Bearing seat

A bearing seat, bearing cavity technology, applied in the direction of bearing components, shafts and bearings, rigid brackets of bearing components, etc., can solve the problems of unreliable performance, high speed of the shredding device, difficult to replace, etc., and prolong the service life of the equipment. , with reasonable and reliable, conducive to the effect of lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

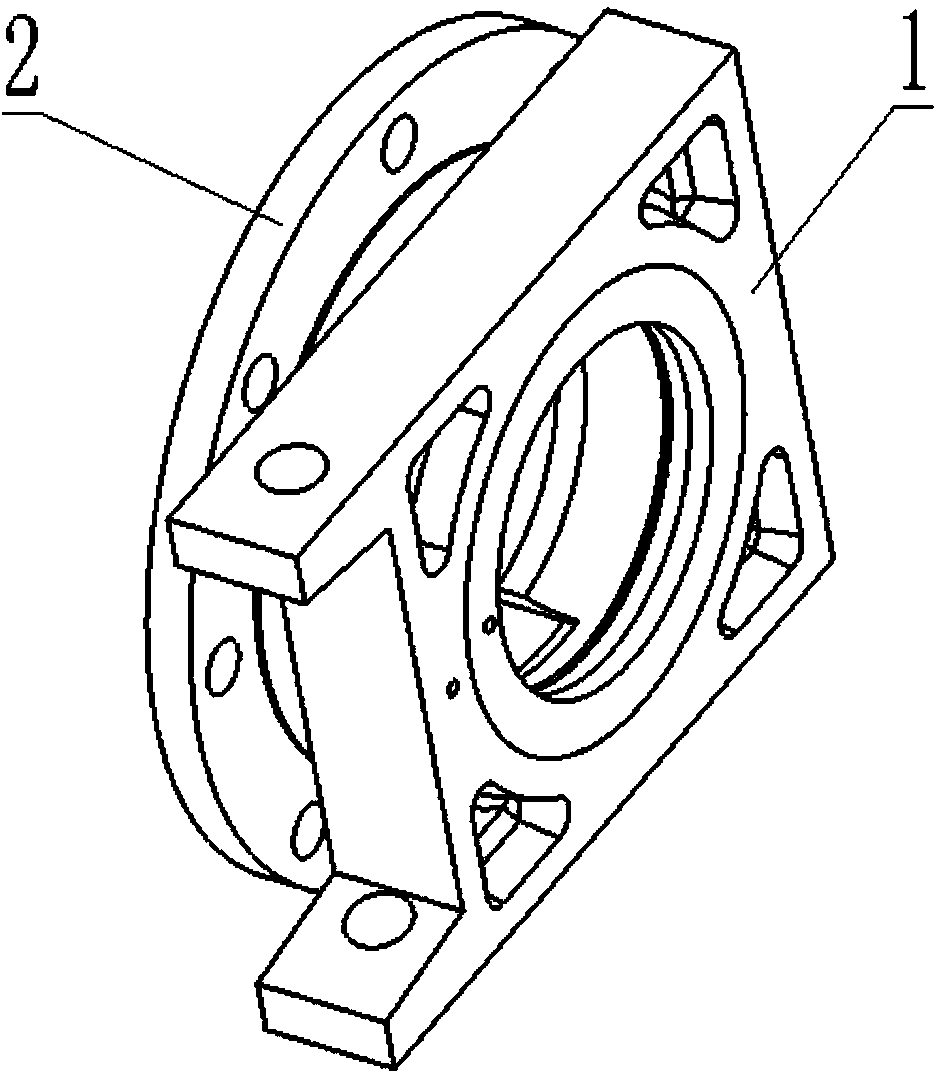

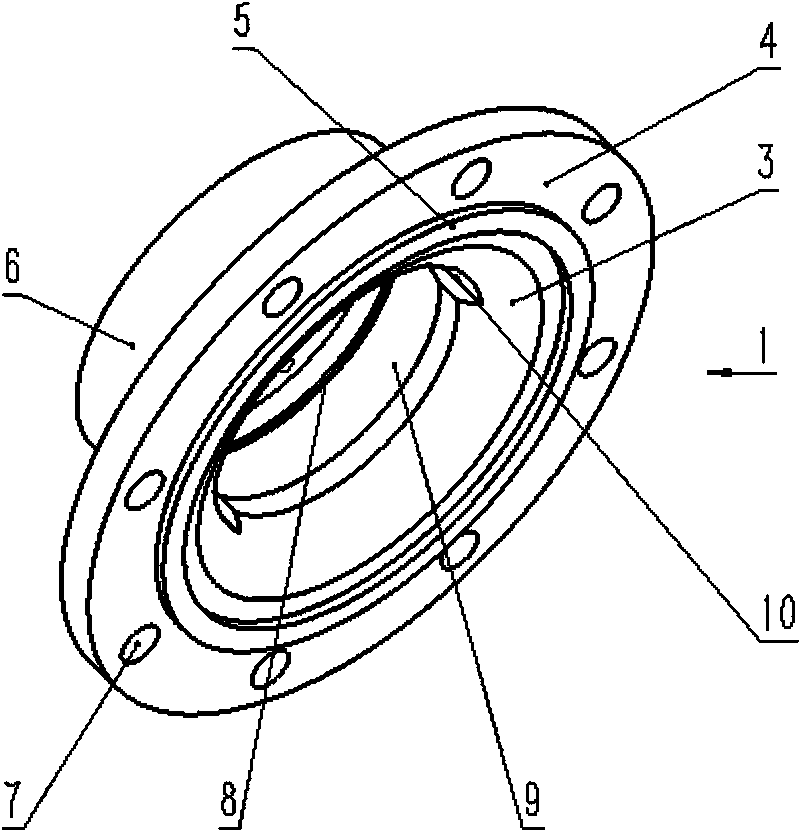

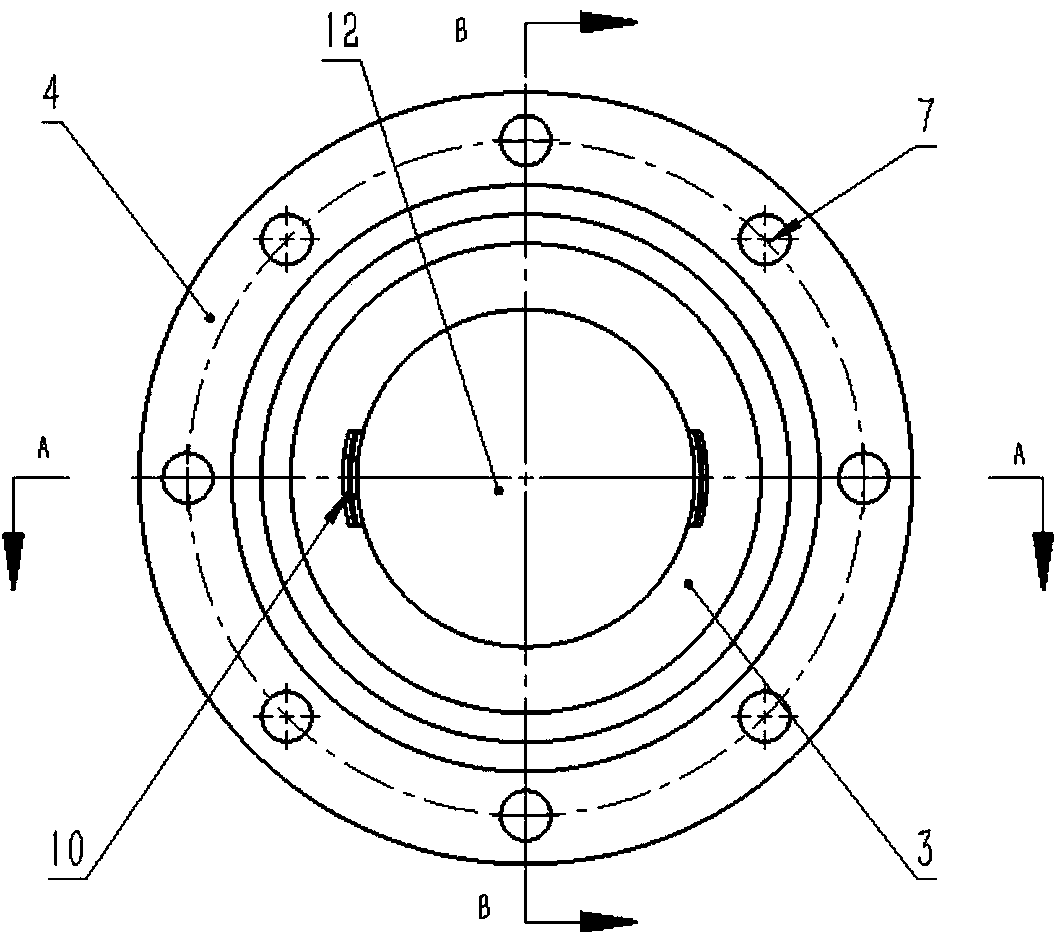

[0018] In the figure, 1. Square sleeve of seat body; 2. Bearing seat body; 3. Large arc opening; 4. Flange plate 5. Positioning notch; 6. Cylindrical boss; 7. Positioning hole; 8. Bearing cavity Oil groove; 9, spherical shape cavity; 10, installation groove; 11, seat body oil hole; 12, bearing cavity; 13, square sleeve center hole; 14, square sleeve oil hole; 15, square sleeve oil groove.

[0019] Depend on figure 1 Can see this bearing seat, it is made of bearing seat body 2 and seat body square cover 1.

[0020] Depend on Figure 2 to Figure 5 It can be seen that one end of the bearing body is a flange 4, and the positioning holes 7 are evenly distributed on the flange. The flange 4 is connected to the cylindrical boss 6 through the large arc opening 3, and the large arc opening is connected with the cylinder. The cavity surrounded by the cylindrical boss is the bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com