Cage pocket machining device

A processing device and cage technology, which is applied in the field of bearing parts processing, can solve the problems of hidden safety hazards for workers, waste cages, and high manufacturing costs, and achieve the effects of high flexibility, high safety, and reduced manufacturing accuracy and assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

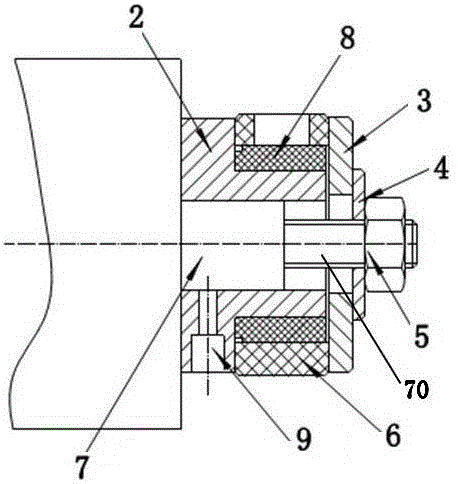

[0013] Embodiment 1 of the cage pocket processing device of the present invention: as figure 1 As shown, it includes a fixing seat, which is provided with a workpiece fixing shaft, and the workpiece fixing shaft includes a central axis 7 extending left and right, and the outer circumference of the central shaft 7 is provided with a fixing sleeve 2, and the fixing sleeve 2 is provided with radially extending screws Hole 9, the fixed sleeve 2 realizes the axial and circumferential positioning with the central axis 7 through the fastening screw in the screw hole 9, the outer circumference of the fixed sleeve 2 is a stepped outer peripheral surface with a large left end and a small right end, and the central axis 7 The right end is provided with a threaded shaft 70, and the threaded shaft 70 protrudes outward from the right end of the fixed sleeve 2, and the threaded shaft 70 is located at the position of the right end of the fixed sleeve 2 and is provided with a baffle plate 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com