Camera calibration method for optical surface shape measurement and device for realizing method

A camera calibration and optical surface technology, applied in the field of precision engineering, can solve problems such as deviation of light position and direction, influence of measurement accuracy, etc., to achieve the effect of improving calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will now be described in further detail in conjunction with the accompanying drawings and embodiments.

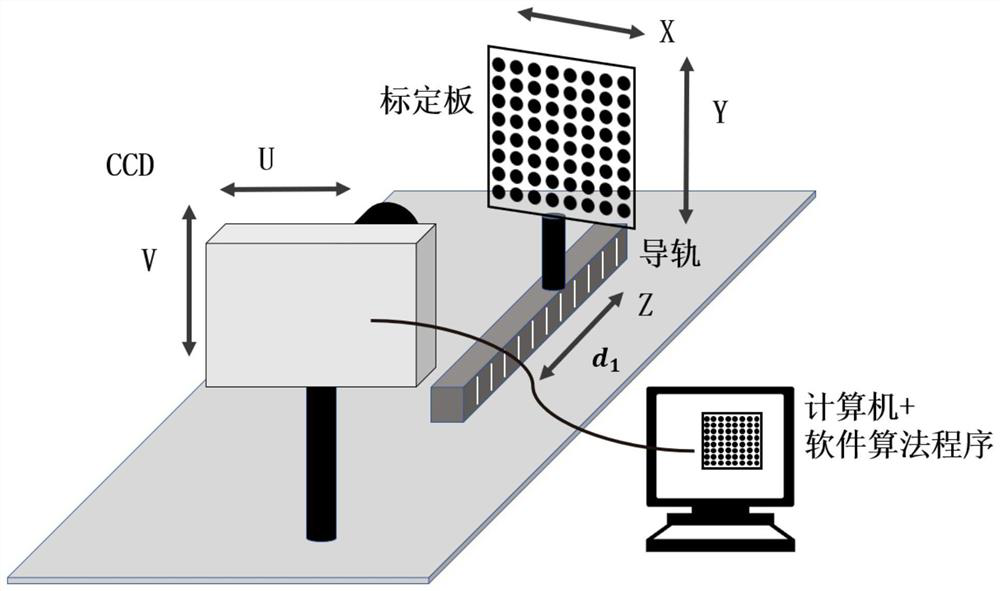

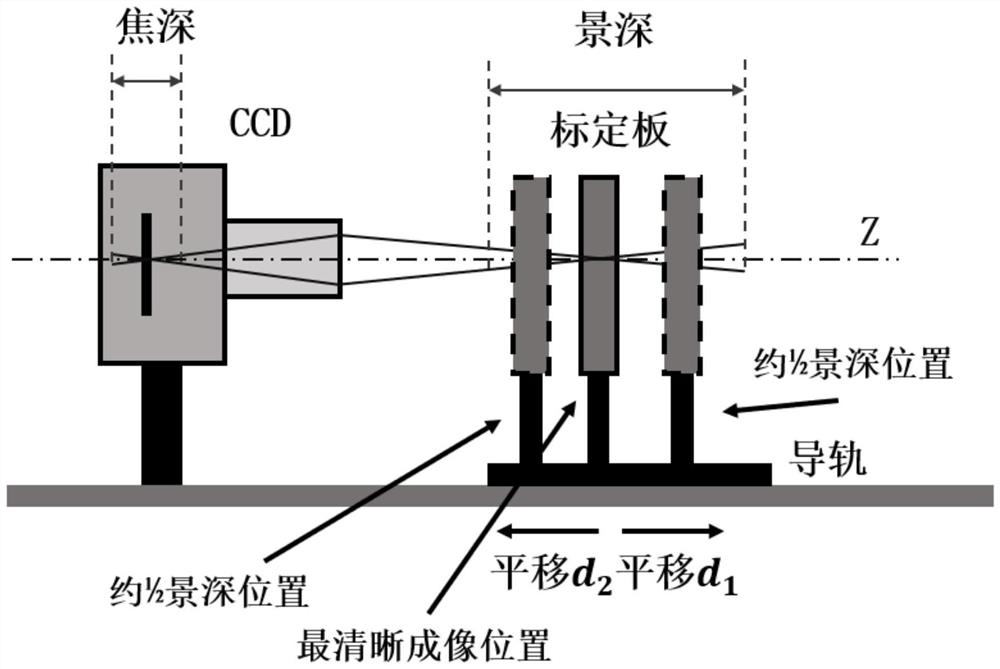

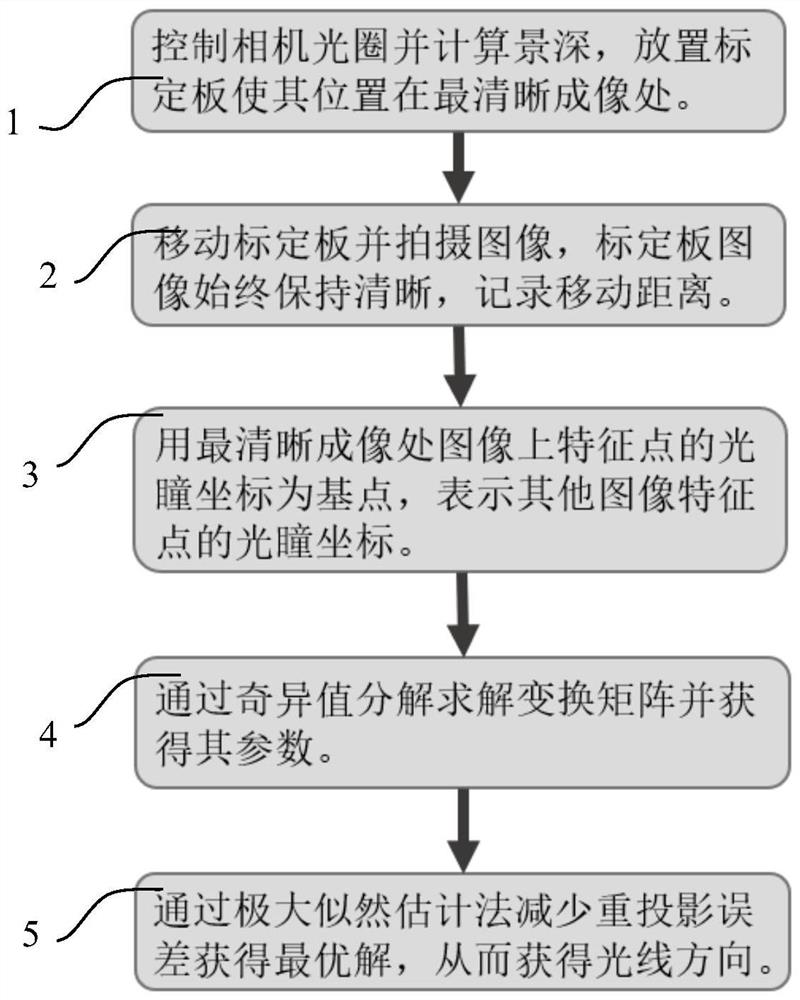

[0017] Such as figure 1 , figure 2 Shown is the schematic diagram of the structure of the calibration device of the present invention, from which it can be seen that the optical path of the experimental equipment, the camera is a small pupil camera, and the image is taken after moving the calibration plate in parallel, see Figure 4 ; image 3 It is a flowchart of the calibration process of the present invention, including the following steps:

[0018] Step 1. Control the camera aperture and calculate the depth of field, and place the calibration plate so that it is at the clearest image;

[0019] Step 2, move the calibration plate and take images, the image of the calibration plate is always clear, record the moving distance;

[0020] Step 3, use the pupil coordinates of the feature points on the image at the clearest imaging point as the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com