High-performance modified polyamide composite material and preparation method thereof

A composite material and polyamide technology, applied in the field of materials science, can solve problems such as poor compatibility, and achieve the effects of improving toughness, improving appearance, and good anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

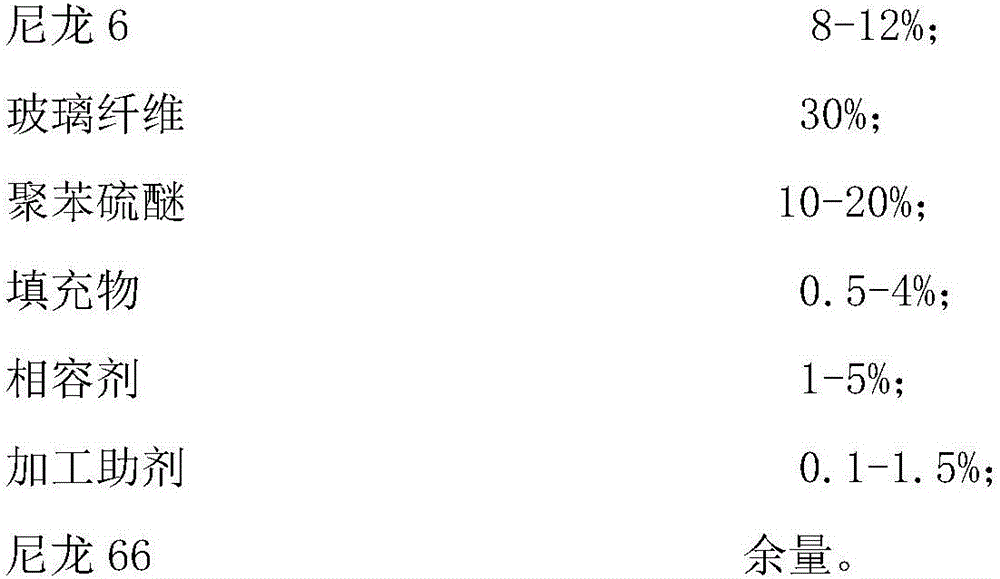

Method used

Image

Examples

Embodiment 1~4

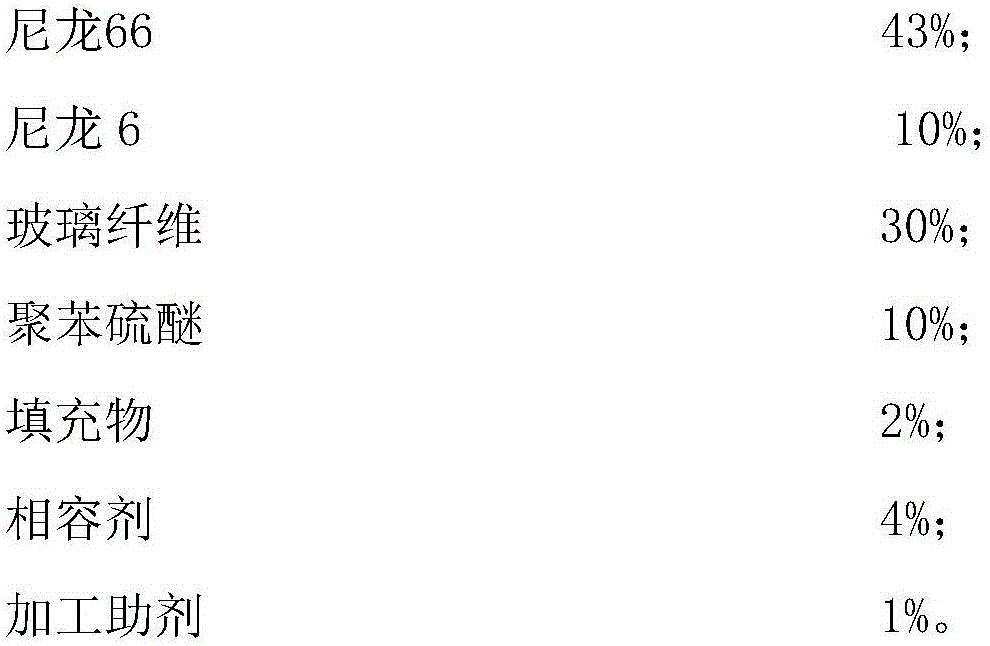

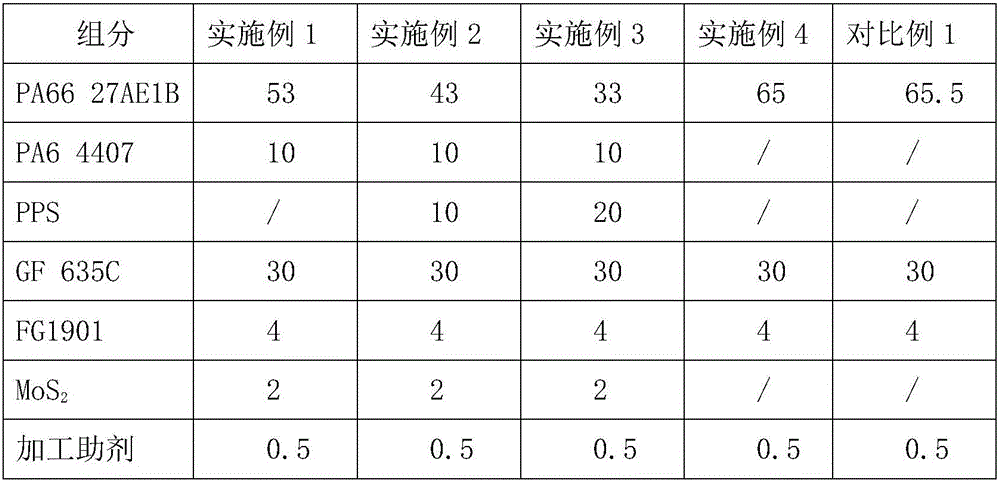

[0030] The parts by weight of each raw material are shown in Table 1, and the test samples were processed and prepared according to the process in Comparative Example 1. (The following raw materials are all commercially available raw materials)

[0031] Table 1 Raw material weight percentage proportioning of embodiment 1~4

[0032]

[0033]

[0034] Composition property test result in table 2 embodiment and comparative example

[0035] Performance

Embodiment 1

[0036] Comparing Example 1 with Comparative Example 1, it can be seen that the addition of PA6 can improve the impact strength of the material. Comparing Example 2 with Comparative Example 1, it can be seen that the addition of PPS can improve the thermal deformation, tensile and bending strength of the material. Comparing Example 3 with Example 2, it can be seen that with the increase of PPS, the tensile bending of the material increases, and the impact strength decreases. Comparing Example 4 with Comparative Example 1, it can be seen that the addition of VTECNSF600 can increase the flow rate of the material, the mechanical properties will decrease, and the thermal properties will not be affected. Optimum formula of the present invention is embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com