Bottle washing machine for large-diameter bottle

A large-caliber bottle and bottle washing machine technology, which is applied in recycling technology, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of bottle washing machines that are prone to falling bottles and affect cleaning efficiency, and avoid hidden dangers of falling off , Simplify the process and avoid the effect of pouring the bottle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

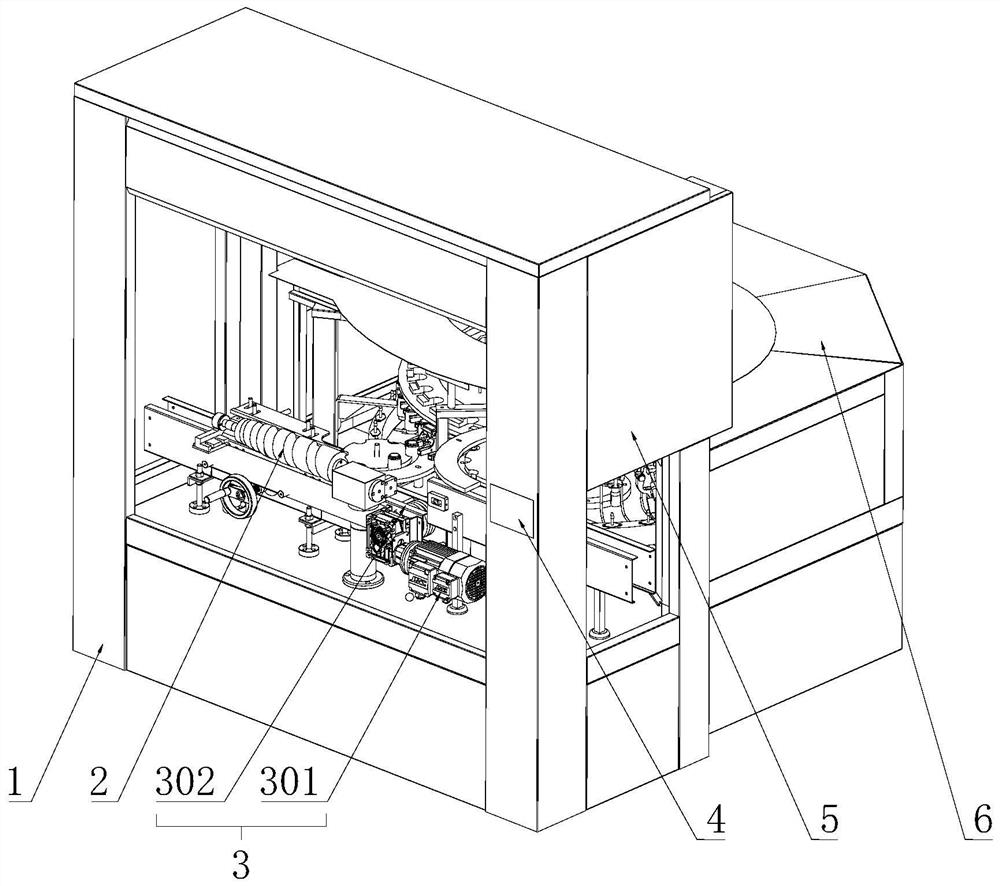

[0030] Such as Figures 1 to 6 As shown, the present embodiment provides a bottle washing machine for large-caliber bottles, including a body 1 and a bottle feeding conveying device 3, a PLC touch screen 4 and an electric control box 5 are installed on the body 1, the machine The back of the body 1 is also provided with a protective cover 6 to protect the internal bottle washing mechanism. The bottle feeding conveying device 3 includes a conveying motor 301 and a conveying chain plate 302. Bottles 28 are placed on the conveying chain plate 302 and are conveyed The motor 301 drives the transmission. Specifically, the conveying chain plate 302 adopts a plastic chain plate. Since the bottle 28 is placed on the conveying chain plate 302 in an upside-down state, the plastic chain plate can avoid friction between the traditional metal chain plate and the mouth of the bottle. There are glitches.

