Rapid bolt fastening device

A fastening device and fast technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of cumbersome operation process and unfavorable work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

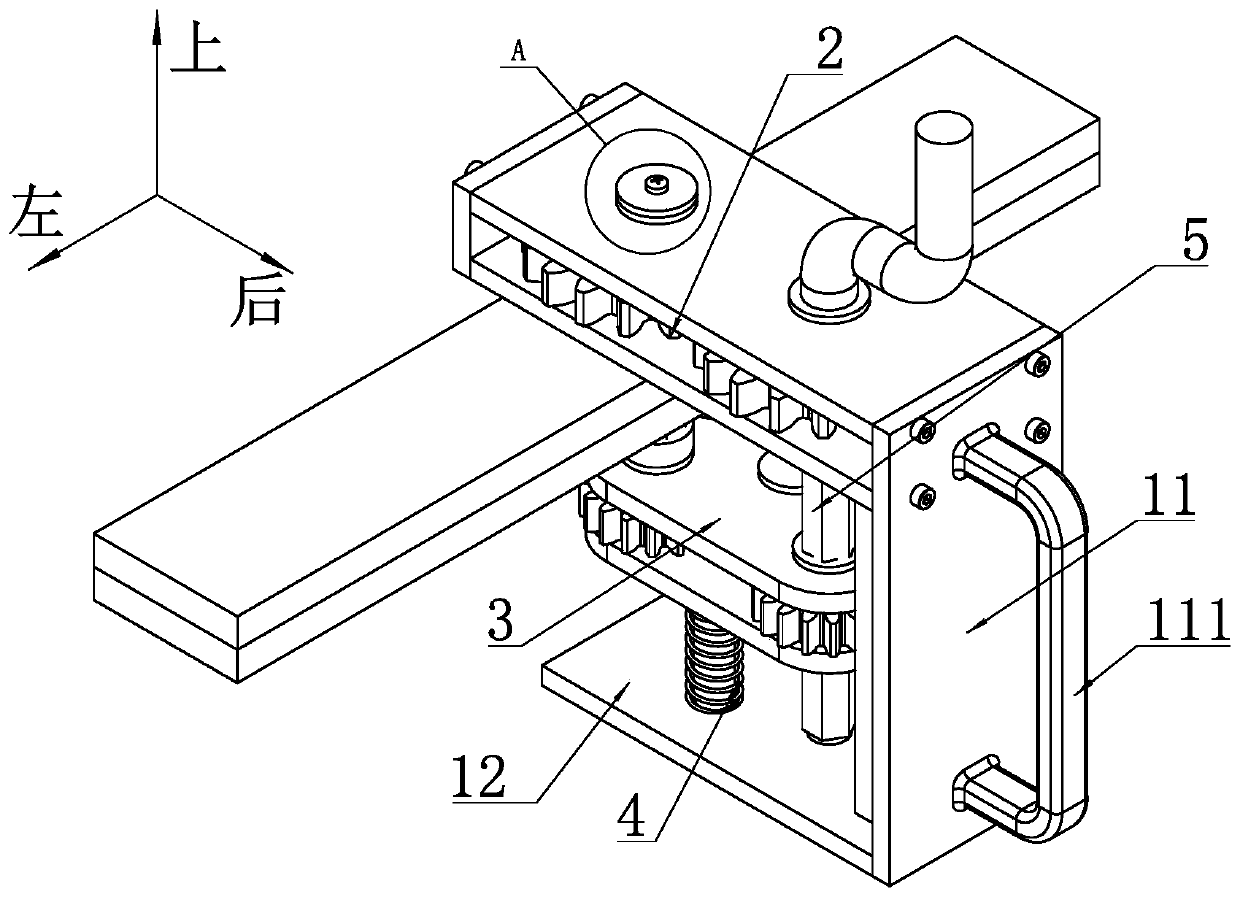

[0051] Such as figure 1 and image 3 As shown, a fast bolt fastening device includes a main frame body, the main frame body includes a riser 11, the lower end of the riser 11 is fixedly provided with a bottom plate 12 extending to the front side by welding, and the The above-mentioned riser 11 and bottom plate 12 jointly form an L-shaped structure.

[0052] An upper tightening unit 2 and a lower tightening unit 3 are sequentially arranged above the bottom plate 12 from top to bottom.

