Small-power motor power testing apparatus with power loss-free and wide measuring range properties

A power testing, wide-range technology, applied in measuring devices, power metering, torque metering, etc., can solve the problems of unestimable measurement errors, increased motor testing costs, and inability to truly reflect the real parameter values of the motor under test, reducing The effect of manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

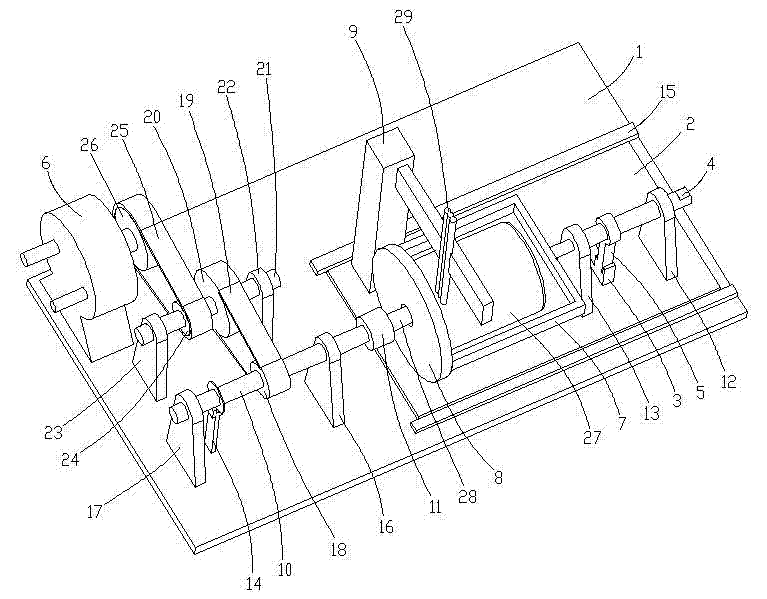

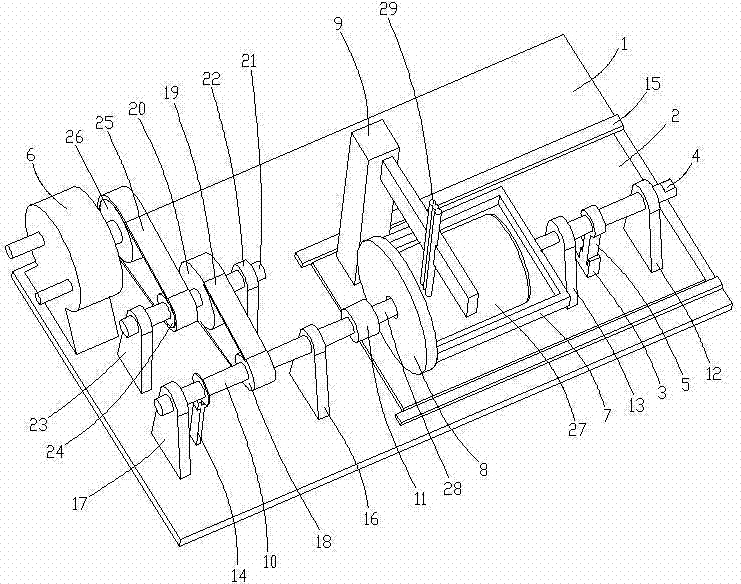

[0019] Such as figure 1 As shown, the base plate 1 is a rectangular flat plate structure, and two guide rails 15 are fixed on the surface of the front portion of the base plate 1 in a symmetrical manner. The two guide rails 15 are parallel, and a rectangular movable plate 2 is arranged between the two guide rails 15 , the sides of the movable plate 2 are slidably matched with the corresponding guide rails 15 . The movable plate 2 is guided by two guide rails 15, and can only slide relative to the base plate 1 in the front-rear direction. A semi-shaft 4 is arranged along the front-to-back direction above the front portion of the movable plate 2. The front portion of the semi-shaft 4 is supported by the first front support seat 12 through a bearing, and the rear portion of the semi-shaft 4 is connected with the second shaft through a bearing. The front support bases 13 are mutually supported, and the first and second front support bases 12, 13 are all fixed on the movable plate...

Embodiment 2

[0027] refer to figure 1 In this embodiment, there is no speed change mechanism, and the input shaft of the work absorber 6 is directly connected to the rear end of the power shaft 10 . The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0029] refer to figure 1 The speed change mechanism in this embodiment can also be replaced by a gear reduction box. The input shaft of the power absorber 6 is directly connected to the output shaft of the gear reduction box, and the rear end of the power shaft 10 is connected to the input shaft of the gear reduction box. The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com