Dismounting and tightening equipment for valve connecting bolt

A technology for connecting bolts and valves, which is applied in the field of dismantling and tightening equipment for connecting bolts of large or heavy valves, and can solve problems such as hidden dangers to the safety of operators, low production efficiency, and inability to adapt to bolting machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises. Moreover, the terms "first", "second", etc. are only used to describe purposes, and cannot be understood as an indication or implies relative importance or implicitly indicated the number of techniques indicated.

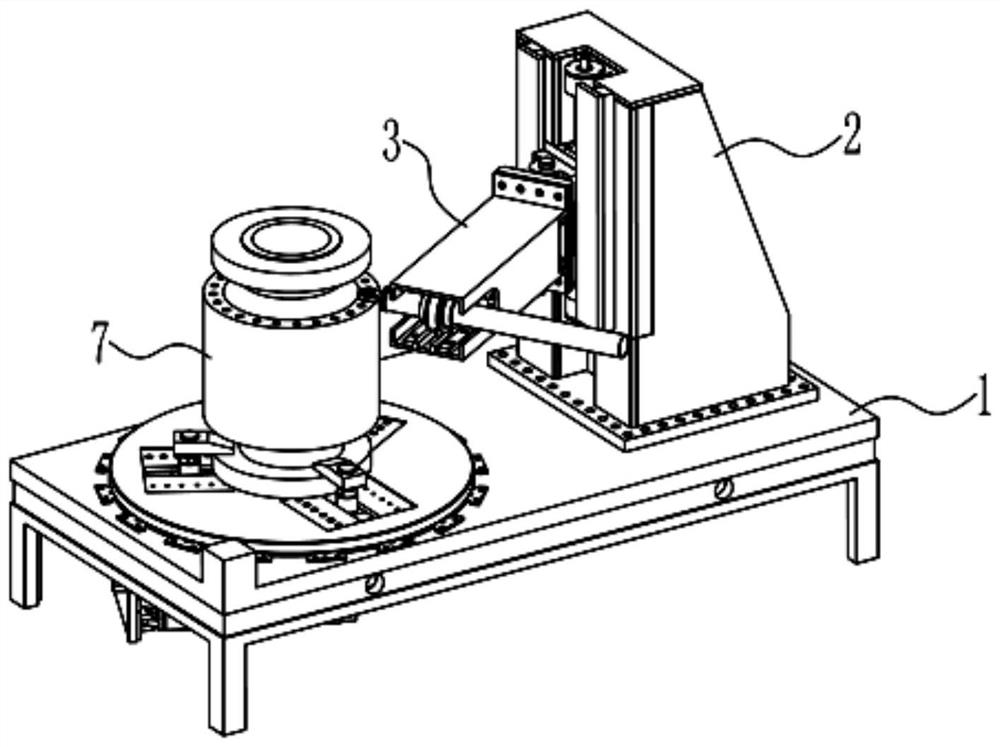

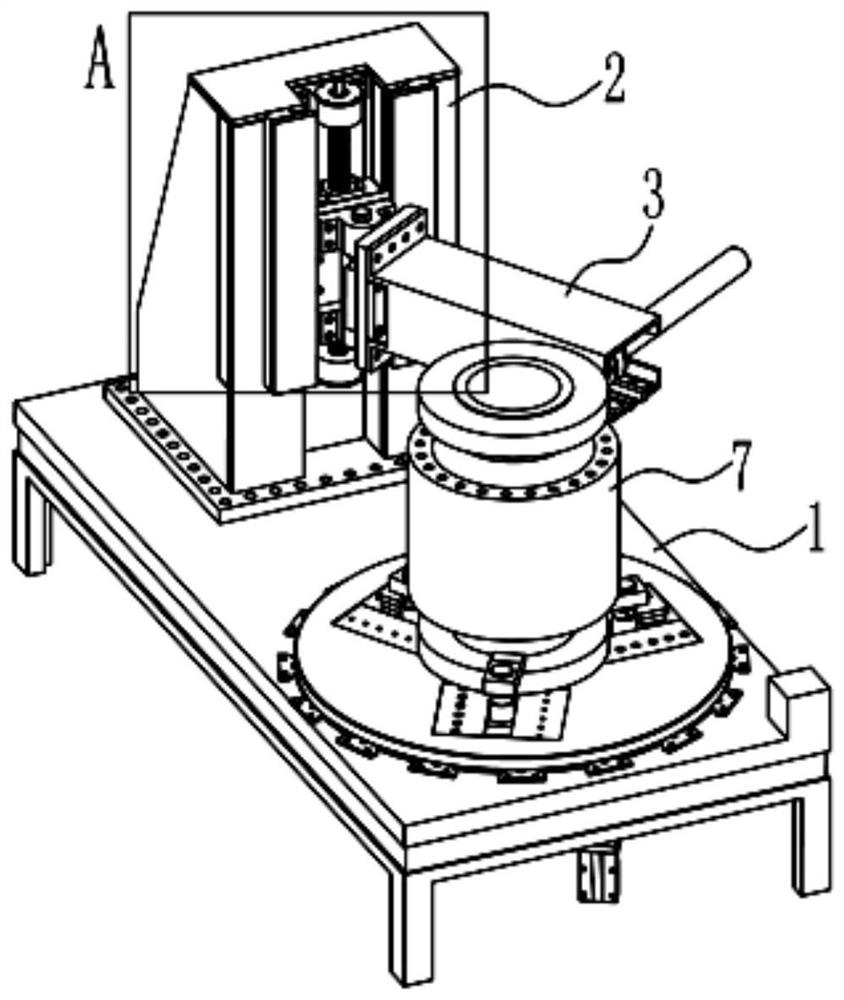

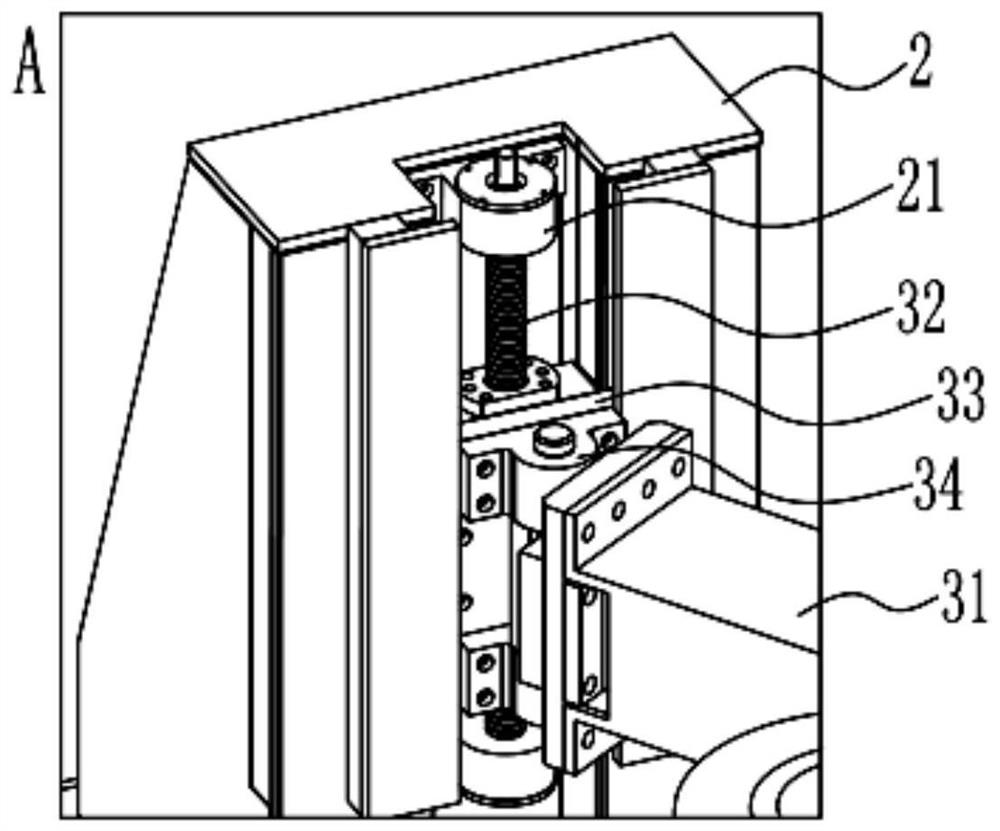

[0032]Such asFigures 1 to 10As shown, the present invention provides a valve connection bolt disassembly and tightening apparatus including a table 1, a column 2, a movable connection arm 3, a wrench connection device 4, a rotating device 5, and a compression device 6; Installing the column 2, the rotating device 5 is ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com