Mold for integrally molding J-shaped reinforced composite material wall plate

A technology of integral molding and composite materials, which is applied in the field of resin-based composite material molding, can solve the problems of increasing material and process costs, surface deviation assembly coordination, and increasing tooling costs, so as to save tooling, reduce manufacturing precision, and reduce The effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

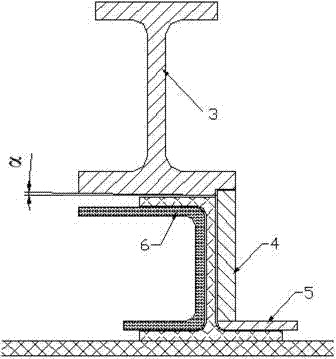

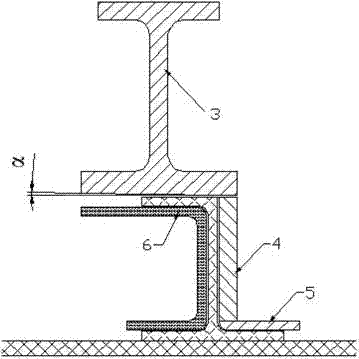

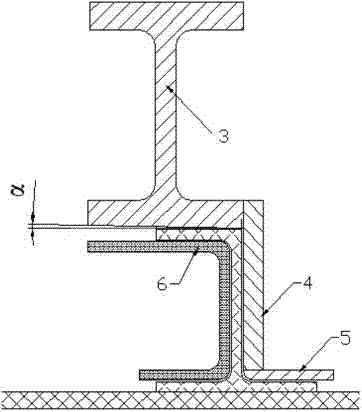

[0036] Example 1: The structure of the integrally formed "J"-shaped stiffened wall panel is as image 3 , "J"-shaped stiffened wall panel has an external dimension of 900mm×520mm×105mm (length×width×height), and the skin 7 is longitudinally provided with 5 “J”-shaped ribs 8, and the material is G0827 / QY9512 , Formed as a whole through RFI technology. The five "J"-shaped reinforced upper flanges and the metal parts at both ends are required to be assembled with the upper skin 12, in order to ensure the outer surface 10 and the metal parts at both ends of the five "J"-shaped reinforced upper flanges and the upper skin For the coordination and consistency of the inner surface profile, the precision of the outer profile 10 of the five "J"-shaped reinforced upper flanges must be controlled within ±0.2mm. Here we adopt the mold solution of the present invention.

[0037] A. Taking into account that the shape of the stiffened plate is flat, the shape mold 1 is designed as a simple plat...

Embodiment 2

[0042] Example 2: Box-shaped structure test piece such as Image 6 , Is composed of "J"-shaped stiffened wall panel and upper skin 12, among which, the stiffened wall panel is a structure with two "J"-shaped reinforced wall panels in the longitudinal direction. The external dimension is 1800mm×800mm×160mm (length×width). ×High), the material system adopts U3160 / QY9512. In order to improve the structural integrity and achieve structural weight reduction, the interface between the ribbed lower flange of the wall panel and the skin is enhanced by stitching, and then the RFI process is used for integral molding. The upper skin is of variable thickness, and the accuracy of the mating surface with the upper flange of the wall panel is within ±0.15mm. Such high accuracy is almost impossible to achieve for parts molded by traditional mold solutions. It is usually necessary to use mechanical processing or secondary compensation on special tooling to reinforce the upper flange surface 10...

Embodiment 3

[0048] Example 3: The structure of stiffened wall panel is as Picture 9 , The shape is curved, the size is 2500mm×700mm×250mm (length×width×height), the skin has 3 "J"-shaped reinforcements in the longitudinal direction, the material is G0827 / QY9512, in order to improve the structural integrity, the lower flange is reinforced The skin is reinforced by stitching, and then integrally formed by the RFI process. The accuracy of the 3 ribs upper flange surface is required to reach ±0.15mm. The mold still uses the mold solution of the present invention, such as Figure 13 .

[0049] A. The shape mold 1 adopts the frame welding structure, and the shape of the shape mold 1 is designed according to the digital model of the stiffened wall plate, such as Picture 10 Shown. Considering the needs of reinforcement positioning and packaging, the outline size of the profile mold 1 is widened by 200mm on the lateral side perpendicular to the reinforcement, and the axial profile mold of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com