Industrial truck having a control unit for regulating the movement of a hydraulic cylinder, and method for controlling the same

A technology for controlling units and trucks, which is applied to fluid pressure actuating devices, hoisting devices, servo motors, etc., and can solve the problems of inaccurate speed adjustment of hydraulic systems, deviations between the actual movement speed of the load and the expected movement speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

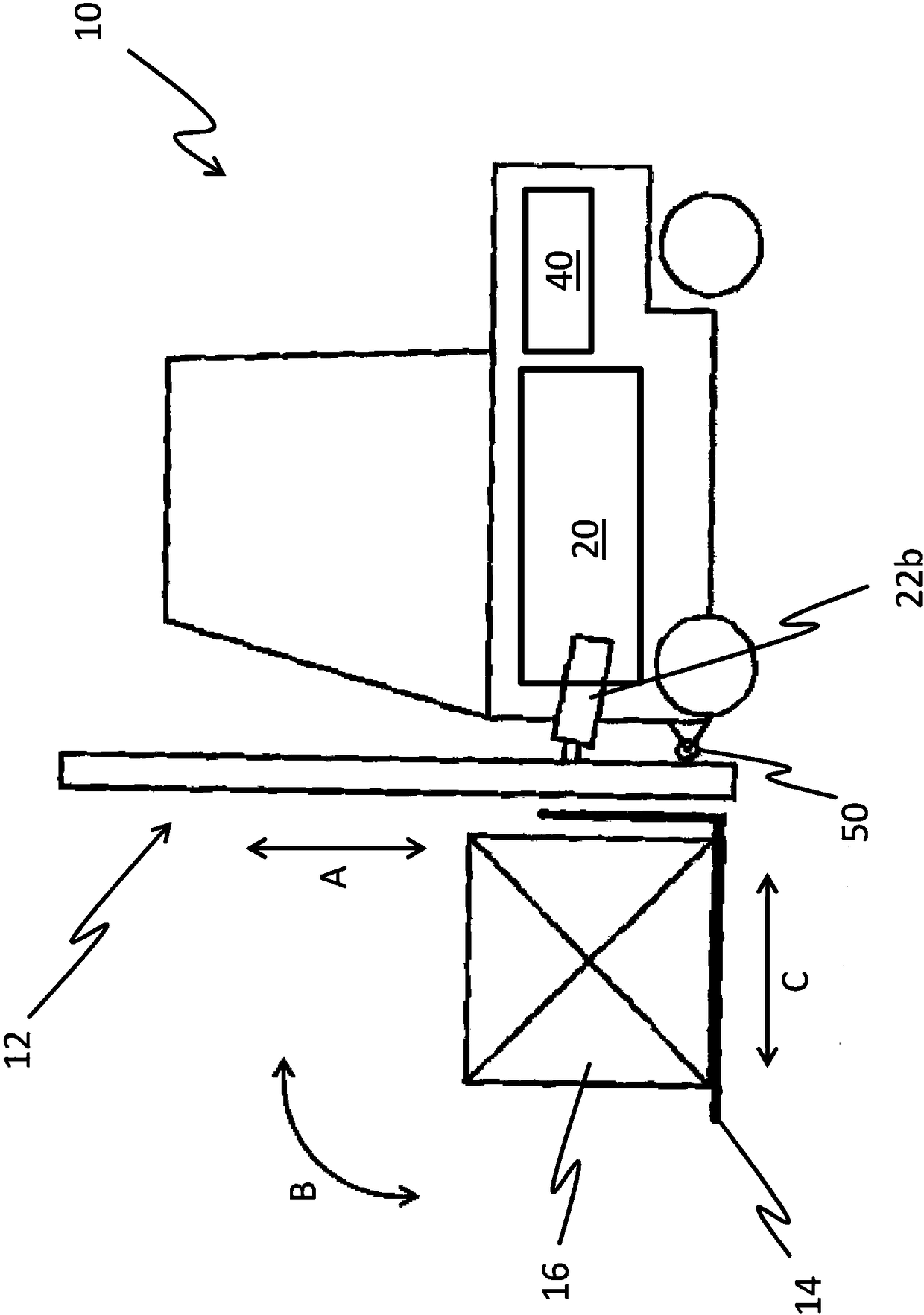

