Double-rotation type bottle brush

A double-rotation, brush body technology, applied in the field of daily cleaning appliances, can solve the problems of difficult cleaning, complex structure of the bottle brush head of the extendable mechanism, and difficulty in guaranteeing the cleaning effect, so as to improve cleaning efficiency and effect and avoid water ingress The effect of cleaning inside the device without dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

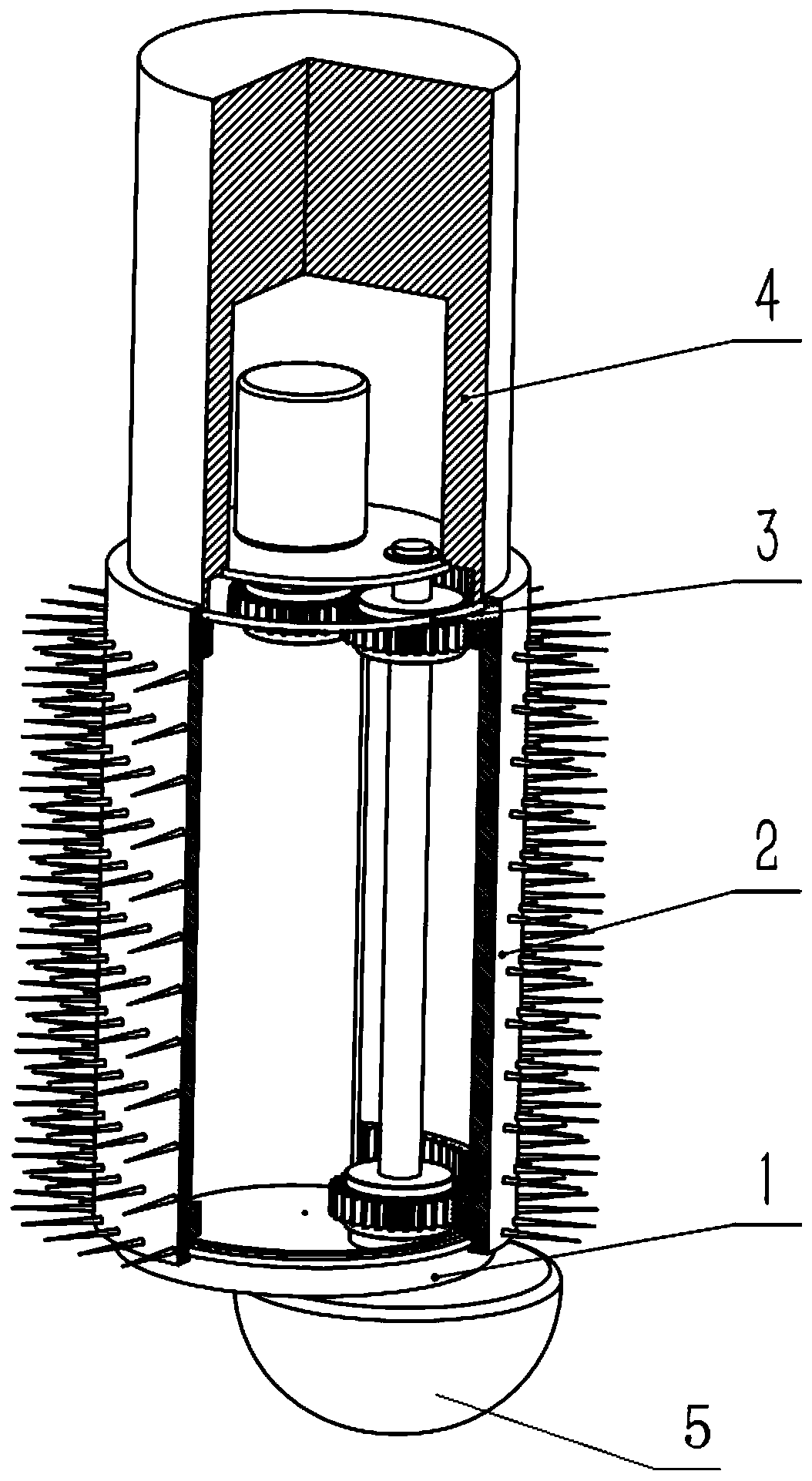

[0033] This embodiment provides a double-rotating bottle brush, including a side brush body 2, a brush head 5, a transmission mechanism 1, and a handle 4. One end of the transmission mechanism 1 is equipped with a brush head 5, and the other end is fixed to the handle 4; the side brush The body 2 is installed on the outside of the transmission mechanism 1, and the transmission mechanism 1 can simultaneously drive the side brush body 2 and the brush head 5 to rotate.

