Patents

Literature

37results about How to "Achieve simultaneous rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

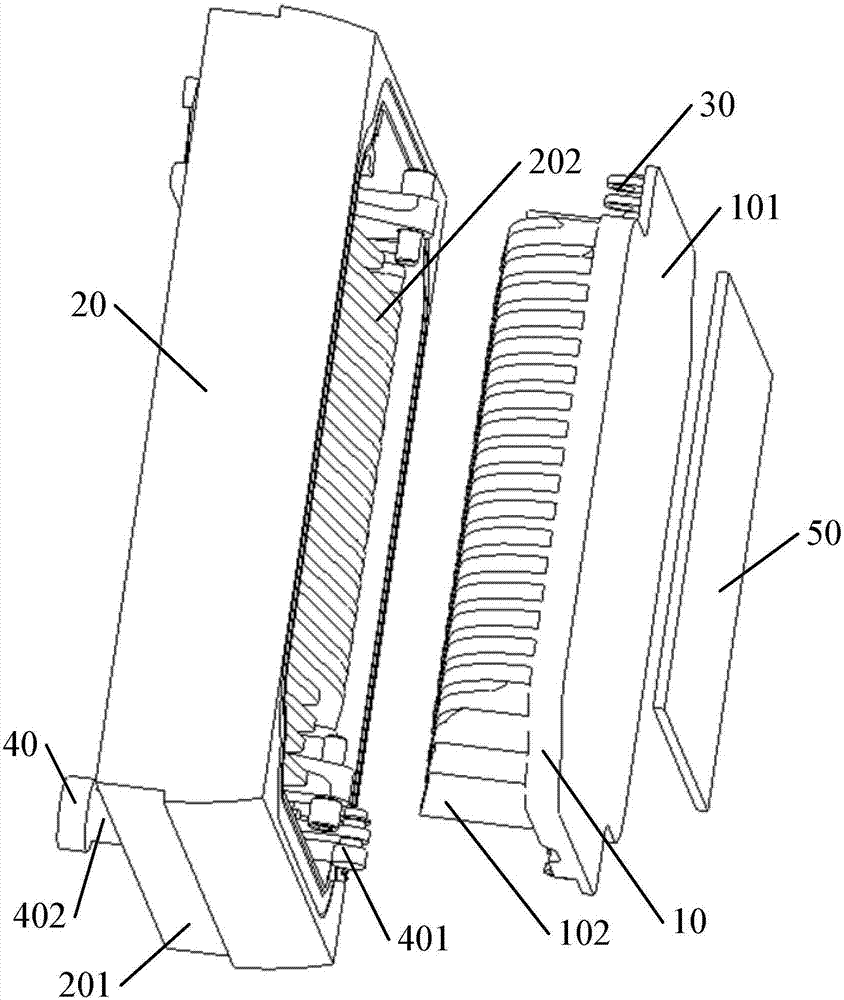

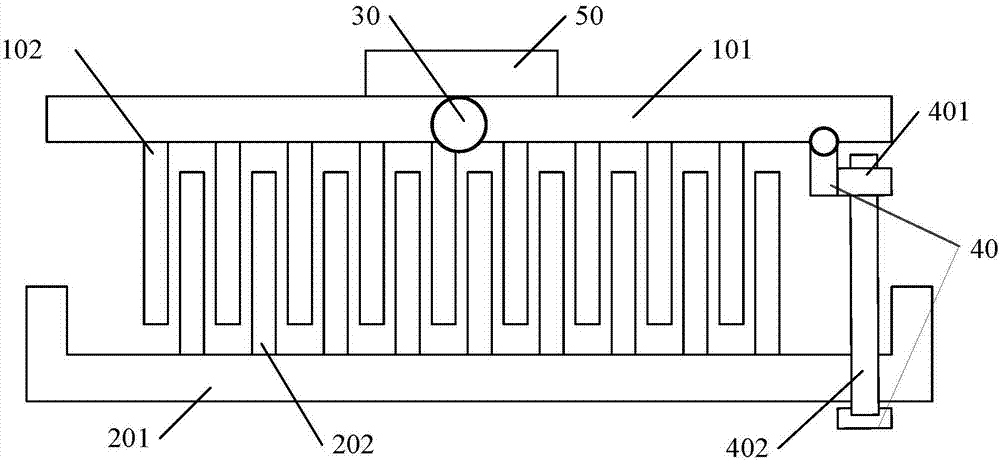

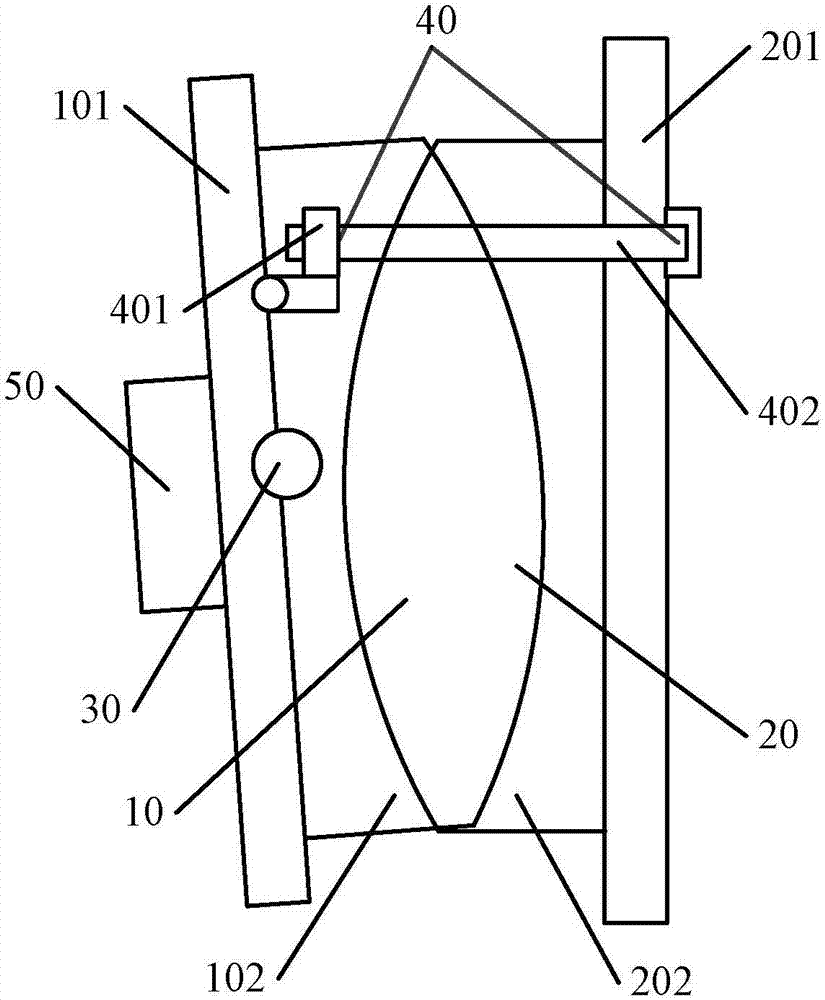

Heat radiation device, radiator, electronic equipment and heat radiation control method

ActiveCN107087377AReduce complexityDoes not affect heat dissipationSemiconductor/solid-state device detailsModifications by conduction heat transferEngineeringElectronic component

The invention discloses a heat radiation device which comprises an adjustable heat radiation assembly, a fixed substrate, a rotating shaft and a connecting assembly. One side of the adjustable heat radiation assembly is provided with an electronic component, and the other side of the adjustable heat radiation assembly is provided with the rotating shaft; and one end of the connecting assembly is connected to the adjustable heat radiation assembly, the other end of the connecting assembly is connected with the fixed substrate, and the connecting assembly drives the adjustable heat radiation assembly to rotate via the rotating shaft. The invention also provides a radiator, electronic equipment and a heat radiation control method. Thus, the electronic component and the adjustable heat radiation assembly can rotate simultaneously by adjusting the connecting assembly, the heat radiation effect is not influenced, the complexity in disposing the electronic component and the heat radiation device is reduced, and the operational convenience is improved.

Owner:HUAWEI TECH CO LTD

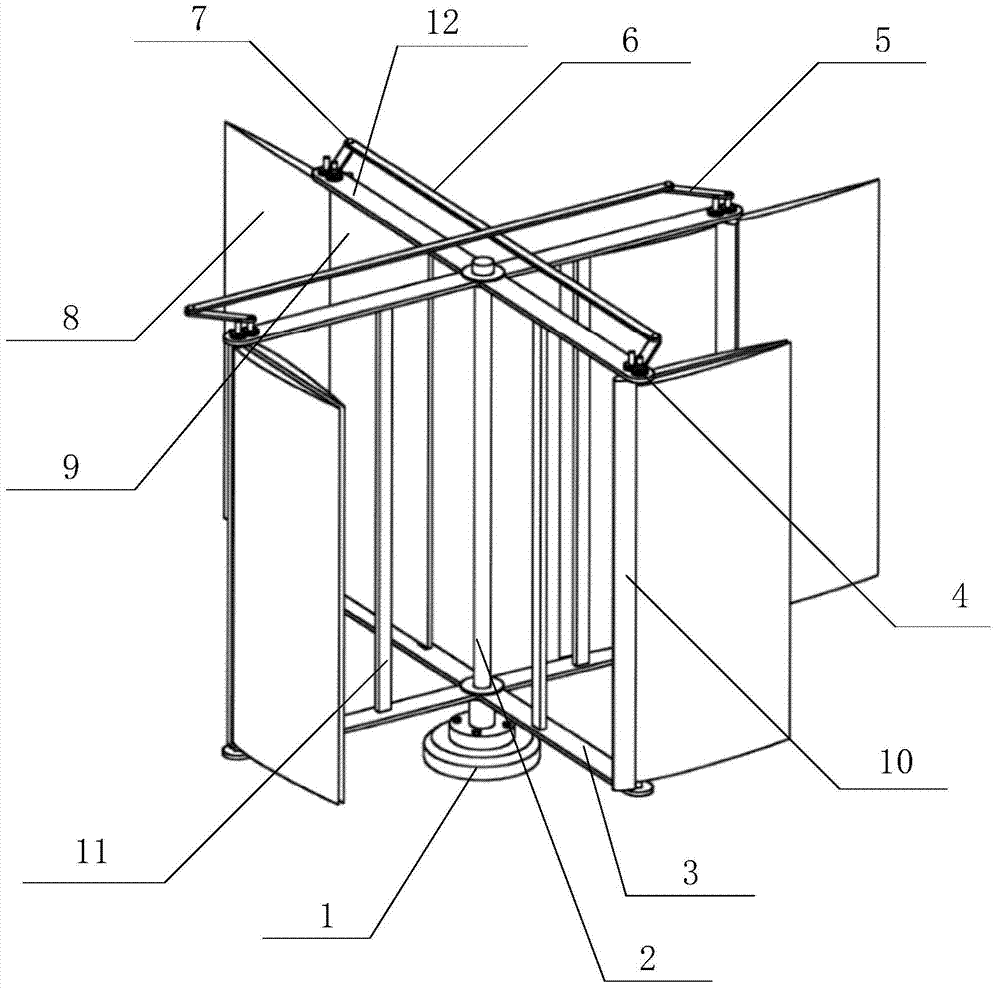

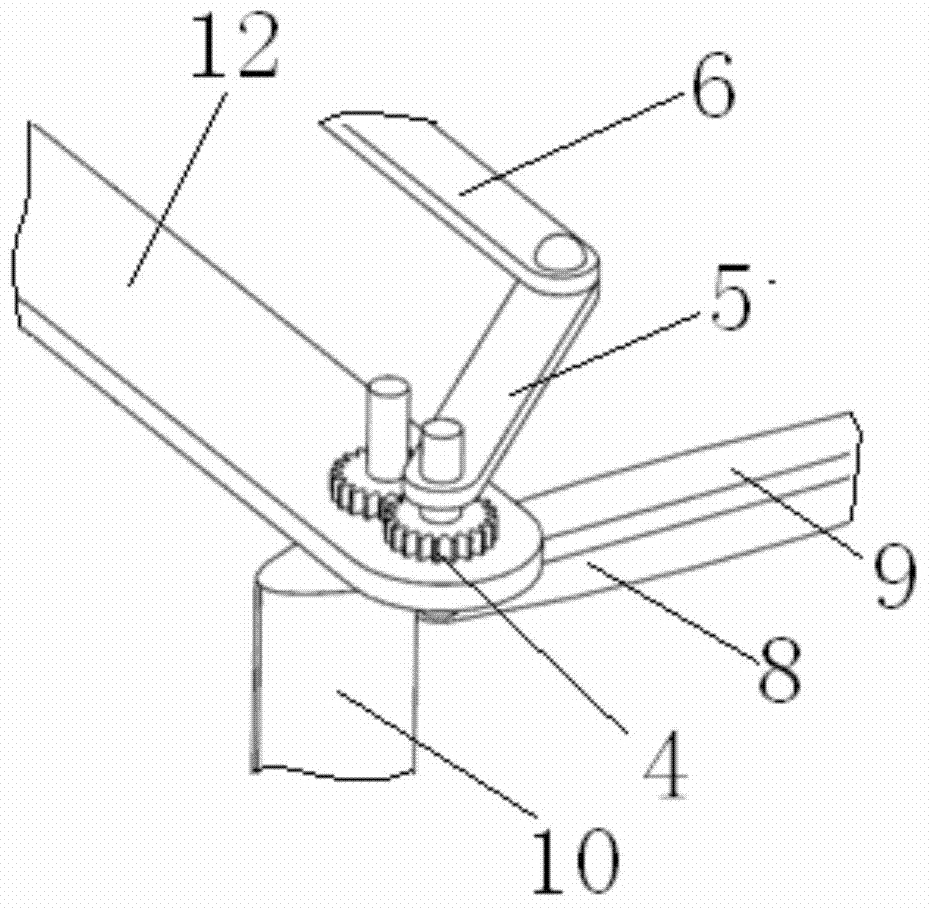

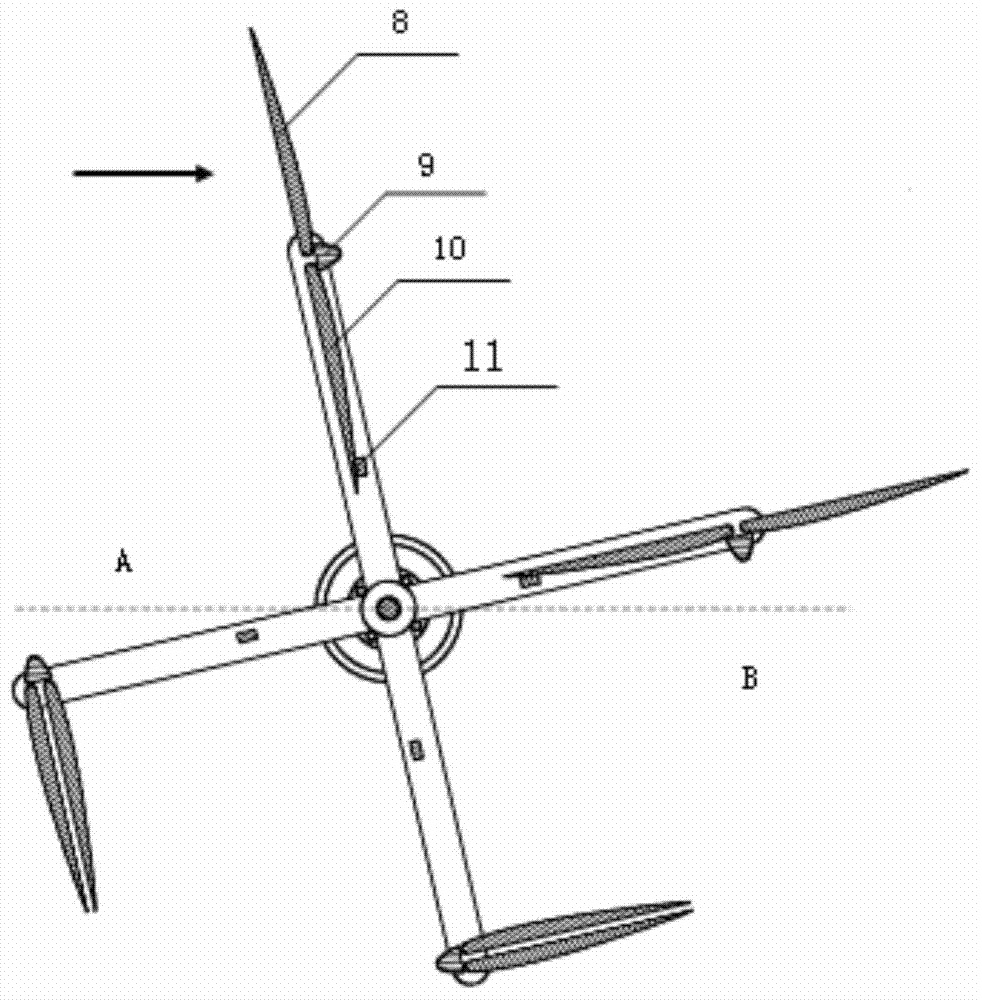

Connecting rod transmitting folding blade vertical shaft impeller

InactiveCN104329218AGood self-startingIncrease the windward areaMachines/enginesRenewable energy generationImpellerAerospace engineering

The invention provides a connecting rod transmitting folding blade vertical shaft impeller. A main shaft is arranged on a bearing base, blade supports are respectively and fixedly arranged at the upper end and the lower end of the main shaft, four blade units are respectively located between the upper blade support and the lower blade support, rotating shafts of all blades are respectively provided with gear units, the two groups of symmetrical blades can rotate synchronously through two connecting rod transmitting mechanisms which connect the two groups of symmetrical blades, and when one group of blades gradually closes, the other group of blades gradually open. The impeller blades rotate around the shaft and can change the positions of the blades, so that the blades can be unfolded as a plane board when facing the wind, the wind facing area is increased, the received rotating torque is improved, the blades can be folded and form NACA wing type blades when facing against the wind, the wind against resistance is reduced, so that the impeller blades have good self-starting performance, the energy catching efficiency can be further improved, and the connecting rod transmitting folding blade vertical shaft impeller has a higher power generating efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

