Precise motion driving device based on bionics principle

A driving device and precision motion technology, which is applied in the field of geometric measurement, can solve the problems of inability to realize large-scale high-precision scanning, inability to realize ultra-fine and smooth motion in the range of motion, and difficulty in combination, and achieve simple structure and high motion resolution , the effect of a large range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

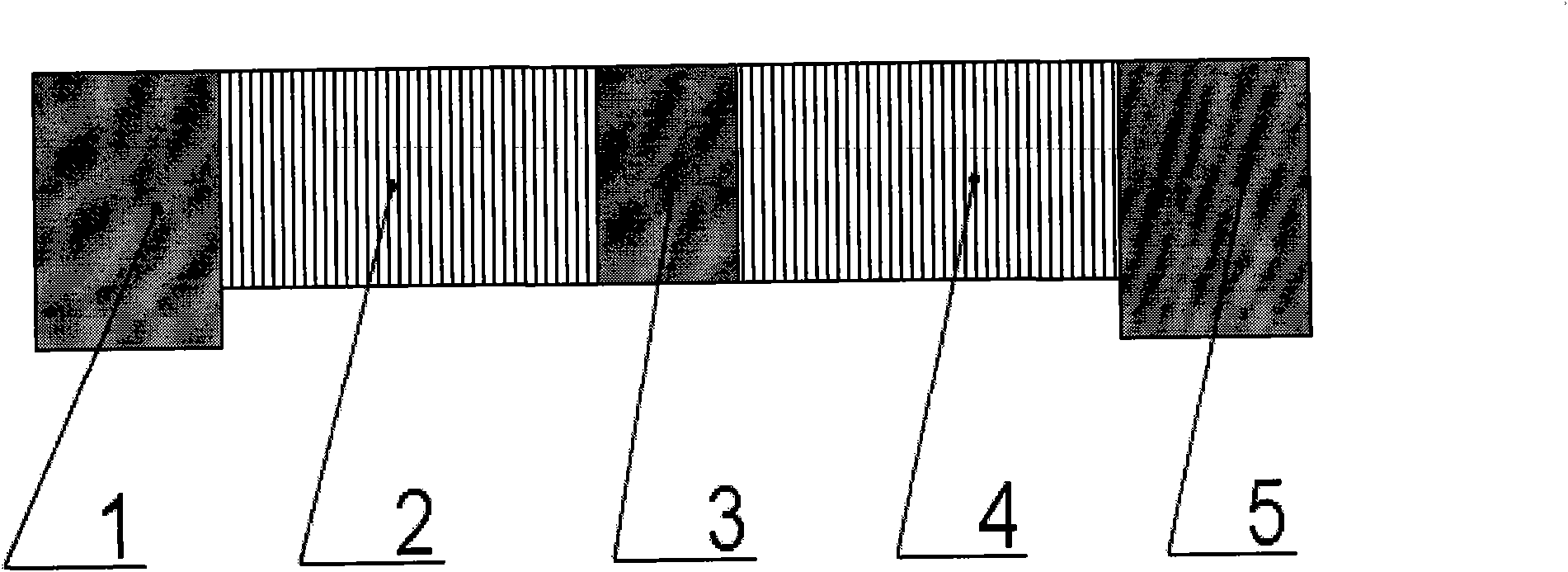

