Fabrication method of forced centering observation pillar for precision engineering measurement and observation pillar

A technology of forced centering and precision engineering, which is applied in the direction of measuring point marking, infrastructure engineering, sheet pile wall, etc. Inconvenient engineering measurement and other problems, to achieve the effect of simple manufacturing and embedding method, reliable observation accuracy, and reducing centering error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

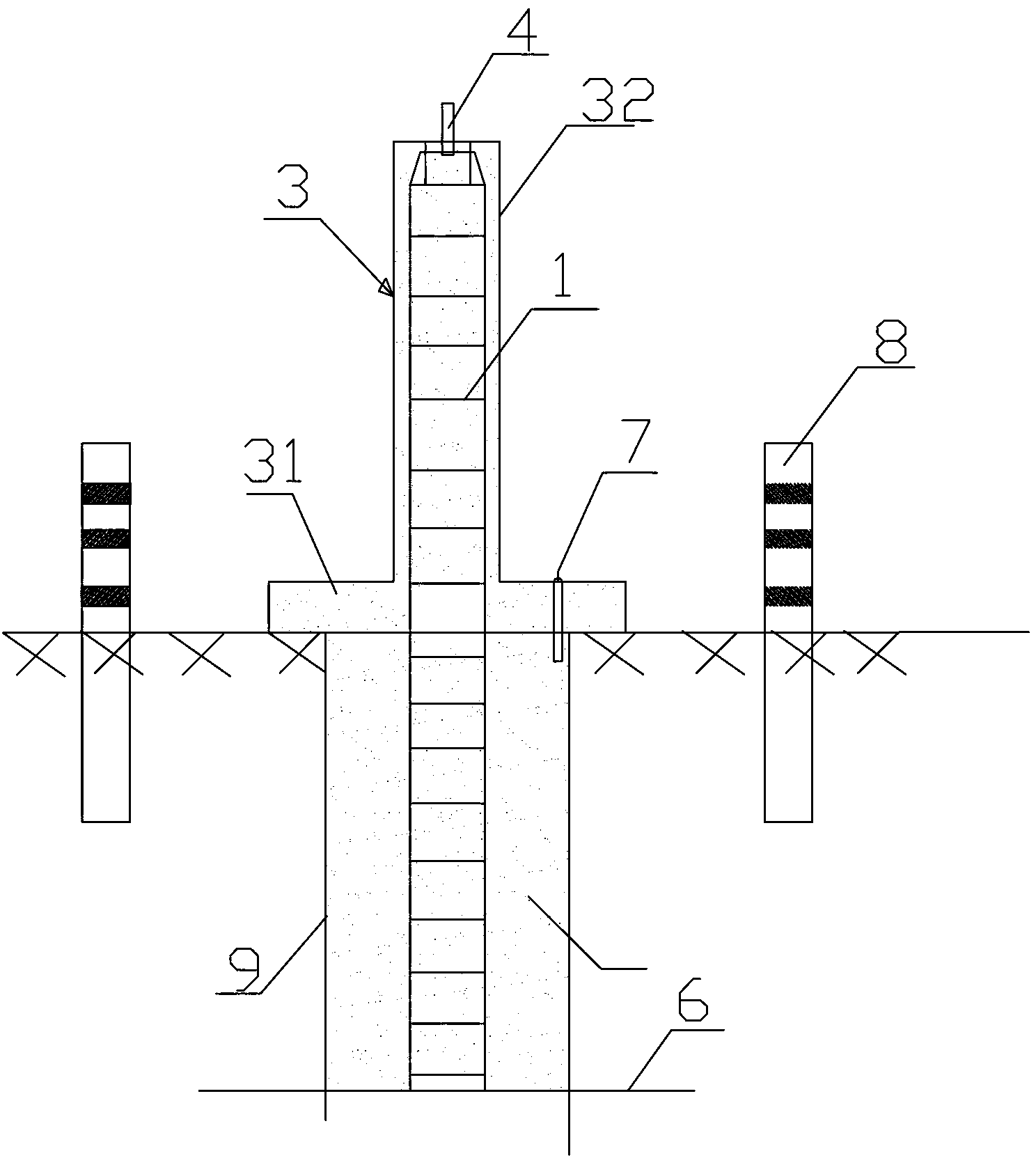

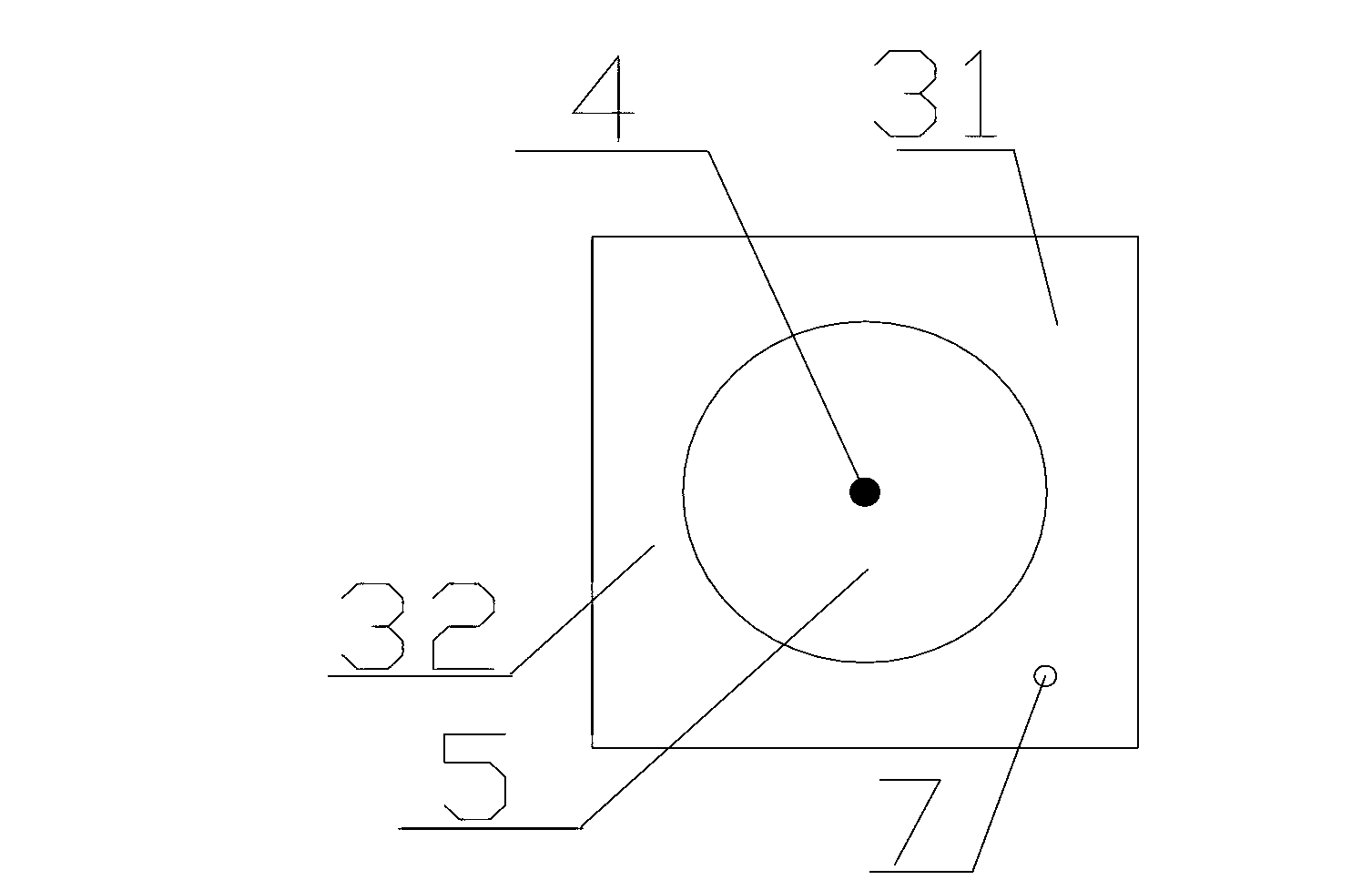

[0030] The manufacturing method of the forced centering observation pier and the observation pier for precision engineering measurement of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

[0031] The manufacturing and embedding method of the forced centering observation pier used for precision engineering measurement of the present invention is as follows: figure 1 , figure 2 shown, including the following steps:

[0032] 1) Manually excavate the pile hole 9, and dig down to the bedrock 6; in the process of manually digging the pile hole 9, it is necessary to control the verticality of the pile hole 9, check the quality of the pile hole, clean up the virtual soil in the pile hole 9, and remove the pile hole 9 stagnant water.

[0033] 2) Hang the reinforcement cage 1 into the pile hole 9. The bottom of the reinforcement cage 1 should be placed on the bedrock 6, and a steel reinforcement cage 1 with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com