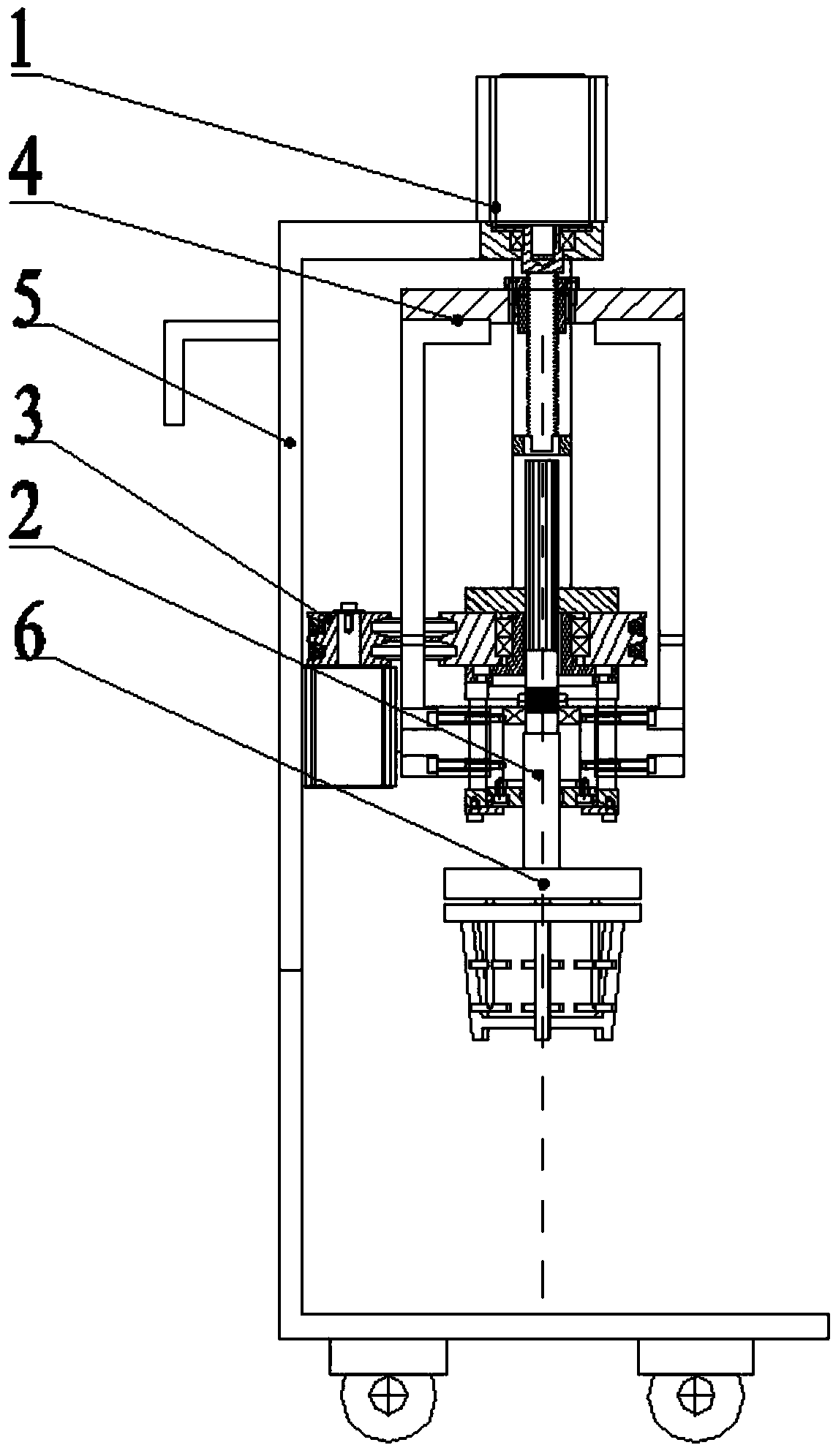

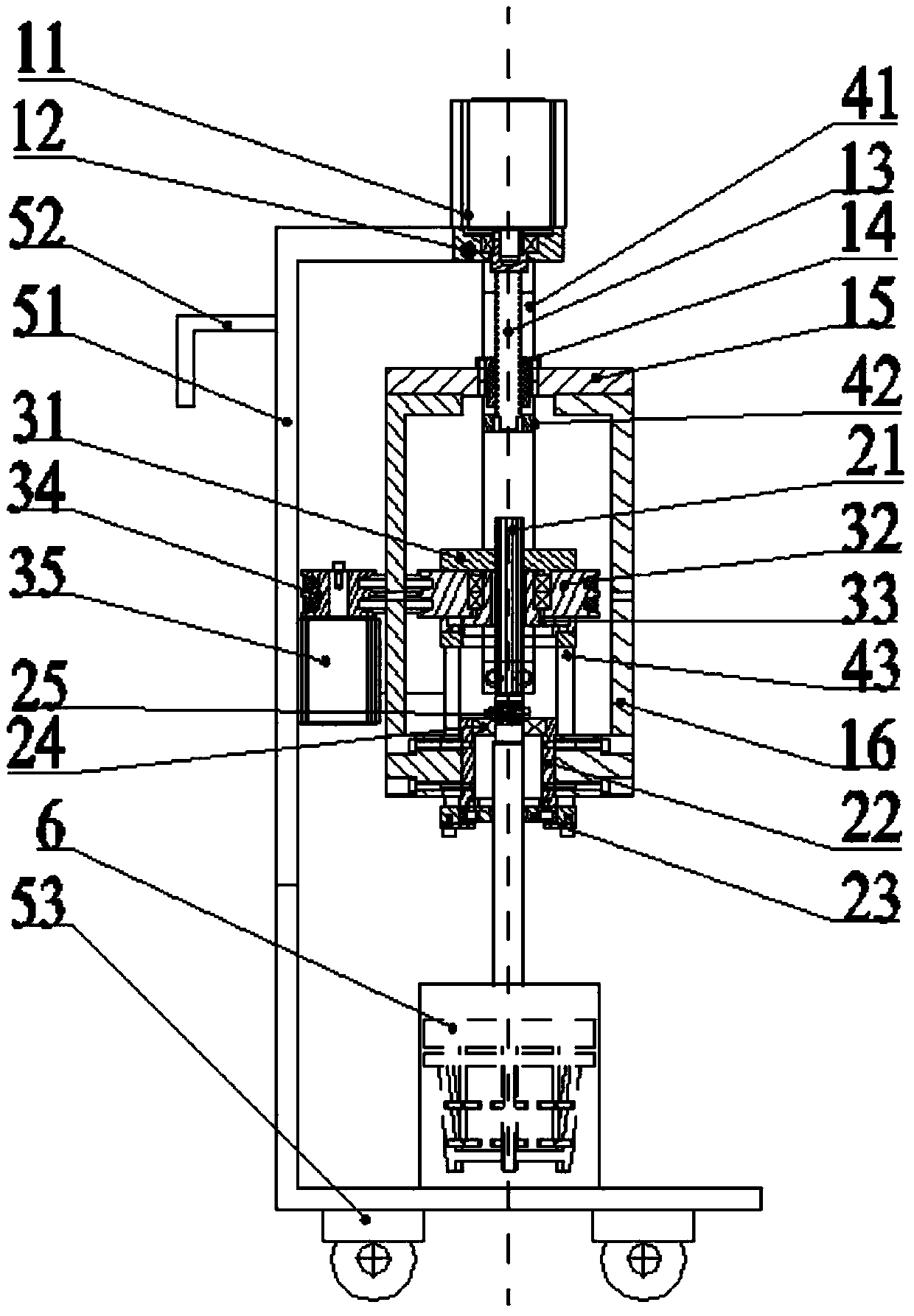

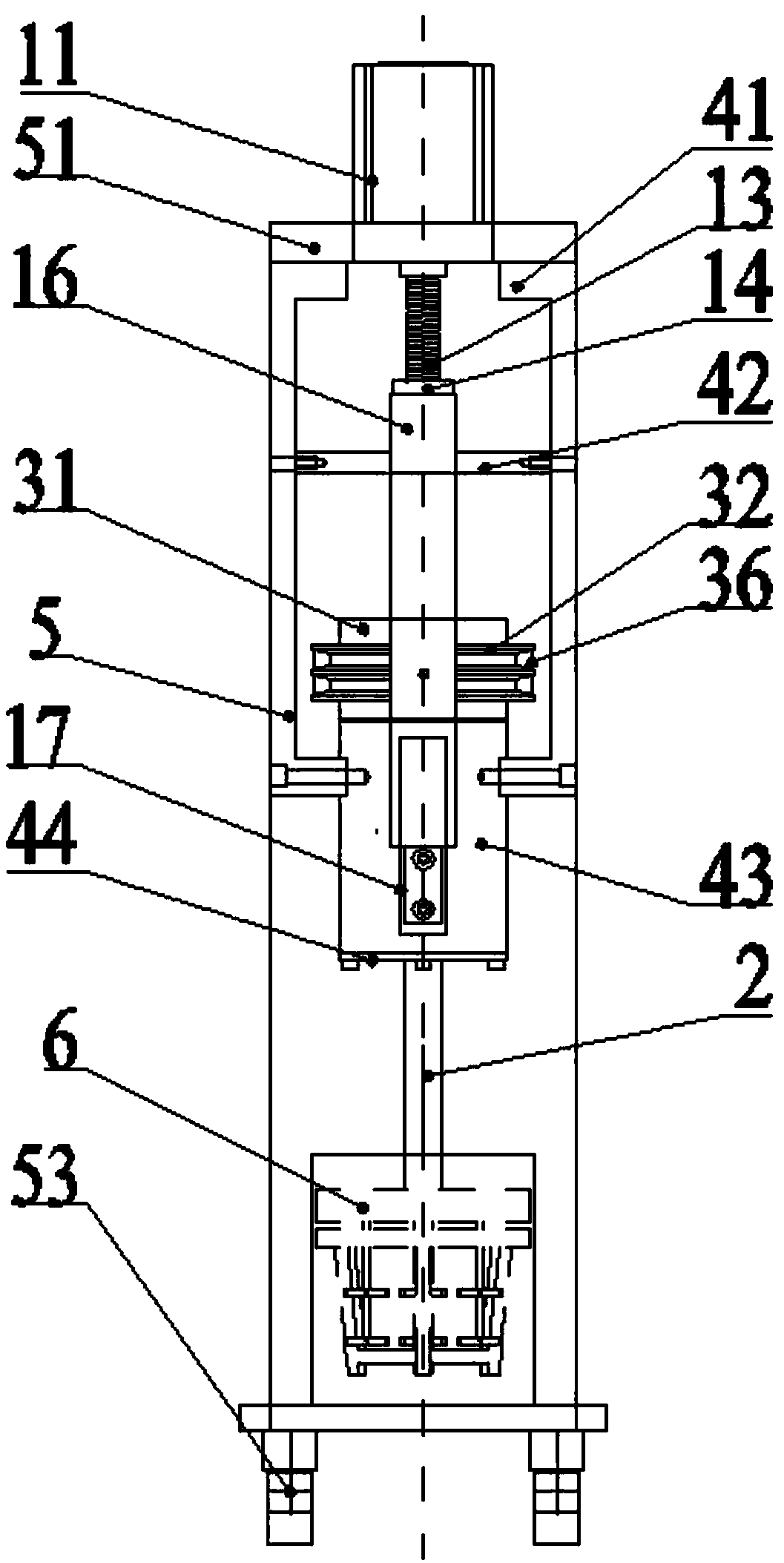

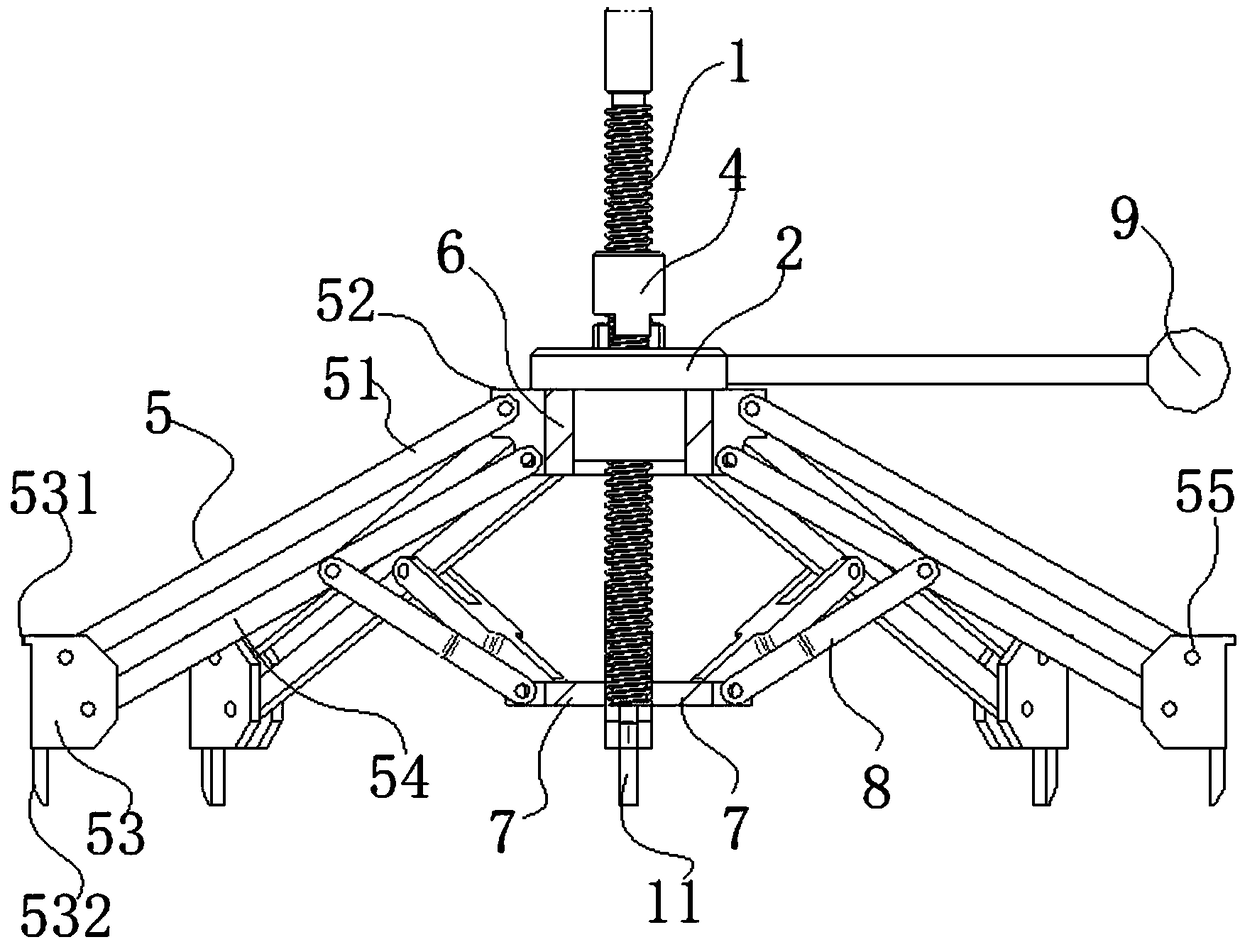

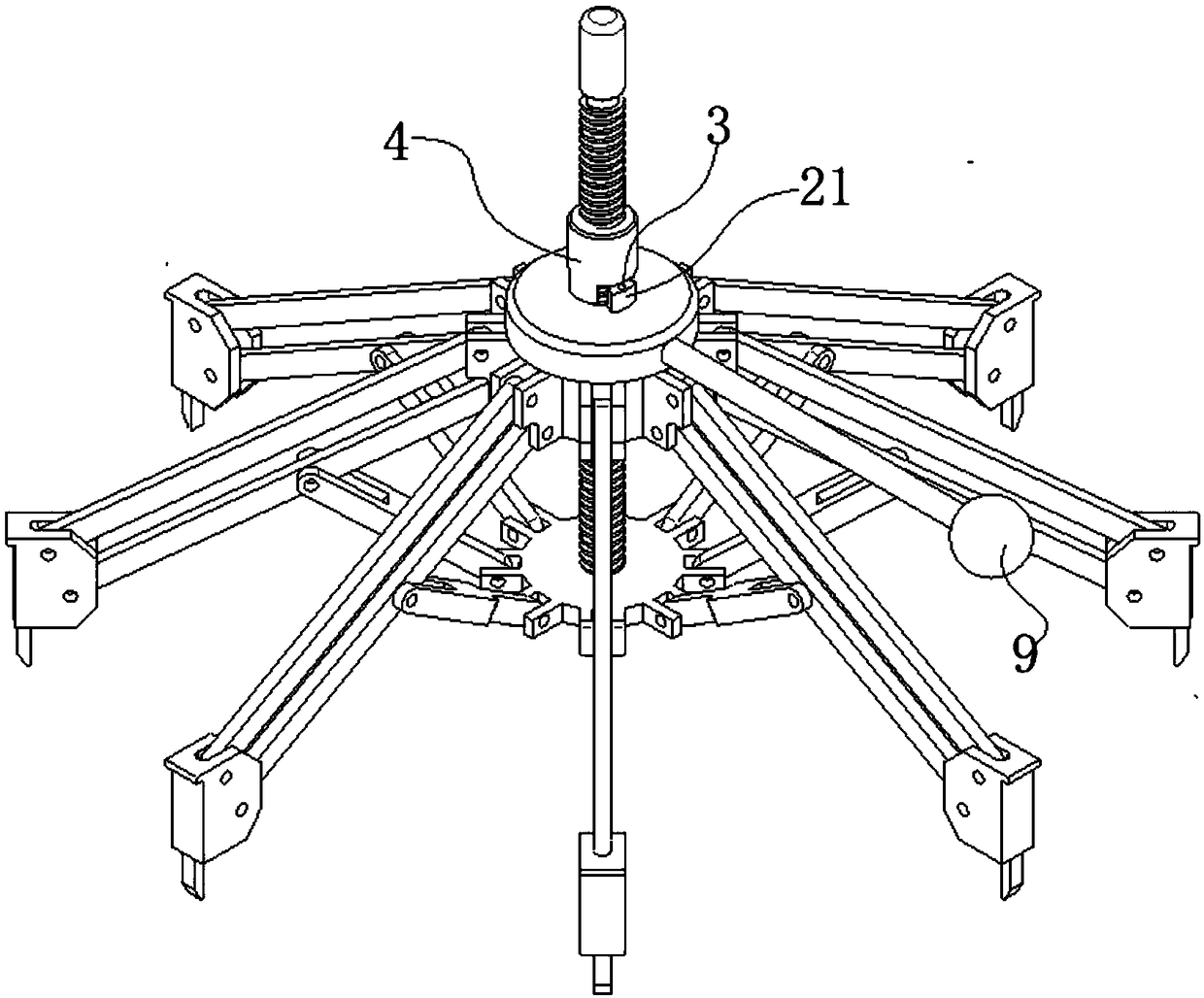

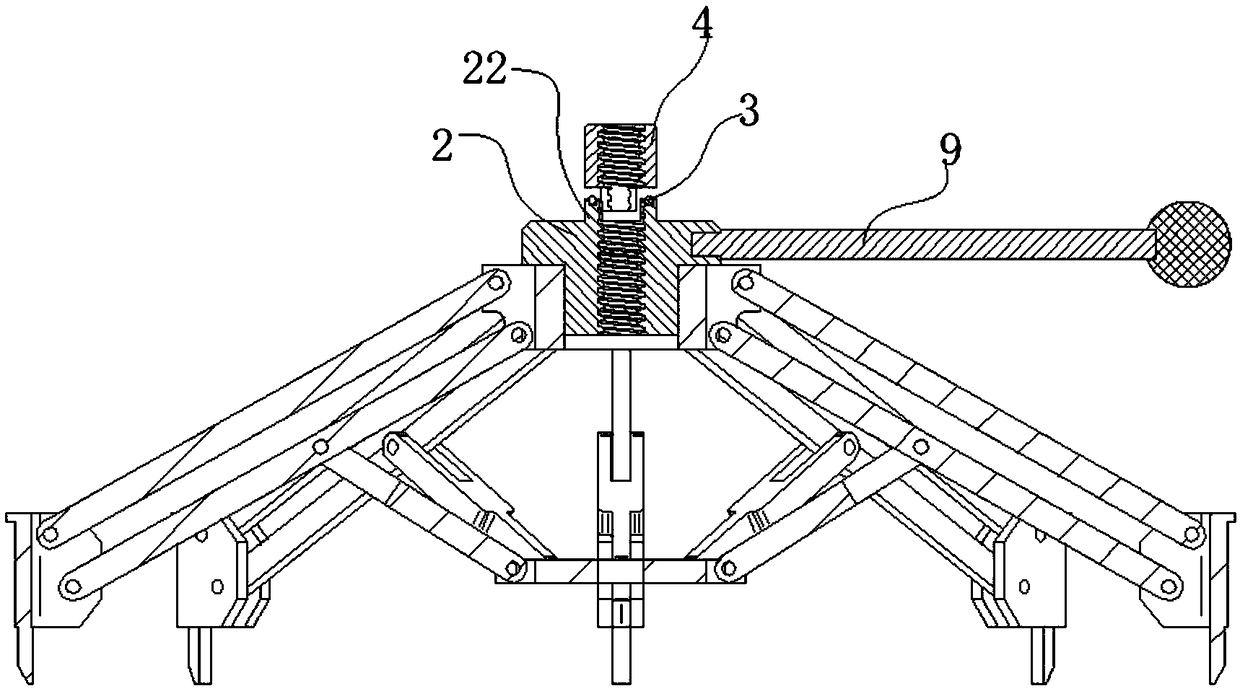

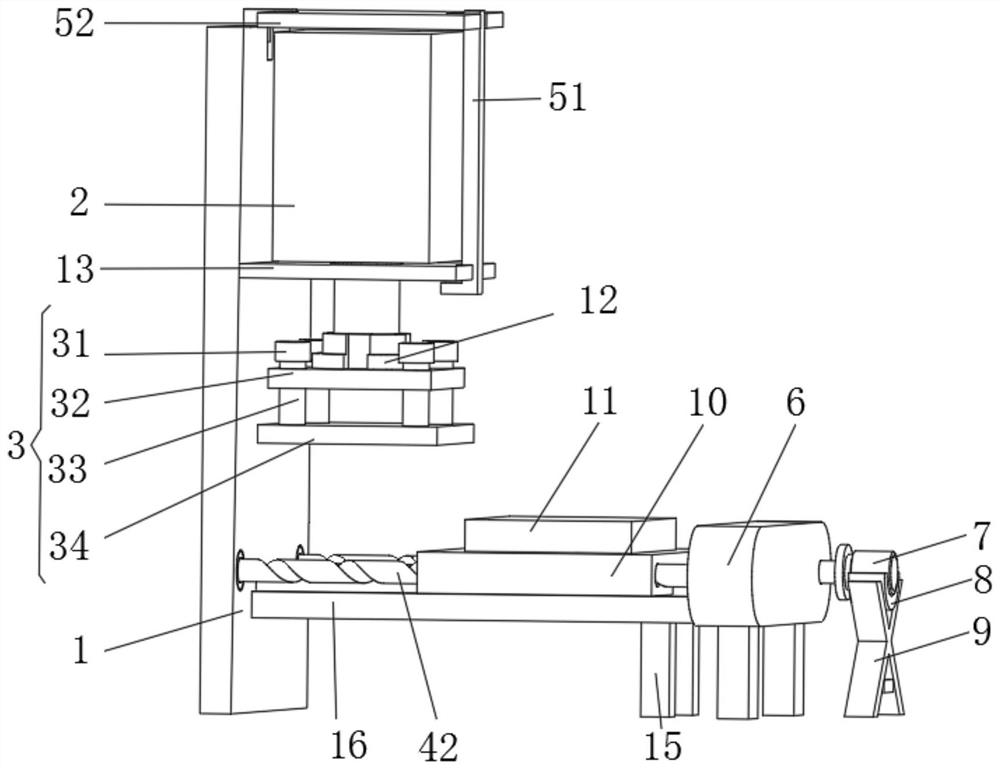

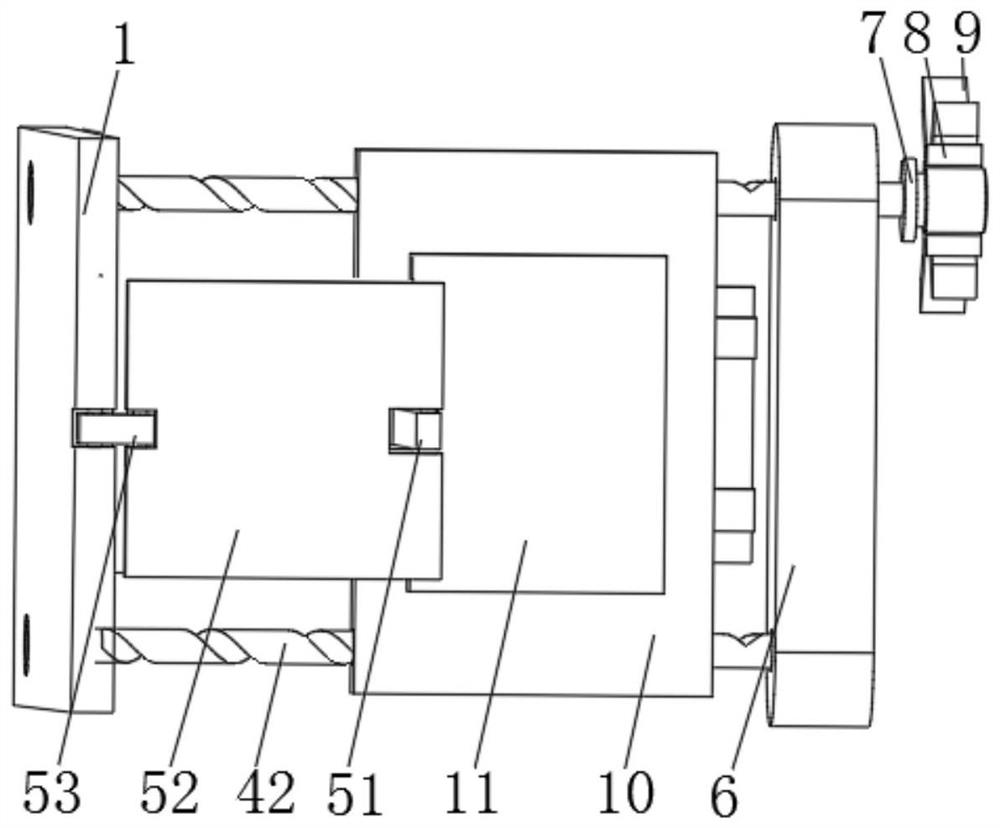

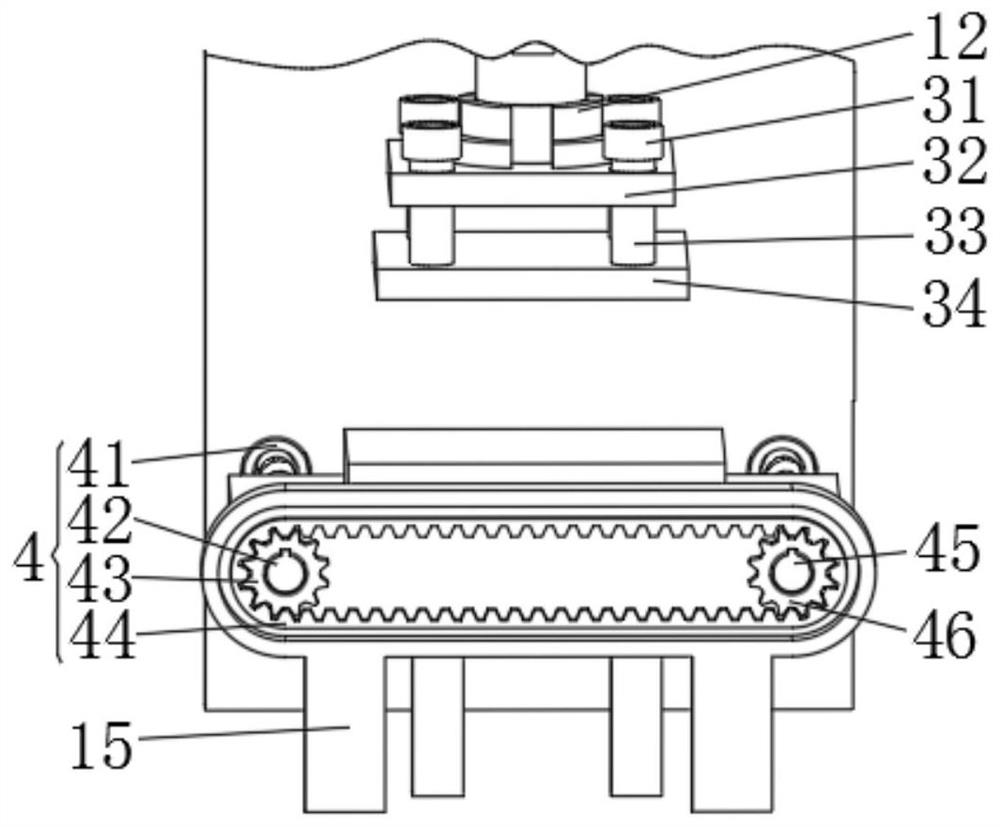

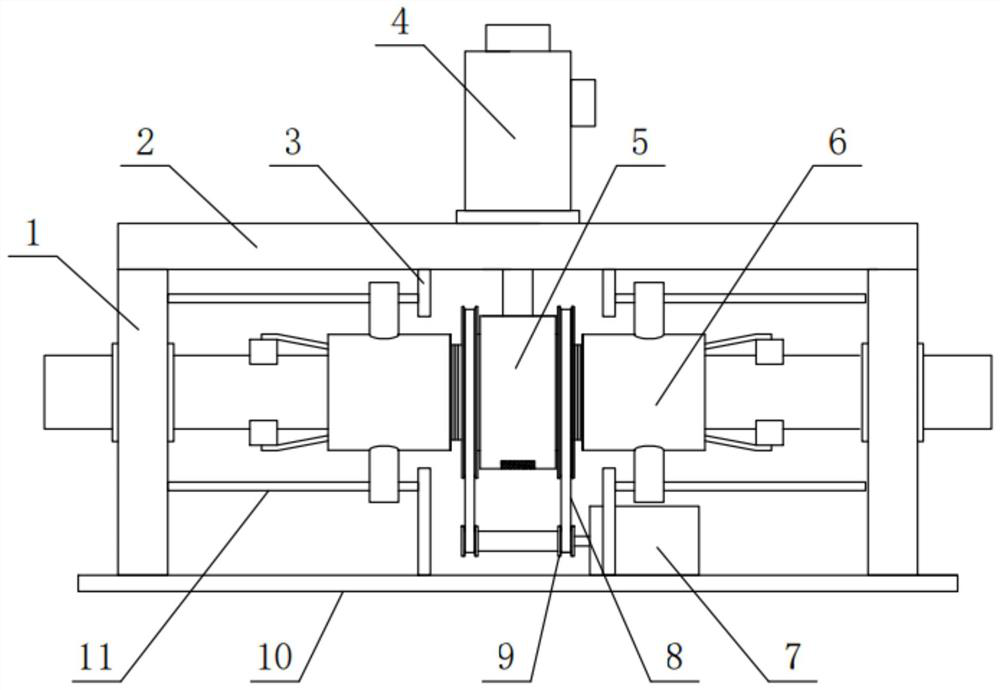

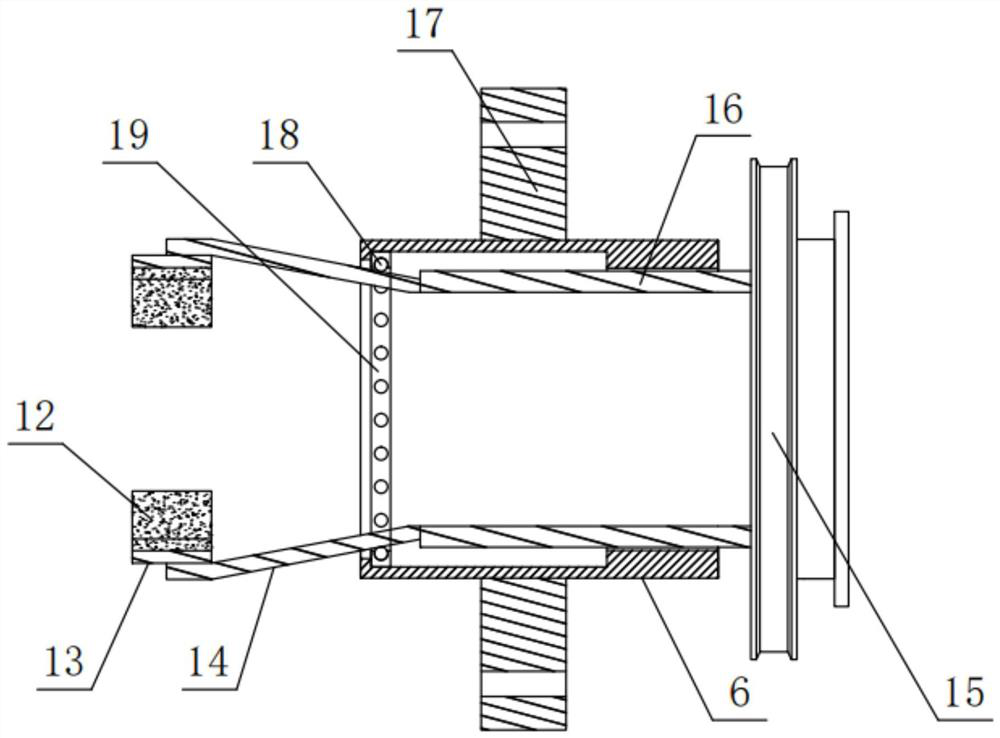

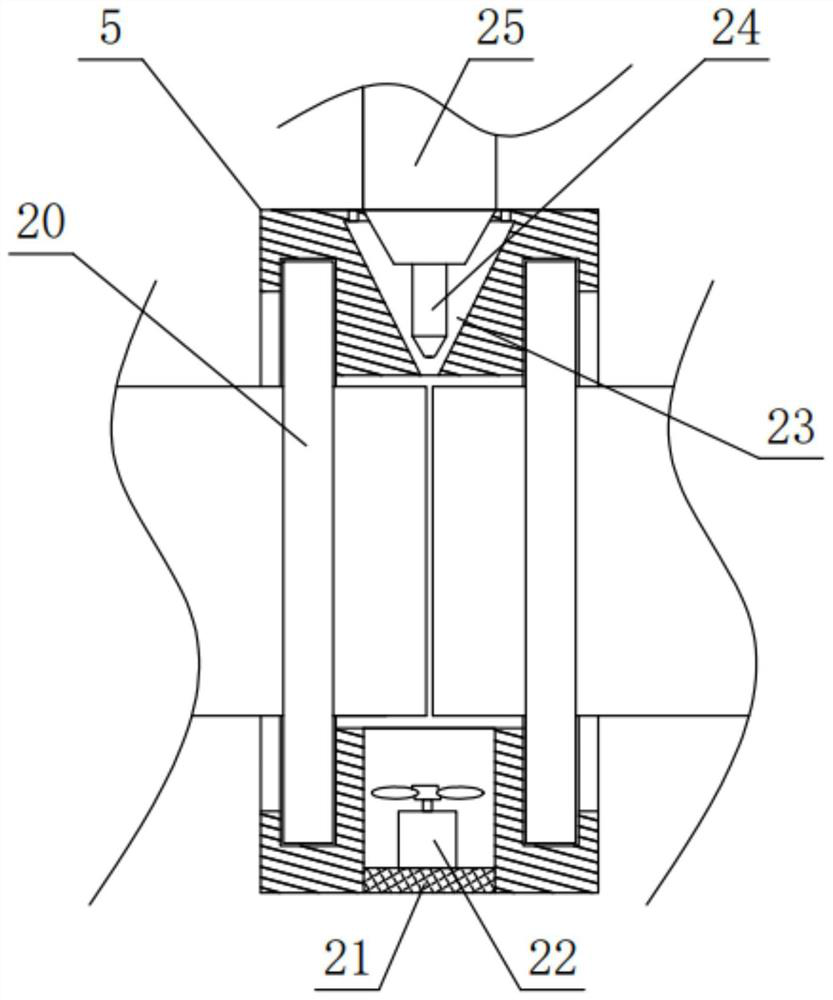

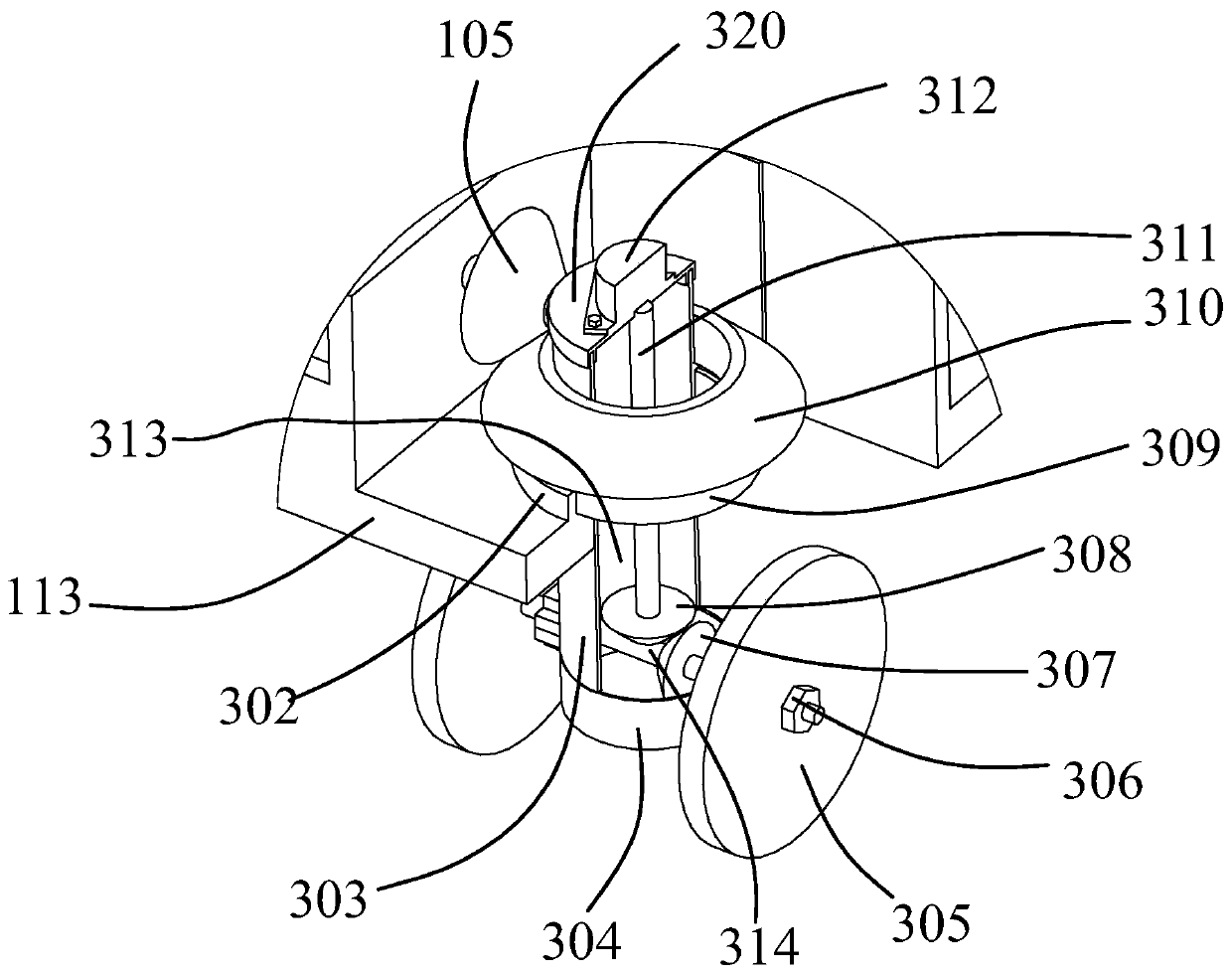

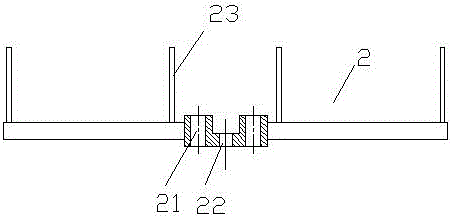

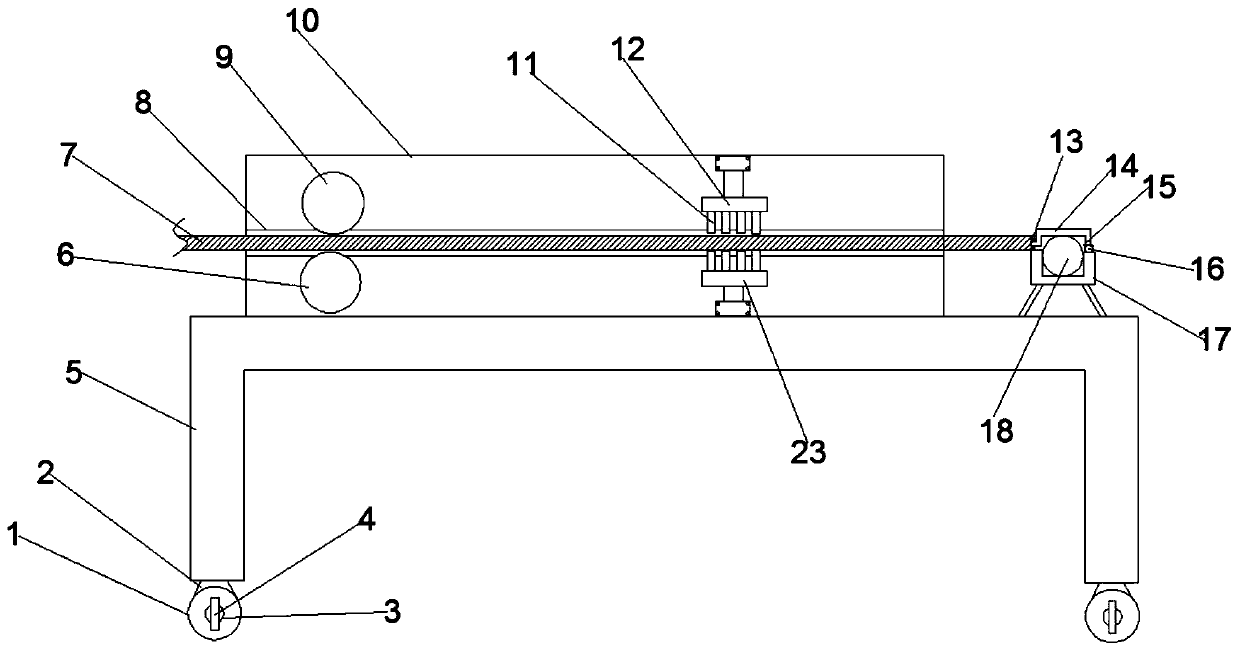

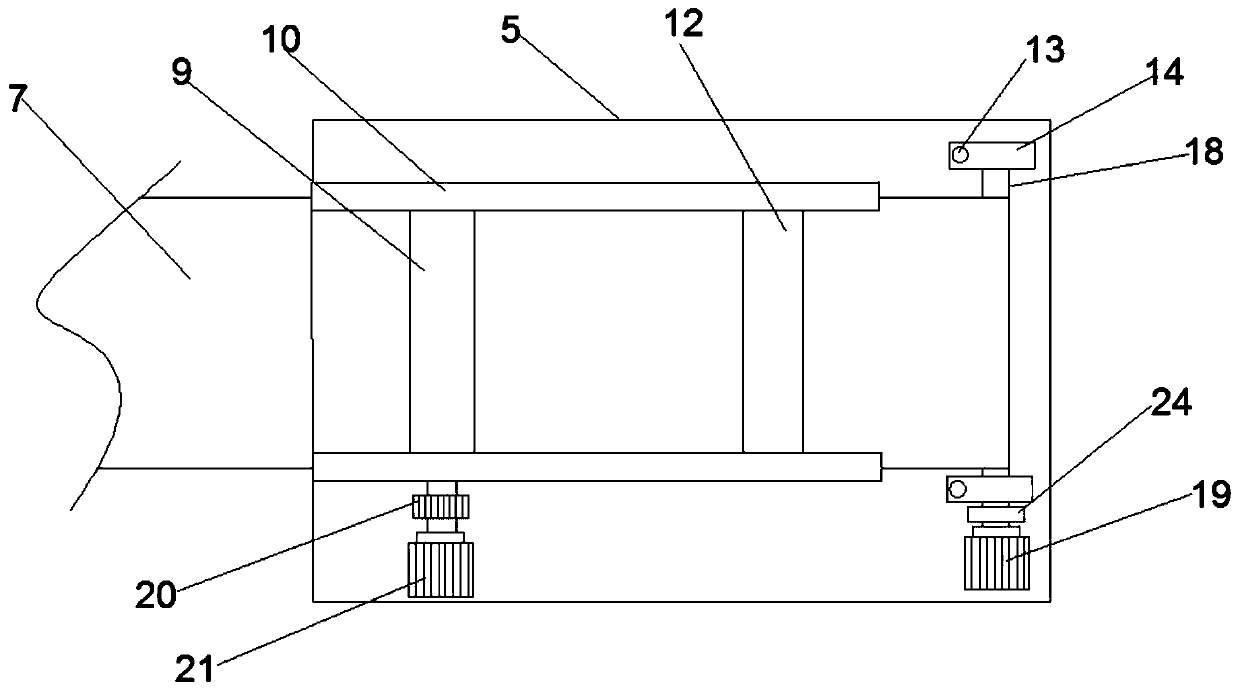

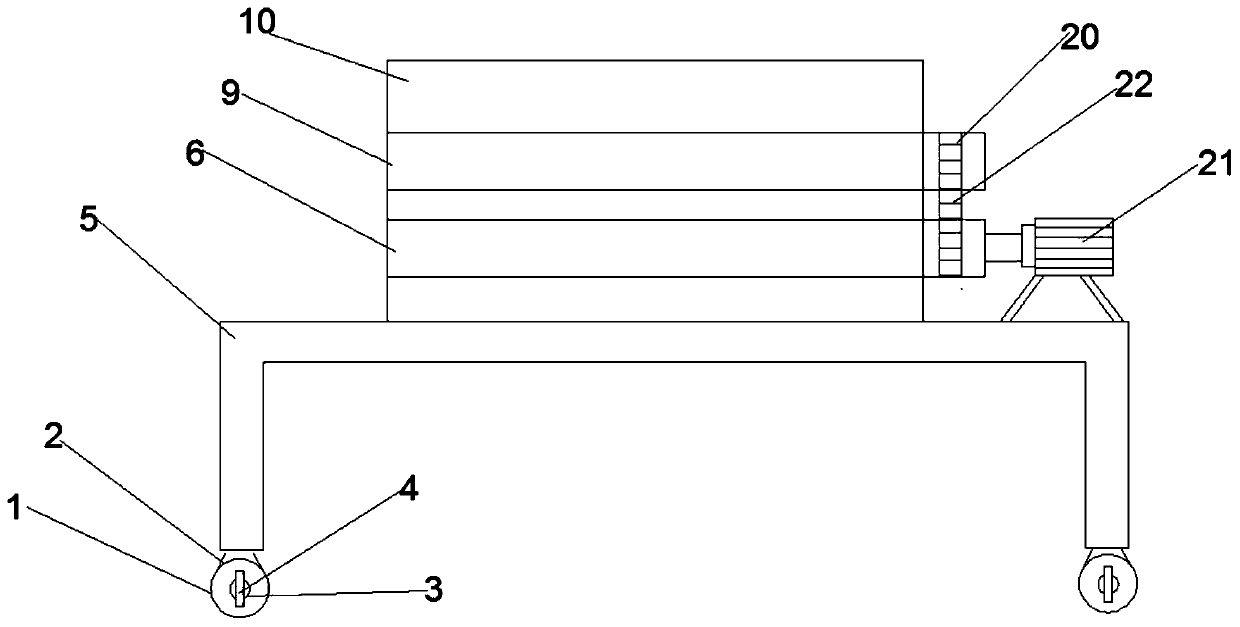

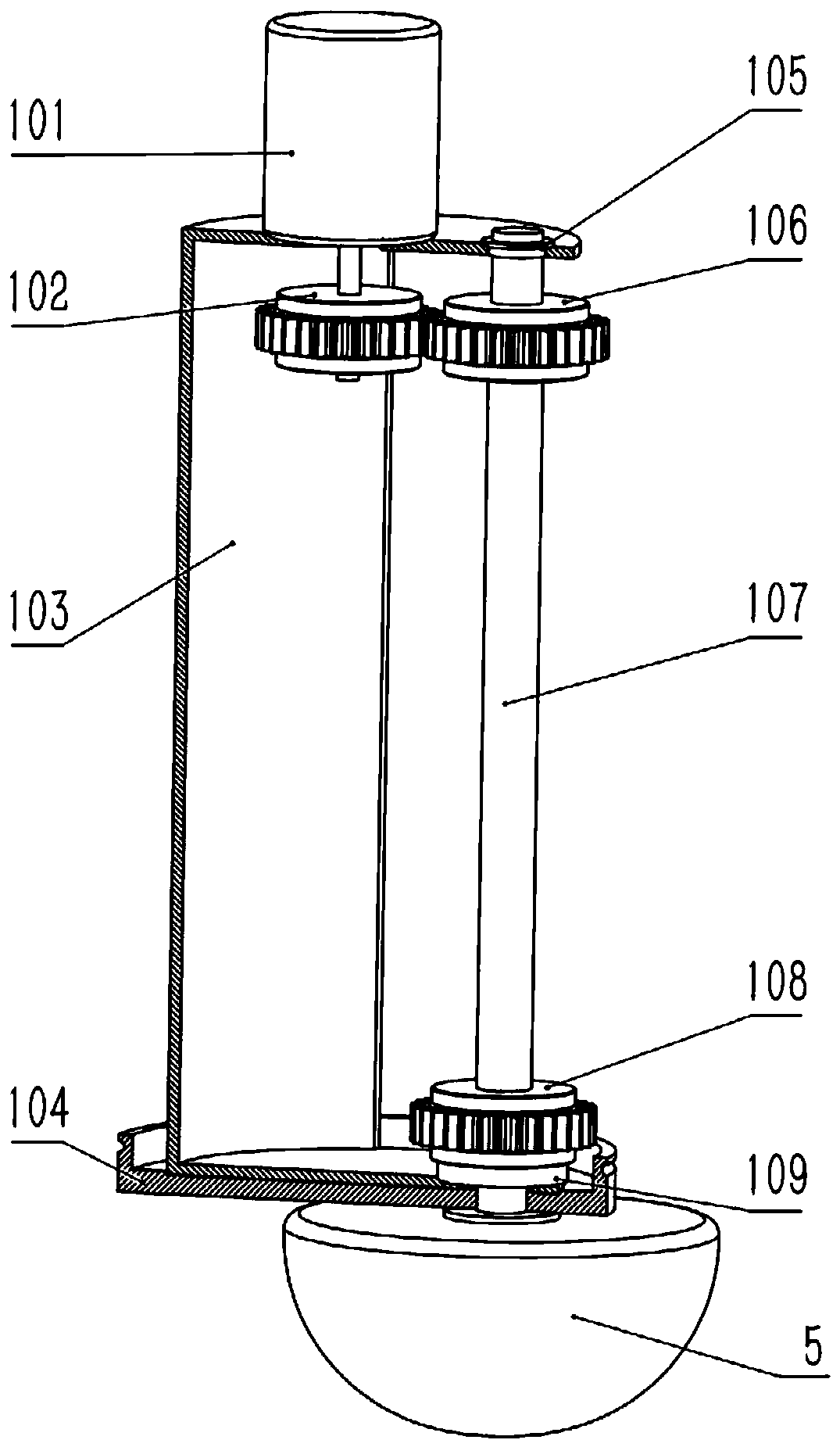

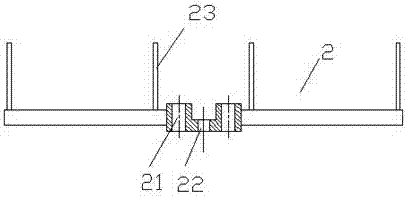

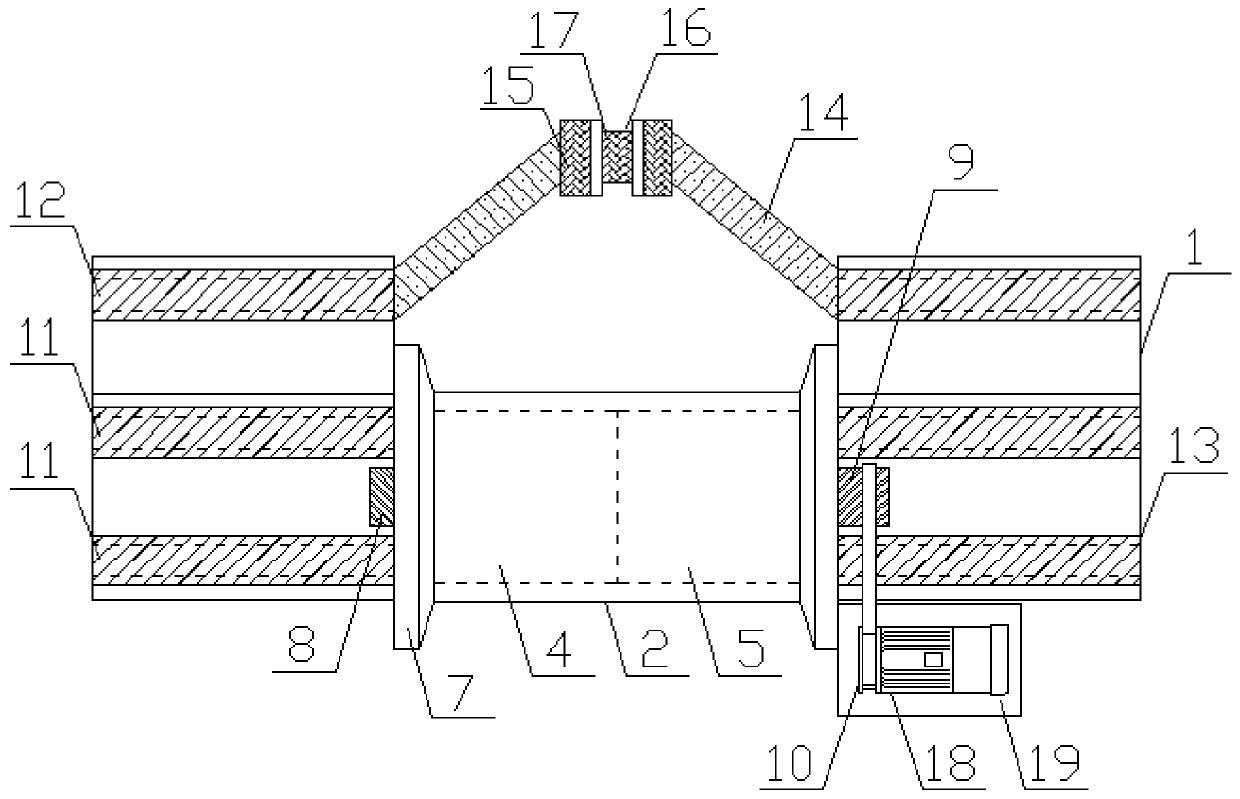

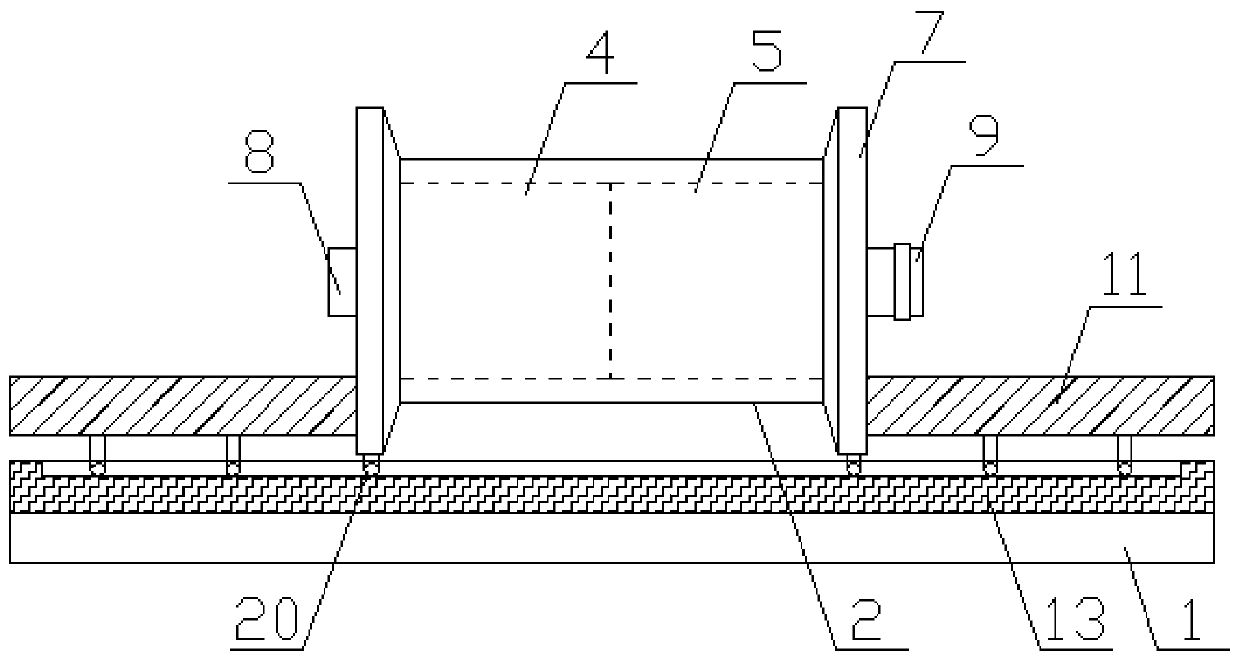

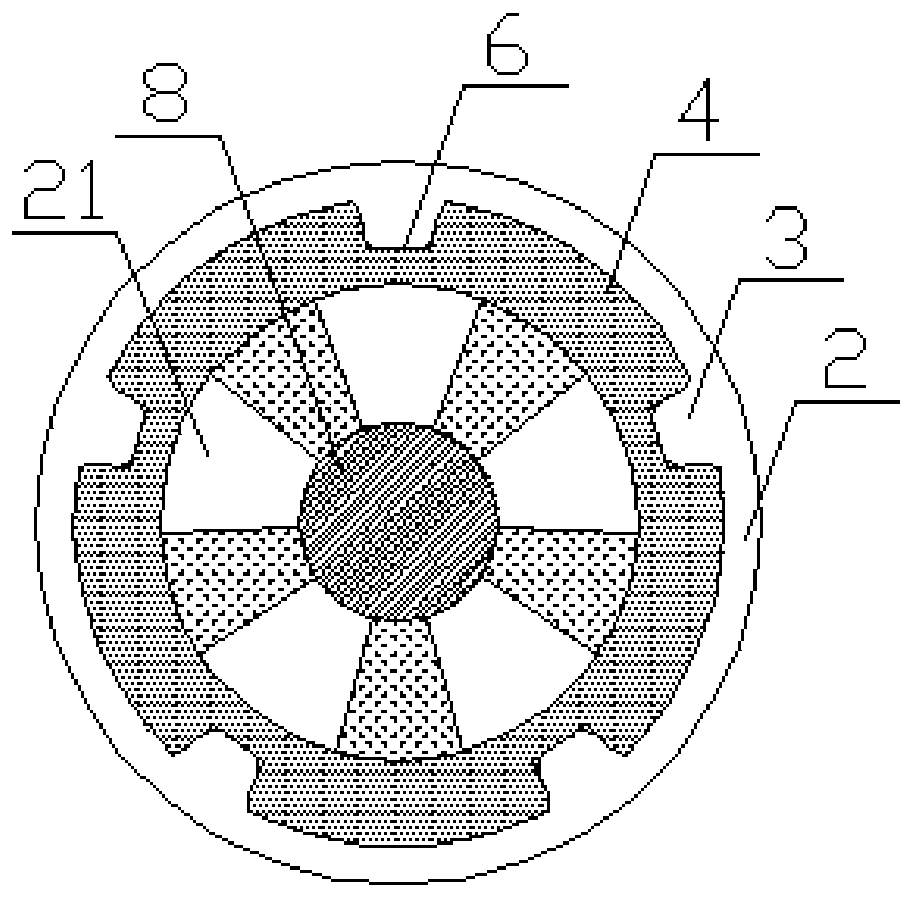

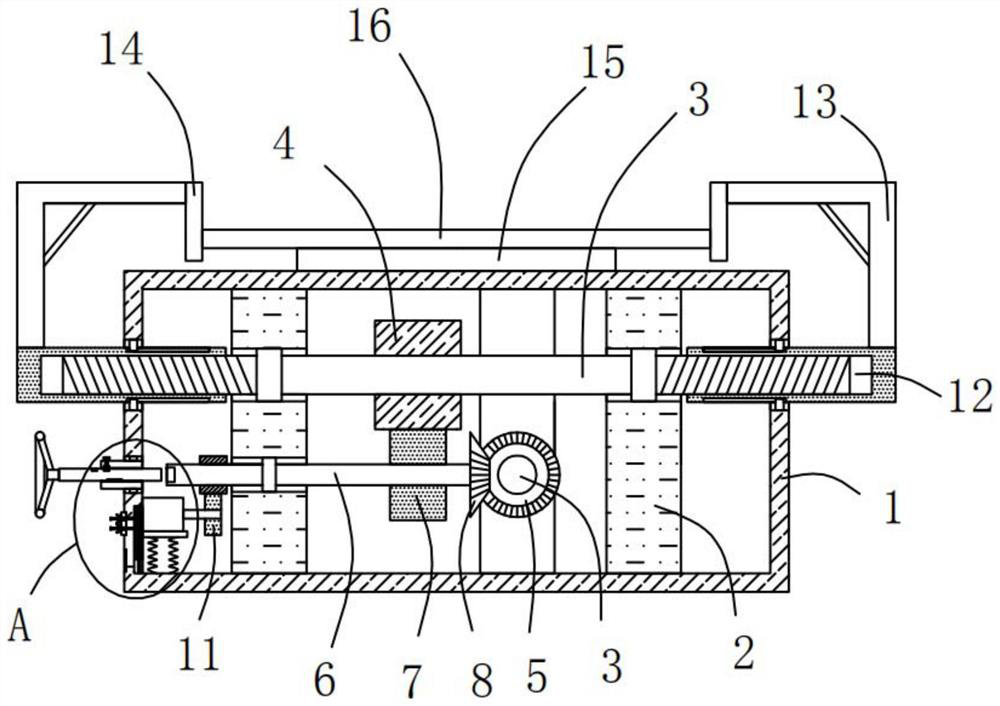

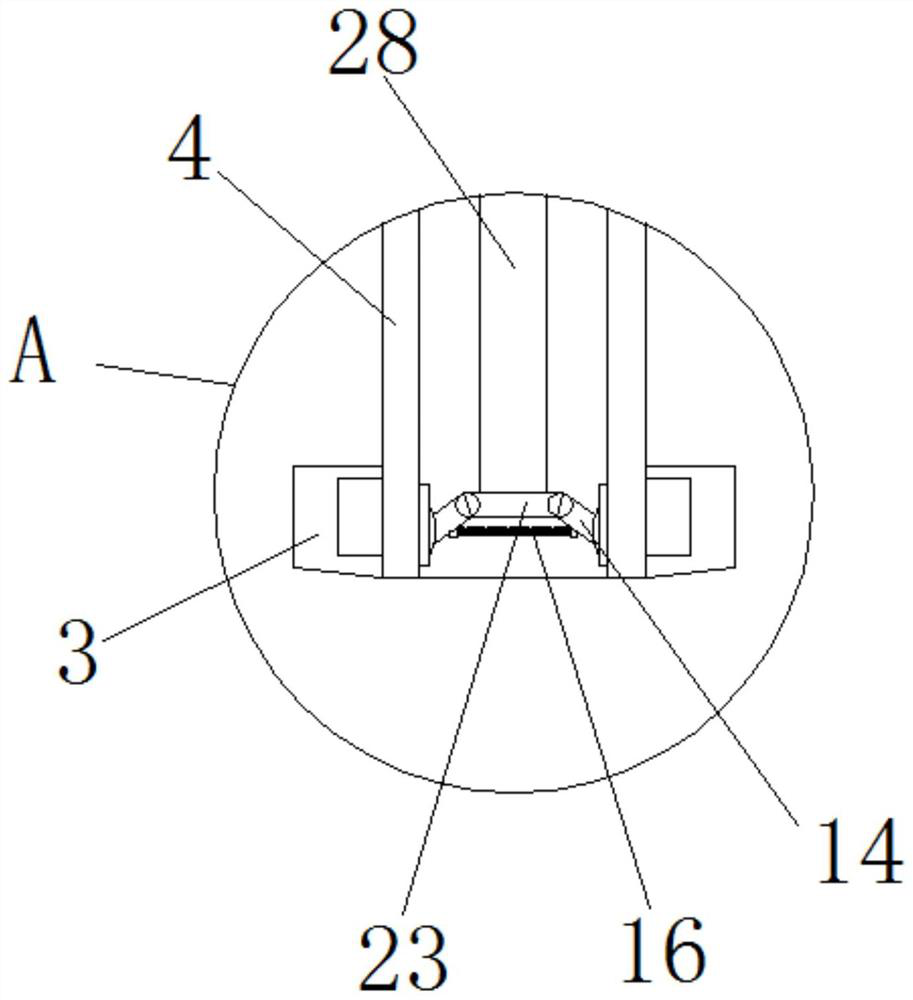

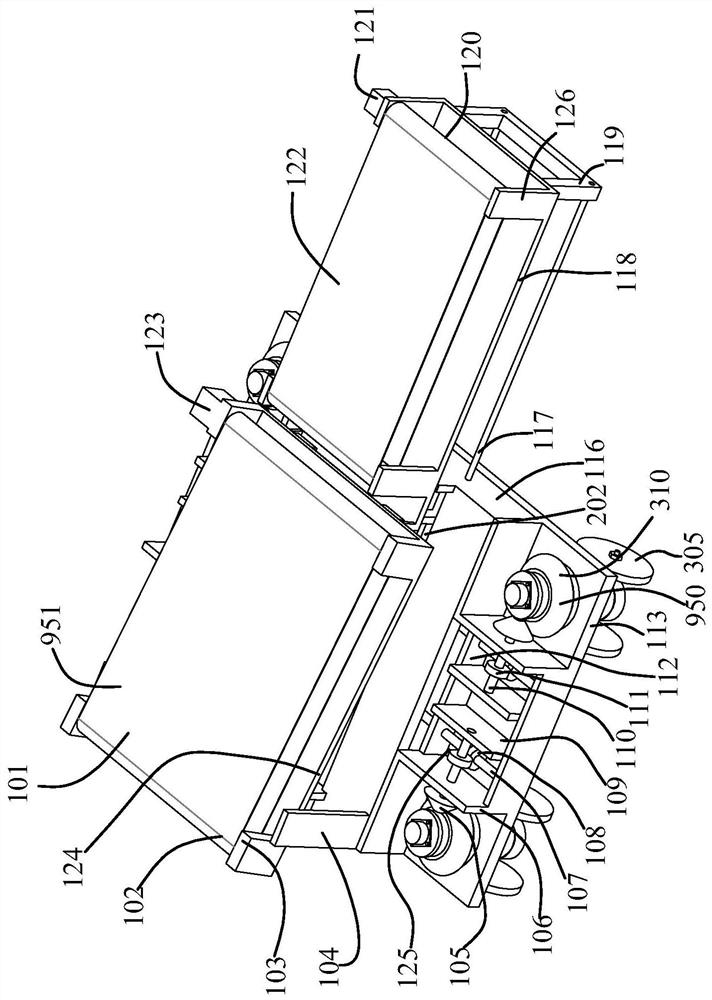

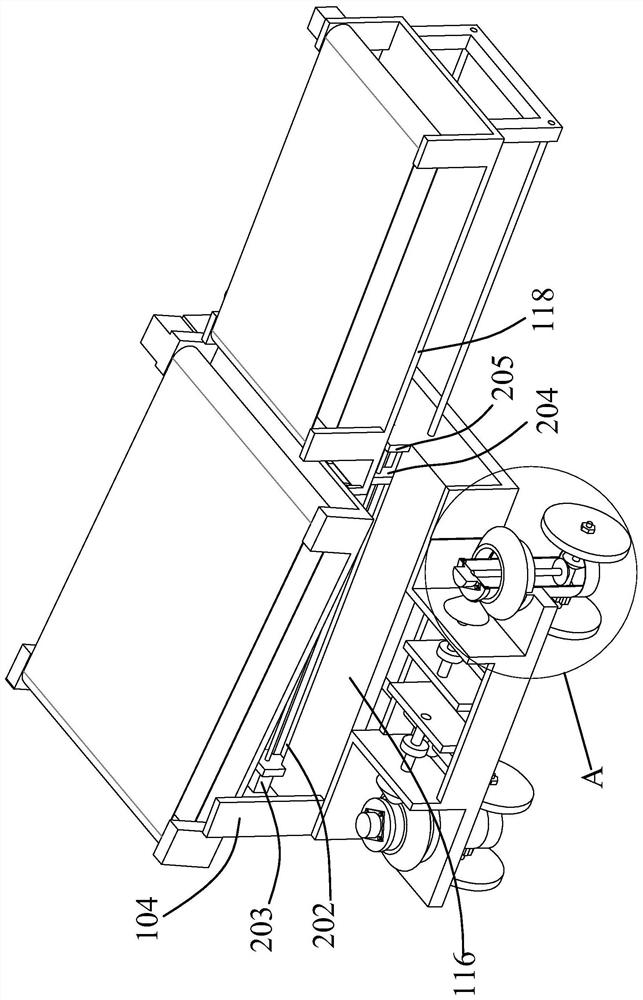

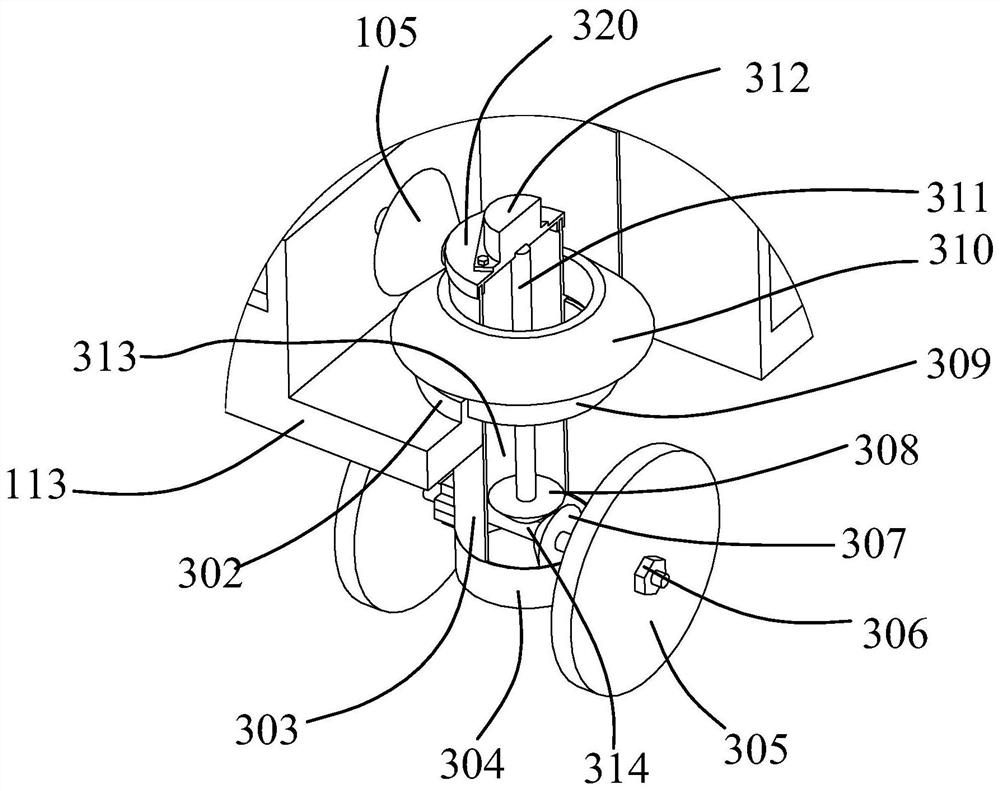

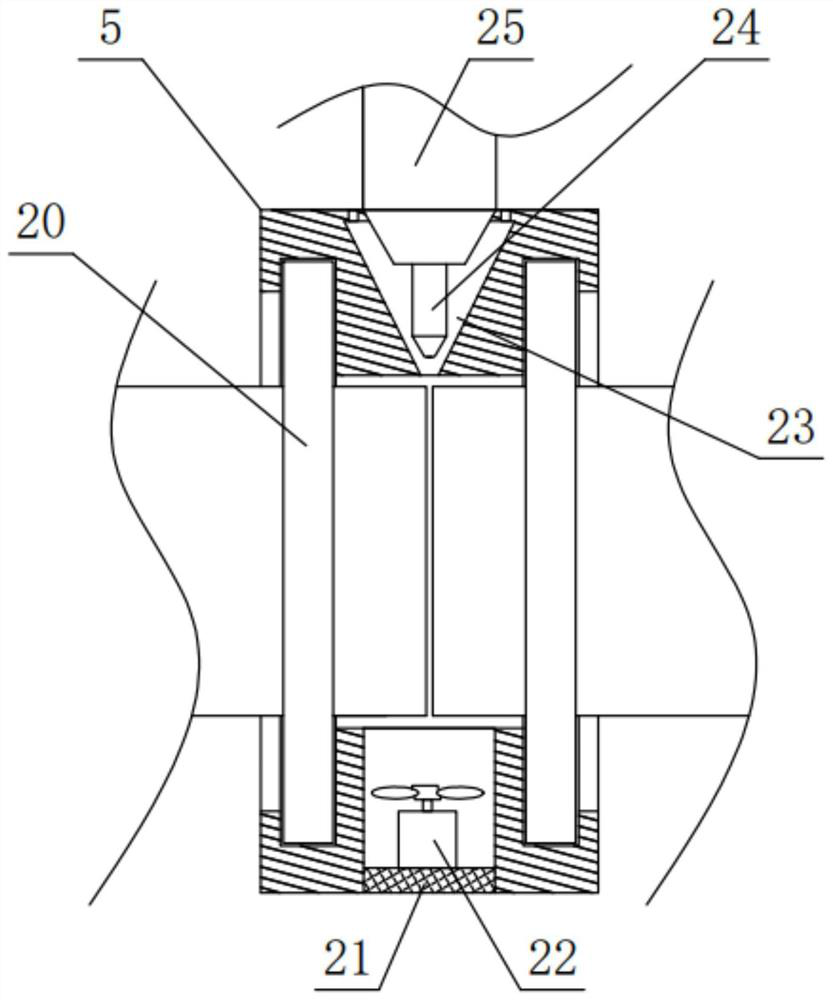

Frame style automatic mixing and stirring device for viscous materials

ActiveCN107694408AAvoid destructionAchieve simultaneous rotationTransportation and packagingRotary stirring mixersElectric machineryEngineering

