate through a transmission belt, the left section of the transverse shaft is transversely sleeved with a bevel gear pair, and the bottom of the bevel gear pair is engaged with a first bevel gear on the connecting rod assembly in a clamped mode. The connecting rod assembly is fixedly connected with a moving part, and a roller on the moving part is sleeved with a film sleeve. The coating device is more convenient and quicker in film guidingand coating, can adapt to straw bales in various shapes, is high in film coating quality, and can realize film coating operation of the straw bales in various shapes.

Owner:朱德文

An equidistant adjustment device for slitting knife equipment

InactiveCN107297780BRealize simultaneous movementKeep relative moving distance in real timeMetal working apparatusFixed frameEngineering

The invention relates to an isometric adjusting device for slitting tool equipment. The isometric adjusting device comprises a fixing frame with a cylindrical cavity, a rotating shaft is mounted at the left end of the fixing frame, a cylinder in the cavity is mounted on the fixing frame, and the rotating shaft and the cylinder are in spline connection. The right side of the cylinder is provided with a plurality of tool rest units in the cavity. Each tool rest unit comprises a nut, a bolt, a ferrule and a spline shaft, wherein the nut is capable of sliding in the cavity, the outer peripheral surface of the nut is provided with a peripheral groove, the left end of the ferrule is provided with an inner peripheral boss in the peripheral groove, the left end of the bolt is connected with the right end of the ferrule and the right end of the spline shaft, and the right end of the bolt is provided with a spline hole. The nut in each tool rest unit is screwed to the bolt in the adjacent tool rest unit, the spline shaft in each tool rest unit is meshed with the spline hole in the adjacent tool rest unit, the nut in the tool rest unit adjacent to the cylinder is in threaded connection with the cylinder, and the spline shaft in the tool rest unit adjacent to the cylinder is meshed with a spline through hole.

Owner:GUANGXI BAISE XINGHE ALUMINUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com