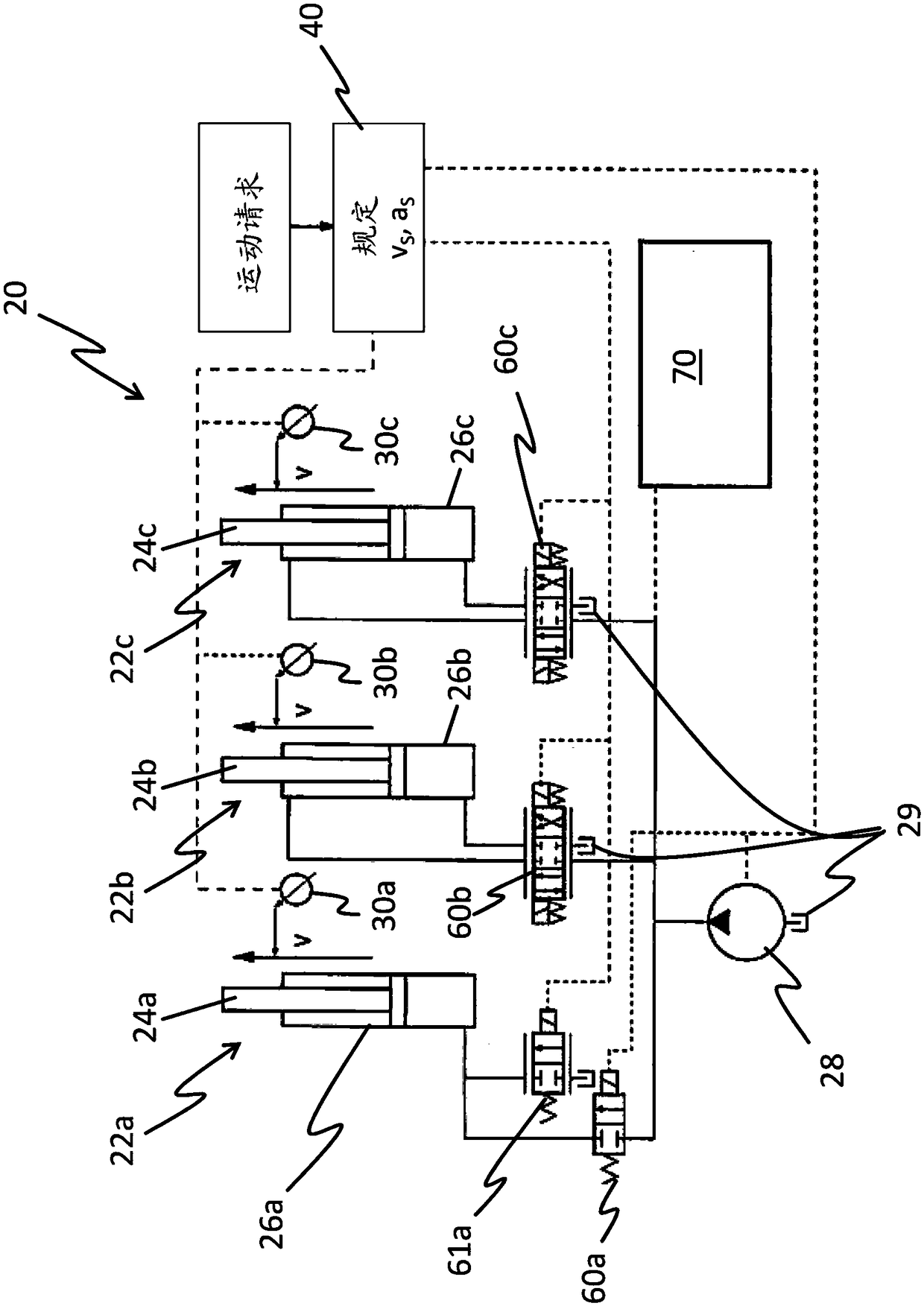

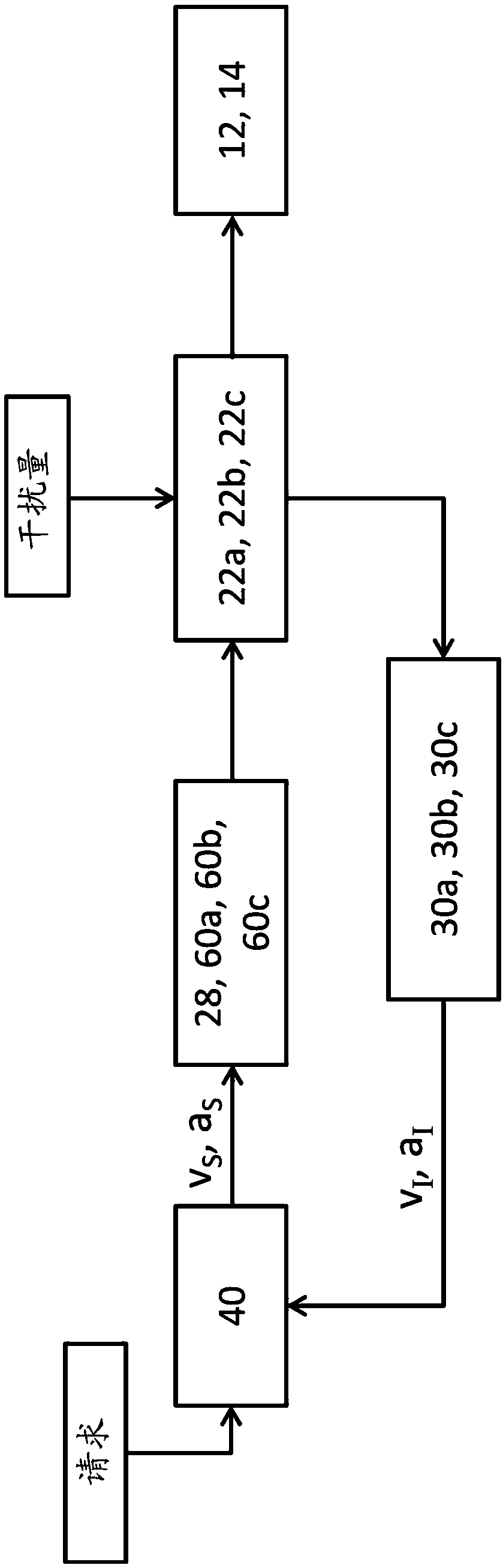

[0019] figure 1 A design of the truck 10 according to the invention is shown. The lifting frame 12 with the load-bearing part 14 is visible, as well as the hydraulic system 20 and the control unit 40 . exist figure 1 The hydraulic system 20 shown in includes a tilt cylinder 22b as a hydraulic cylinder. In order to measure the velocity or acceleration of the piston rod of the tilt cylinder 22b, said tilt cylinder 22b has figure 2 The sensor shown in. The entire lifting frame 12 can be tilted in the direction of movement marked with B by means of the tilting cylinders 22b. Furthermore, the truck can have one or more lifting cylinders for raising and lowering the lifting frame 12 or the load-bearing part 14 in the direction of movement marked with A. FIG. The truck can also have one or more push cylinders for moving the lifting frame 12 or the load-bearing part 14 in the direction of movement marked C. In addition, in figure 1 A deformation sensor for detecting the bendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com