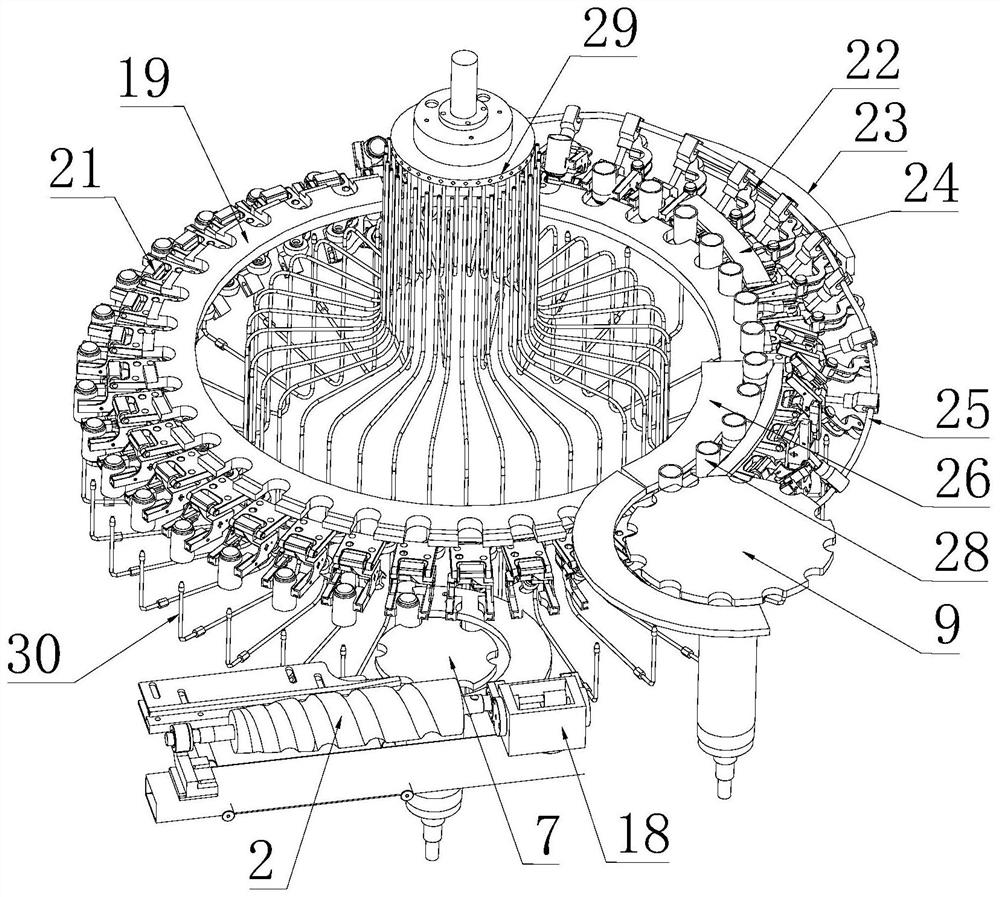

[0031] The bottle washing machine also includes a bottle-dividing dragon 2, a bottle-f...

Embodiment 2

[0040] Based on Embodiment 1, the bottle washing mechanism includes a water diversion pan 29 and several flushing pipes 30, the water diversion pan 29 is arranged above the turntable 8, the flush water pipe 30 is arranged below the turntable 8, and several of the flushing pipes 30 communicates with the water source through the water diversion plate 29; specifically, the water source is pumped into the water inlet pipe through the water diversion plate 29, and then flows into the flushing pipe 30 through the water diversion plate 29. Carry out high-pressure water spray cleaning to improve cleanliness and save water consumption.

Embodiment 3

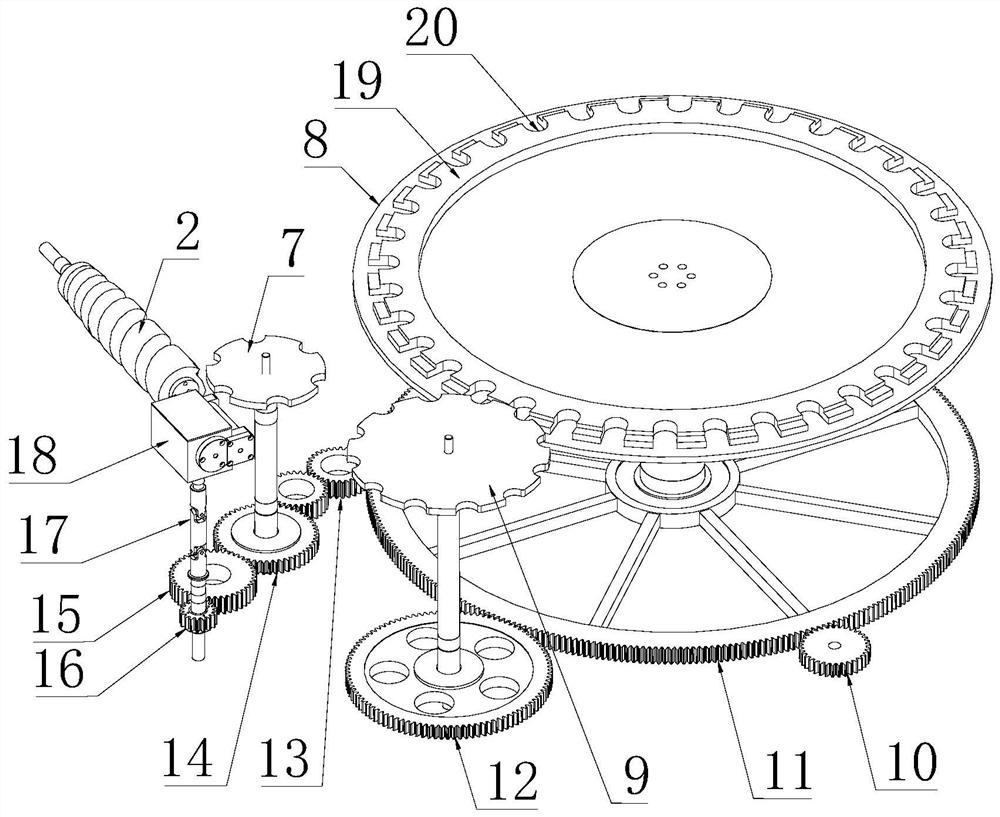

[0042] Based on Embodiment 1, the driving mechanism includes a driving gear 10, a driven gear 11, a bottle output dial driving gear 12, a reversing gear 13, a bottle feeding dial driving gear 14, an idler gear 15, and a corner gear box driving gear 16 , universal drive shaft 17 and corner gear box 18, the driving gear 10 is meshed with the driven gear 11, and the driven gear 11 is meshed with the bottle output dial drive gear 12, and the driven gear 11 is connected by changing The gear 13 is meshed with the bottle-feeding dial drive gear 14, and the bottle-feeding dial drive gear 14 is meshed with an idler gear 15 and a corner gear box driving gear 16 in turn. The shaft 17 transmits power to the corner gear box 18, and the corner gear box 18 drives the bottle-separating Jiaolong 2 to rotate.

[0043] During the driving process, the driving gear 10 is powered by the power source, the driving gear 10 drives the driven gear 11 to rotate, the driven gear 11 drives the upper turnta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com