Aluminum foil winding device convenient to use

A winding device and aluminum foil technology, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of aluminum foil sales impact, low work efficiency, uneven aluminum foil, etc., and achieve good sales effect and work efficiency High and smooth winding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

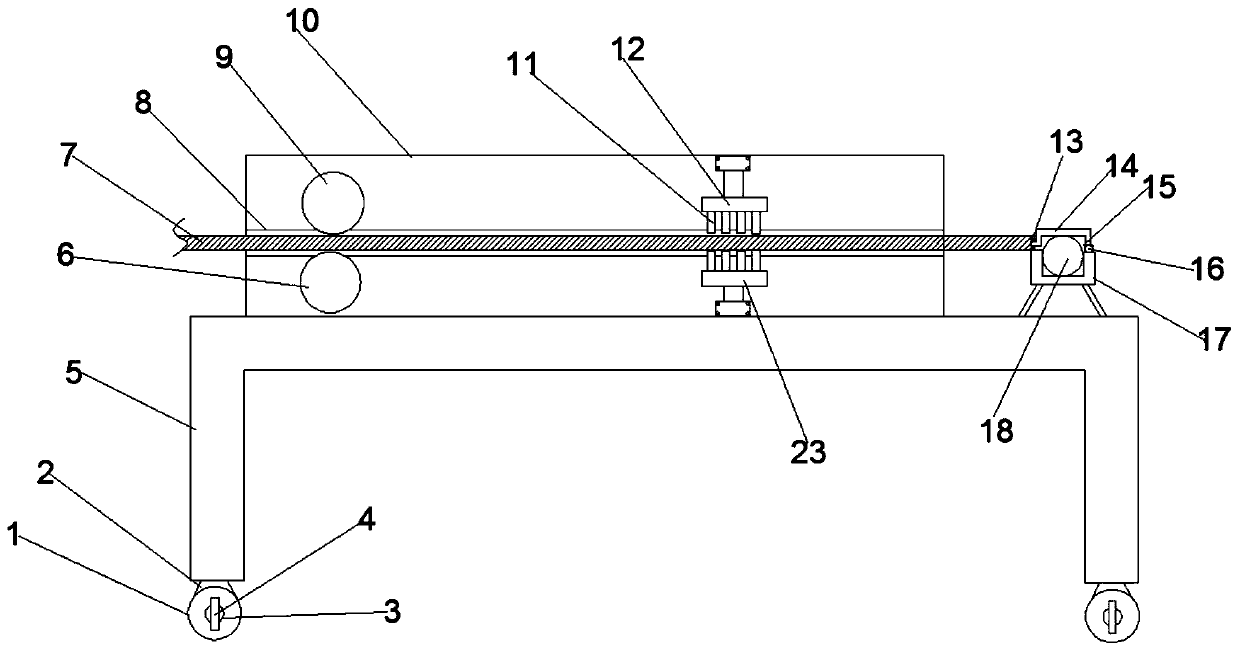

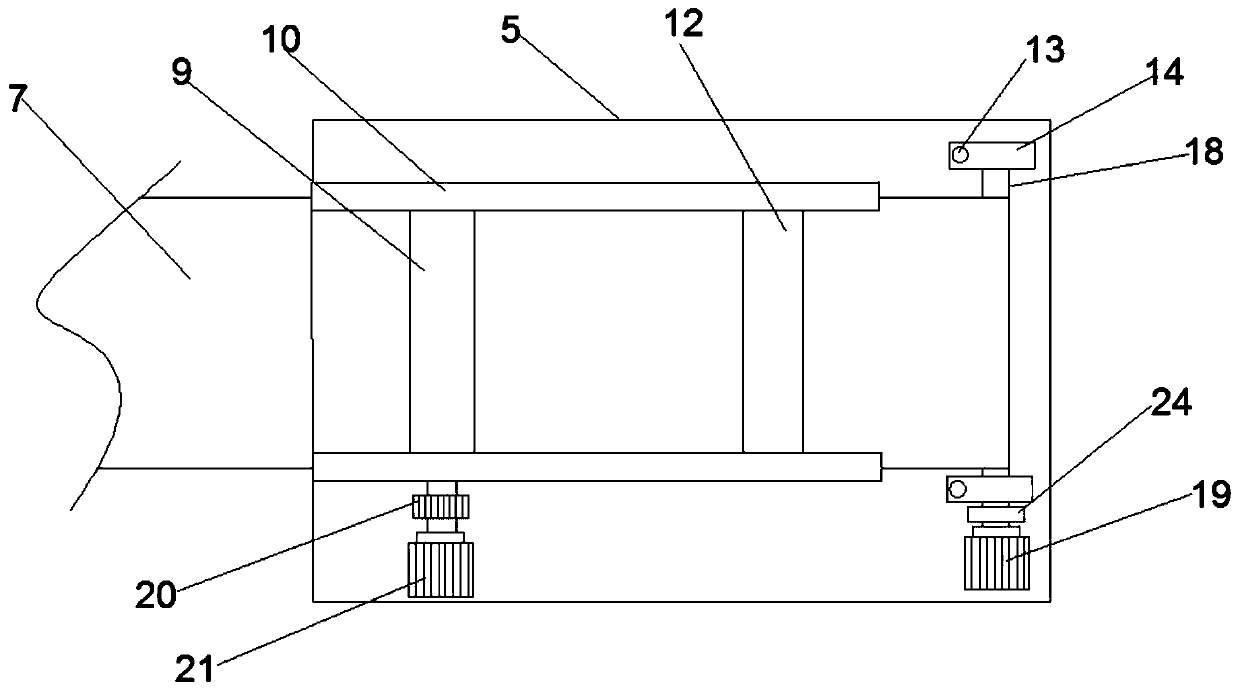

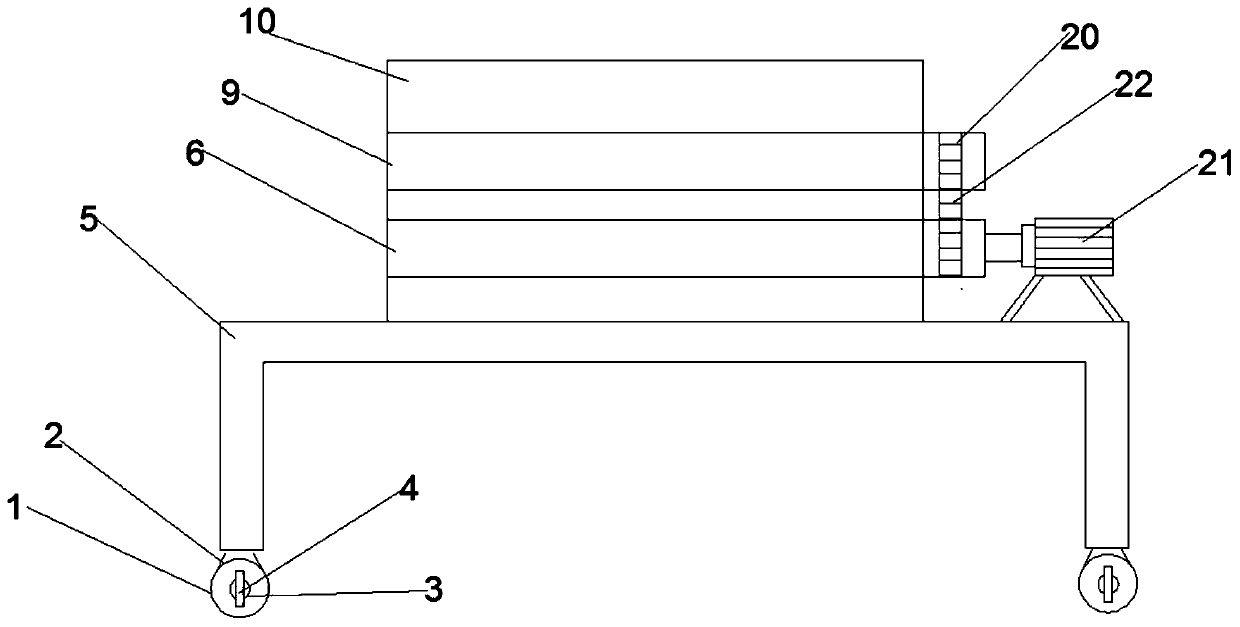

[0034] refer to Figure 1-3 , the present invention provides an aluminum foil 7 winding device, including a support frame 5, a fixing mechanism connected to the support frame 5 for installing the winding roller 18, and a fixing mechanism connected to the support frame 5 for driving the winding roller 18 to rotate The rotating mechanism, the support frame 5 is connected with a guide mechanism, the guide mechanism includes a guide plate 10 connected to the support frame 5, the guide plate 10 is provided with a guide groove 8, and the guide plate 10 is also connected with a leveling mechanism.

[0035] The working principle and process of this technical solution are as follows: when using a kind of aluminum foil 7 rewinding device in the present application, the aluminum foil 7 is passed through the guide groove 8, an adhesive is applied on the rewinding roller 18, and the aluminum foil is rolled The starting end of 7 is bonded to the winding roller 18, and then the staff turns o...

Embodiment 2

[0038] refer to Figure 1-3 , based on Embodiment 1, the leveling mechanism of this embodiment includes a first leveling roller 6 connected below the guide groove 8 and a second leveling roller 9 connected above the guide groove 8, the first leveling roller 6 and the second leveling roller The two leveling rollers 9 are connected with a driving mechanism that drives the rotation of the first leveling roller 6 and the second leveling roller 9 .

