A portable tire loading device and an operation method thereof

A portable and tire loading technology, which is applied in tire installation, tire parts, transportation and packaging, etc., can solve the problems of load-bearing nut slipping and continuous load-bearing, etc., and achieve the effect of avoiding jamming, ingenious conception and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

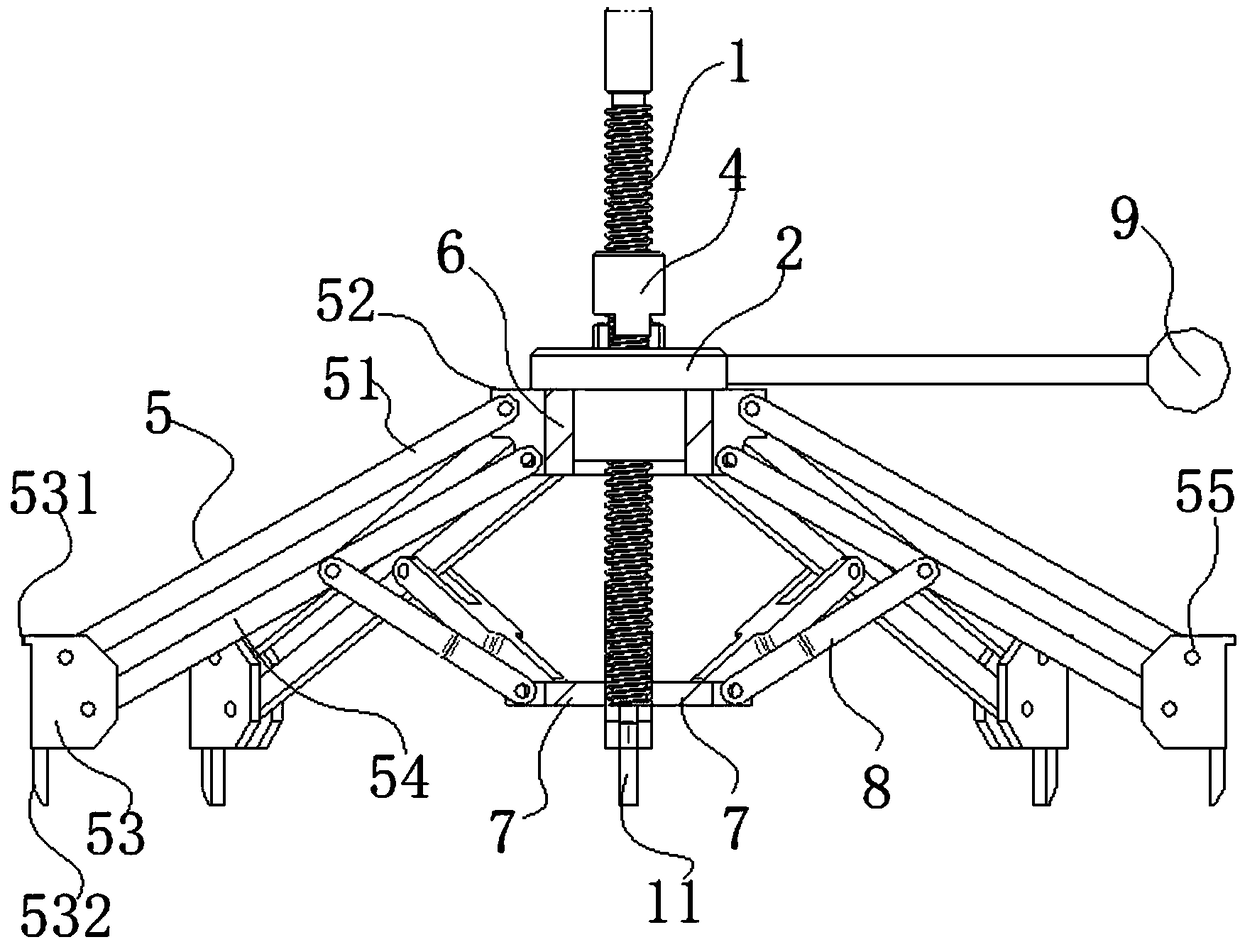

[0045] The portable tire fitting device of the present embodiment, as figure 1 ,2 , 3 and 4, including guide screw 1, hinge four-bar mechanism 5, guide sleeve 6, fixed seat 7, support rod 8 and double nut anti-skid wire mechanism, wherein: said hinge four-bar mechanism 5 includes upper connecting rod 51. Displacement seat 52, support block 53, lower connecting rod 54 and pin 55; the guide sleeve 6 is sleeved on the outer edge of the double-nut anti-skid wire mechanism; Distributed, and connected to the side of the guide sleeve 6 through the displacement seat 52; the upper link 51 and the lower link 54 are in a parallel relationship up and down, and one end of them is fixed in the groove of the displacement seat 52 by a pin 55; Be fixed in the groove of support block 53 by pin 55; After the top of described guide screw rod 1 is threadedly connected with double nut anti-skid wire mechanism, after the bottom passes through fixed seat 7, it is fixedly connected with fixed seat 7; ...

