A push ball transmission device

A kind of transmission device and sphere technology, which is applied in the direction of transmission device, friction transmission device, belt/chain/gear, etc., can solve the problems that are not suitable for linear, circular, and spiral transmission applications, and the terrain of cave space is complex and cannot be reached. , to achieve the effect of convenient replacement of wearing parts, simple structure and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

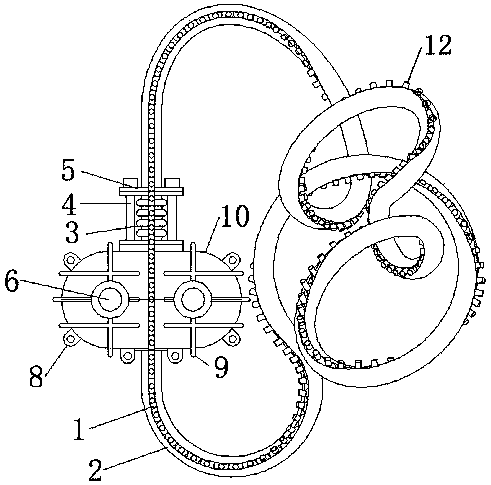

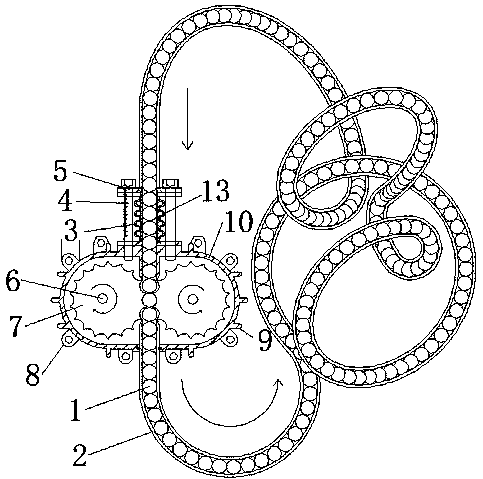

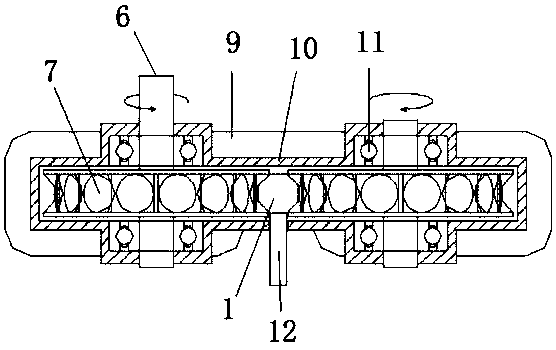

[0018] Such as figure 1 , figure 2 As shown, a push ball transmission device of the present invention includes a ball 1, an open pipe 2, a bellows expansion joint 3, a casing 4, a shaft 6, a ball wheel 7, a casing 10, a bearing 11, and a ball handle 12 , Socket expansion tube 13. The open pipe 2 is a fixed serpentine curve; one end of the open pipe 2 is connected to one end of the bellows expansion joint 3, the other end of the open pipe 2 is connected to one end of the shell 10, and the other end of the bellows expansion joint 3 is connected to the other end of the shell 10; the ball 1 It is a whole connected with the ball handle 12 , the ball 1 is located in the open pipe 2 , and the ball handle 12 is located at the opening of the open pipe 2 .

[0019] Such as figure 2 , Figure 4 As shown, the open pipe 2 and the bellows telescopic joint 3 are connected by a flange 5, the open pipe 2 and the casing 4 are connected by a circlip, and the bellows telescopic joint 3 plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com