Water drop proof tap

A faucet, anti-drip technology, applied in the direction of lift valve, valve details, engine components, etc., can solve the problems of increasing assembly process, lack of flexibility, increasing manufacturing cost, etc., reducing accessories and materials, reducing manufacturing accuracy, and reducing manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

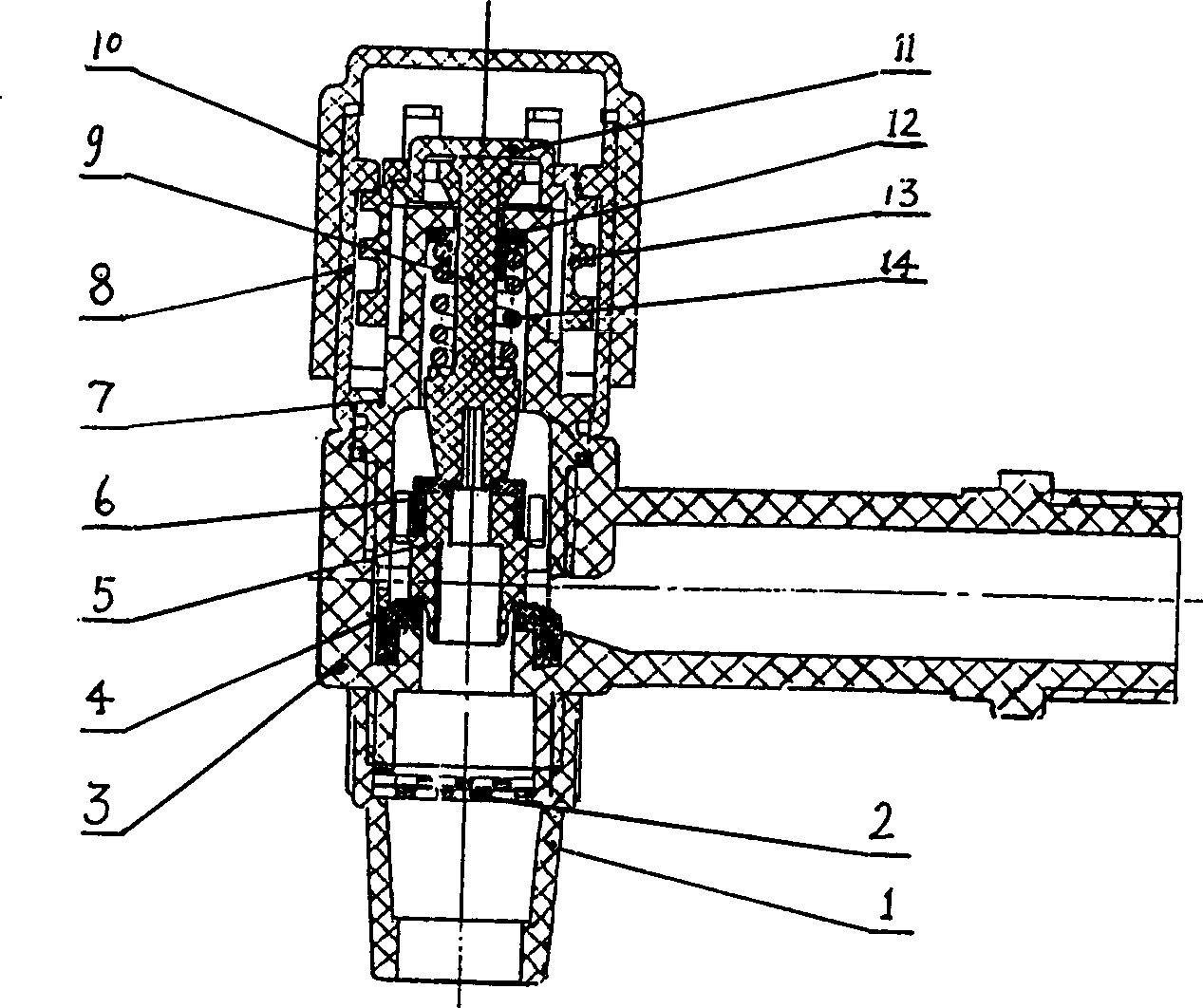

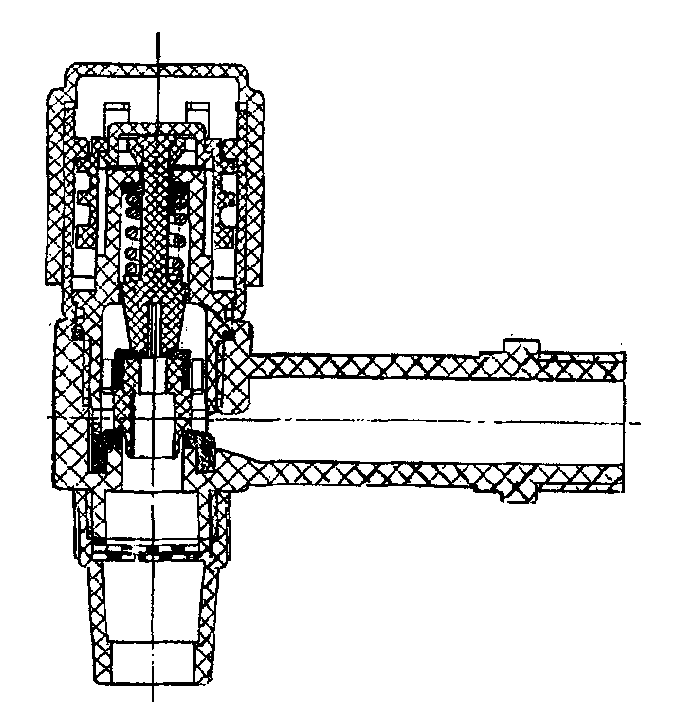

[0008] figure 1 It is a longitudinal sectional structure diagram of the present invention.

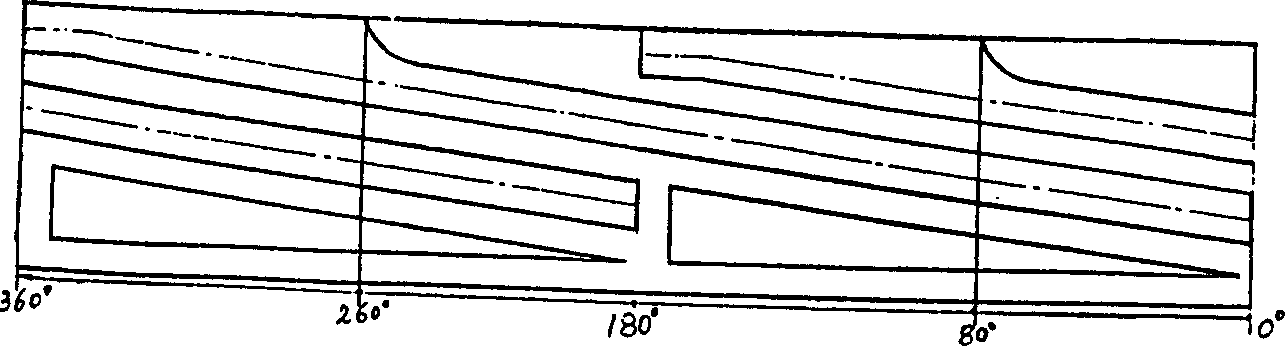

[0009] figure 2 It is the expanded view of the outer wall of the pull cover.

[0010] In the figure, 1. Faucet 2. Filter net 3. Valve body 4. Valve body sealing ring 5. Valve core 6. Valve core sealing ring 7. Valve cap 8. Handle seat 9. Valve stem 10. Handle 11. Buckle cover 12. Stem sealing ring 13. Pull cover 14. Spring

[0011] figure 1 Shown is a rotary opening and closing floating spool valve, which consists of a three-way valve body (3), a floating spool (5), a valve stem (9), a bonnet (7), a sealing ring and a valve stem control device Composition; the upper end of the valve stem (9) passes through the valve stem sealing ring (12), the valve cap (7) and the pull cover (13) and then thermally sinters, and the snap-in buckle cover (11) connects it with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com