Connecting rod transmitting folding blade vertical shaft impeller

A vertical axis impeller and folding blade technology, applied in the direction of engines, wind engines, machines/engines, etc., can solve the problems of difficult self-starting and low energy capture efficiency, and achieve reduced headwind resistance, good self-starting performance, and improved rotational torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

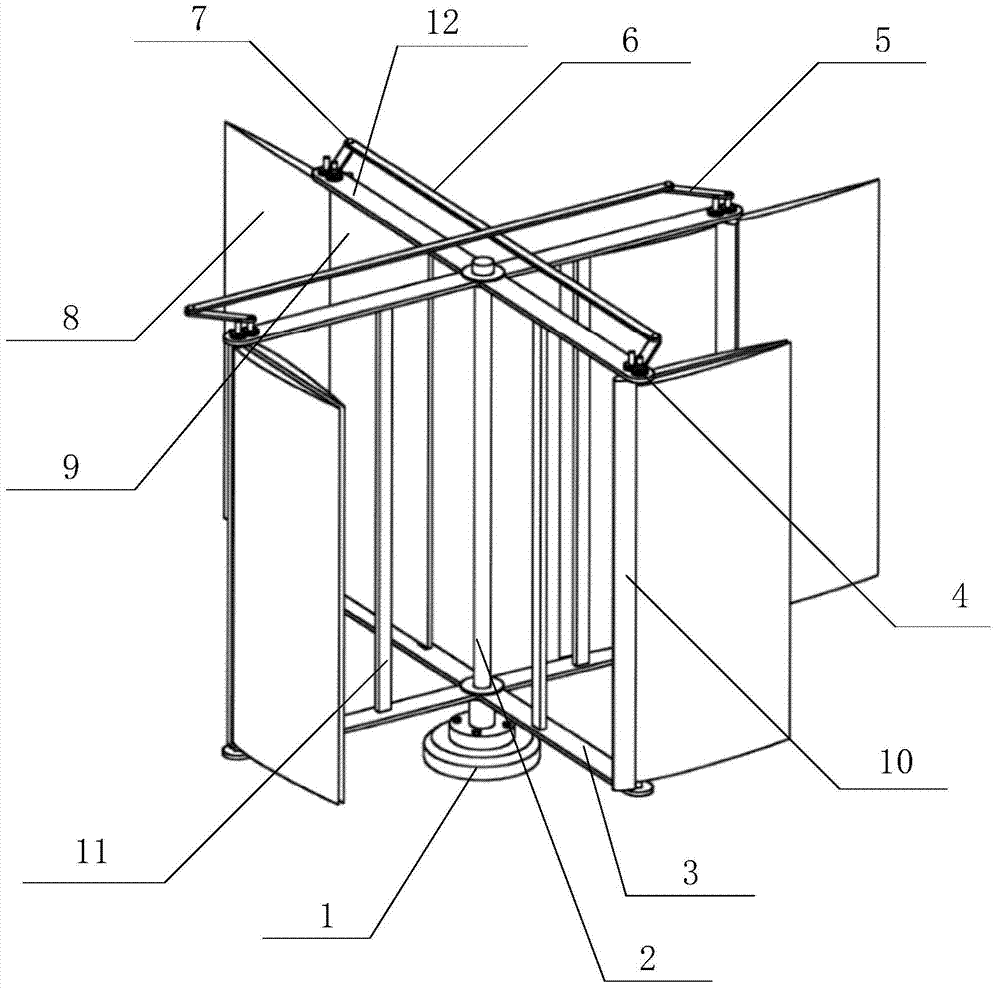

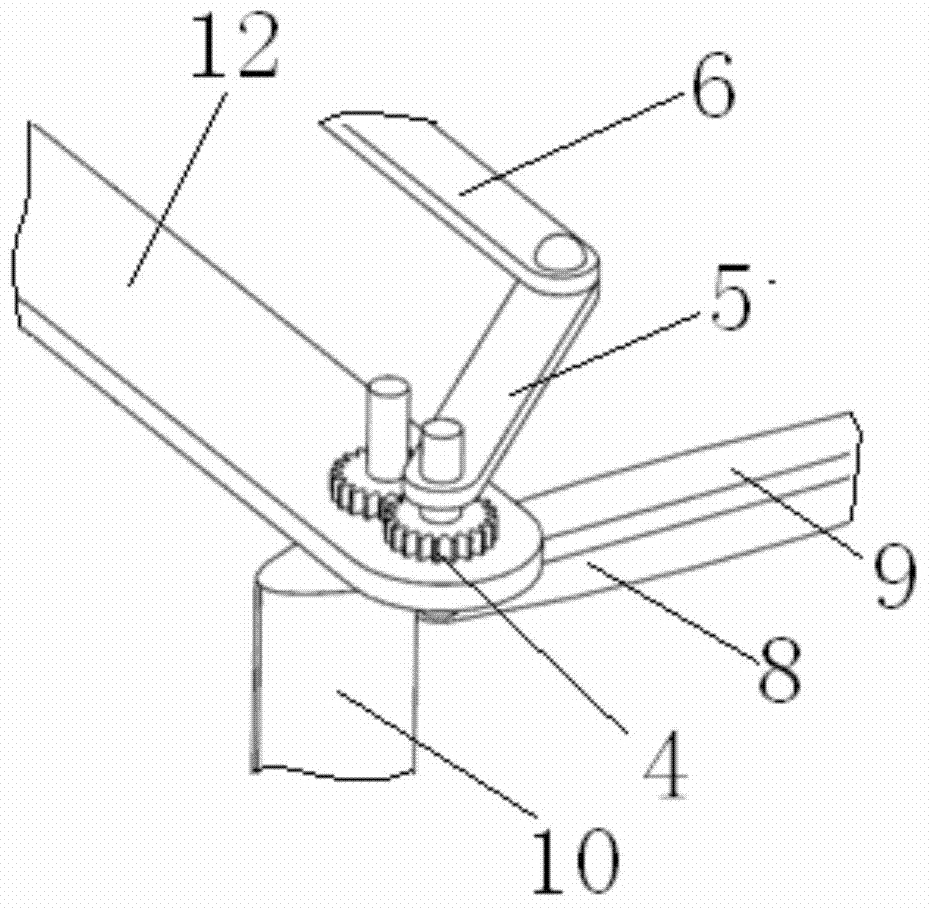

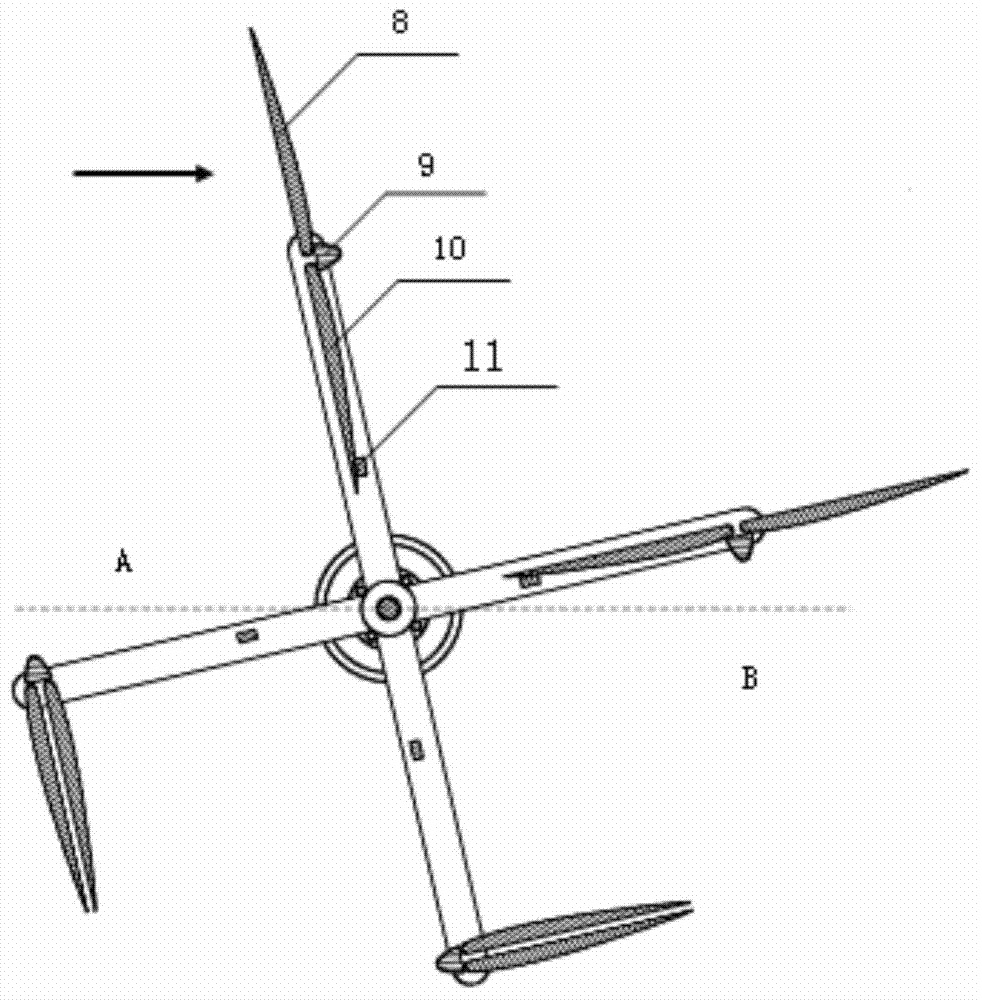

[0026] This embodiment is a folding blade type vertical axis impeller driven by connecting rods, including a bearing seat 1, a main shaft 2, two blade supports, four sets of gear sets 4, two sets of connecting rod transmission mechanisms, four blade sets and four Barrier 11. Wherein: the main shaft 2 is installed on the bearing seat 1 through the bearing. The blade brackets are respectively fixedly mounted on the upper and lower ends of the main shaft 2, forming an upper blade bracket 12 and a lower blade bracket 3; The lower ends of the lower blades are fixedly connected to each rod of the lower blade support 11 respectively. The four blade groups are respectively located between the upper blade support 12 and the lower blade support 11 , and are installed on the top ends of the rods of the blade support 3 through shaft hole clearance fit....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com