Screw hoist and working method thereof

A hoist and screw technology, which is applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problem that the load-bearing nut cannot continuously bear the load, and achieve the effect of avoiding jamming, simple operation and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

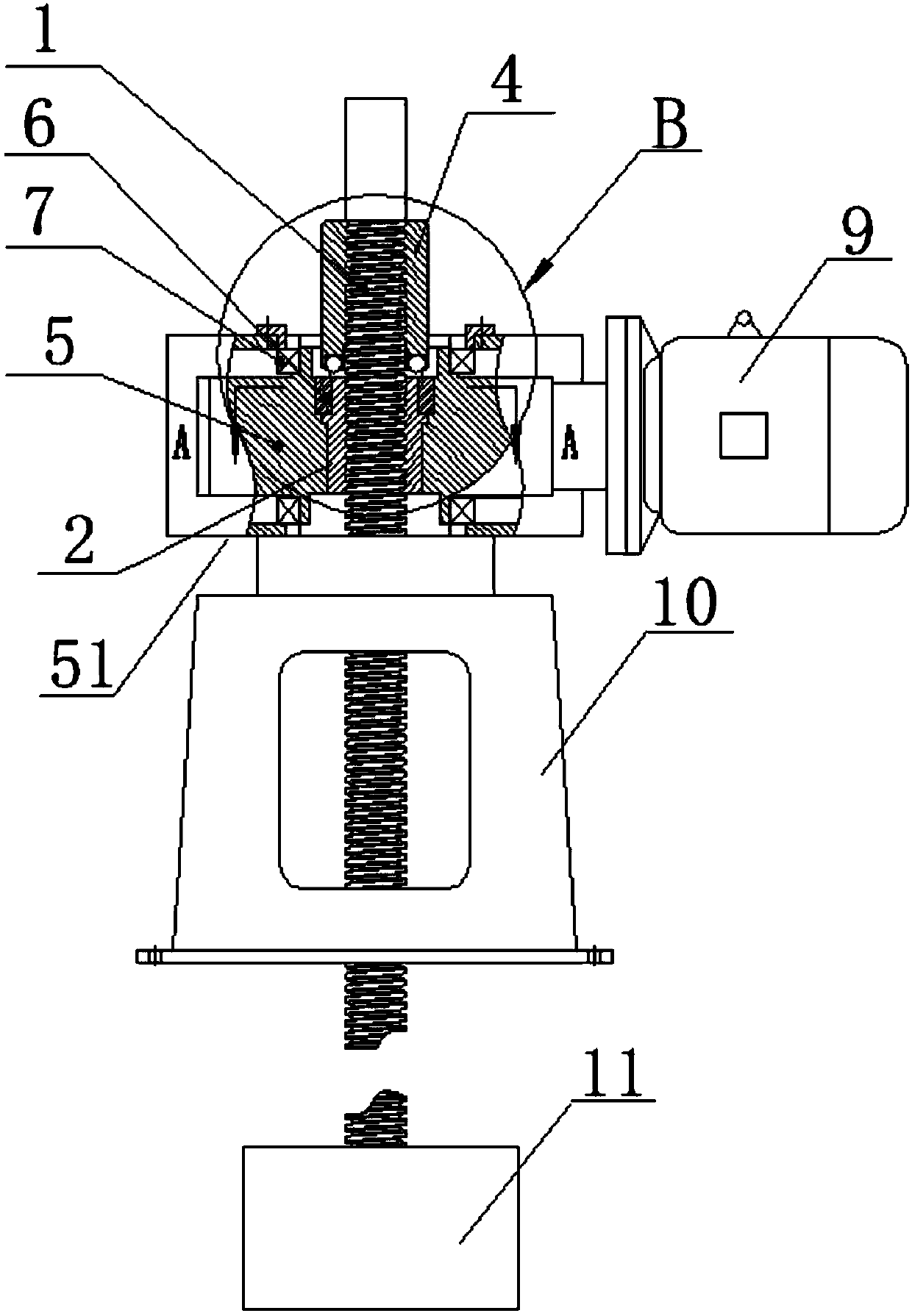

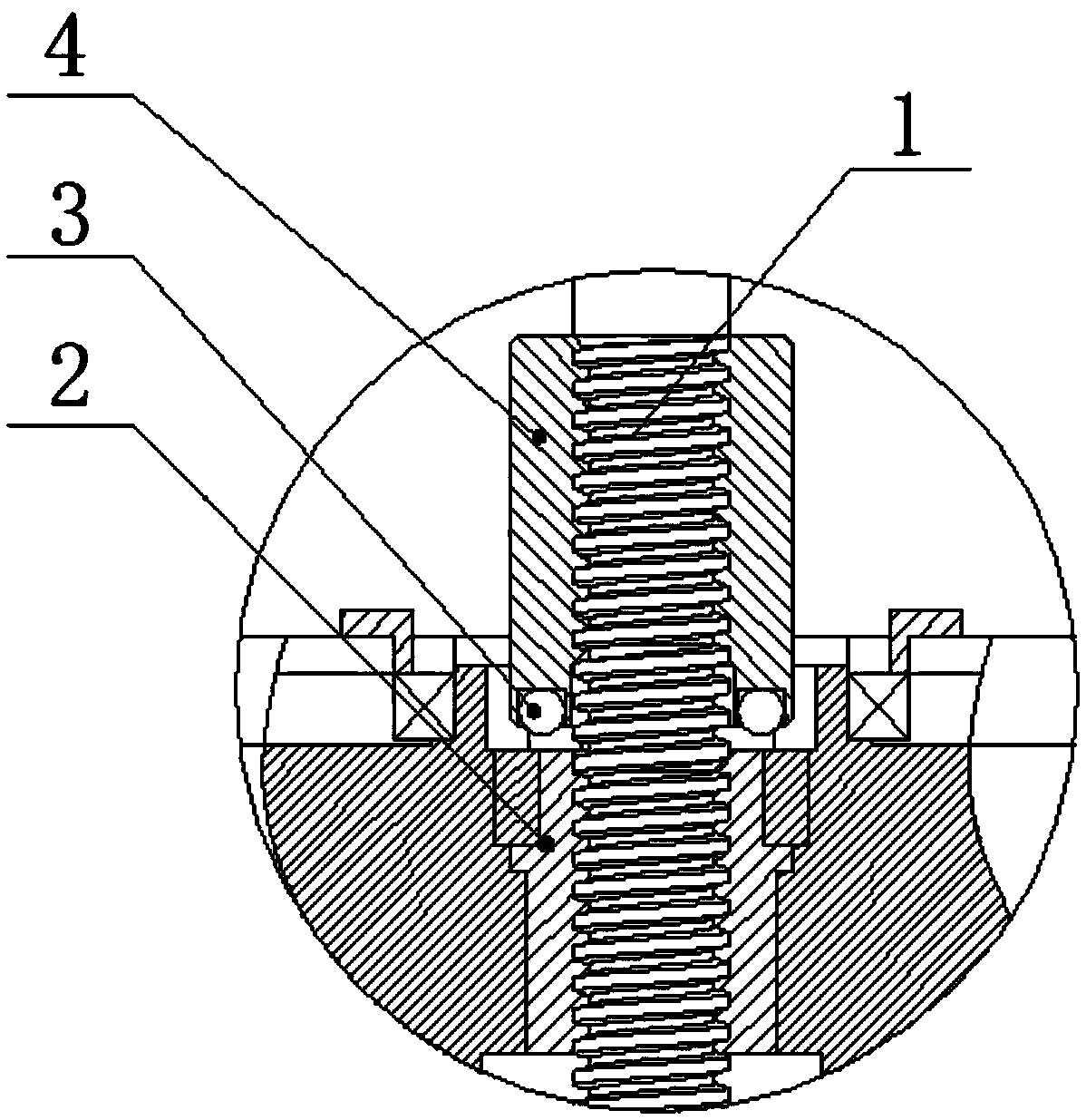

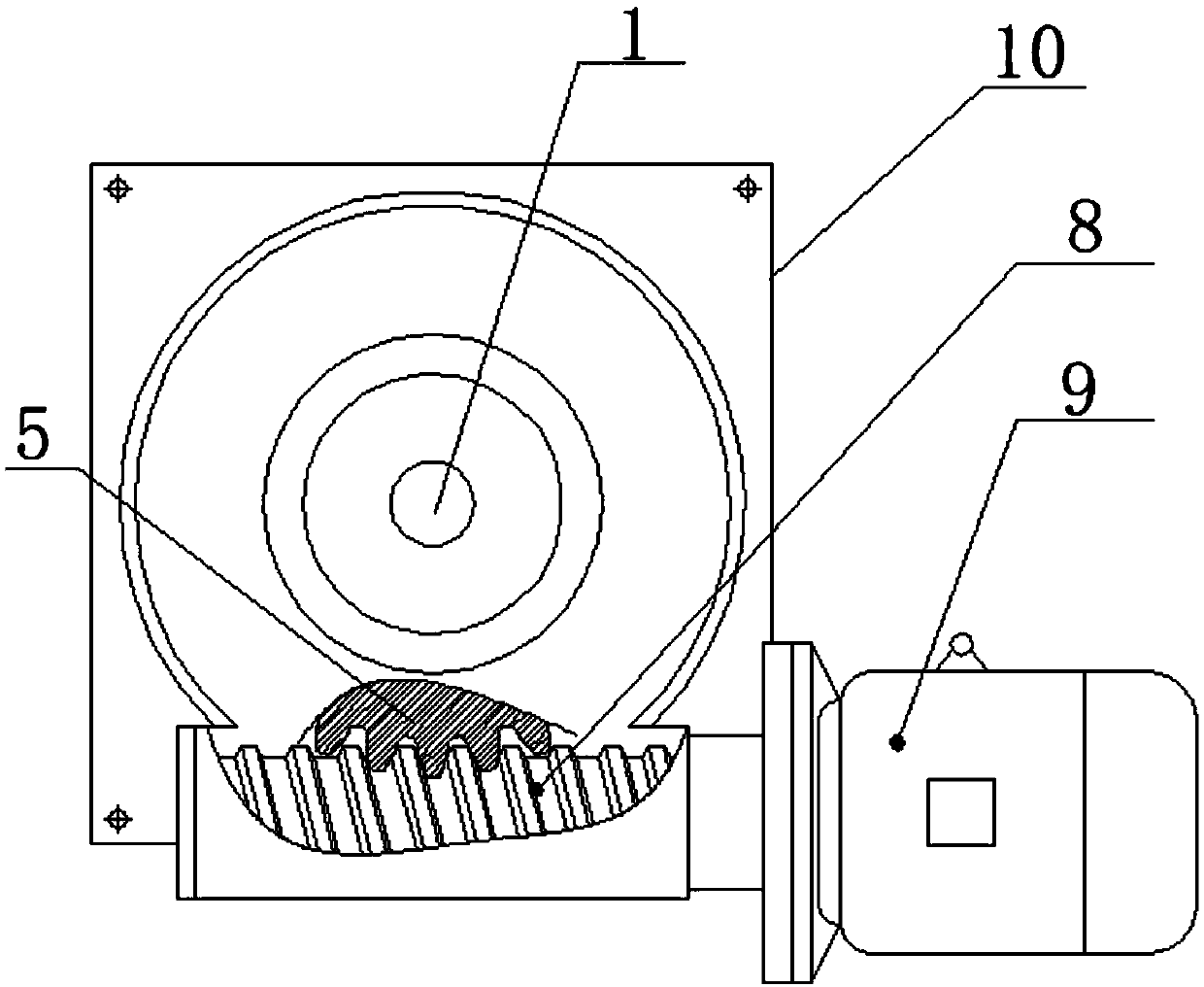

[0046] The screw hoist of the present embodiment, such as figure 1 , 2, 3, including a screw 1, a motor 9, a worm wheel 5, a bearing assembly 7, a worm 8, a support 10, a gate 11 and a double-nut anti-slip wire mechanism, wherein: the worm wheel 5 is fixed to the support through the bearing assembly 7 On the seat 10, the bearing assembly 7 includes a bearing and a bearing seat, and the bearing seat is fixed on the support 10; the motor 9, the worm 8 and the worm wheel 5 are sequentially connected by transmission, and the center of the worm wheel 5 is embedded with a double-nut anti-skid wire mechanism; After the screw rod 1 is threadedly connected with the double-nut anti-skid wire mechanism, the bottom end is