The invention discloses a frame style automatic mixing and stirring device for viscous materials, which comprises a lifting device, a rotary shaft system, a rotary device, a rotary shaft supporting device, a main body support, a clamping device and a planet wheel stirring device. A vertical motor of the lifting device is arranged on the main body support; the rotary shaft system is connected withthe rotary device through a spline; the rotary shaft system is connected with the rotary shaft supporting device; the rotary shaft supporting device is connected with the lifting device; the rotary device is fixed onto a side wall of the main body support; the clamping device is located on a bottom plate of a frame system; the planet wheel stirring device is connected with the rotary shaft system.The frame style automatic mixing and stirring device for the viscous materials provided by the invention has the remarkable advantages of simple structure, stability in operation, high mixing efficiency and good stability, large torque shift and transfer are realized during a working process, a starting resistance moment is reduced, the motor is prevented from burning out, and the device automatically rotates in a forward and backward direction and lifts up and down, so that the automation level is high, and the manpower is saved.

Owner:QINGDAO UNIV OF SCI & TECH

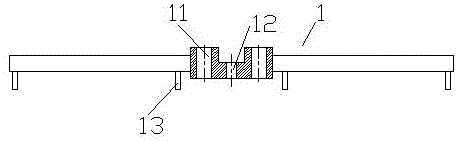

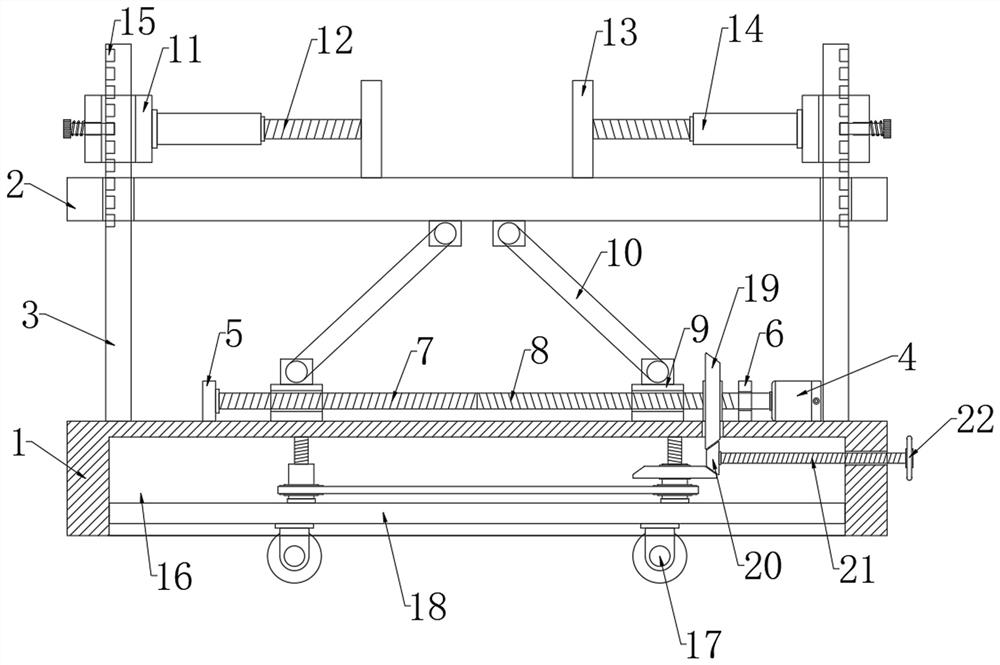

A portable tire loading device and an operation method thereof

PendingCN109017172AAvoid the difficulty of reinstallingThe operation process is simple and convenientTyre repairingEngineeringScrew thread

Owner:安徽世界村智能装备有限公司

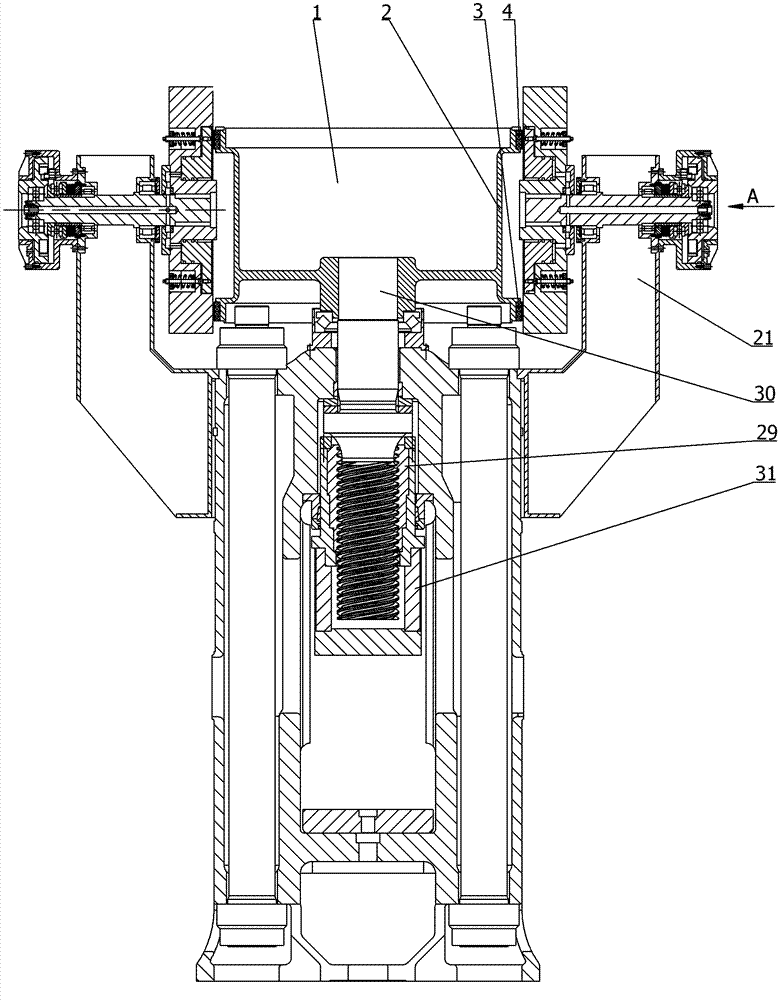

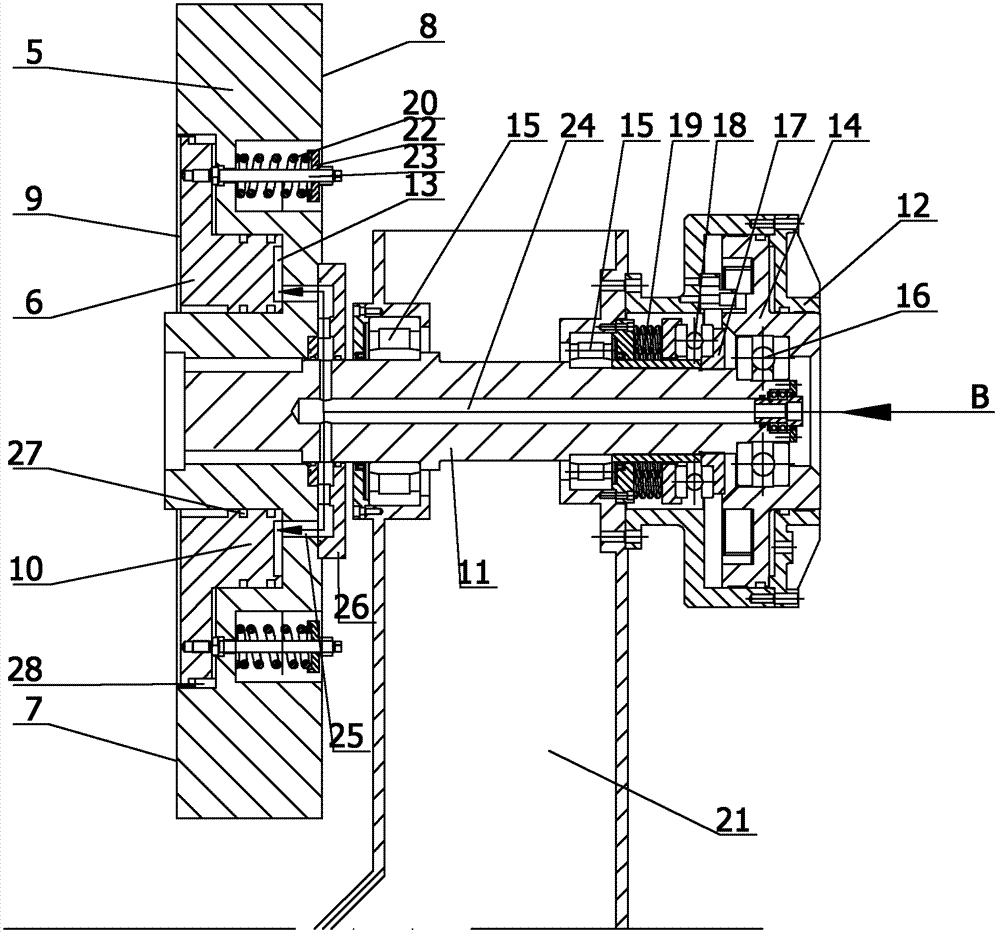

