New type series-parallel connection jogging robot

A robot and micro-displacement driver technology, applied in the direction of manipulators, manufacturing tools, etc., can solve problems such as complex structure and difficult motion analysis, and achieve the effect of high motion resolution, expanded application field, and less transmission levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

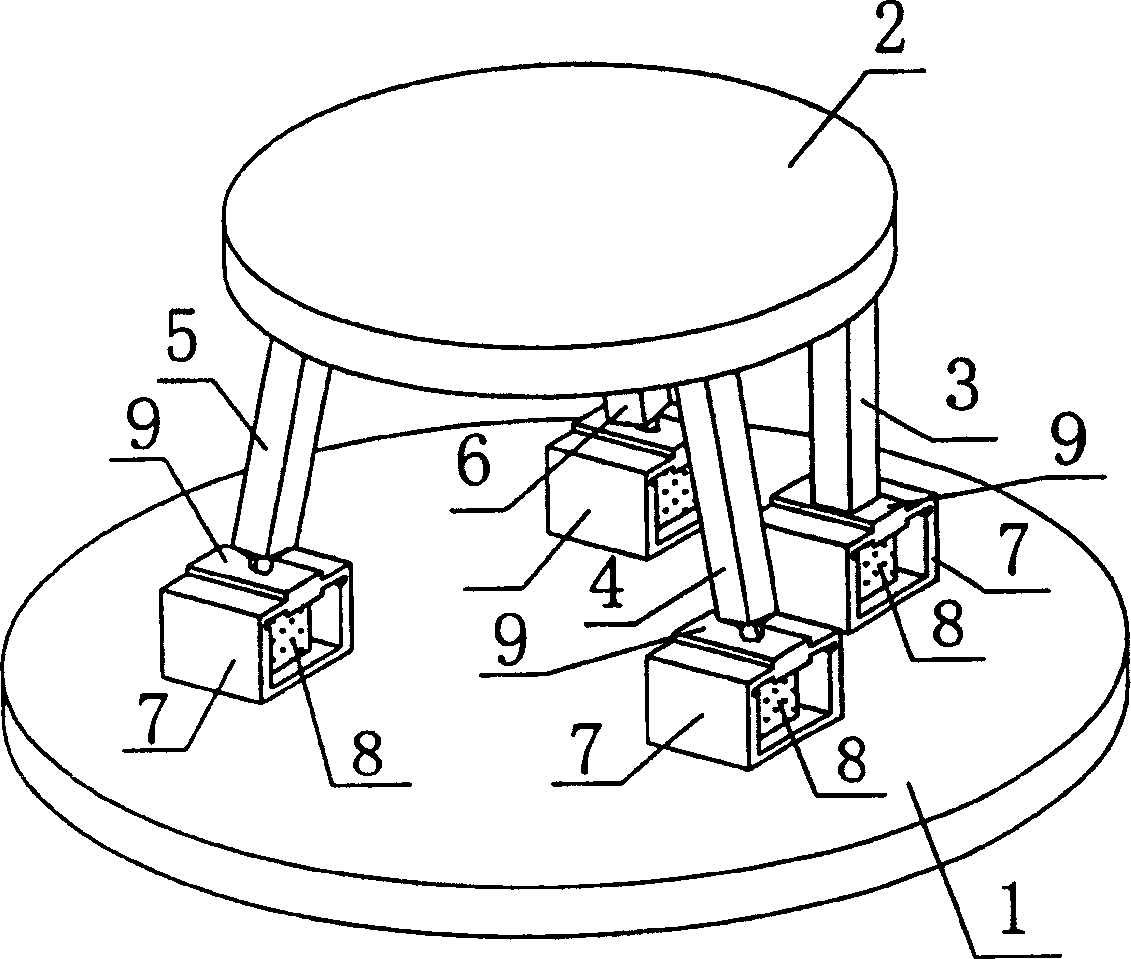

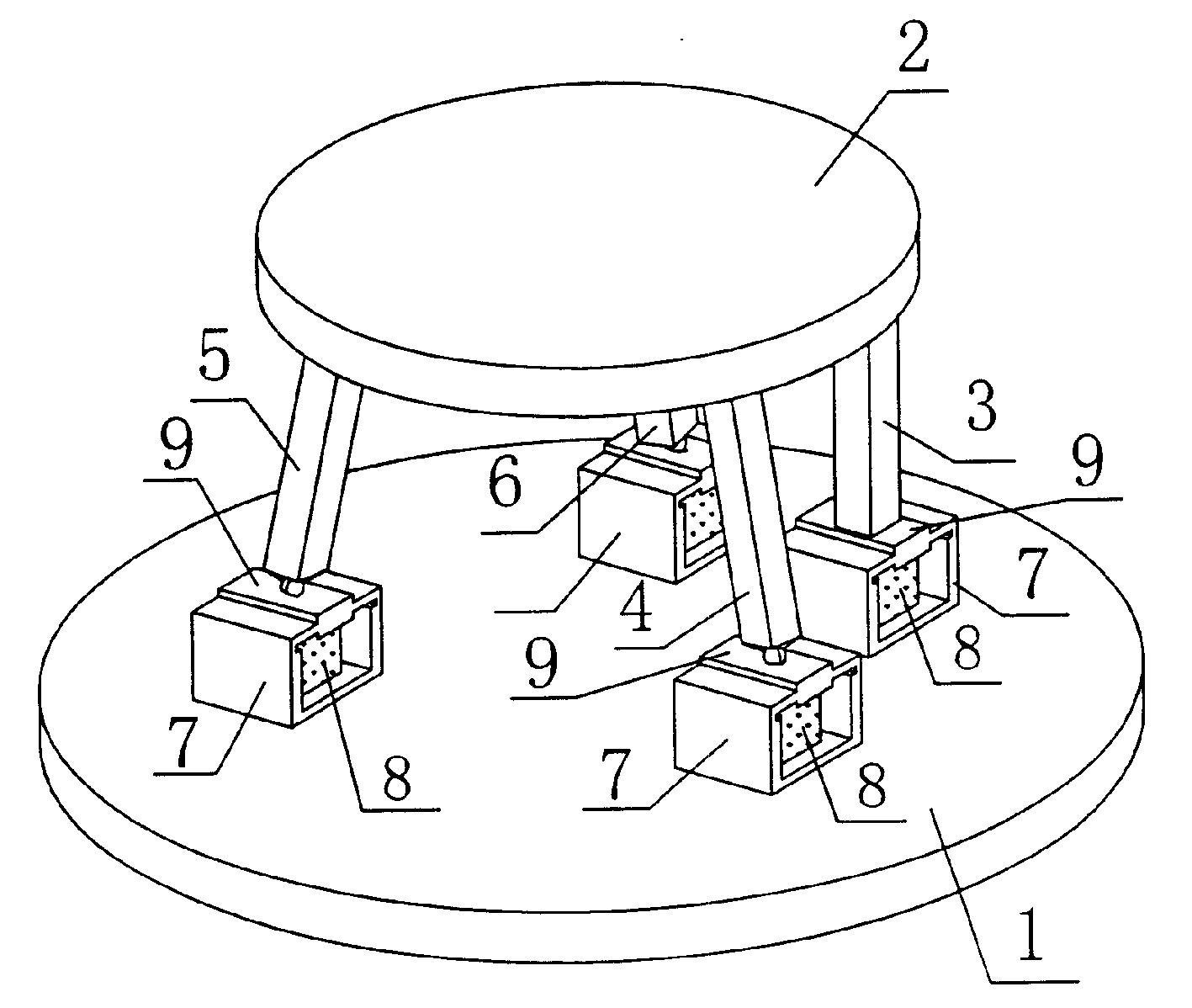

[0016] structure as attached figure 1 As shown, it is a four-degree-of-freedom hybrid micro-robot, which consists of a base 1, a workbench 2, fixed length rods 3, 4, 5, 6, and a piezoelectric ceramic micro-displacement device 8. The base 1 and the workbench 2 They are connected by four fixed-length rods, one end of one fixed-length rod 3 is directly connected with the base 1 through the flexible moving pair of parallel plates, and the other end is directly connected with the workbench 2 through a flexible ball joint; the other three fixed-length rods One end of the long rods 4, 5, 6 is connected to the flexible moving pair of the parallel plate through a flexible Hooke hinge, and the other end is connected to the workbench 2 through a spherical hinge. The positioning seat is rigidly positioned on the base, thereby constituting the body of the micro-motion robot with the base, and is processed and formed at one time. The piezoelectric ceramic micro-displacement driver 8 is loc...