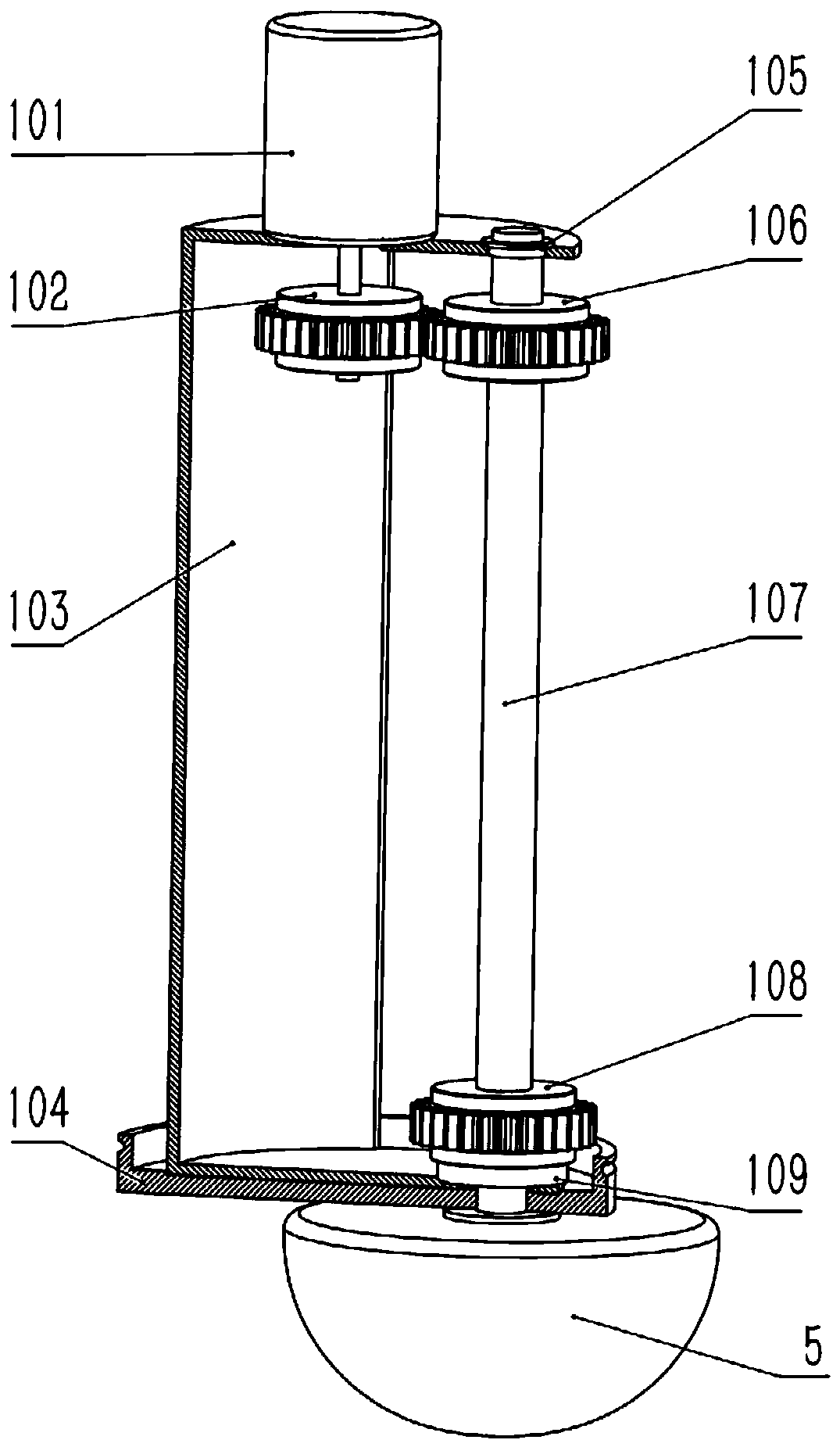

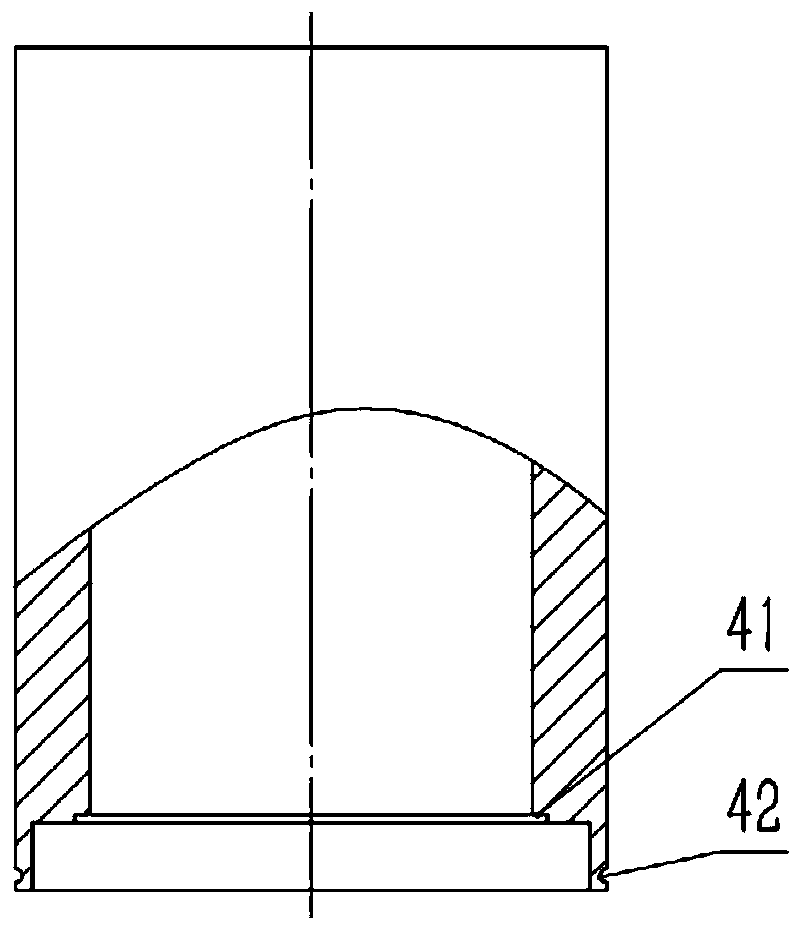

[0034] Such as figure 2 As shown, the transmission mechanism 1 includes an inner housing 103, a motor 101, a cover plate 104, a gear set and a transmission shaft 107, and the motor 101 is installed above the inner housing 103; the motor 101 is connected to the transmission shaft 107 through a gear set, One end of the drive shaft 107 is connected to the brush head 5 , and the motor 101 drives the brush head 5 to rotate. In order to ensure the cleaning range of the brush head 5, the brush head 5 is installed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com