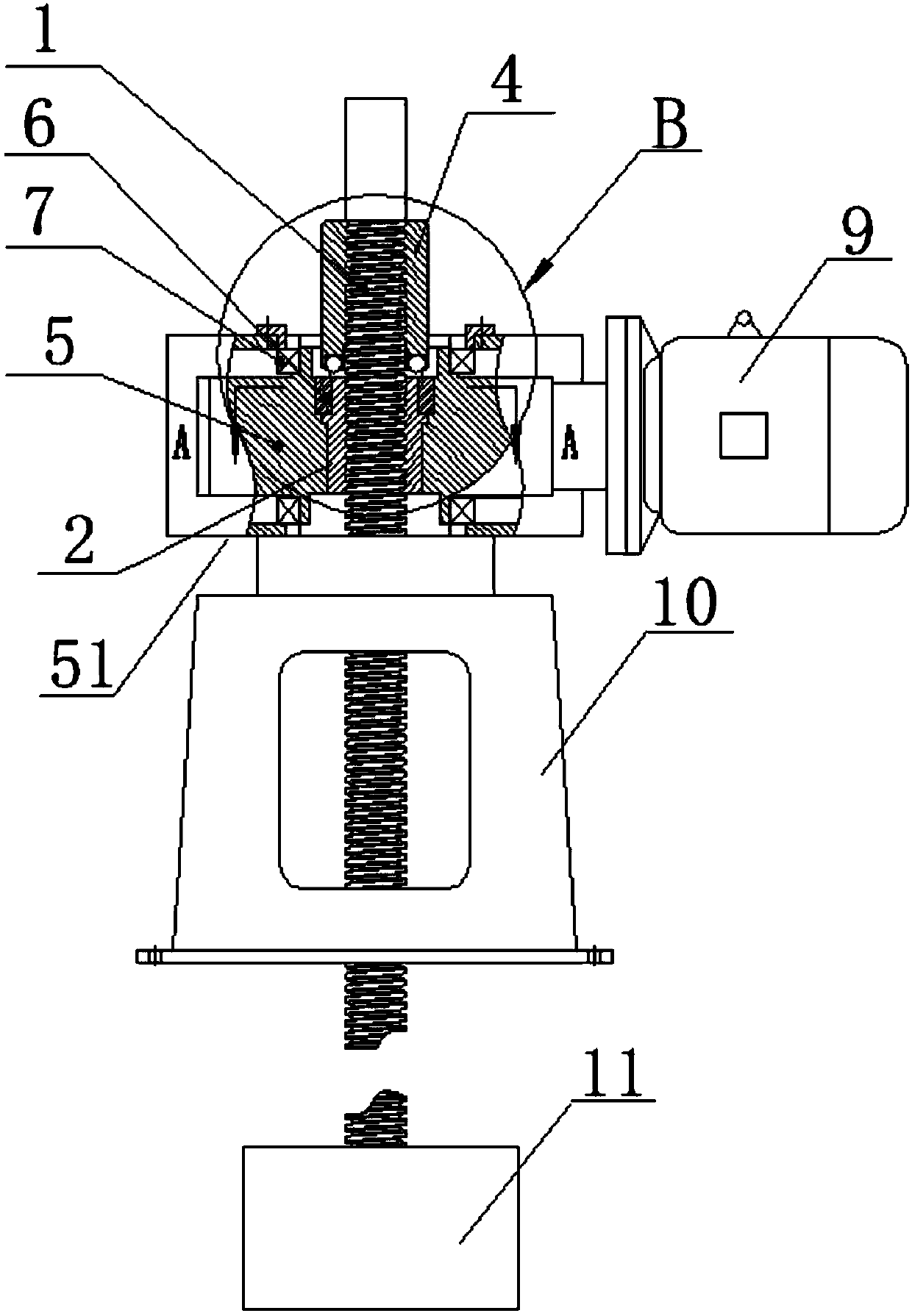

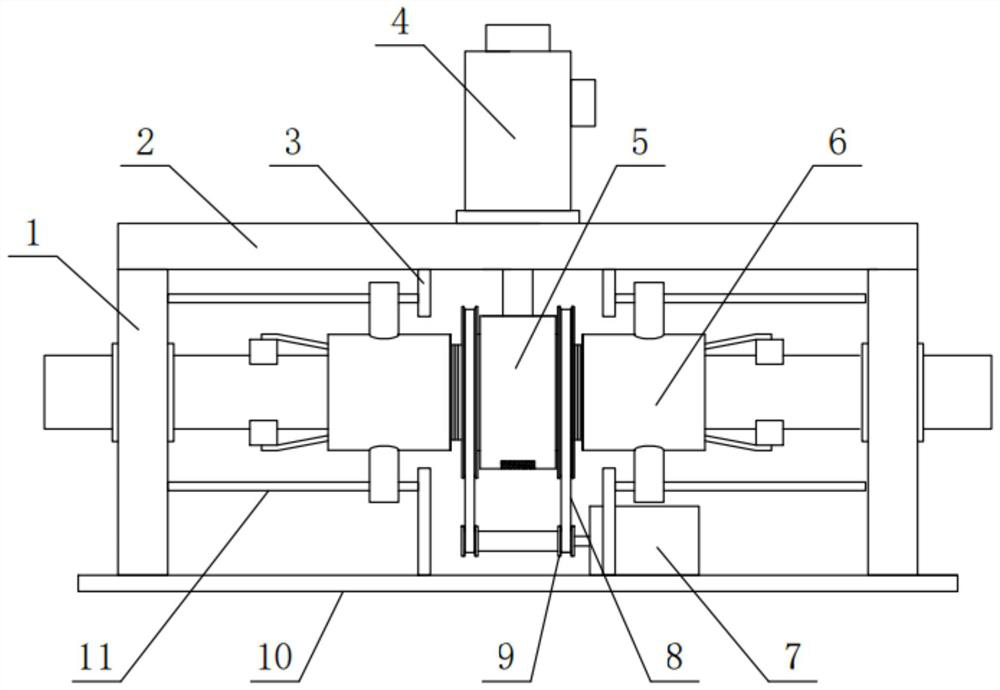

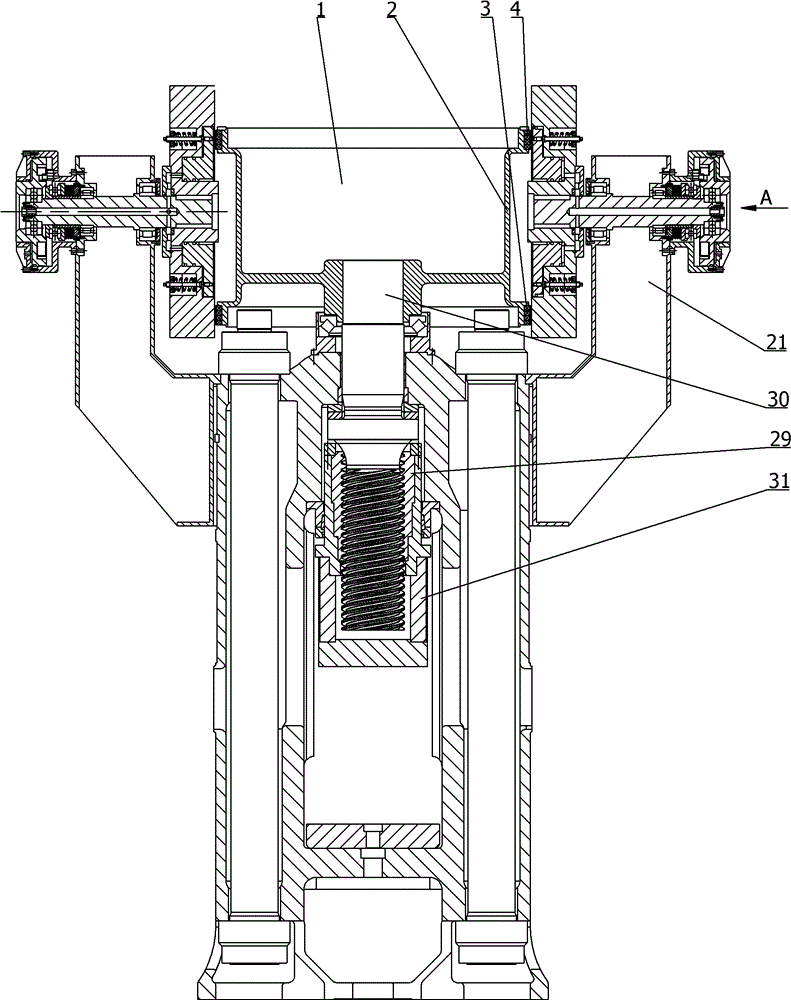

Friction screw press

ActiveCN103357807ACompact structureAchieve simultaneous rotationForging press drivesEngineeringFlywheel

The invention discloses a friction screw press comprising a flywheel. The flywheel is connected with a slider through a screw pair, a first edge and a second edge are arranged on the flywheel, the first edge is arranged opposite to a first end of a first friction wheel, the second edge is arranged opposite to a first end of a second friction wheel, a rotating shaft is arranged at the center of a second end of the first friction wheel, the rotating shaft is hermetically connected with a first cylinder, a first return mechanism is arranged between the rotating shaft and the first cylinder, a chamber serving as a second cylinder is further arranged at the first end of the first friction wheel, the second cylinder is hermetically connected with a second end of the second friction wheel, the second friction wheel rotates along with the first friction wheel, and a second return mechanism is further arranged between the first friction wheel and the second friction wheel. The friction screw press is compact in structure due to the design of the first and second friction wheels, the first cylinder and the second cylinder are designed skillfully, the first friction wheel and the second friction wheel can rotate simultaneously, and the first friction wheel can move axially relative to the first friction wheel.