Embodiment 2

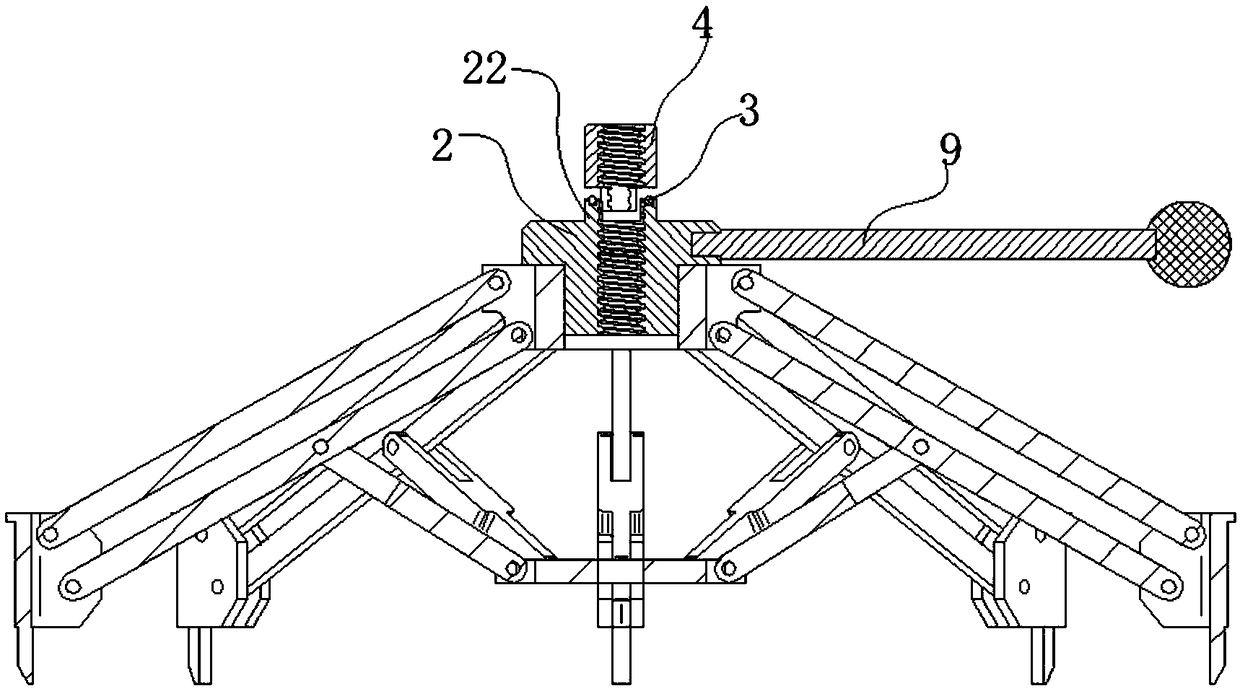

[0048] The basic structure of the portable tire loading device of this embodiment is the same as that of Embodiment 1. The improvement is that the auxiliary nut 4 is located above the main nut 2, and the top of the main nut 2 is provided with a symmetrical protrusion 22, such as Figure 7 , 8 As shown, the end of the auxiliary nut 4 is provided with a locking groove 41 and a locking platform 42 corresponding to the locking protrusion 22, and the simultaneous rotation of the main nut and the auxiliary nut is realized after the two are engaged.

[0049] When the main nut 2 slips out of order, the auxiliary nut 4 is rotated, and the card protrusion 22 and the card table 42 are overlapped together after a little contact, so that the main nut 2 drives the auxiliary nut 4 to move with the guide screw 1, and the auxiliary nut 4 and the The main nut 2 engages, and after the main nut 2 idles for a certain angle, the card protrusion 22 and the card table 42 are completely in contact wit...

