Multifunctional optical quality detector

A technology of optical quality and detection devices, which is applied in the field of optical components, can solve problems such as the inability to measure local errors of components, the inability to detect error information, and the difficulty in obtaining error information, etc., to achieve short measurement time, low manufacturing accuracy, and low manufacturing accuracy requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

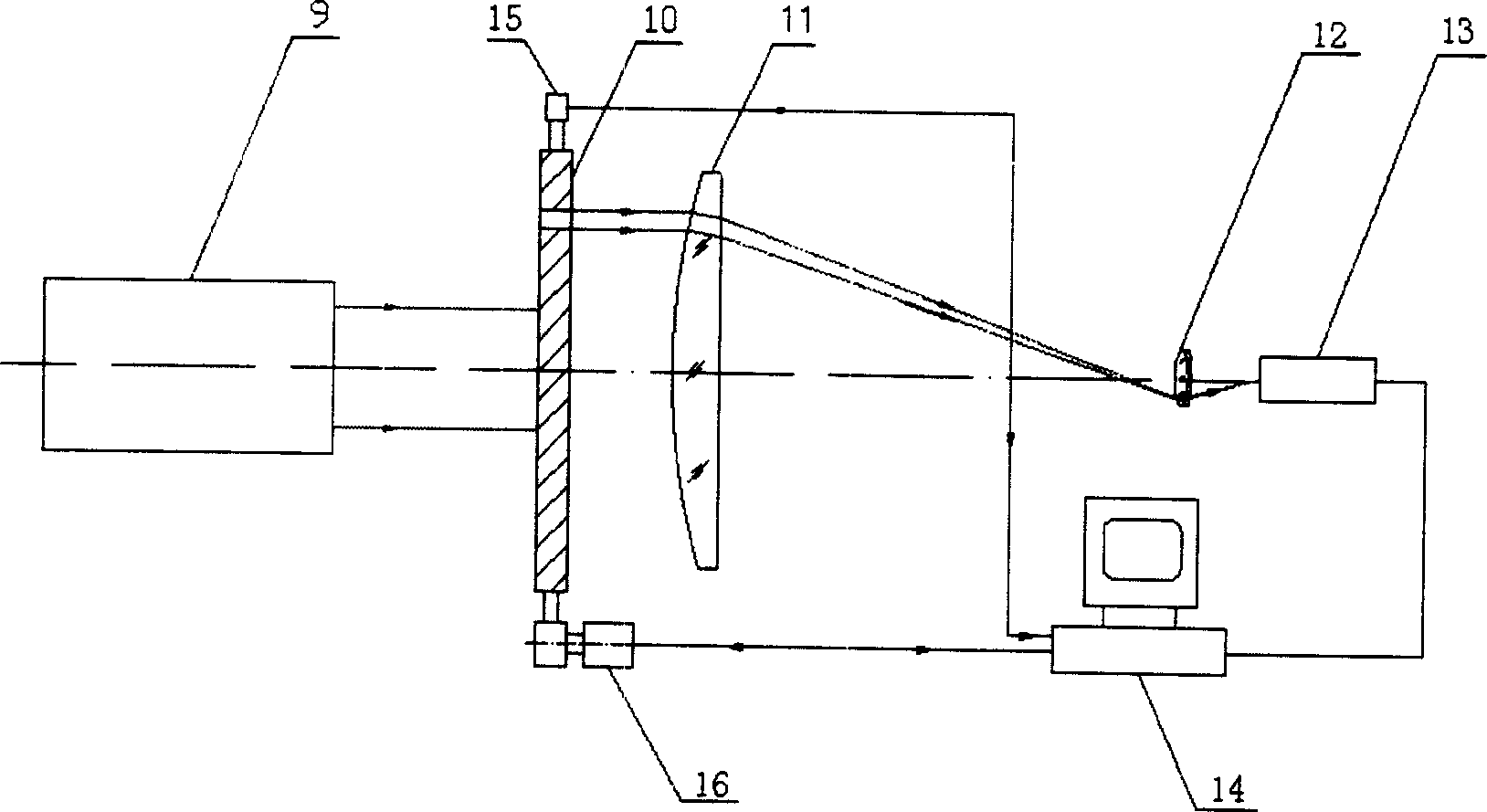

[0028] see image 3 , image 3 It is a structural schematic diagram of an embodiment of the multifunctional optical quality detection and analysis device of the present invention. As can be seen from the figure, the multifunctional optical quality detection device of the present invention is composed of a standard collimator 9, a scanning Hartmann diaphragm 10, a focused lens 11 to be inspected, and a microscope objective lens 12 on a common optical axis. , CCD camera 13, described scanning Hartmann diaphragm 10 is installed on the diaphragm support, and this support top is fixed with encoder 15, and stepper motor 16 is housed below, also has computer 14, and described CCD camera 13 is positioned at the focus position of microscope objective lens 12, and described CCD camera 13, encoder 15 and stepper motor 16 are all connected with computer 14; Under the control of computer 14, drive scanning type Hartmann aperture by stepper motor 16 10 rotates around the optical axis. On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com