Owner:SHANGHAI YUNLIANG FORGING PRESS

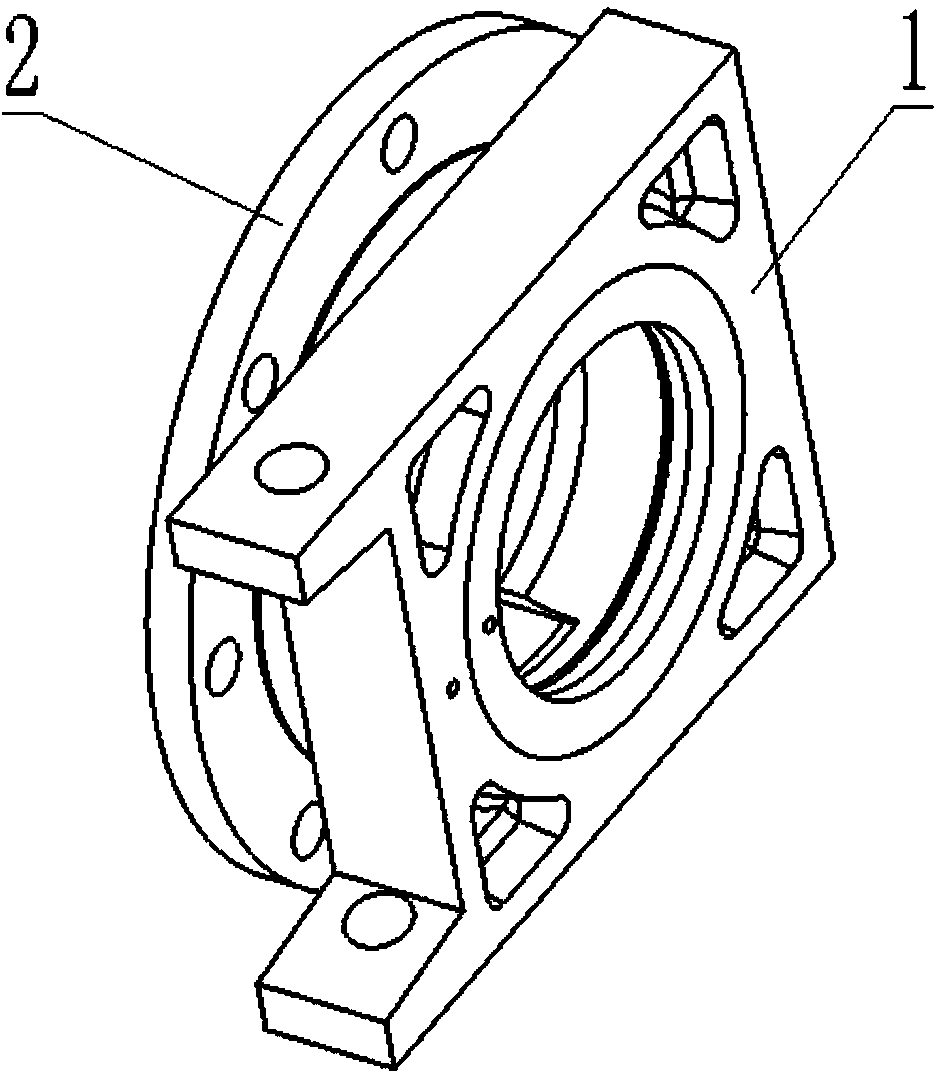

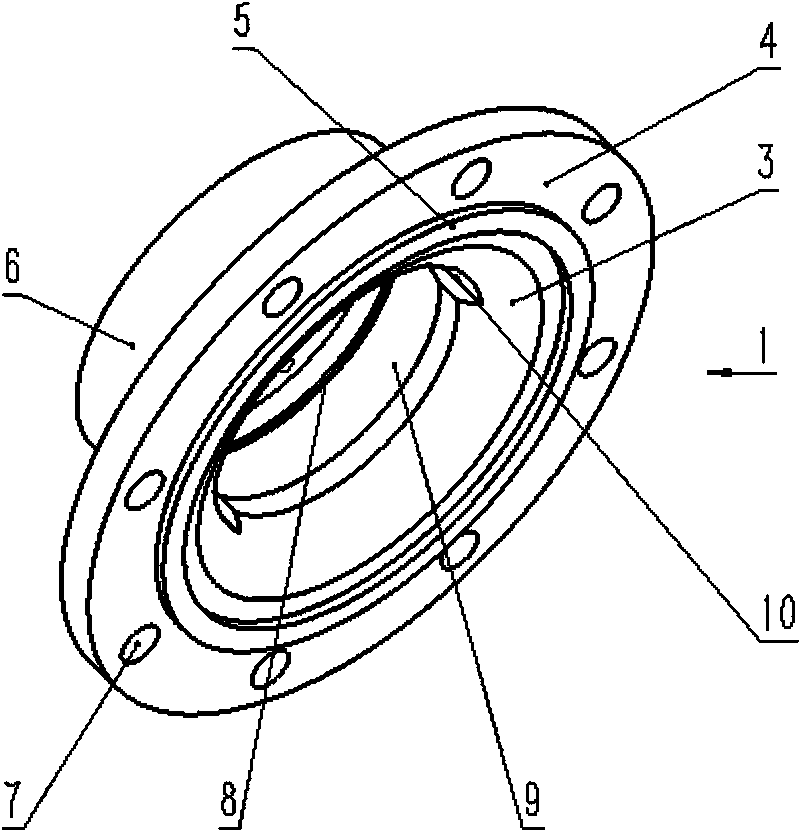

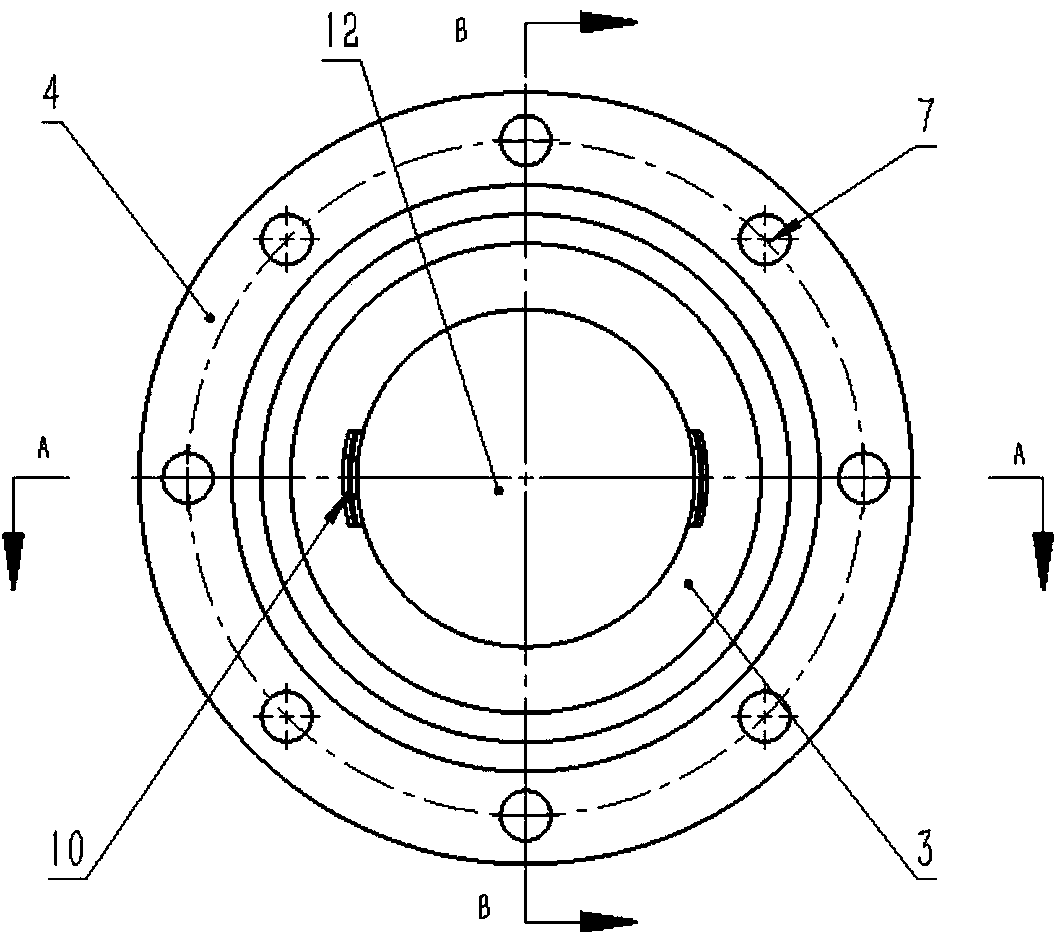

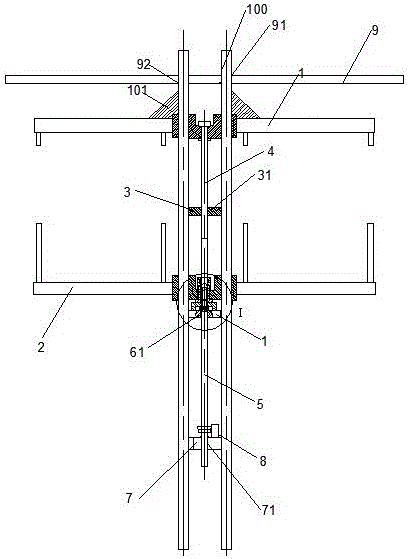

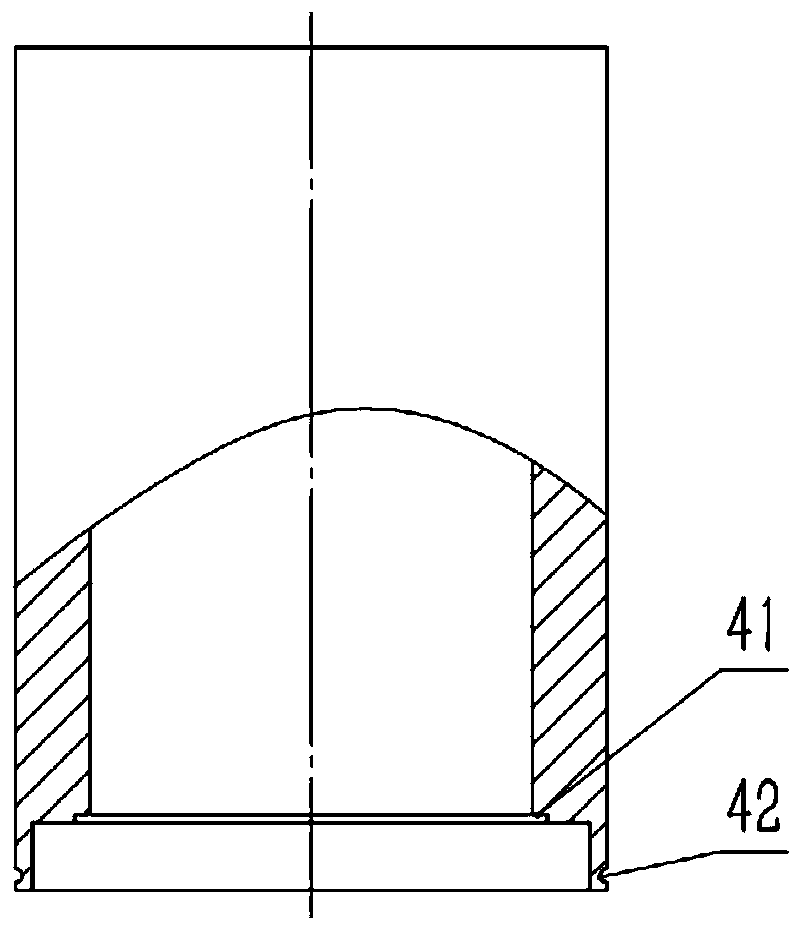

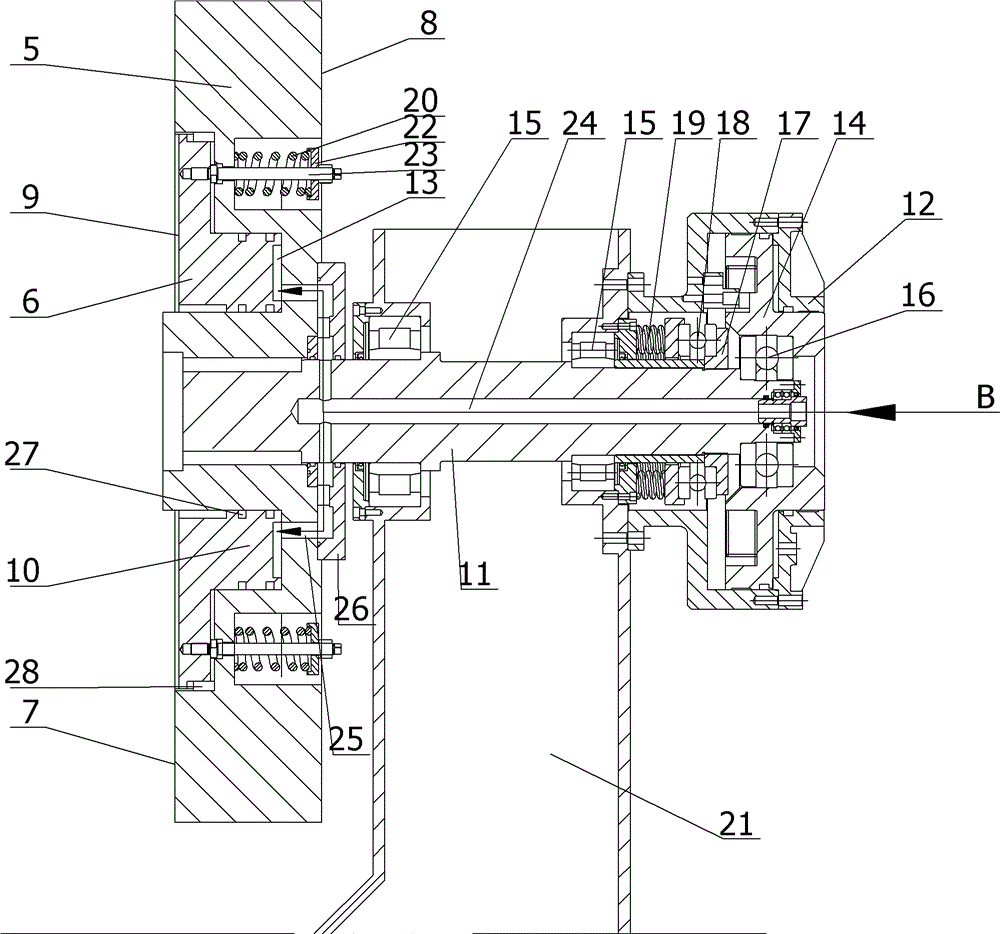

Bearing seat

InactiveCN104373466AReasonable and reliable cooperationImprove reliabilityBearing unit rigid supportRabbetFlange

The invention relates to a bearing seat which comprises a bearing seat body (2) and a seat body square sleeve (1), wherein one end of the bearing seat body (2) is provided with a ring flange (4), positioning holes (7) are uniformly distributed on the ring flange (4), the ring flange (4) is connected with a cylindrical lug boss (6) through a large arc-shaped opening (3), and the cylindrical lug boss (6) is internally provided with a spherical cavity (9); a circle of positioning rabbet (5) is arranged between the ring flange (4) and the large arc-shaped opening (3), a bearing cavity is internally provided with an installation groove (10), the bearing cavity is internally provided with an oil groove (8), and the oil groove (8) is connected with a seat body oil hole (11); and a square sleeve center hole (13) is formed in the middle of the seat body square sleeve (1), the square sleeve center hole (13) sleeves the cylindrical lug boss (6), and the frame of the seat body square sleeve (1) is provided with a square sleeve oil hole (14) and a square sleeve oil groove (15). The device disclosed by the invention is capable of bearing higher rotating speed and higher load as being high in strength, being conveniently positioned and installed with the frame of a silage maize harvester shredding device, being convenient to position and reducing the failure rate of the silage maize harvester shredding device as having a fine adjustment function on the installation concentricity of the silage maize harvester shredding device.

Owner:内蒙古长明机械股份有限公司

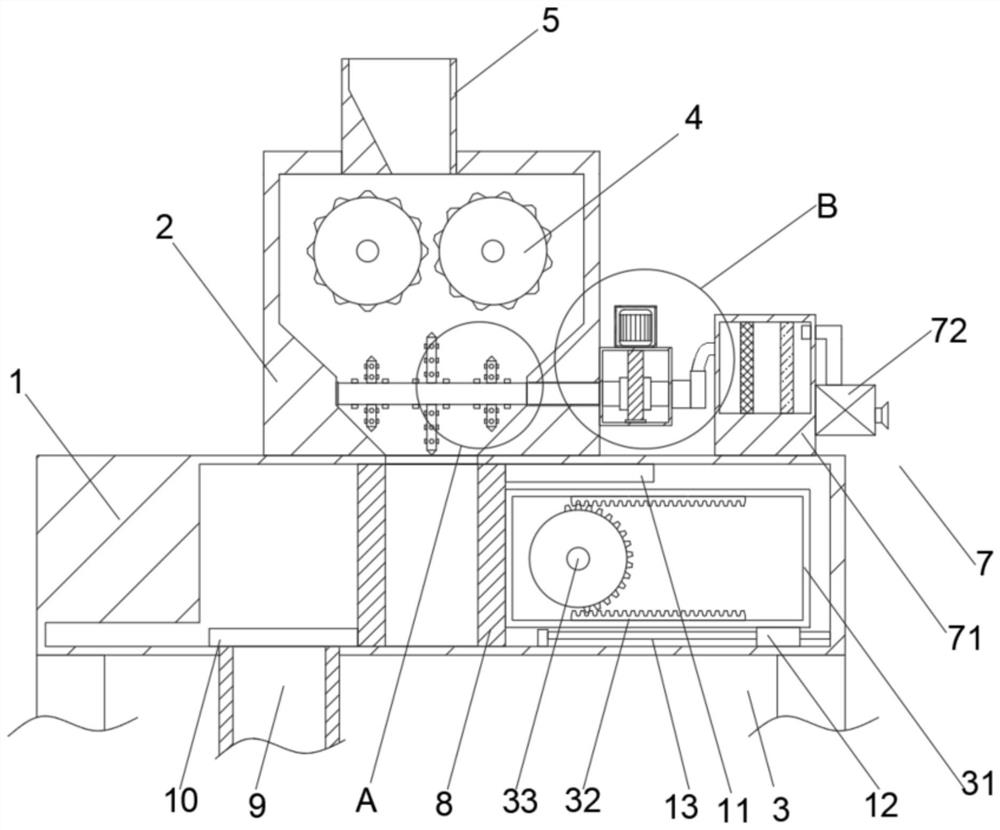

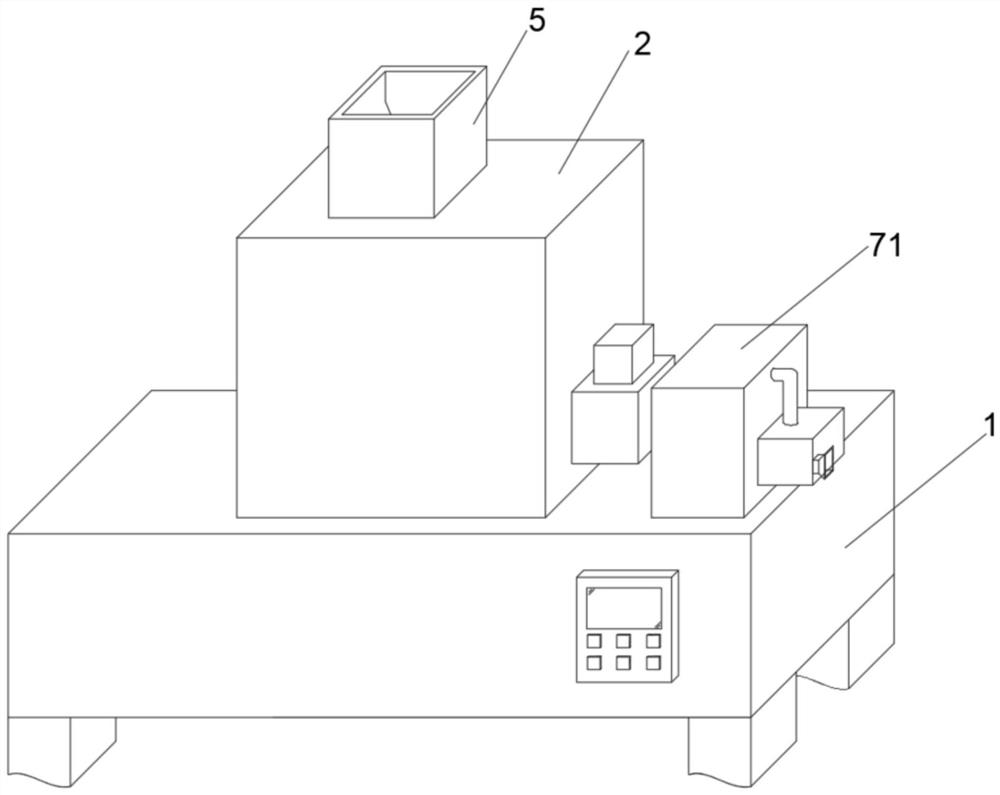

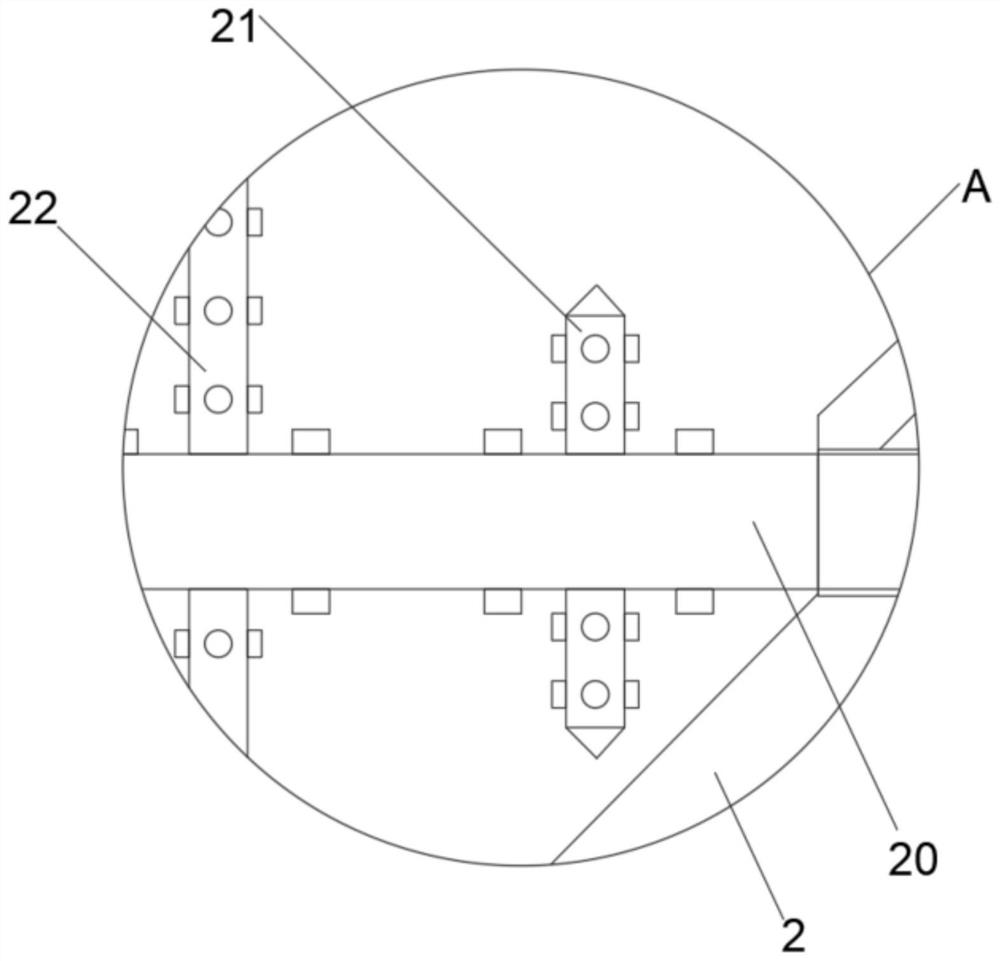

Anti-return feeding device for low-all-vanadium roasting of rotary kiln and using method of anti-return feeding device

InactiveCN113188328ARealize shreddingRealize anti-blocking treatmentRotary drum furnacesGrain treatmentsGear driveGear wheel

The invention discloses an anti-return feeding device for low-all-vanadium roasting of a rotary kiln and a using method of the anti-return feeding device. The anti-return feeding device comprises a bottom box, wherein a feeding box is arranged at the top of the bottom box; a No. 2 ventilation rod is rotationally connected to the interior of the feeding box; a rotating mechanism is arranged on one side of the feeding box, and connected with the No. 2 ventilation rod; a filtering mechanism is arranged at the top of the bottom box; the filtering mechanism is connected with the rotating mechanism; and a feeding mechanism is arranged in the bottom box. The anti-return feeding device has the beneficial effects that a No. 1 belt wheel and a No. 2 belt wheel are additionally arranged, so that simultaneous rotation of a half gear and a No. 2 gear is achieved; crushing rollers are additionally arranged, so that raw materials are crushed through the crushing rollers; a No. 4 ventilation rod and a No. 3 ventilation rod are additionally arranged, so that anti-blocking treatment on internal materials is achieved; the filtering mechanism is additionally arranged, so that filtering treatment on external air is achieved; and the half gear and a rack are additionally arranged, so that the half gear drives a connecting frame to move in a reciprocating mode through the rack.