[0039] The aluminum foil 7 passes between the first leveling roller 6 and the second leveling roller 9 during the winding process, and the first leveling roller 6 and the second leveling roller 9 are driven to rotate through the driving mechanism, so that they can pass through The protruding or depressed places on the aluminum foil 7 between the first leveling roller 6 and the second leveling roller 9 can be pressed to make the passing aluminum foil 7 more smooth, the operation is simple, and the treatment effect on the aluminum foil 7...

Embodiment 3

[0041] refer to Figure 1-3 , based on Embodiment 2, the driving mechanism of this embodiment includes a gear 201 connected to the first leveling roller 6, a gear 202 connected to the second leveling roller 9, between the gear 201 and the gear 202 Connected by a gear chain 22, the second leveling roller 9 is connected with a first motor 21, the output shaft of the first motor 21 is connected with the second leveling roller 9 through a coupling, and the shell of the first motor 21 is connected to the supporting frame 5 on.

[0042] In the present application, by starting the first motor 21 by the staff, the output shaft of the first motor 21 can be rotated, so that the second leveling roller 9 connected with the output shaft of the first motor 21 is rotated, because the second leveling roller 9 It is connected with the first leveling roller 6 through the gear 20 and the gear 20 chain, so the first leveling roller 6 can be rotated while the motor drives the second leveling roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com