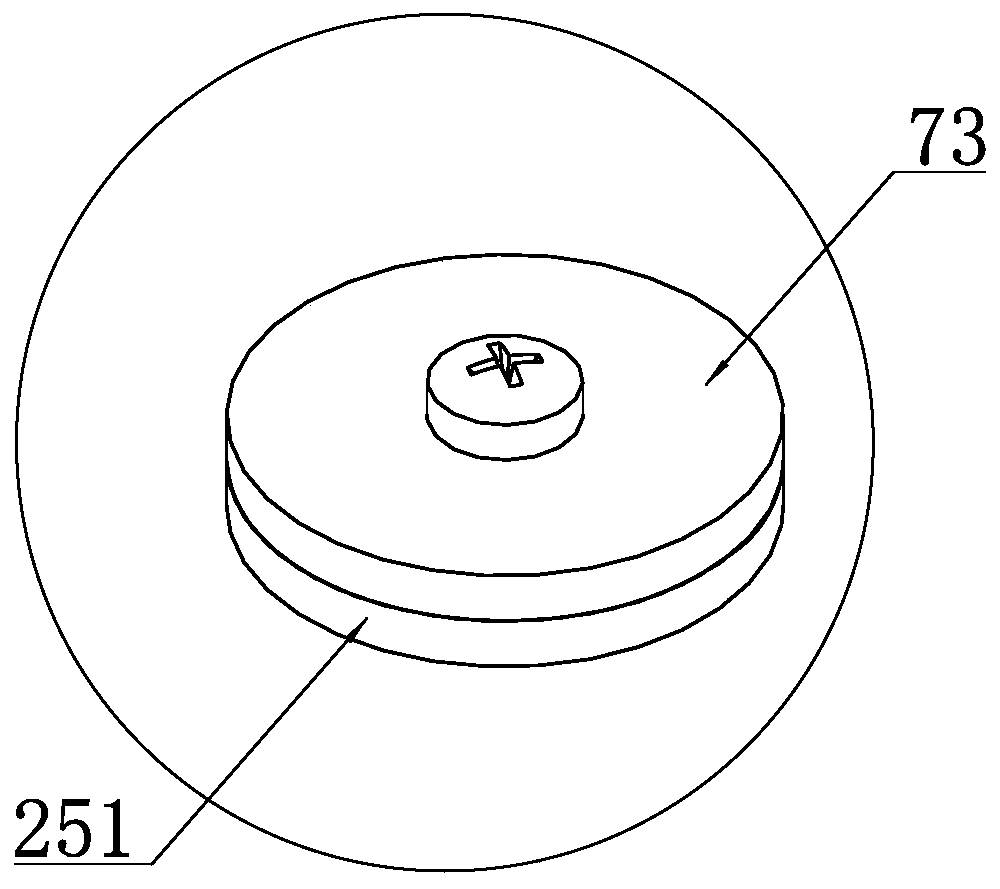

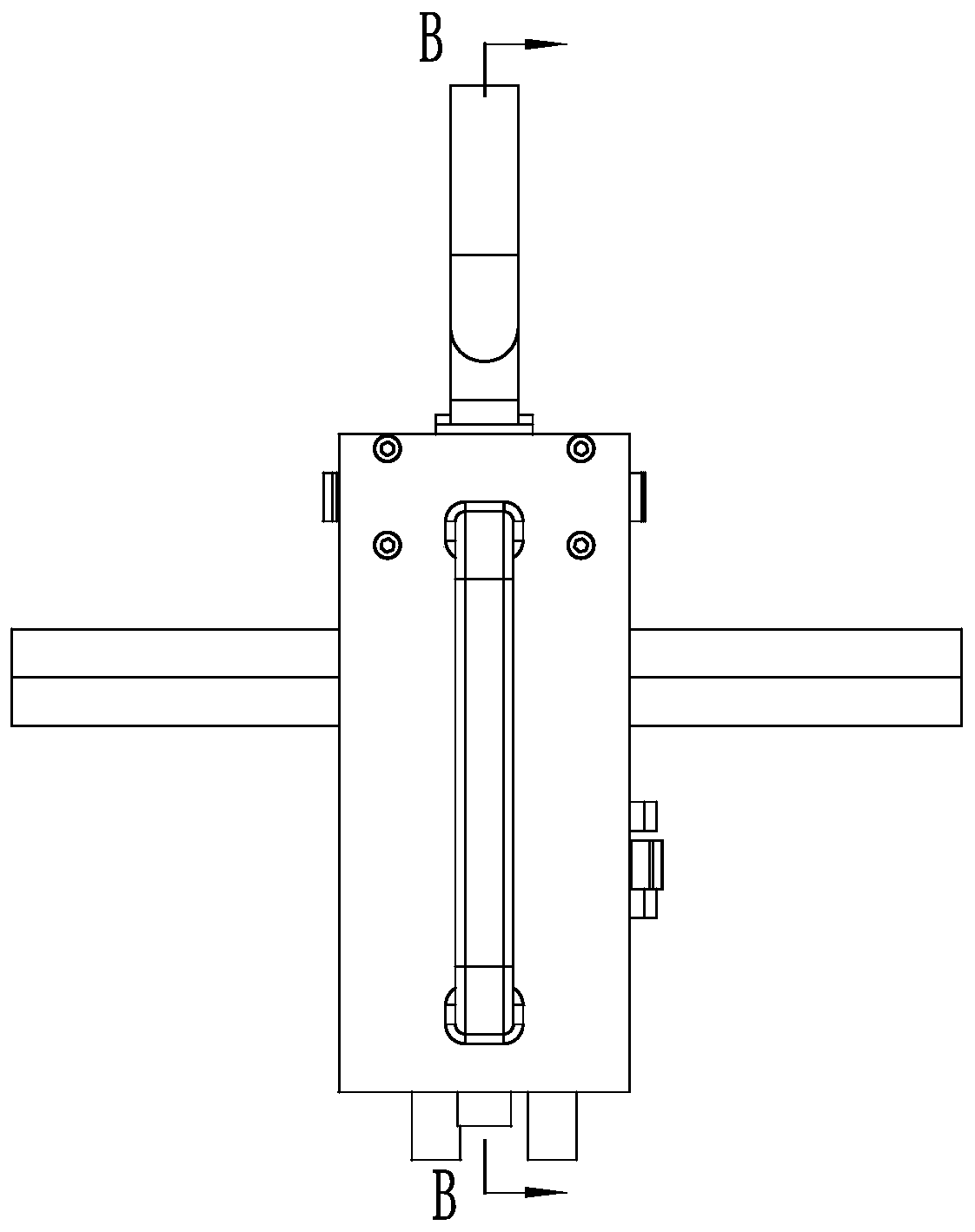

[0053] Such as figure 1 , Figure 6 and Figure 11 As shown, the upper screwing unit 2 sequentially includes a first upper horizontal plate 21 and a second upper horizontal plate 22 from top to bottom, and the rear ends of the first upper horizontal plate 21 and the second upper horizontal plate 22 They are respectively fixedly connected with the above-mentioned risers 11 by screws. Between the first upper horizontal plate 21 and the second upper horizontal plate 22, an upper driving gear ...

Embodiment 2

[0069] A connecting shaft is arranged between the first rotating shaft 241 and the third rotating shaft 331, and the upper end of the connecting shaft is fixedly connected with the first rotating shaft 241. The third rotating shaft 331 is provided with a through hole matched with the connecting shaft, the lower tightening unit can slide up and down along the connecting shaft, and the through hole is connected with the connecting shaft. The shaft cooperates to limit the relative rotation between the connecting shaft and the lower driving gear. A concave portion is disposed on the upper end surface of the first rotating shaft 241 . The top of the upper driving gear 24 is provided with a drive handle, the drive handle is L-shaped, and the suspended end of the horizontal part of the drive handle is provided with a raised portion matched with the concave portion, and the The cooperation between the above-mentioned recessed part and the raised part restricts the relative rotation b...

Embodiment 3

[0071] A connecting shaft is arranged between the first rotating shaft 241 and the third rotating shaft 331, and the upper and lower ends of the connecting shaft are fixedly connected to the first rotating shaft 241 and the third rotating shaft 331 respectively. The first upper horizontal plate 21 is provided with a motor mounting frame, and a torque motor is fixedly arranged on the motor mounting frame, the output shaft of the torque motor is fixedly connected with the first rotating shaft 241, and the rest of the structure is the same as Embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com