Owner:CHENGYU VANADIUM TITANIUM TECH CO LTD

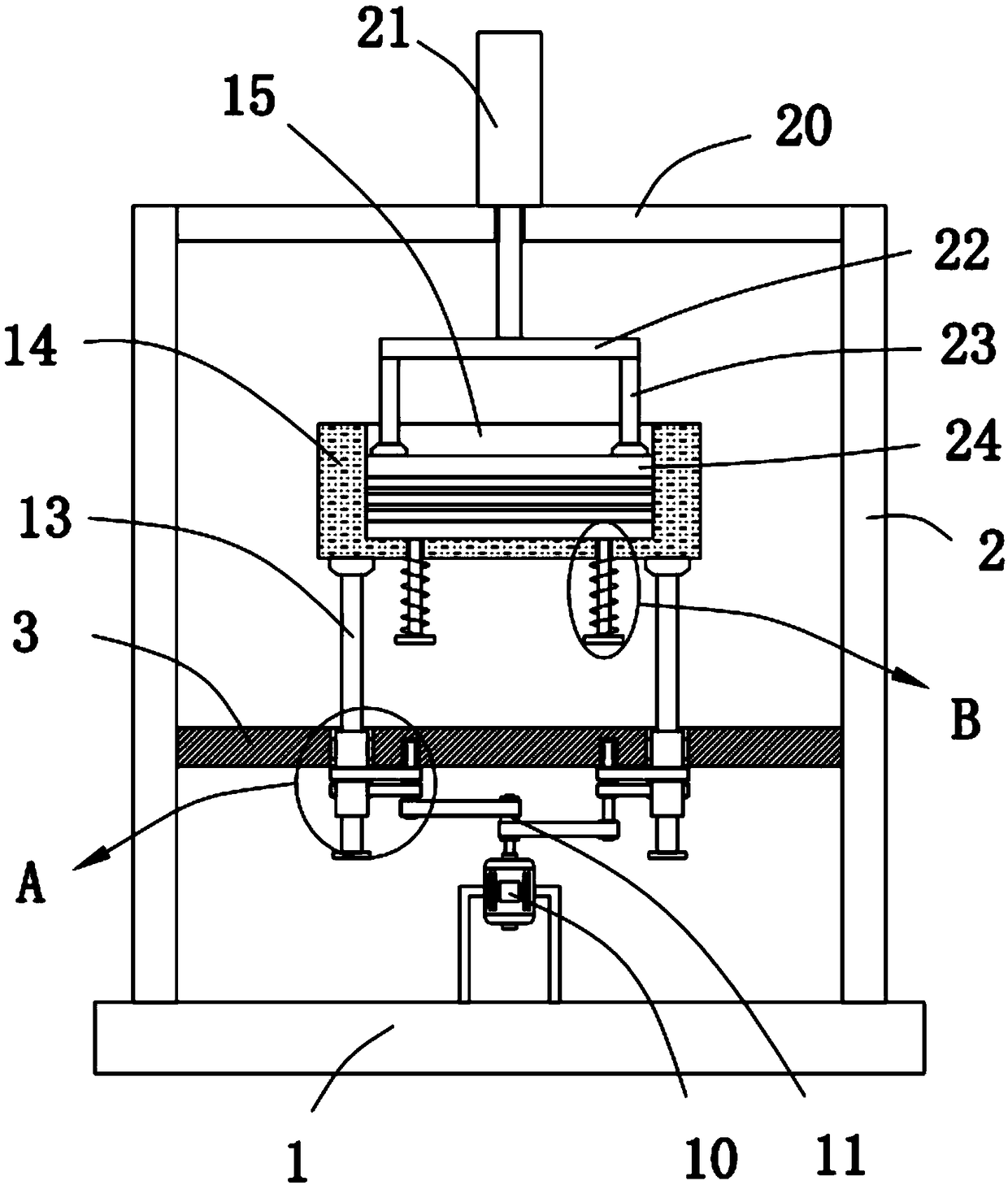

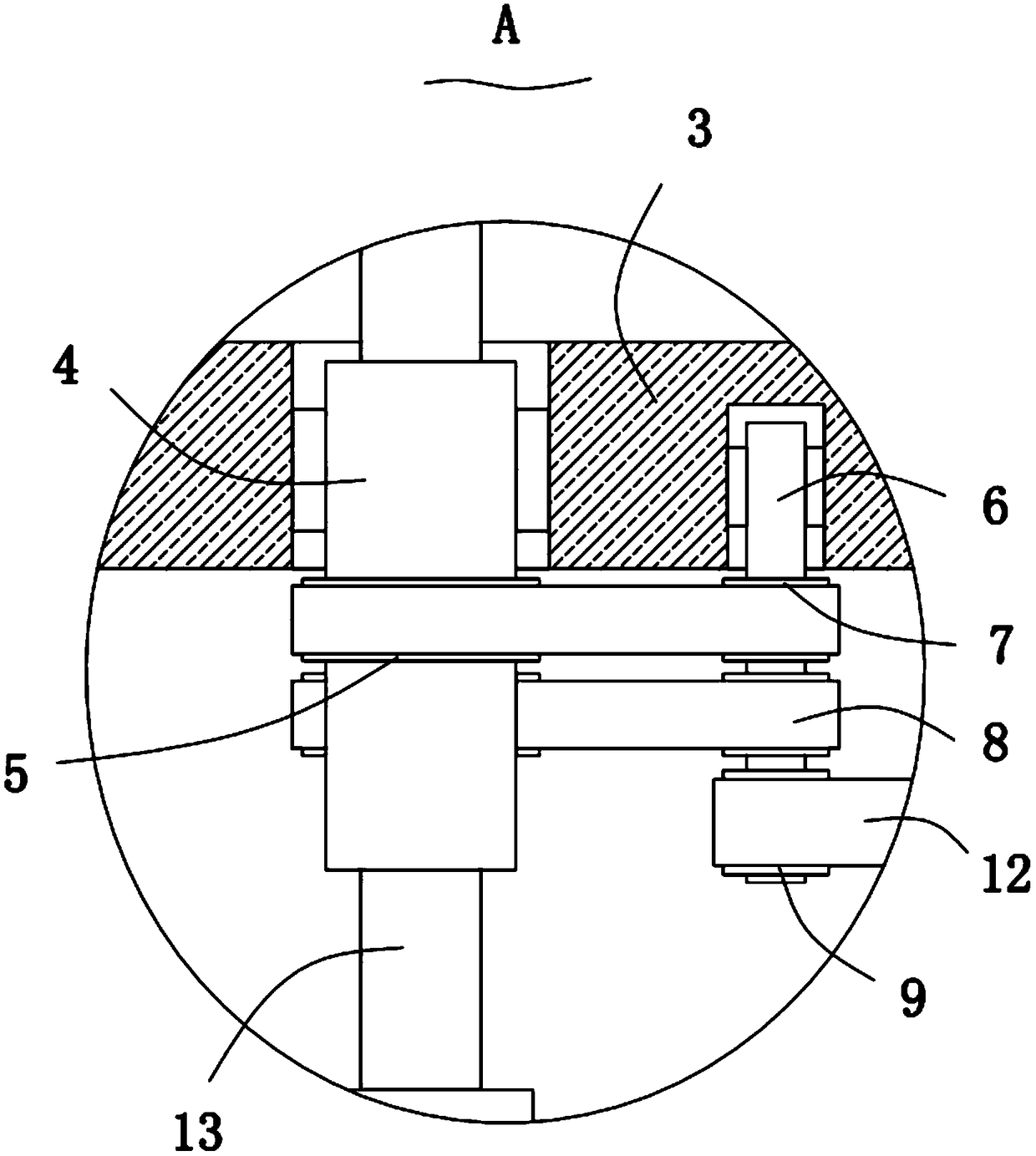

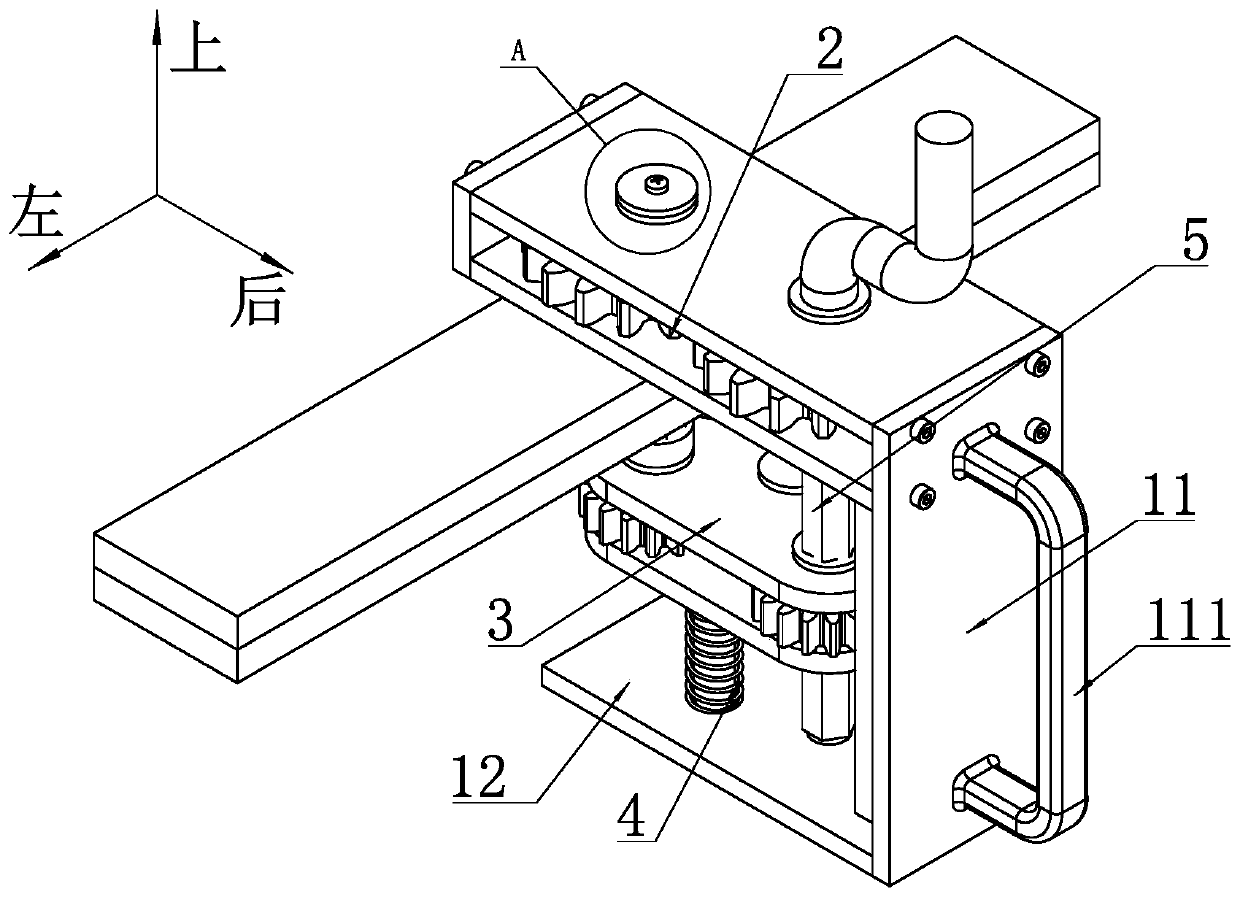

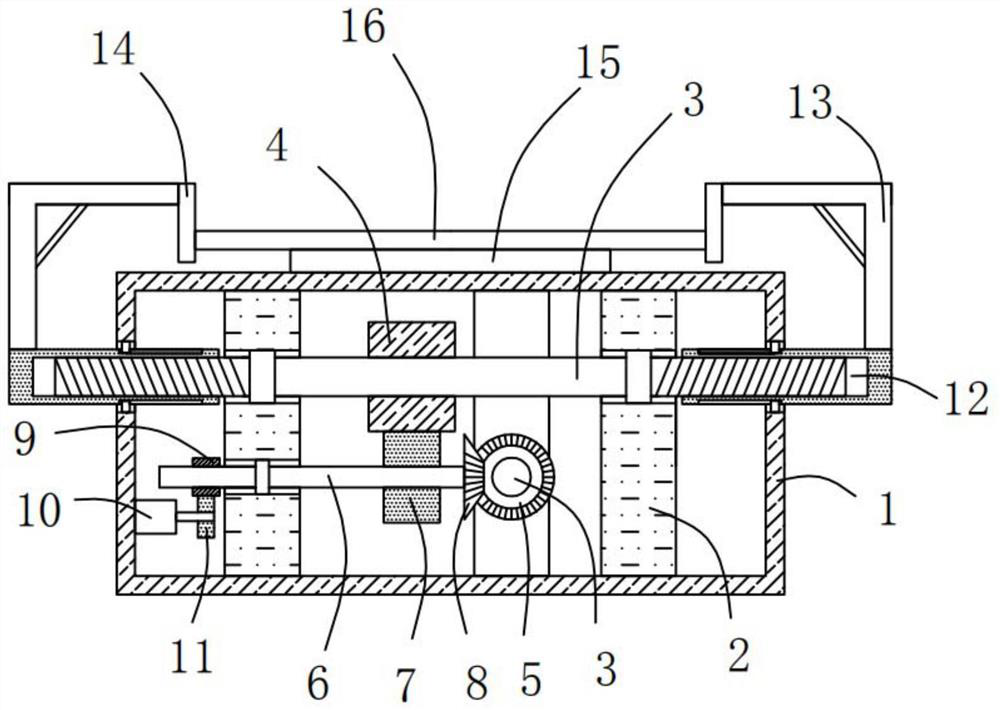

Reciprocating film pressing device for rubber diaphragm

The invention discloses a reciprocating film pressing device for a rubber diaphragm. The reciprocating film pressing device comprises a fixed side plate, a hydraulic cylinder, a pre-fixing unit, a lower die moving unit, a hydraulic cylinder fixing unit, a gear fixing box, a connecting block, a fixed supporting plate, supporting columns and a supporting sliding rail. The supporting sliding rail isfixedly connected to the right side of the lower end of the fixed side plate, two supporting columns are fixedly connected to the lower side of the supporting sliding rail, a sliding block is arrangedat the upper end of the supporting sliding rail, the fixed supporting plate is fixedly connected to the upper end of the fixed side plate, and the hydraulic cylinder is arranged at the upper end of the fixed supporting plate. The pre-fixing unit comprises limiting blocks, a first pressing plate, sliding columns and a second pressing plate, the upper end of the first pressing plate is fixedly connected with the connecting block, the first pressing plate is fixedly connected with a piston rod of the hydraulic cylinder through the connecting block, and a lower die can transversely move, so thatwhen a worker places the die, the movable die is prevented from suddenly descending, and personnel injuries are effectively reduced.

Owner:埃福贝密封技术(苏州)有限公司

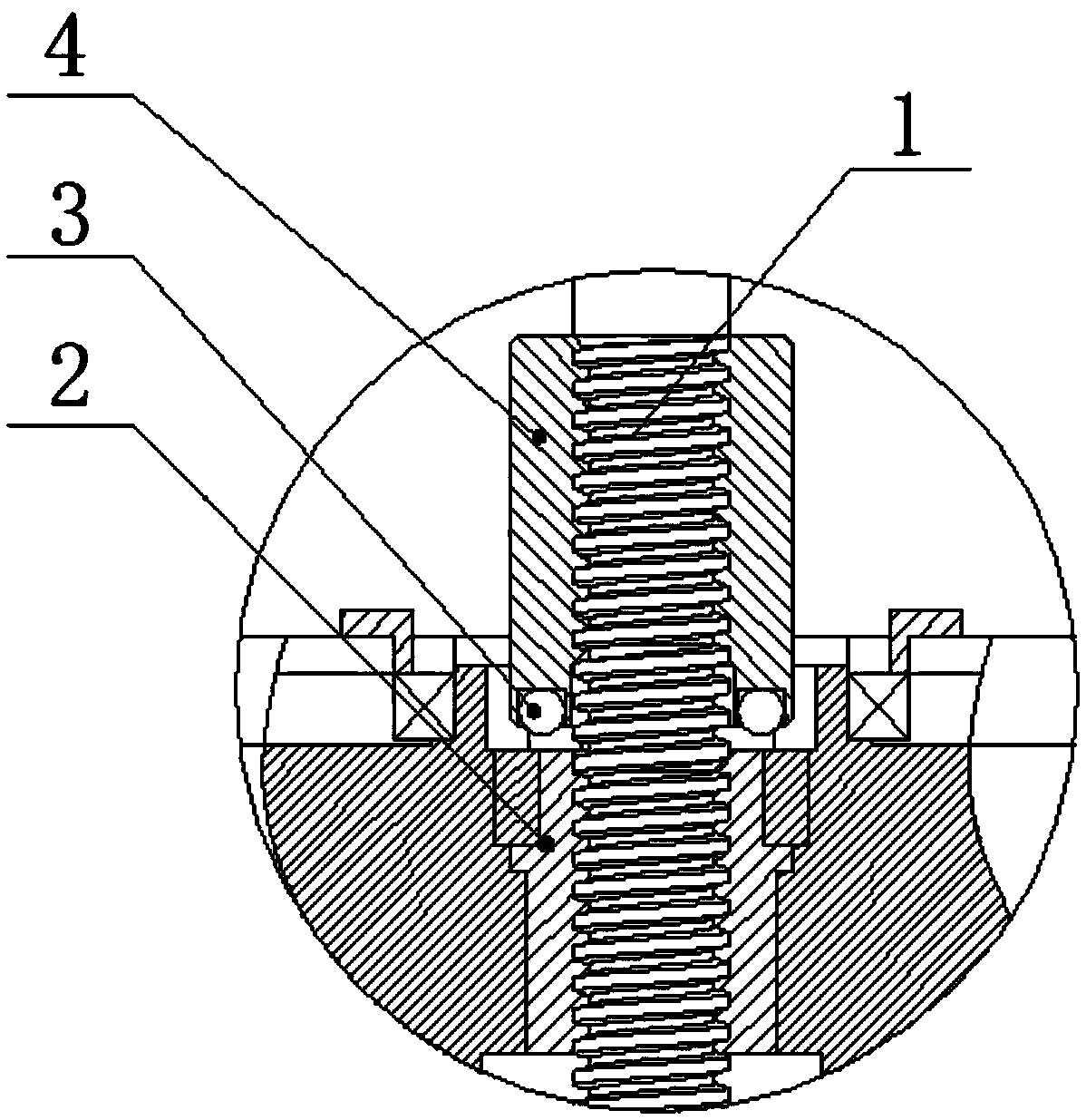

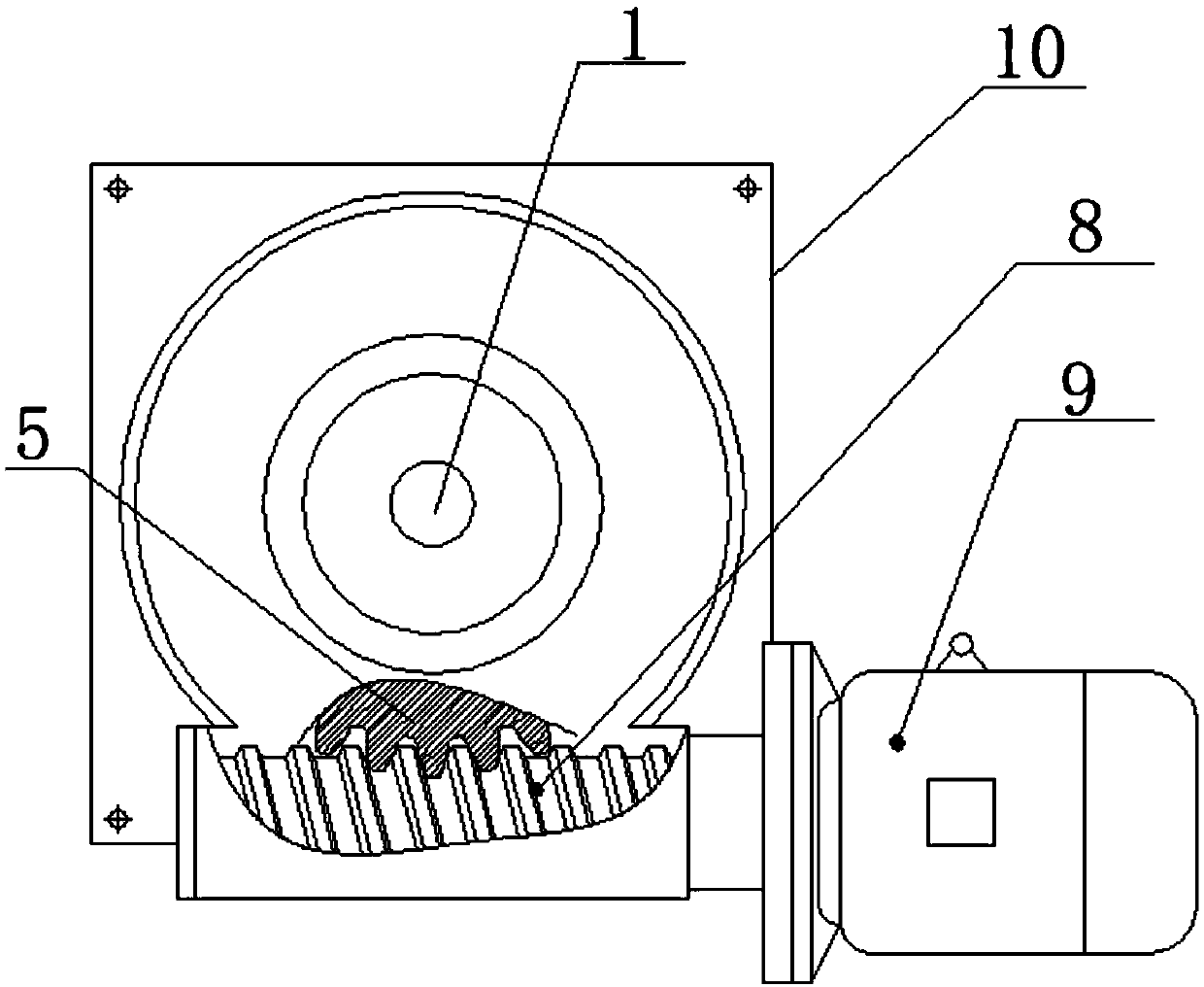

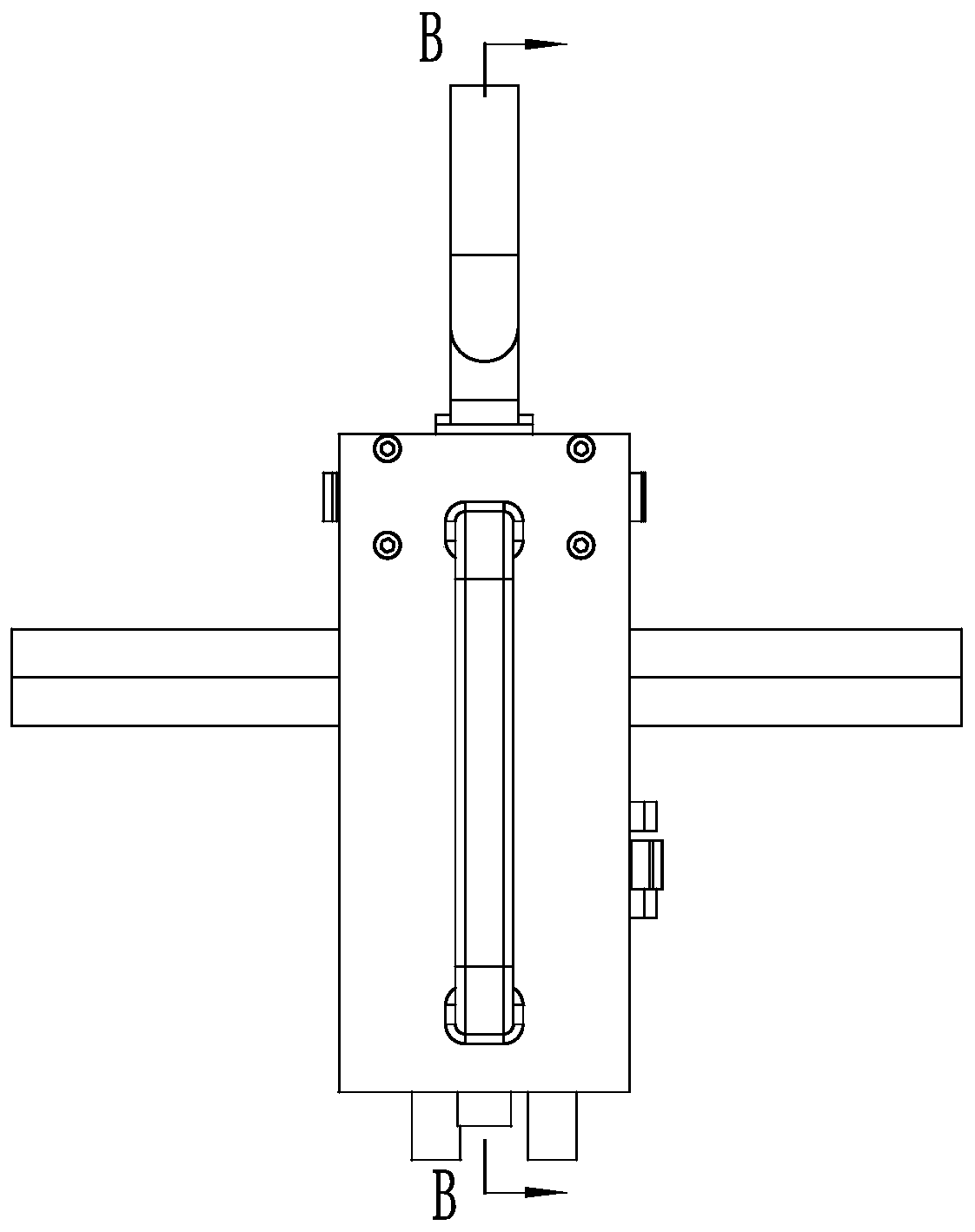

Screw hoist and working method thereof

The invention discloses a screw hoist and a working method thereof, and belongs to the technical field of hoisting or bearing equipment. The screw hoist comprises a screw rod, a motor, a worm wheel, abearing assembly, a worm, a supporting seat, a gate plate and a double-nut anti-skid wire mechanism, wherein the worm wheel is fixed to the supporting seat through the bearing assembly. The motor, the worm and the worm wheel are in sequential connected in a transmission mode, and the double nut anti-skid wire mechanism is embedded in the center of the worm wheel. The bottom end of the screw rod is fixedly connected with the gate plate after the screw rod is threaded to the double-nut anti-slip wire mechanism. According to the screw hoist and the working method thereof, the technical problem that wire sliding exists in a bearing nut in a screw rod mechanism of the screw type hoist is solved through the double-nut anti-slip wire mechanism.

Owner:ANHUI GVG NEW MATERIAL CO LTD

High-frequency mixed-pressing board lamination equipment with conveniently-regulated layer number

PendingCN109413895AAdjust vertical heightEasy to move out of workMultilayer circuit manufactureEngineeringPulley

Owner:AOSHIKANG TECH CO LTD

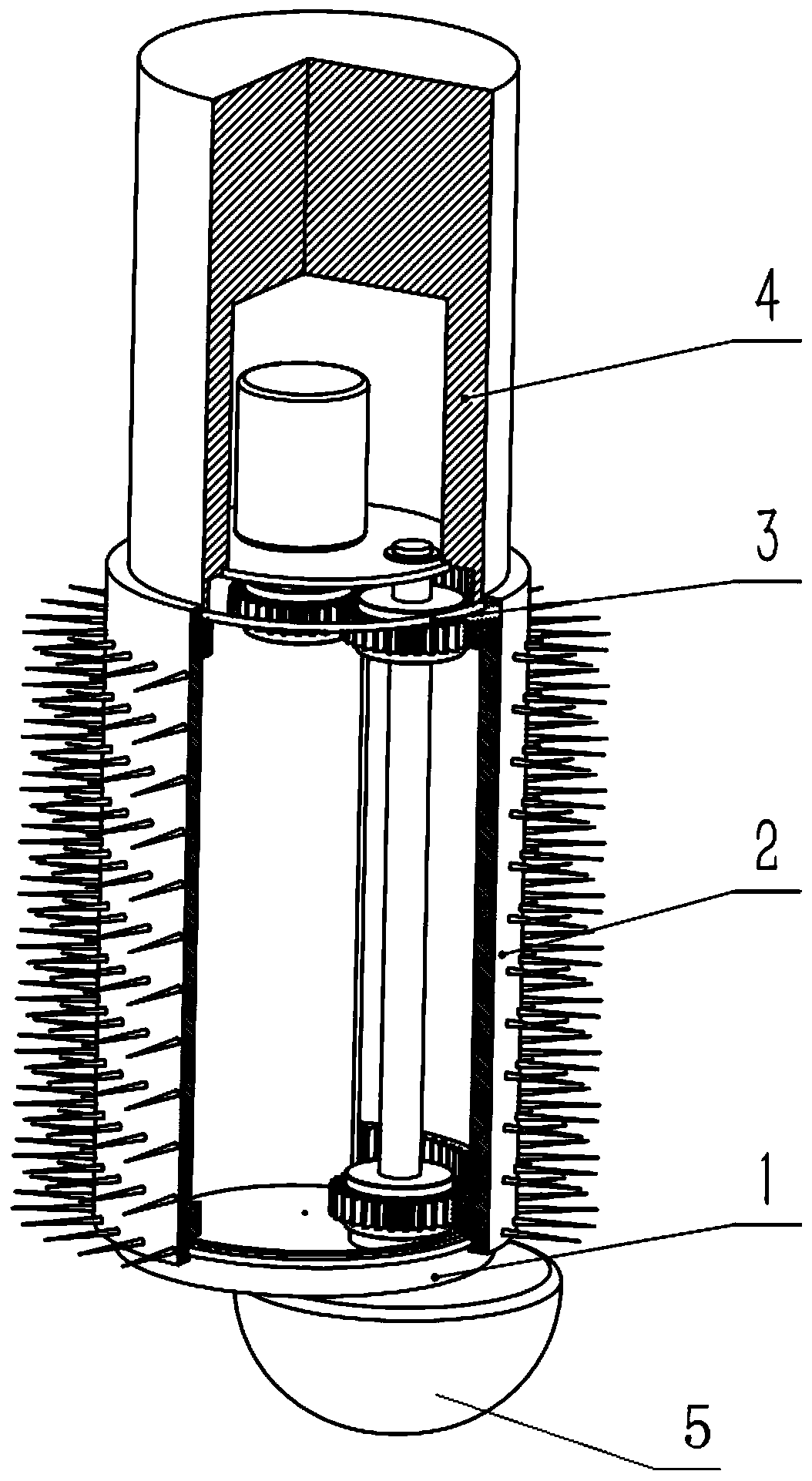

Plastic pipe for industrial dust collection and preparation method thereof

ActiveCN112856084AAvoid scratchesEasy to weldHuman health protectionPipe laying and repairLow-density polyethyleneThermoplastic

The invention discloses a plastic pipe for industrial dust collection and a preparation method thereof. The plastic pipe comprises a dust collection plastic pipe, wherein the dust collection plastic pipe is made of linear low-density polyethylene thermoplastic as a raw material through a thermoplastic technology, and a welding port is formed in the end of the dust collection plastic pipe. Fusion welding ports of two dust collection plastic pipes are placed on fusion welding equipment in a left-right alignment mode, a rotating inner barrel is driven to rotate through the transmission effect of a belt, and due to the thread relation between the rotating inner barrel and a tightening sliding barrel, the tightening sliding barrel rotates outwards, so that an elastic pressing plate at the outer end of the rotating inner barrel is extruded, a fixing clamping ring at the outer end of the elastic pressing plate is fixedly clamped outside the plastic pipe, a clamping cotton cushion is bonded to the inner ring wall of the fixing clamping ring, the plastic pipe is well protected, the situation that the fixing clamping ring slides relative to the plastic pipe and scratches the plastic pipe is avoided, meanwhile, by arranging the clamping cotton cushion, the friction force between the clamping cotton cushion and the plastic pipe is increased, and therefore the plastic pipe is driven to rotate synchronously.

Owner:公元管道(江苏)有限公司

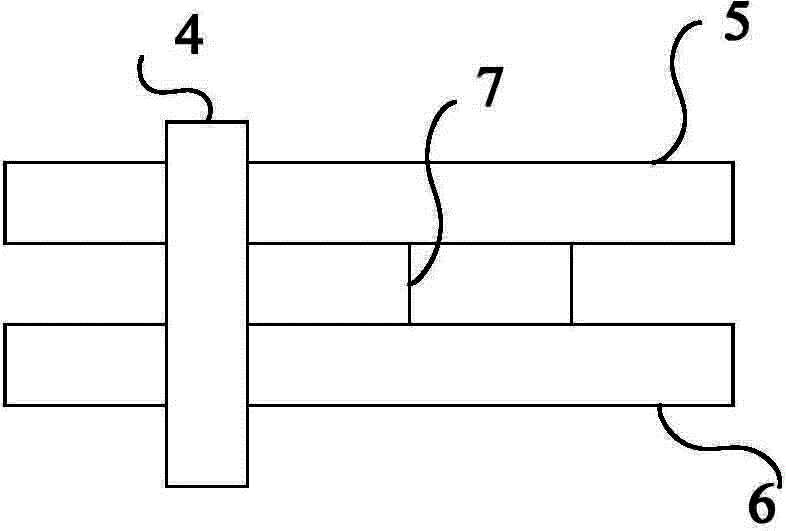

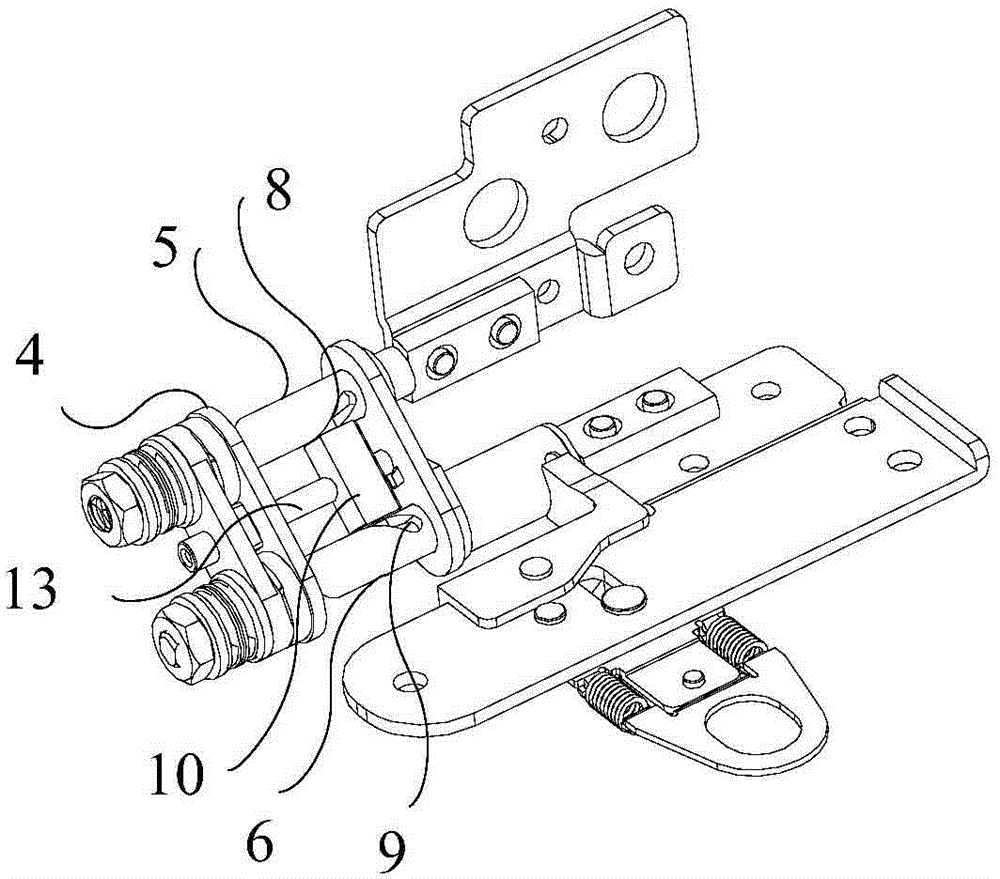

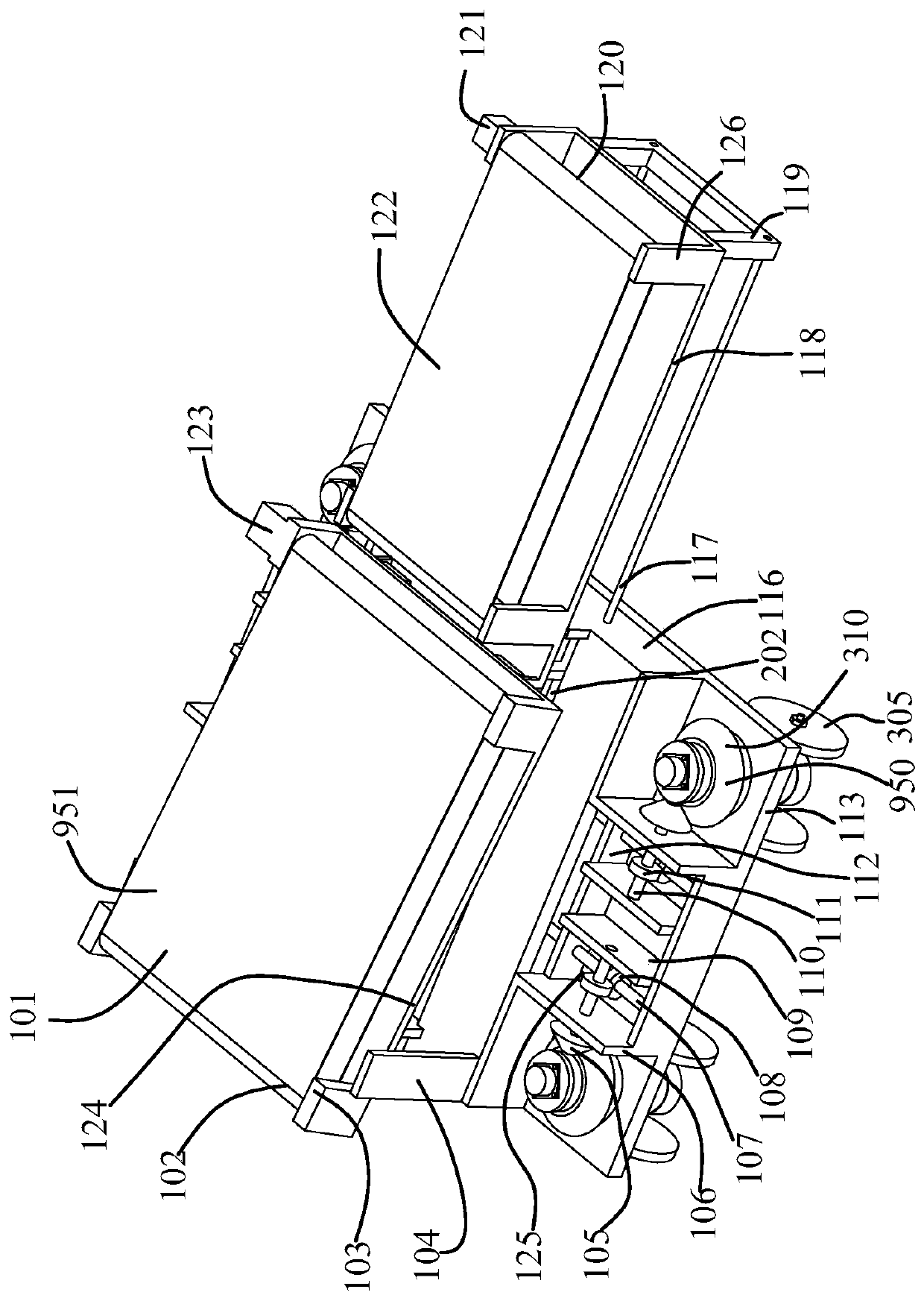

Electronic device

InactiveCN104832530AAchieve simultaneous rotationNot easy to feel stuckDigital data processing detailsPivotal connectionsEngineeringMechanical engineering

Owner:LENOVO (BEIJING) LTD

Boxed cotton transport equipment

InactiveCN110294265AEfficient deliveryPrecise transportationConveyorsEngineeringMechanical engineering

Owner:王德胜

Novel traffic lamp holder

InactiveCN107435919AAchieve simultaneous rotationAchieve fixationLighting support devicesRoad vehicles traffic controlAutomatic controlEngineering

The invention discloses a new type of traffic light frame, which includes an upper light frame, a lower light frame, a guiding block, two traffic columns and a lifting device. A first hole is fixed on two traffic poles, the middle section of the upper light frame is provided with a second hole between the two first holes, and four clip columns are correspondingly arranged on the left and right below the upper light frame , the lower light frame is also a left and right corresponding structure, which can slide up and down on the two traffic columns by means of two third holes correspondingly arranged on the left and right sides of the middle section, and the middle section of the lower light frame is located at the two A fourth hole is arranged between the first and third holes; the present invention is compact in overall structure, safe and reliable, easy to use, low in production cost, suitable for popularization and use, and can realize automatic control clamping and loosening of traffic lights, so that traffic lights settings and splits.