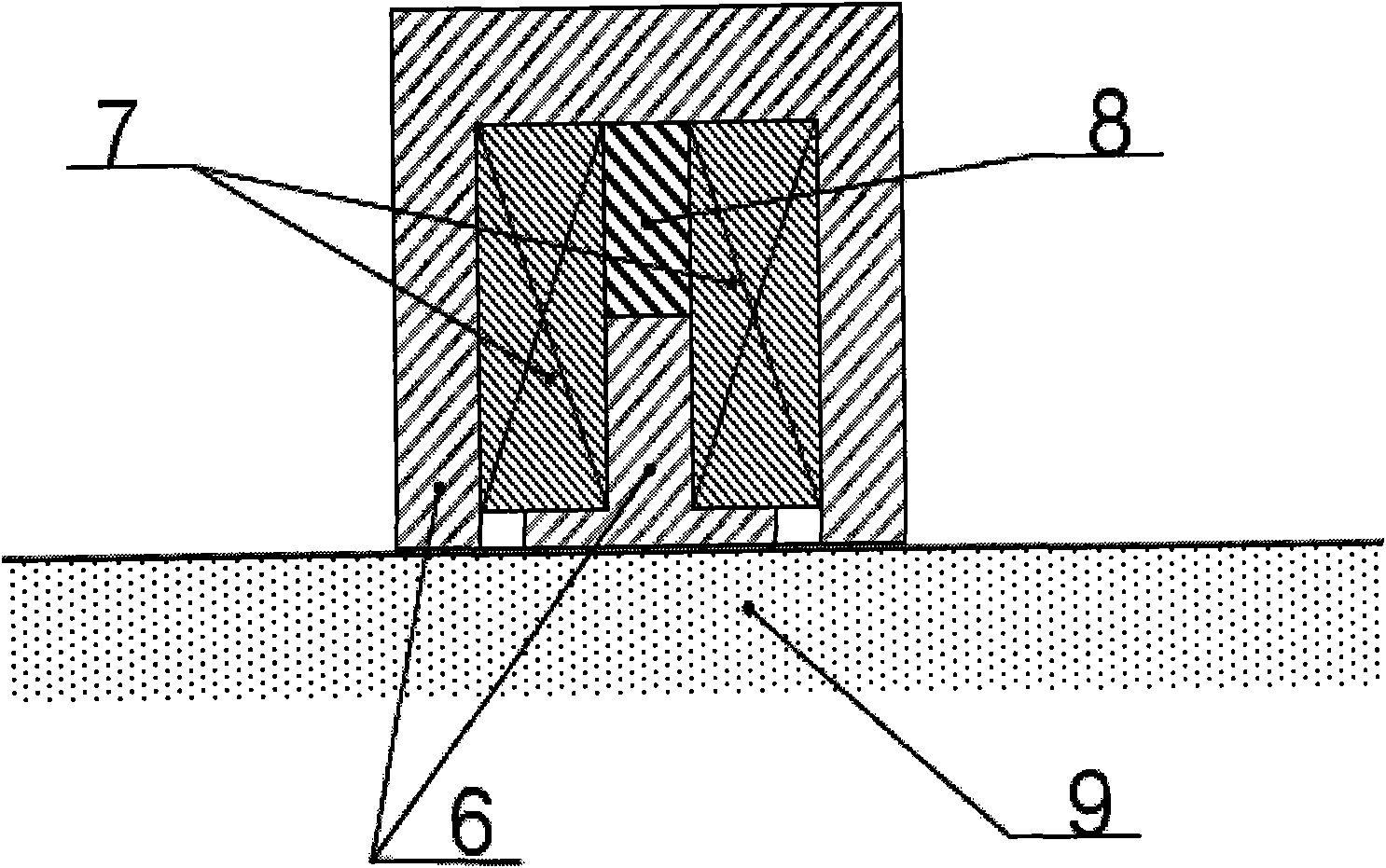

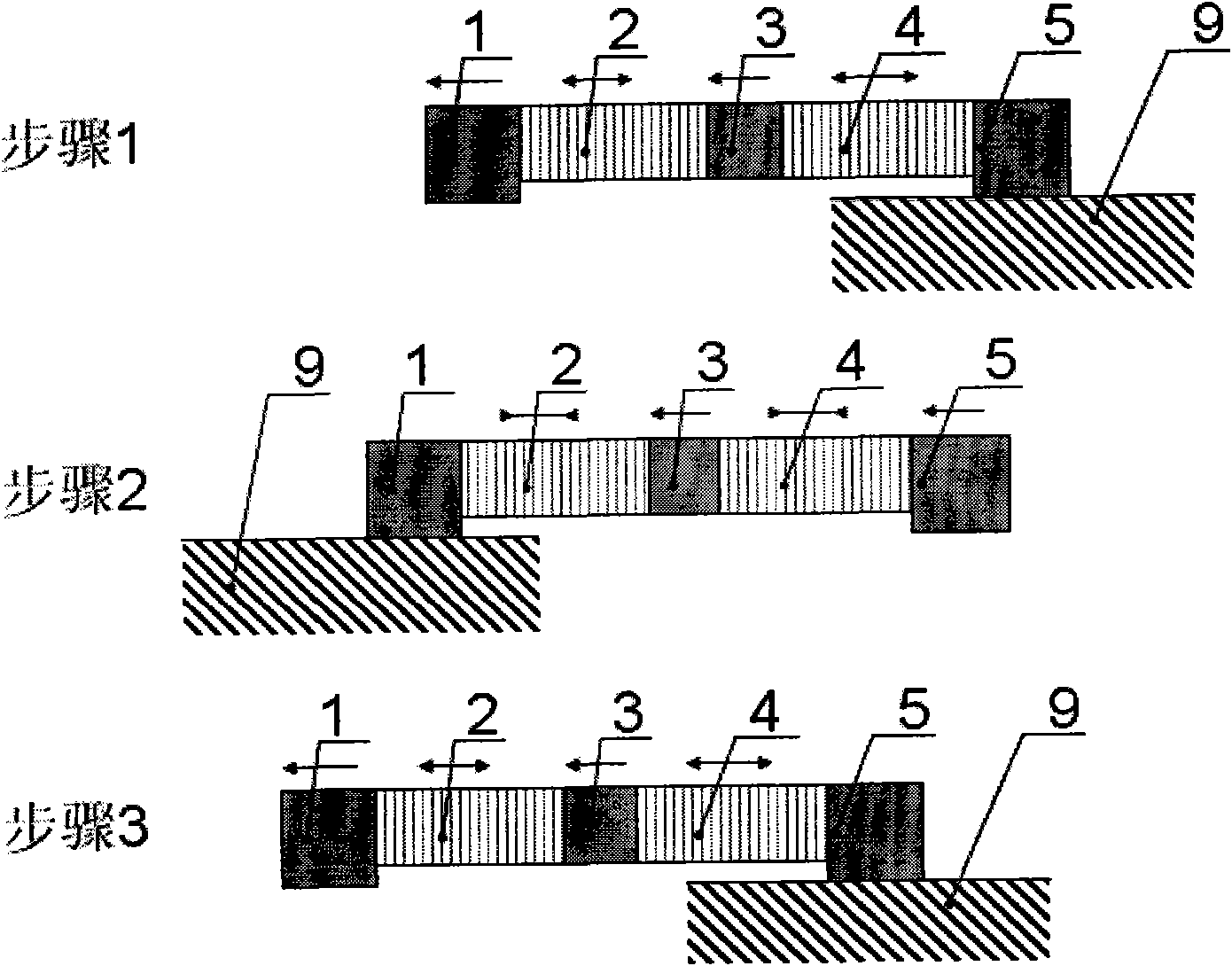

[0034] A precision motion drive device based on the principle of bionics, such as figure 1 As shown, it consists of a front suction cup, a front piezoelectric ceramic micro-displacement drive element, a motion output fulcrum, a rear piezoelectric ceramic micro-displacement drive element, and a rear suction cup, and its peripheral equipment is an iron soft magnetic magnetic plate for a fixed drive device;

[0035] The front suction cup, the front piezoelectric ceramic micro-displacement drive element, the motion output fulcrum, the rear piezoelectric ceramic micro-displacement drive element, and the rear suction cup are arranged in a straight line, and the front piezoelectric ceramic micro-displacement drive element and the rear piezoelectric ceramic micro-displacement drive element The direction of motion is also on this straight line;

[0036] One end of the front piezoelectric ceramic micro-displacement drive element and one end of the rear piezoelectric ceramic micro-displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com