Embodiment 2

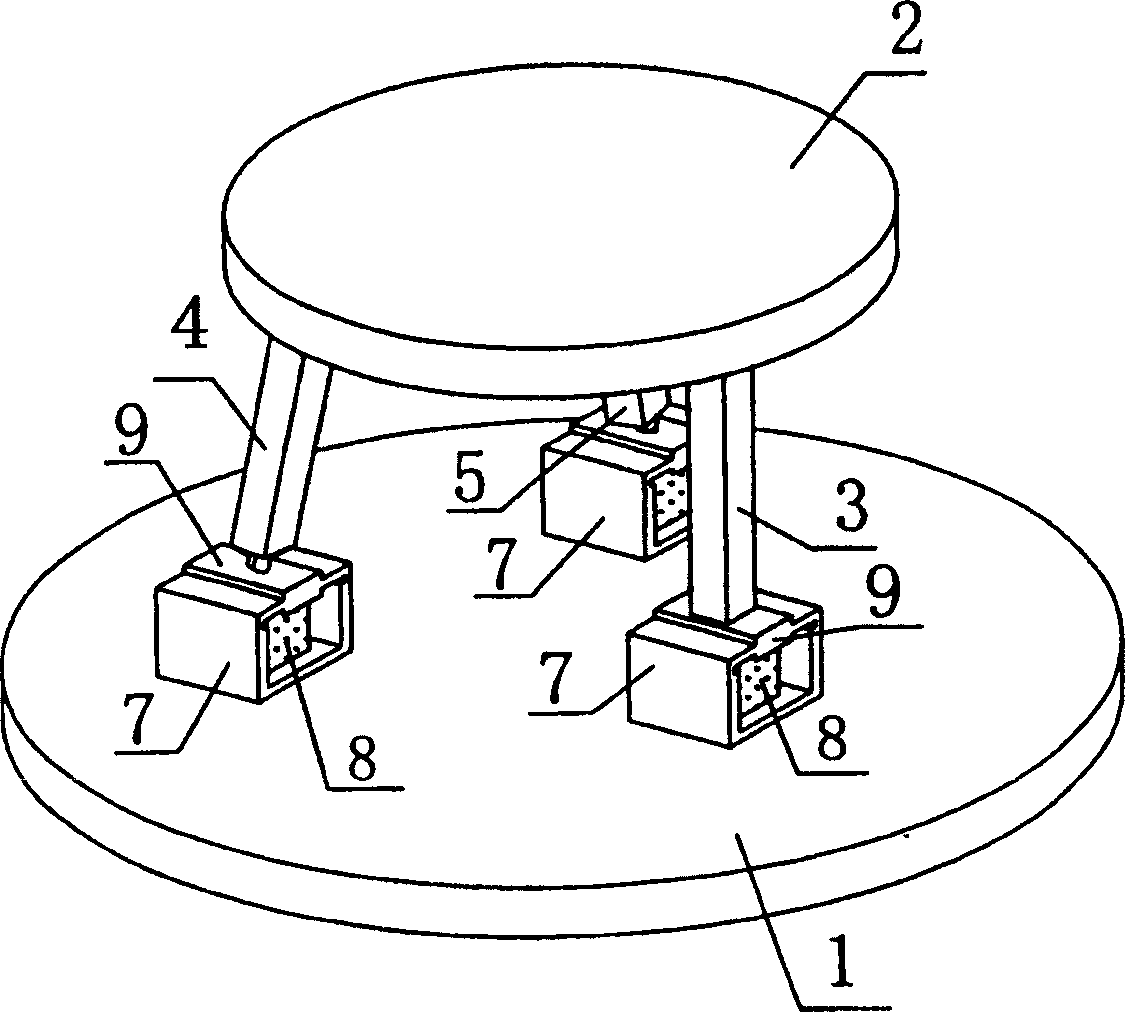

[0018] structured as figure 2 As shown, it is a three-degree-of-freedom hybrid micro-motion robot, which is composed of a base 1, a workbench 2, a fixed length rod 3, 4, 5, and a piezoelectric ceramic micro-displacement device 8. The base 1 and the workbench 2 They are connected by three fixed-length rods, one end of one fixed-length rod 3 is connected with the base 1 through the flexible moving pair of parallel plates, and the other end is connected with the workbench 2 through a flexible Hooke hinge; the other two fixed-length rods One end of the rods 4 and 5 is connected with the flexible moving pair of the parallel plate through a flexible ball joint, and the other end is connected with the workbench 2 through a flexible ball joint. The three fixed-length rods all adopt piezoelectric ceramic micro-displacement drivers, and the drivers are arranged at one end of the fixed-length rods connected with the base.

[0019] The position layout of the fixed-length bar in embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com