Machine for cutting material with one blade for two-purpose

A cutting machine, dual-purpose technology, applied in metal processing and other directions, can solve the problems of difficult cutter adjustment, high production accuracy and cost, low machining accuracy, etc., to reduce production accuracy and cost, extend service life, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

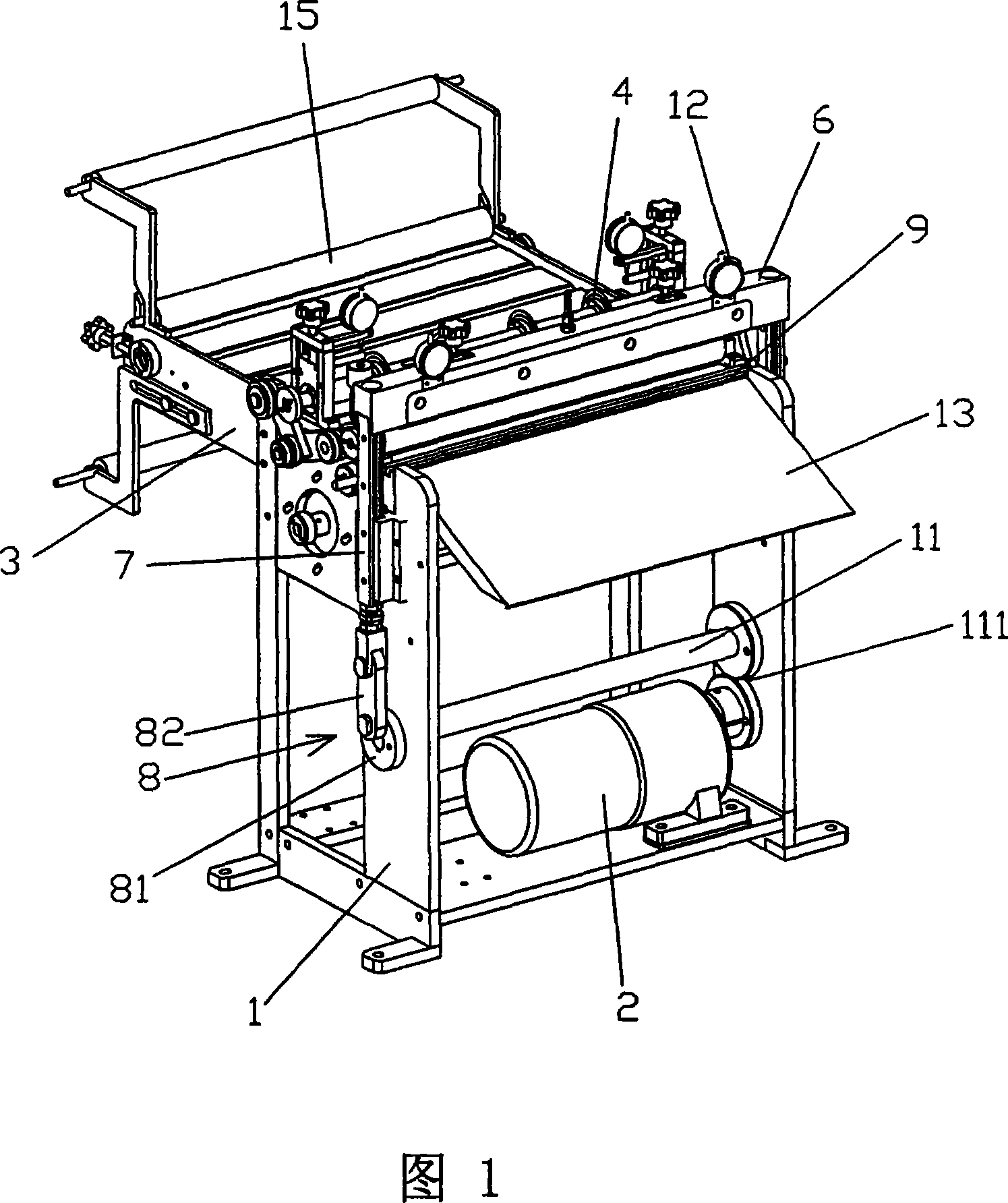

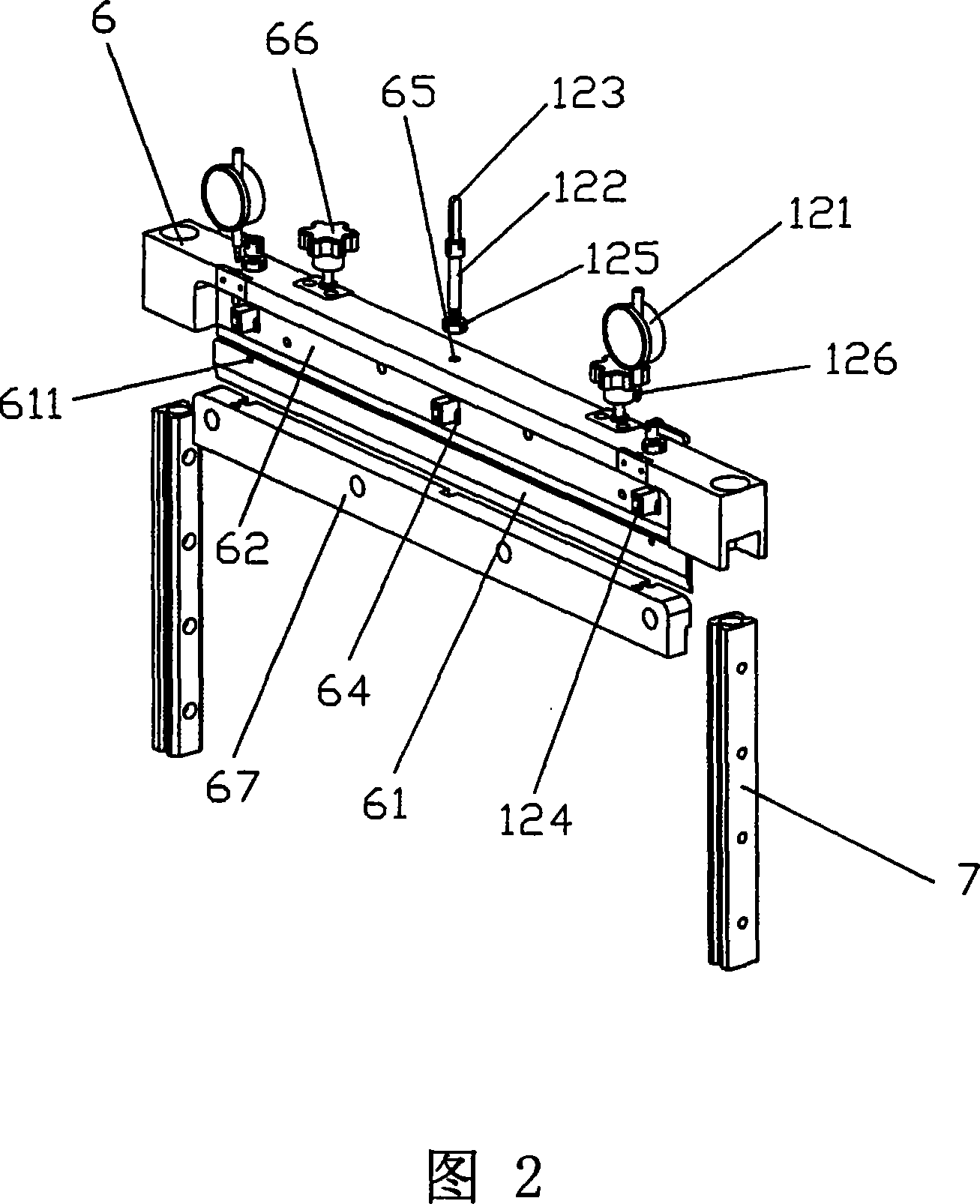

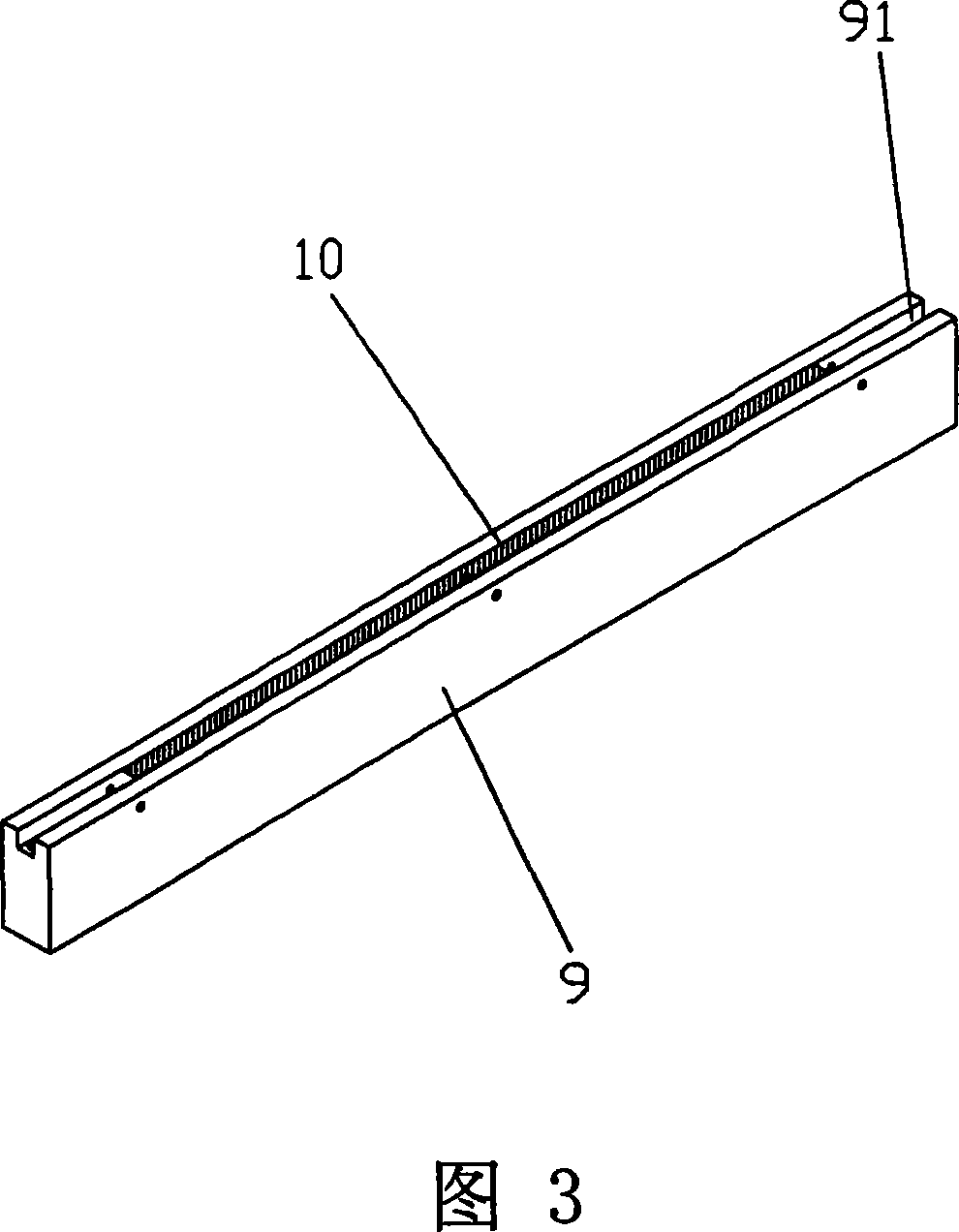

[0013] See shown in Fig. 1,2,3,4, the present invention comprises frame 1 and motor 2, and frame 1 top is provided with feeding frame 3, and feeding frame 3 top is provided with cutting hob 4, frame 1 both sides outer walls Linear guide rails 7 are respectively provided, the upper end of the linear guide rail 7 is connected with the knife rest 6, and the lower end is connected with an eccentric mechanism 8, the eccentric mechanism 8 includes an eccentric wheel 81 fixedly connected to one end of the transmission rod 11 and a connecting rod 82 connected with the linear guide rail 7, The connecting rod 82 is connected with the eccentric wheel 81, the transmission rod 11 is connected with the motor 2 through the gear pair 111, a knife holder 9 is arranged directly below the knife holder 6, and a knife groove 91 is opened on the upper surface of the knife holder 9, and a useful PVC is arranged in the knife groove 91. The knife bar 10 made of material is also provided with a cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com