fixedly connected with the gate plate 11. The double-nut anti-skid wire mechanism includes the screw rod 1 and the main nut 2 and the auxiliary nut 4 which are sleeved on the screw rod 1; The main nut 2 is fixedly connected to the center of the worm wheel 5, and a gap i...

Embodiment 2

[0048] The screw hoist of present embodiment, basic structure is the same as embodiment 1, and improvement is: as figure 1 , 4 As shown, also includes flat key 6, such as Figure 5 , 6 As shown, the upper outer edge of the main nut 2 is provided with a keyway 21, and the center of the worm wheel 5 is also provided with a groove matching the keyway 21, and the combination of the keyway 21 and the groove forms a square groove for accommodating the flat key 6 , the flat key 6 is embedded in the square groove to achieve the purpose of the worm wheel 5 driving the main nut 2 to rotate; the auxiliary nut 4 is located above the main nut 2, and the top of the main nut 2 is provided with a symmetrical protrusion 22, which can be one or more ,Such as figure 1 , 5 , 6, there are 2 in this embodiment, such as figure 1 , 7 , 8, 9, and 10, the end of the auxiliary nut 4 is provided with a slot 41 and a card table 42 corresponding to the protrusion 22, and the main nut 2 and the auxili...

Embodiment 3

[0051] The screw hoist of this embodiment has the same basic structure as that of Embodiment 3, and the improvement is that a sliding mechanism is provided at the end of the card table 42 and / or in the card slot 41, which can be steel balls, lubricating graphite gaskets, etc. In the embodiment, it is a lubricating graphite gasket, which is arranged at the end of the card table 42 and in the card slot 41, which can prevent the card protrusion 22 from being stuck in the card slot 41 when the roles of the main nut 2 and the auxiliary nut 4 are transferred; A gap of 2 mm is reserved between the slots 41 at the ends.

[0052] The operating method of the present embodiment screw hoist, the steps are:

[0053] Step 1. Closing the gate: start the motor 9, the motor drive shaft drives the worm 8 to rotate forward, the worm 8 drives the worm wheel 5 to rotate in the horizontal direction, the worm wheel 5 drives the main nut 2 to rotate through the flat key 6, the main nut 2 bears the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com