Owner:广州创码信息科技有限公司

Aluminum foil winding device convenient to use

The invention relates to an aluminum foil winding device convenient to use. The aluminum foil winding device convenient to use comprises a supporting frame, a fixing mechanism connected to the supporting frame and used for installing a winding roller and a rotating mechanism connected to the supporting frame and used for driving the winding roller to rotate, wherein a guide mechanism is connectedto the supporting frame, the guide mechanism comprises a guide plate connected to the supporting frame, a guide groove is formed in the guide plate, and a leveling mechanism is further connected to the guide plate. According to the aluminum foil winding device, the working efficiency is high in the process of winding the aluminum foil, and meanwhile, the winding aluminum foil is flat, the windingaluminum foil layer is tightly adhered to the layer, the later-stage marketing effect is good, and the income of a manufacturer is improved.

Owner:四川恒诚信电子科技有限公司

Rapid bolt fastening device

InactiveCN111376209AAchieve simultaneous rotationTo achieve a fixed connectionMetal-working hand toolsGear wheelClassical mechanics

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +3

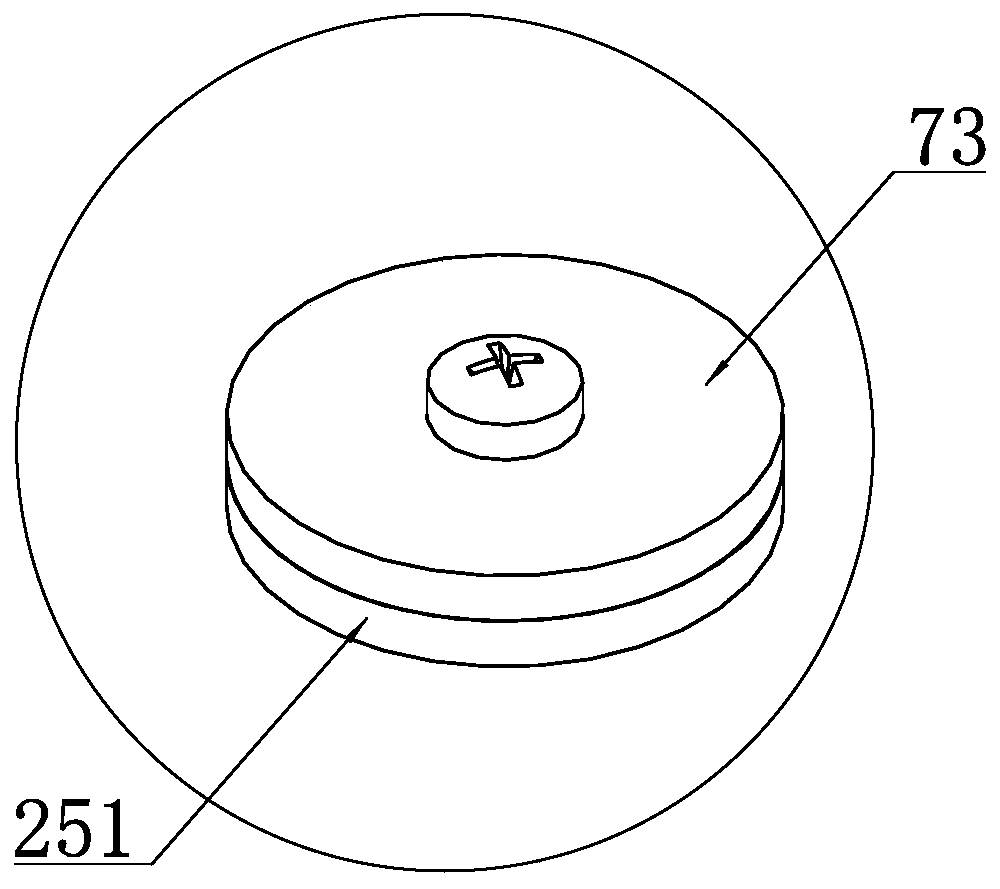

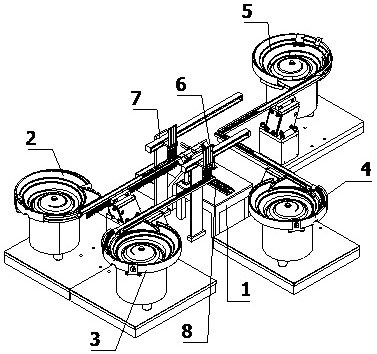

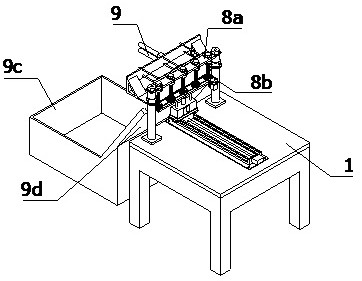

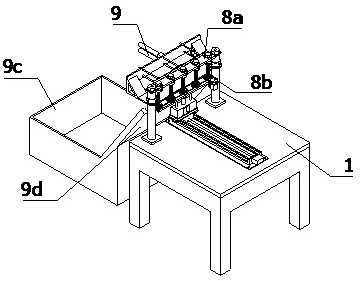

Bolt and nut automatic screwing and assembling equipment

ActiveCN113843616AImplement automatic assemblyImprove assembly efficiencyAssembly machinesMetal working apparatusClassical mechanicsEngineering

The invention relates to the field of automatic assembling, in particular to bolt and nut automatic screwing and assembling equipment. The equipment comprises an assembling table, an automatic assembling device arranged on the assembling table, a bolt vibration disc, a nut vibration disc, a flat washer vibration disc and a rubber pad vibration disc, and the bolt vibration disc, the nut vibration disc, the flat washer vibration disc and the rubber pad vibration disc are arranged around the assembling table. A first robot used for feeding nuts and a second robot used for feeding bolts, flat washers and rubber pads are further arranged beside the assembling table, the automatic assembling device comprises a bolt positioning mechanism and a nut assembling mechanism, the bolt positioning mechanism and the nut assembling mechanism are both arranged on the assembling table, and the nut assembling mechanism is further located below the bolt positioning mechanism. According to the equipment, through cooperation between the bolt positioning mechanism and the nut assembling mechanism, automatic assembling of bolts and nuts is achieved, synchronous assembling of multiple bolt kit is completed, and the assembling efficiency is improved.

Owner:浙江科腾精工机械股份有限公司

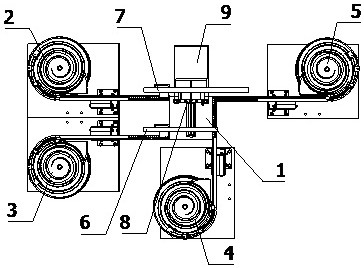

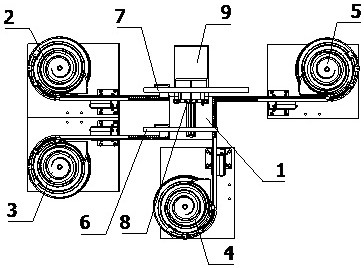

A bolt and nut automatic knob assembly equipment

ActiveCN113843616BImplement automatic assemblyImprove assembly efficiencyAssembly machinesMetal working apparatusStructural engineeringWasher

The invention relates to the field of automatic assembly, in particular to an automatic knob assembly device for bolts and nuts, comprising an assembly table, an automatic assembly device arranged on the assembly table, and a bolt vibration plate, a nut vibration plate and a flat washer surrounding the assembly table. Vibrating plate and rubber pad vibrating plate, the side of the assembly table is also equipped with a first robot for feeding nuts and a second robot for feeding bolts, flat washers and rubber pads. The automatic assembly device includes a bolt positioning mechanism and a nut assembly mechanism , the bolt positioning mechanism and the nut assembly mechanism are both arranged on the assembly table, and the nut assembly mechanism is also located below the bolt positioning mechanism. The present application realizes the automatic adjustment of the bolt and the nut through the cooperation between the bolt positioning mechanism and the nut assembly mechanism. Assembly, and the simultaneous assembly of multiple bolt sets is completed, which improves assembly efficiency.

Owner:浙江科腾精工机械股份有限公司

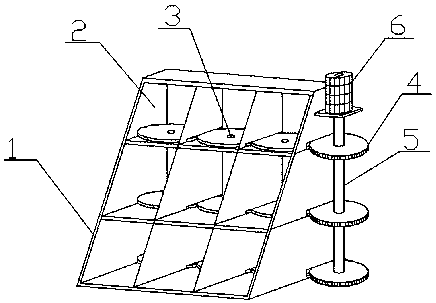

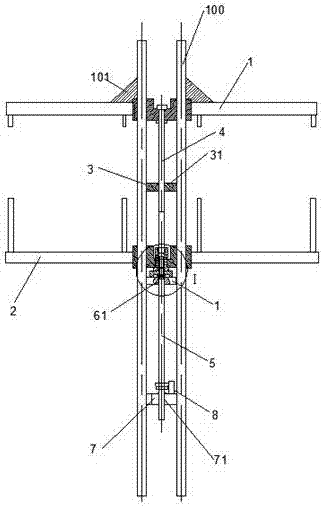

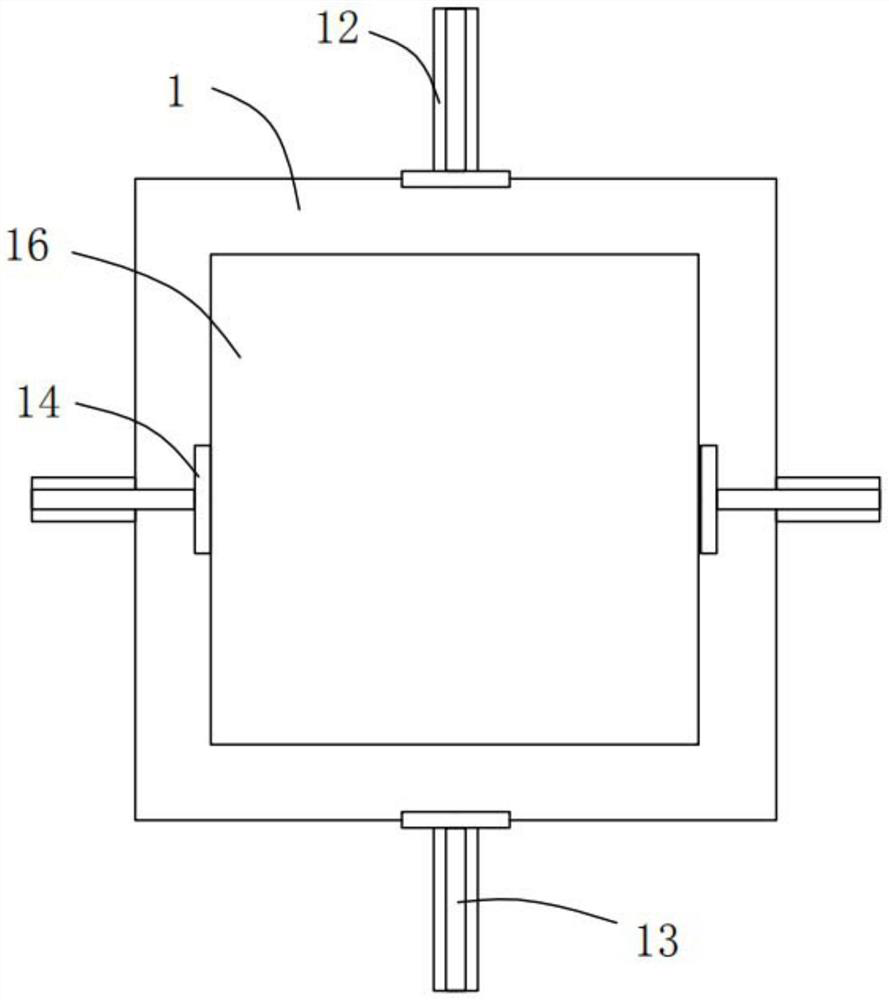

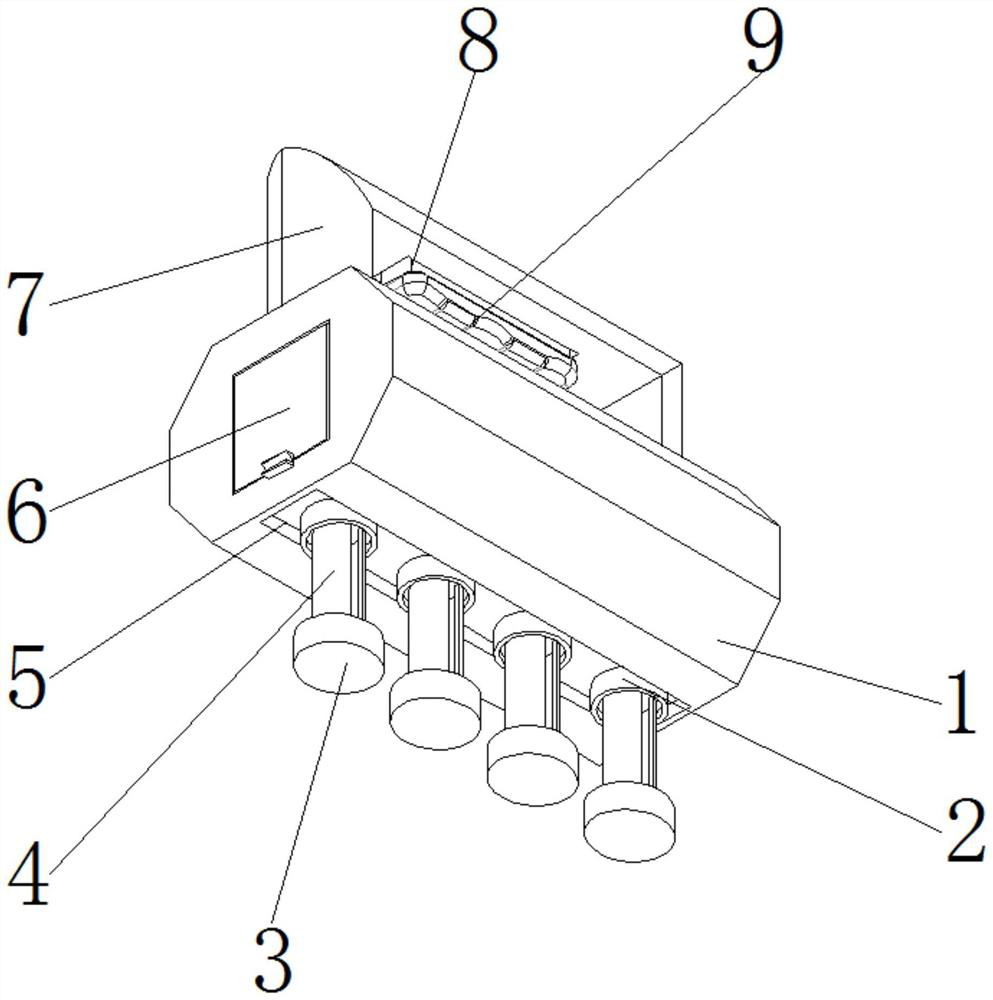

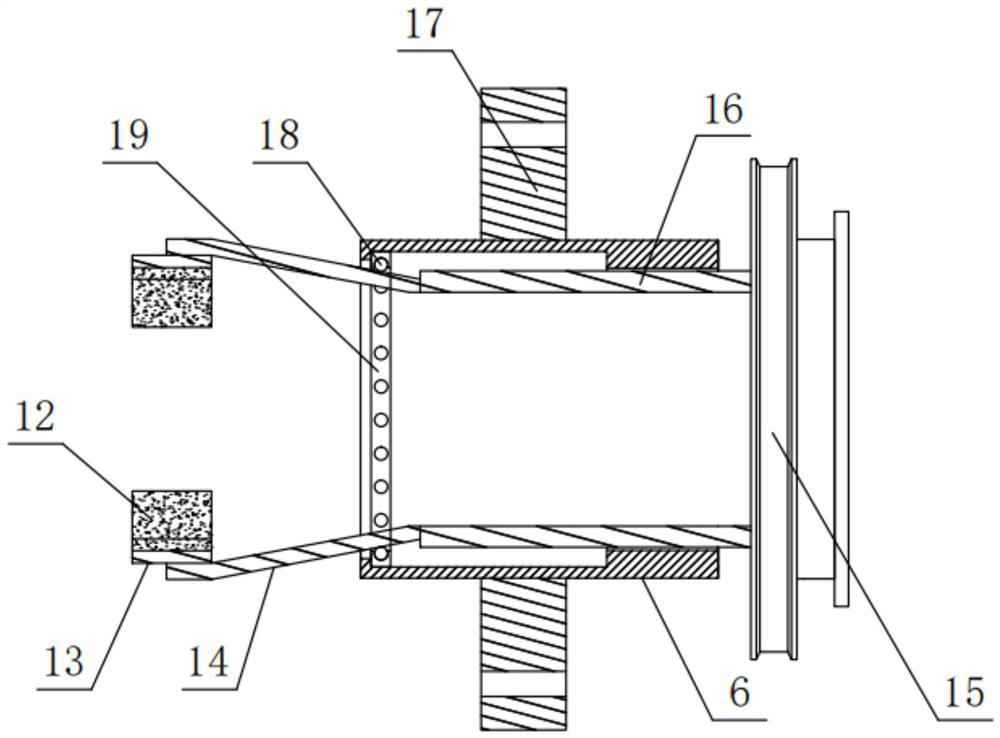

Detection tool for radiographic real-time imaging of multiple parts

InactiveCN108020568AImprove detection efficiencyStrong linkageMaterial analysis by transmitting radiationMesh gridEngineering

The invention discloses a detection tool for radiographic real-time imaging of multiple parts. The detection tool comprises a grid rack, wherein multiple grids are arranged in the grid rack in a rectangular array, rotating discs are connected with the bottoms of the grids through shafts, drive wheels are connected with the rotating discs, and the drive wheels are driven by a motor. The detection tool can simultaneously detect multiple parts without affecting the detection result of each part and has the characteristic of high detection efficiency. Besides, the detection tool has the characteristics that the linkage property is high and the detection results are unified.

Owner:GUIZHOU HONGLIN MACHINERY

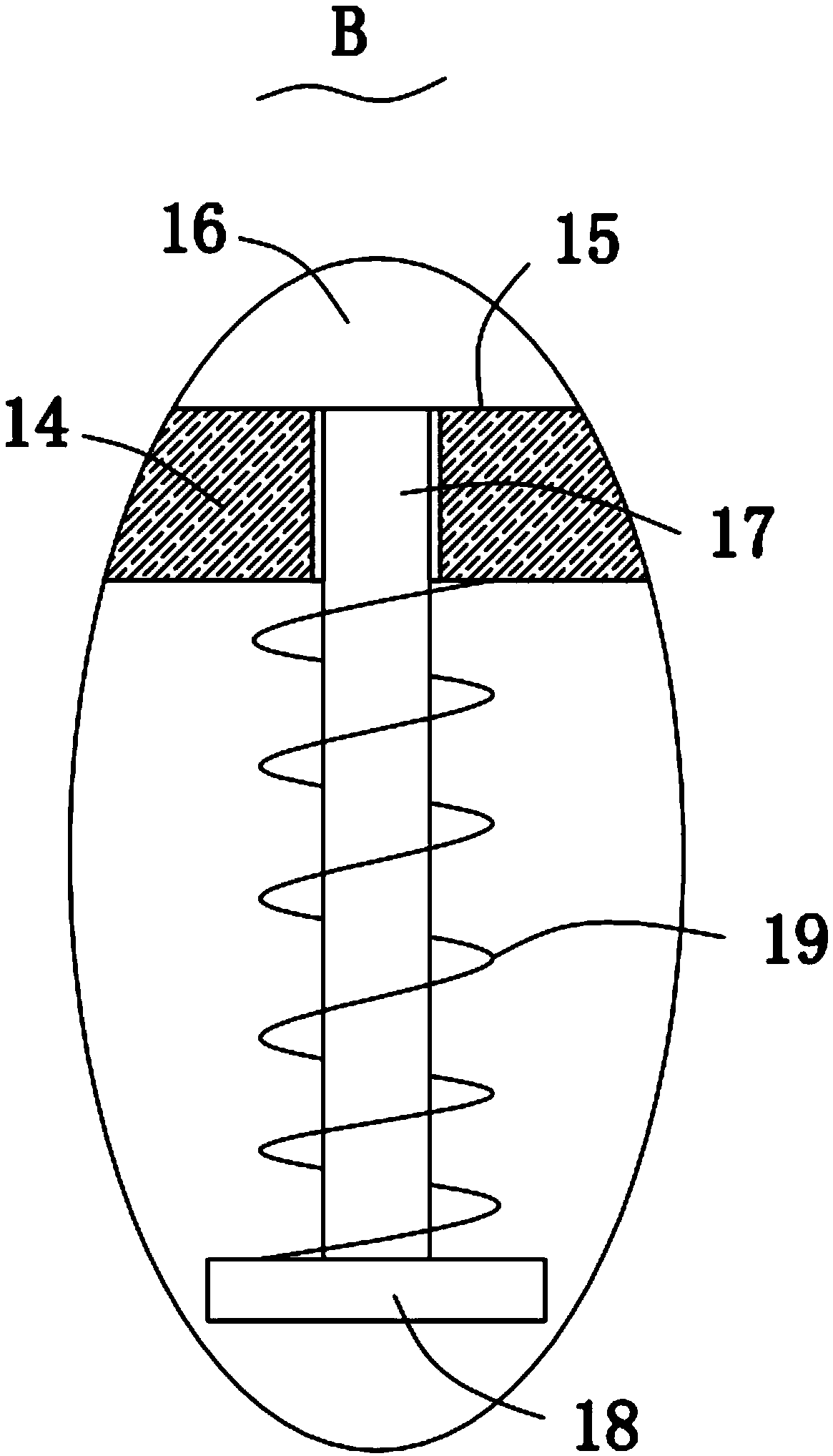

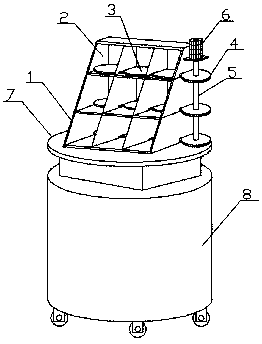

Double-rotation type bottle brush

ActiveCN111317250AAchieve simultaneous rotationEasy to cleanBrush bodiesHollow article cleaningPhysicsEngineering

The invention discloses a double-rotation type bottle brush and aims at solving the problem that in the prior art, a bottle brush cannot efficiently clean the inner wall of a bottle body. The bottle brush comprises a side brush body, a brush head, a transmission mechanism and a handle, the brush head is installed at one end of the transmission mechanism, and the other end of the transmission mechanism is fixed to the handle; the side brush body is installed on the outer side of the transmission mechanism, the brush body and the brush head can rotate synchronously through the transmission mechanism, and therefore the inner wall of the bottle body container can be efficiently cleaned.