Embodiment 3

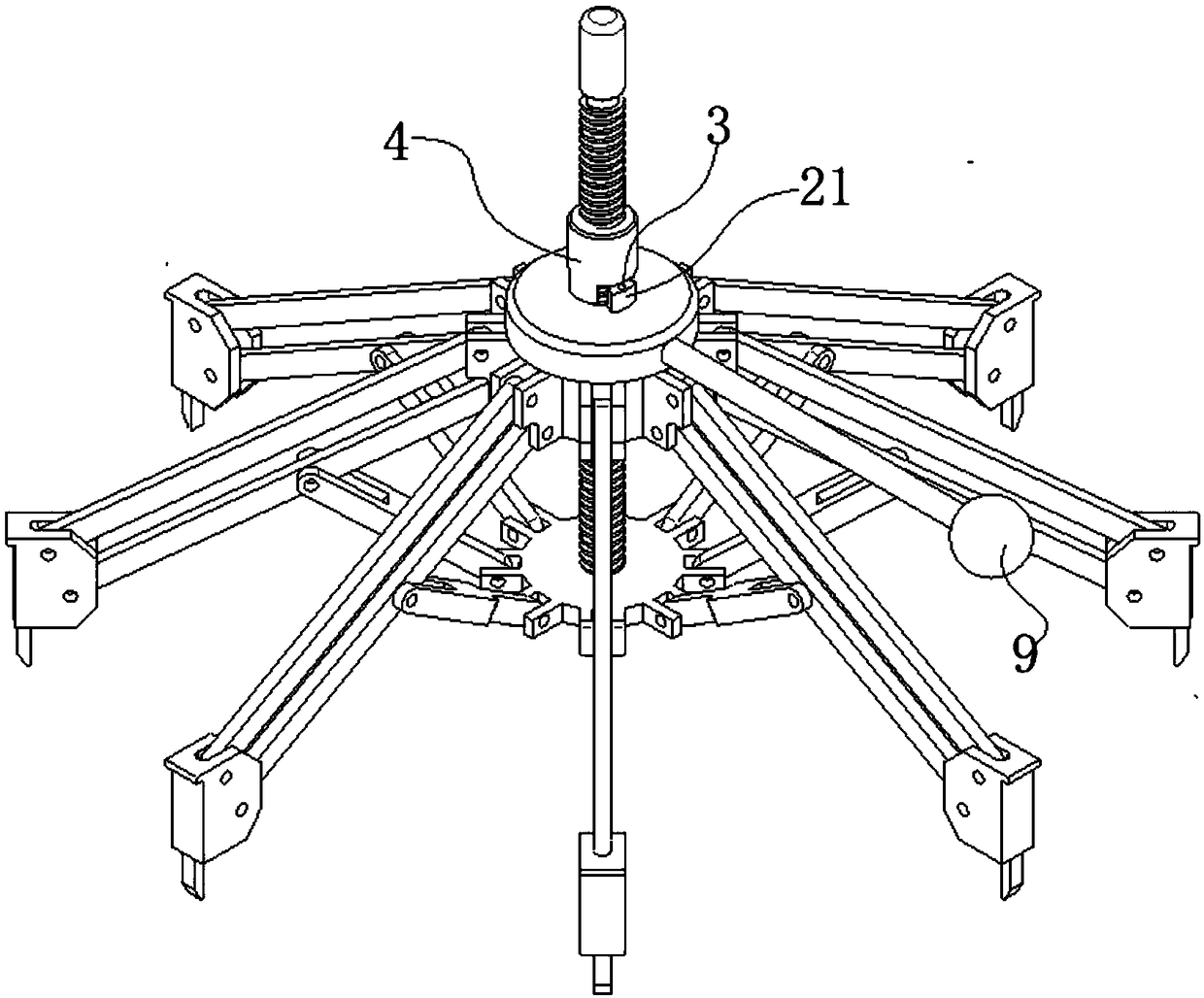

[0051] The portable tire installation device of present embodiment, basic structure is the same as embodiment 3, and improvement is: as Figure 4 As shown, the hinged four-bar mechanism 5 is 8 symmetrically arranged, as Figure 5 , 6 As shown, the upper part of the main nut 2 is provided with a gear edge 21, which blocks the top end of the guide sleeve 6 and exerts positive pressure on the guide sleeve 6; the end of the protrusion 22 and / or the slot 41 is provided with a sliding mechanism, It can be a steel ball, lubricating graphite gasket, etc., to avoid jamming when the roles of the main and auxiliary nuts are transferred. When the roles of 2 and auxiliary nut 4 are transferred, the protrusion 22 is stuck in the groove 41; the end of the protrusion 22 leaves a gap of 2 mm between the grooves 41 .

[0052] The operation method of the portable tire loading device of the present embodiment, the steps are:

[0053] Step 1. Tire expansion: place the support block 53 of the wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com