Owner:SHANDONG UNIV

Traffic light bracket

InactiveCN106958797AAchieve simultaneous rotationAchieve fixationLighting support devicesRoad vehicles traffic controlAutomatic controlEngineering

Owner:广州创码信息科技有限公司

A bridge hoisting device

ActiveCN108249334BImprove stabilityAchieve simultaneous rotationWinding mechanismsStructural engineeringMechanical engineering

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

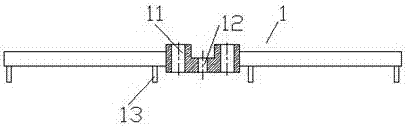

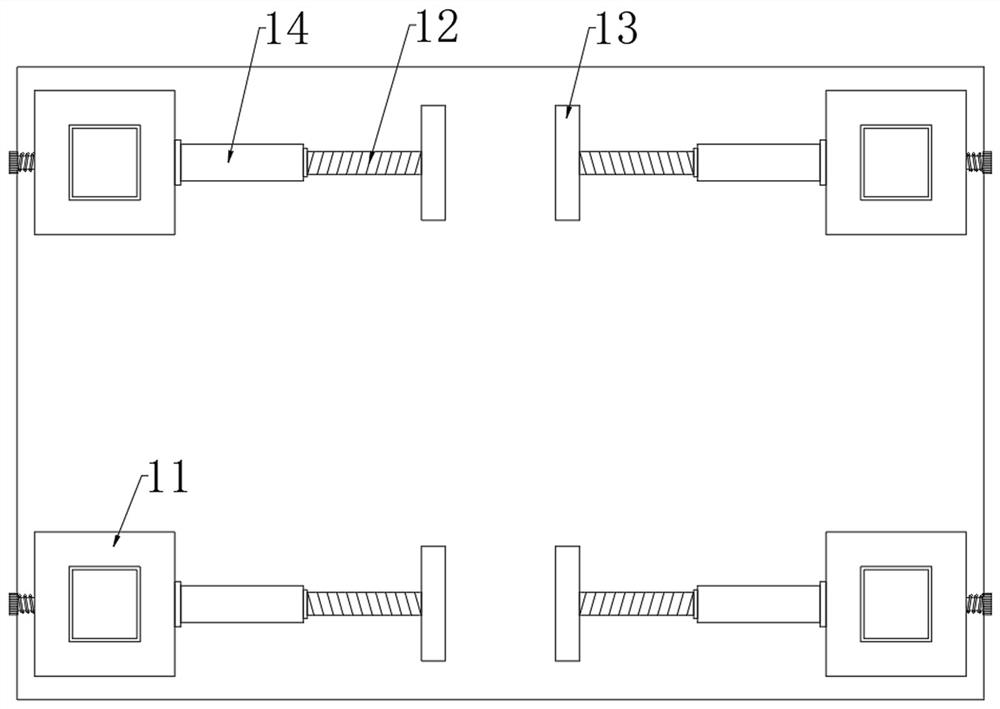

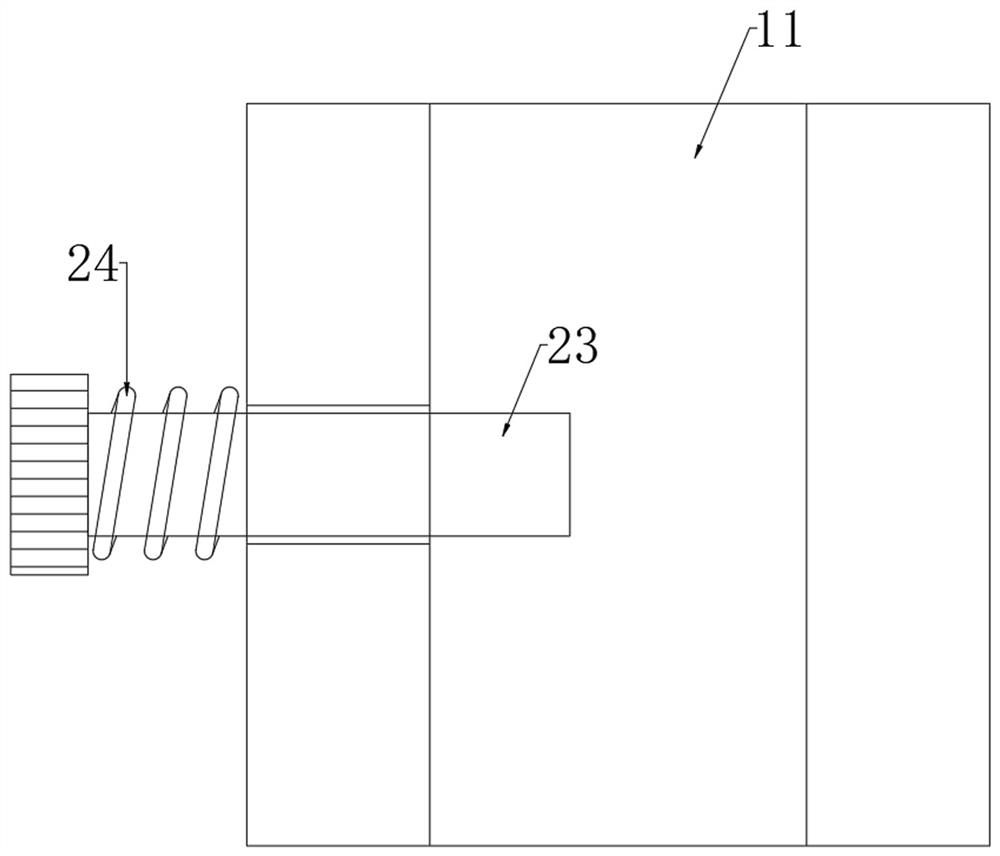

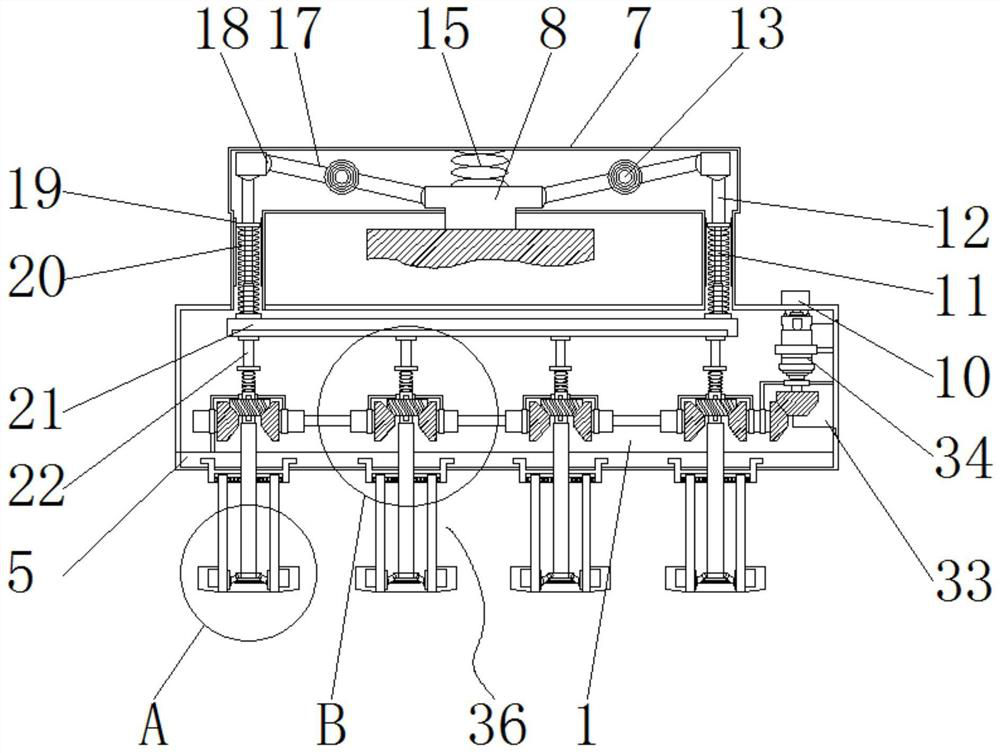

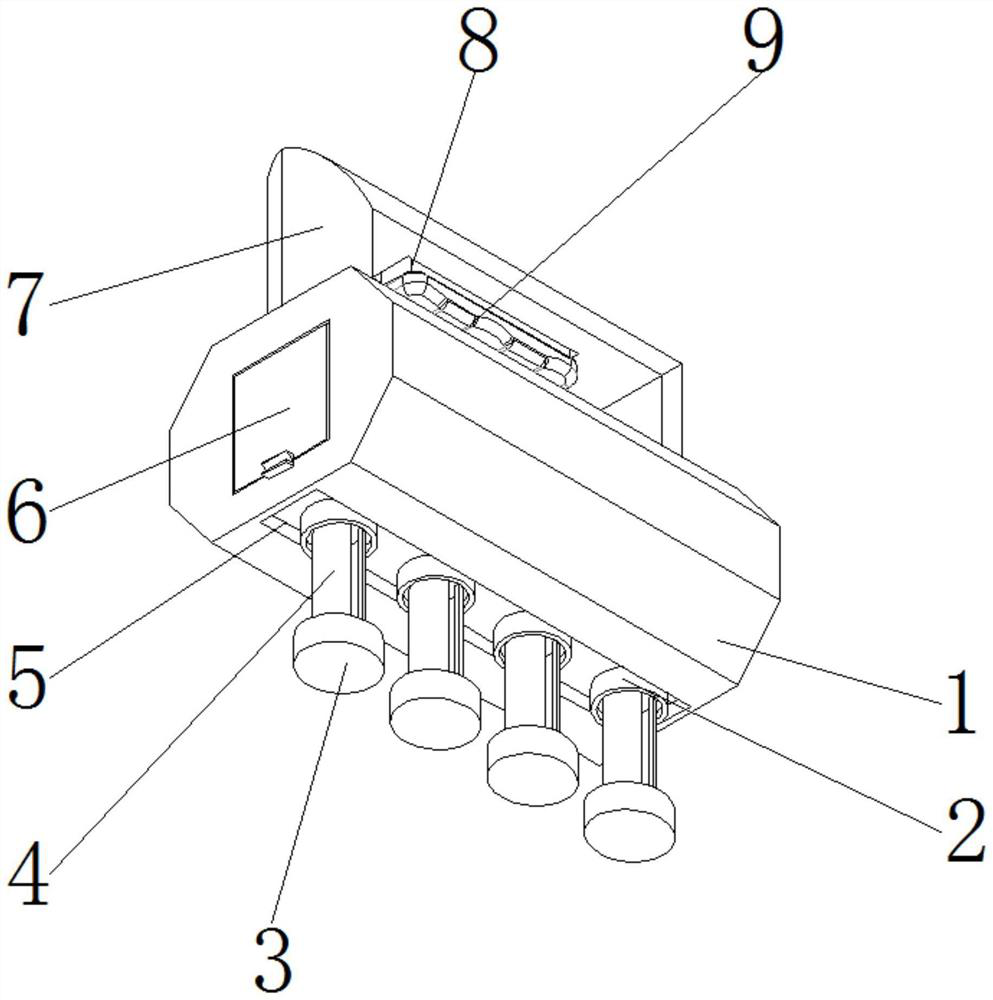

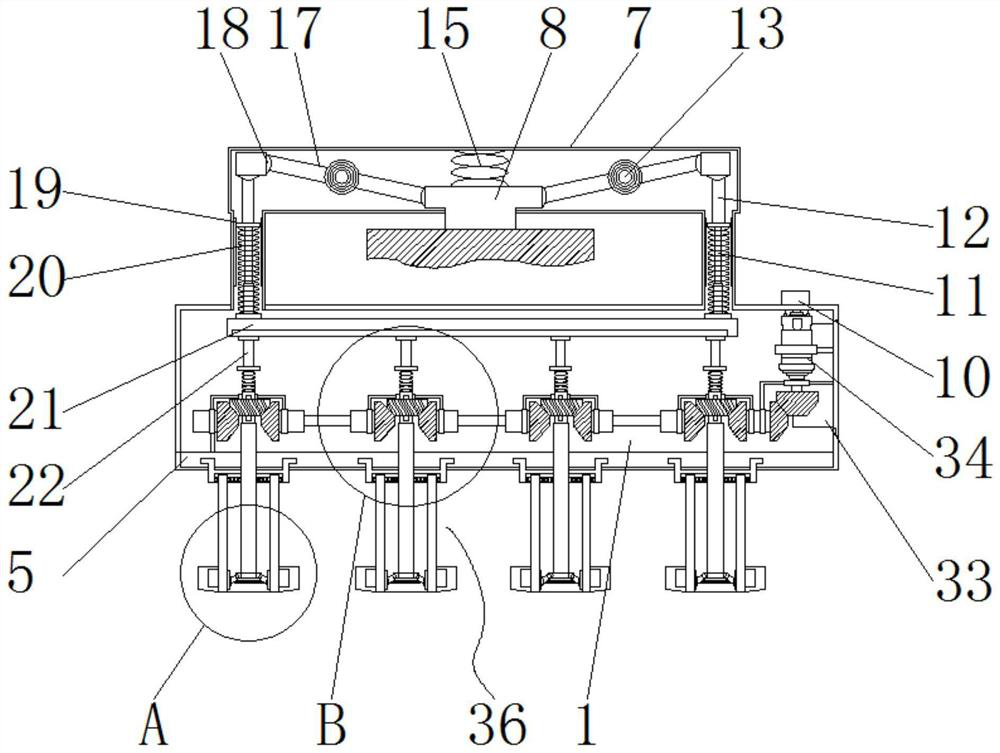

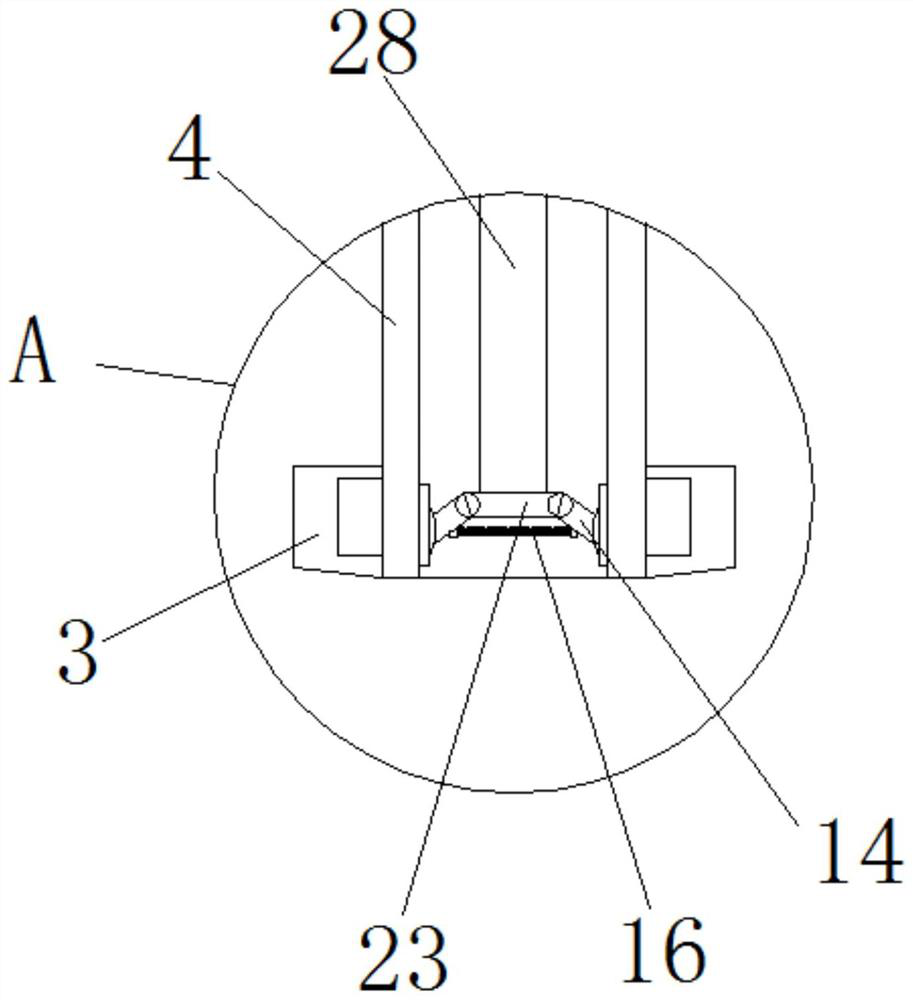

Clamping device for PCB production

PendingCN112399714AAchieve simultaneous rotationRealize simultaneous movementPrinted circuit manufactureGear wheelEngineering

The invention provides a clamping device for PCB production. The clamping device for PCB production comprises a supporting box; four supporting blocks which are all fixedly mounted in the supporting box; two rotating rods which are rotationally connected with two corresponding supporting blocks respectively; a first gear which is fixedly arranged on the outer side of one of the rotating rods in asleeving mode; a first bevel gear which is fixedly arranged on the outer side of the other rotating rod in a sleeving mode; a driving rod installed on the corresponding supporting block in a rotatingmode; and a second gear which is fixedly arranged on the outer side of the driving rod in a sleeving mode, wherein the second gear is engaged with the first gear. The clamping device for PCB production has the advantages of being convenient to use and capable of conveniently processing the four sides of a PCB.

Owner:AOSHIKANG TECH CO LTD

Energy-saving transformation equipment for industrial water pumps

InactiveCN112194042AHeight adjustableAchieve relative movementLifting framesWork benchesEngineeringProcess engineering

The invention discloses energy-saving transformation equipment for industrial water pumps. The energy-saving transformation equipment for the industrial water pumps comprises a base, a supporting plate is arranged above the base, four supporting columns are rotatably connected to the base, the four supporting columns all penetrate through the supporting plate and are slidably connected with the supporting plate, the exteriors of the four supporting columns are sleeved with rectangular sleeves slidably connected with the four supporting columns, limiting mechanisms are arranged between the fourrectangular sleeves and the corresponding supporting columns, clamping pieces are rotatably connected to the outer walls of the four rectangular sleeves, a servo motor is fixedly connected to the base, and a lifting mechanism is arranged between the servo motor and the supporting plate. The energy-saving transformation equipment for the industrial water pumps is reasonable in structure, capable of carrying out clamping on the industrial water pumps, capable of carrying out clamping on the industrial water pumps of different sizes, good in practicability and capable of carrying out lifting onthe industrial water pumps so that the improving can be conveniently carried out on the industrial water pumps, and meanwhile moving can be conveniently carried out on the base.

Owner:孟红梅

A cleaner suitable for cleaning mahjong mats

InactiveCN110252698BEasy to cleanEasy to squeeze multiple timesCleaning using toolsProcess engineeringMechanical engineering

The invention provides a cleaning device suitable for cleaning mahjong mats, and relates to the technical field of cleaning equipment. The cleaning device suitable for cleaning mahjong mats includes a box body, the top of the box body is respectively connected with a handle and a switch, the top of the inner wall of the handle is connected with a return spring, and the end of the return spring far away from the handle is connected with a general adjustment seat , both sides of the general adjustment seat are connected with support rods. The cleaning device suitable for cleaning the mahjong mat is pressed up by the set general adjusting seat, and the movable seat is moved downward by squeezing the support rod by utilizing the principle of leverage. The return spring and the sliding spring seat are used to realize the return operation, which is convenient for people to perform multiple extrusions and saves time and effort. The stability of the equipment during work is improved through the set telescopic rod, and through the cooperation of the set support plate, support rod and cleaning mechanism, multiple cleaning mechanisms can be moved up and down at the same time, which greatly improves the cleaning efficiency and saves costs.

Owner:SHAOXING UNIVERSITY

A box of cotton transport equipment

InactiveCN110294265BEfficient deliveryPrecise transportationConveyorsAgricultural engineeringMechanical engineering

Owner:王德胜

Cleaner suitable for cleaning mahjong mat and cleaning method thereof

InactiveCN111842239AEasy to cleanEasy to squeeze multiple timesCleaning using toolsProcess engineeringCleaning methods

The invention provides a cleaner suitable for cleaning a mahjong mat and a cleaning method thereof, and relates to the technical field of cleaning devices. The cleaner suitable for cleaning the mahjong mat comprises a box, the top of the box is connected with a handle and a switch, a reset spring is connected with the top of the inner wall of the handle, the end, away from the handle, of the resetspring is connected with a total adjusting base, and supporting rods are connected with the two sides of the total adjusting base. According to the cleaner suitable for cleaning the mahjong mat, by pressing the total adjusting base upwards, the supporting rods are squeezed, and a movable base is moved downwards by using the lever principle. By using the reset spring and sliding spring seats, reset operation is achieved, it is convenient for people to squeeze the supporting rods many times, and time and labor are saved. By arranging telescoping rods, the stability of the device during work isimproved; through the cooperation of the supporting plates, support rods and cleaning mechanisms, it can be achieved that the cleaning mechanisms move up and down at the same time, the cleaning efficiency is greatly improved, and the cost is reduced.

Owner:SHAOXING UNIVERSITY

A kind of plastic pipe for industrial dust collection

ActiveCN112856084BAvoid scratchesEasy to weldHuman health protectionPipe laying and repairLow-density polyethyleneThermoplastic

The invention discloses a plastic pipe for industrial dust collection, comprising a dust collection plastic pipe. The dust collection plastic pipe is made of linear low-density polyethylene thermoplastic as a raw material and formed by thermoplastic technology. The end of the dust collection plastic pipe is A welding port is provided. By aligning the welding ports of the two dust-collecting plastic pipes on the welding equipment, the rotating inner cylinder is driven to rotate by the driving action of the belt. Due to the thread relationship between the rotating inner cylinder and the tightening sliding cylinder, the receiving The tight sliding cylinder rotates to the outside, so as to squeeze the elastic pressure plate at the outer end of the rotating inner cylinder, so that the fixed clamp ring at the outer end of the elastic pressure plate is clamped on the outside of the plastic pipe, and is bonded on the inner ring wall of the fixed clamp ring. Clamping cotton pads can protect the plastic pipe well, and avoid the relative sliding between the fixed clamping ring and the plastic pipe, which will cause scratches on the plastic pipe. Thereby, the plastic pipe is driven to rotate synchronously.

Owner:公元管道(江苏)有限公司

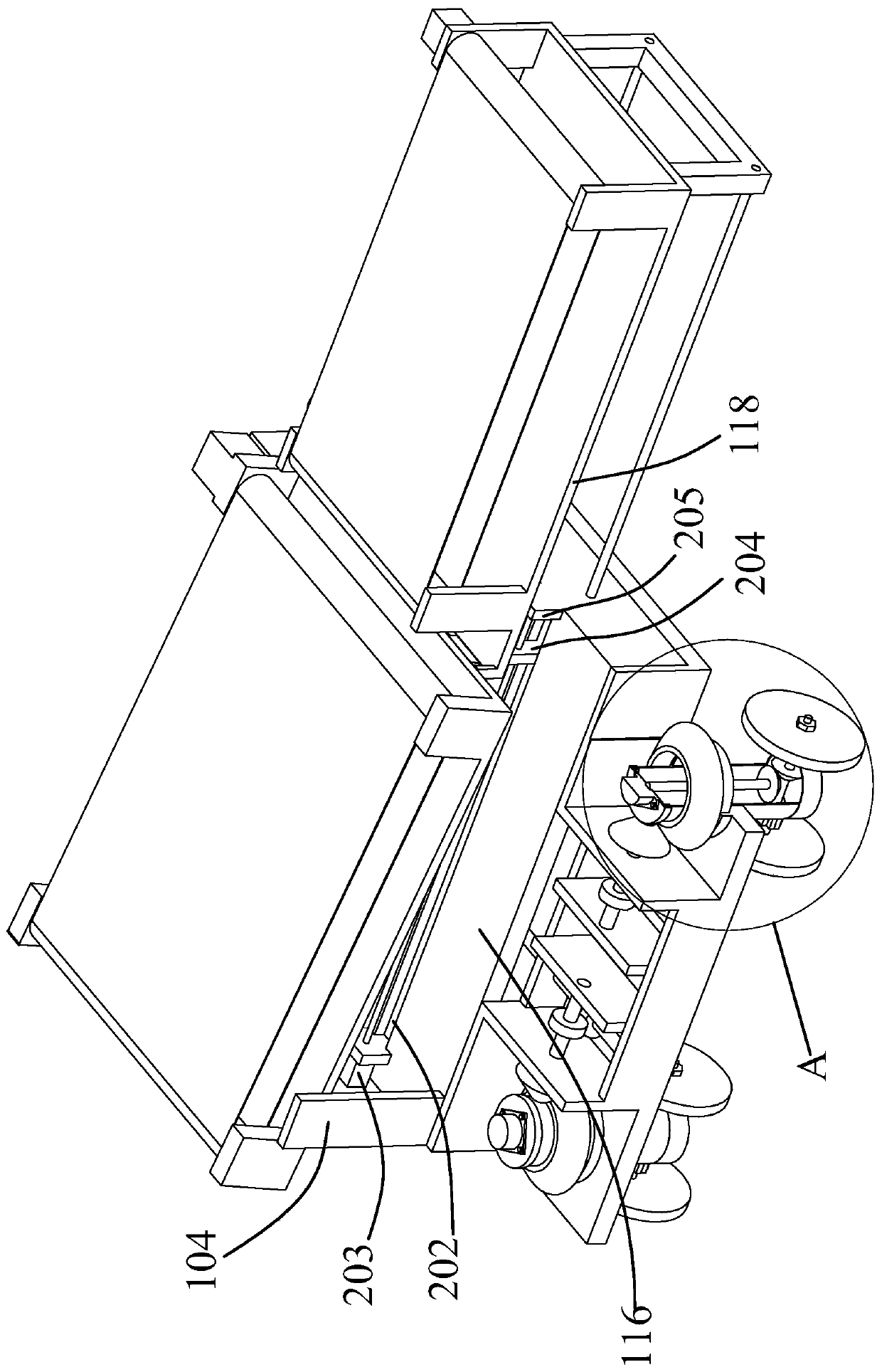

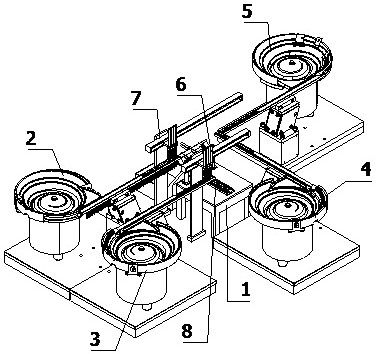

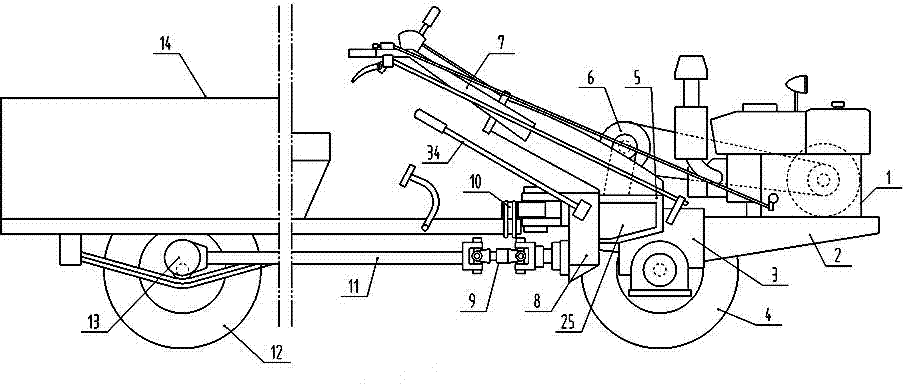

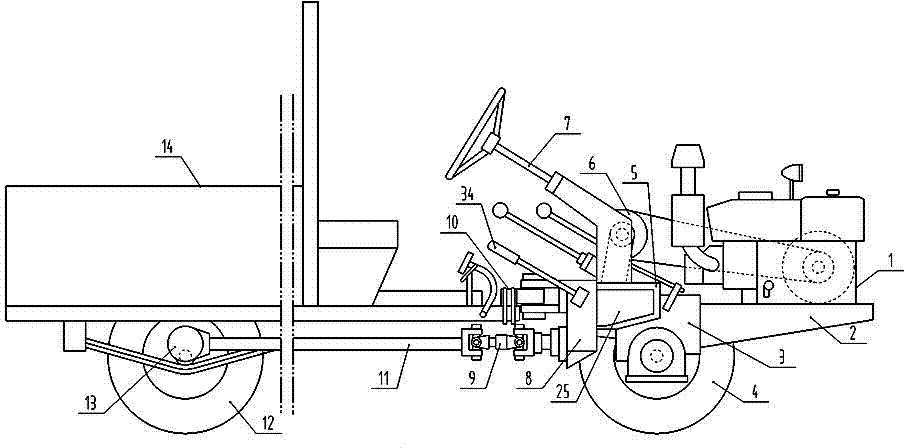

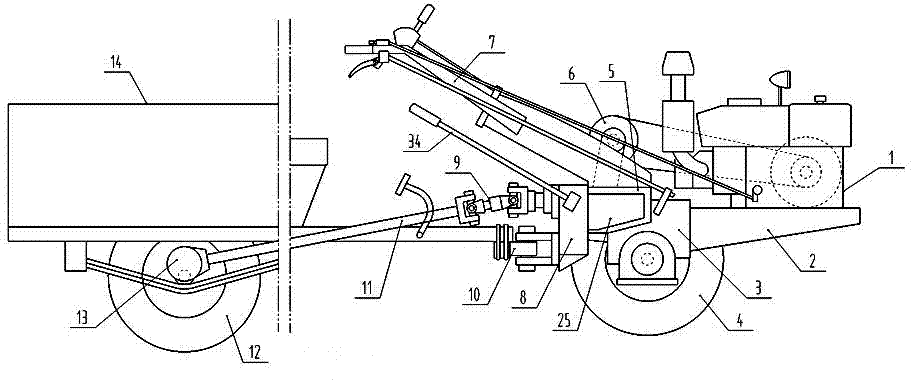

Full-wheel-drive tractor chassis driven by gears

ActiveCN103587413AAchieve simultaneous rotationSimple structureControl devicesUniversal jointDrive shaft

Provided is a full-wheel-drive tractor chassis driven by gears. According to the full-wheel-drive tractor chassis driven by the gears, a diesel engine, a front transmission case, front wheels, a steering control device, a trailer adapting piece, a rear transmission case, a trailer and rear wheels are installed on a support; a main shaft, a middle shaft and an auxiliary shaft which are installed in a gearbox are all spline shafts; a side transmission case is installed on the outer side face of the gearbox; one ends of the main shaft, the middle shaft and the auxiliary shaft in the gearbox extend into the side transmission case; the shaft heads of the main shaft, the middle shaft and the auxiliary shaft are provided with a main shaft auxiliary gear, a middle shaft auxiliary gear and an auxiliary shaft auxiliary gear respectively; the rear transmission case installed at the rear end of the gearbox is the rear transmission case below which an output cone gear shaft is located; the output cone gear shaft drives the rear wheels via a universal transmission joint, a rear transmission shaft and a rear axle assembly; due to the fact that the side transmission case is additionally arranged on the side face of the gearbox, a branch, distributed by the side transmission case, of the power transmitted by the gearbox is transmitted to the rear transmission case, the rear transmission case drives the rear transmission shaft through the universal joint, then the rear axle assembly drives the rear wheels to rotate, and the rear wheels and the front wheels rotate synchronously.

Owner:通海宏兴工贸有限公司

Friction screw press

ActiveCN103357807BCompact structureAchieve simultaneous rotationForging press drivesFreewheelEngineering

The invention discloses a friction screw press comprising a flywheel. The flywheel is connected with a slider through a screw pair, a first edge and a second edge are arranged on the flywheel, the first edge is arranged opposite to a first end of a first friction wheel, the second edge is arranged opposite to a first end of a second friction wheel, a rotating shaft is arranged at the center of a second end of the first friction wheel, the rotating shaft is hermetically connected with a first cylinder, a first return mechanism is arranged between the rotating shaft and the first cylinder, a chamber serving as a second cylinder is further arranged at the first end of the first friction wheel, the second cylinder is hermetically connected with a second end of the second friction wheel, the second friction wheel rotates along with the first friction wheel, and a second return mechanism is further arranged between the first friction wheel and the second friction wheel. The friction screw press is compact in structure due to the design of the first and second friction wheels, the first cylinder and the second cylinder are designed skillfully, the first friction wheel and the second friction wheel can rotate simultaneously, and the first friction wheel can move axially relative to the first friction wheel.

Owner:SHANGHAI YUNLIANG FORGING PRESS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com