Turntable material collecting and transferring mechanism for injection molding product feeder

A technology of injection molding products and material transfer mechanism, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high quality requirements, reduce the efficiency of injection mold space usage, inconvenience, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

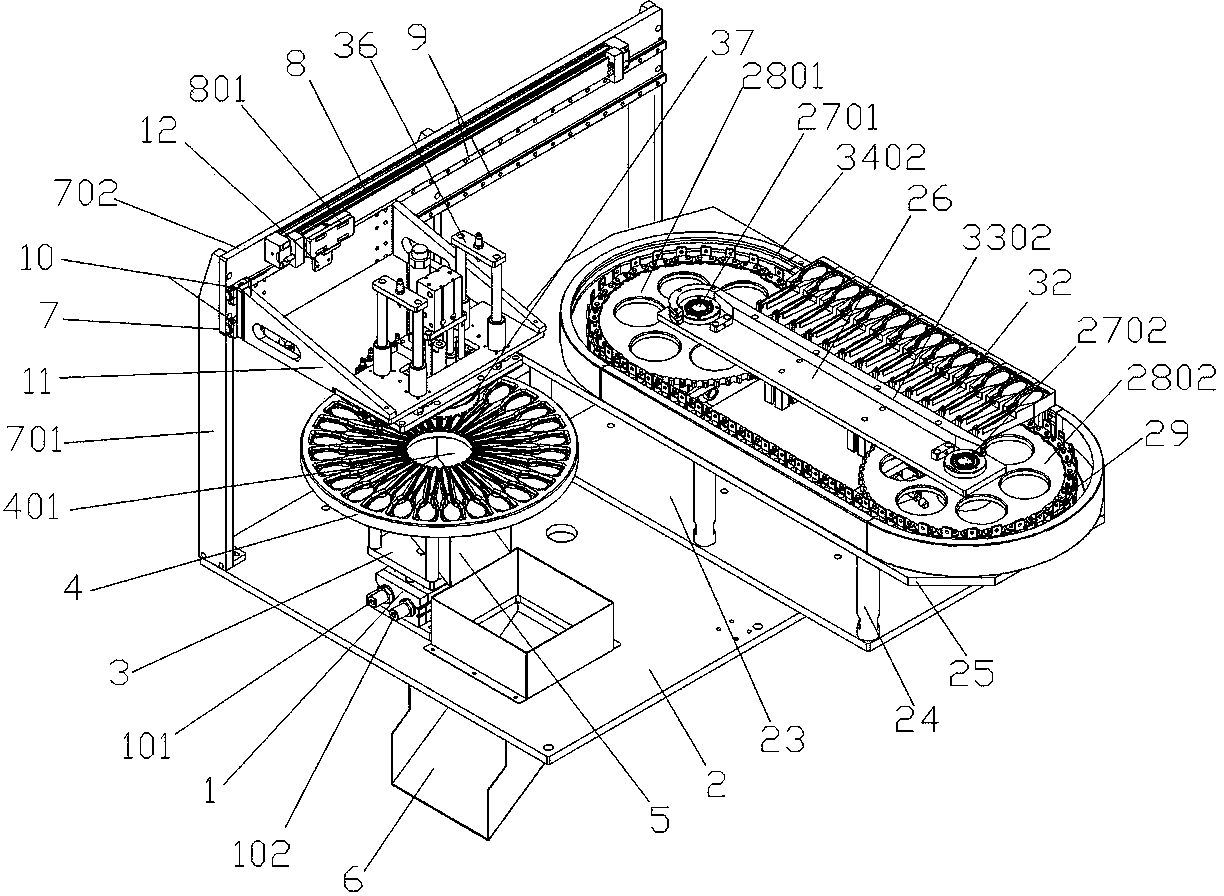

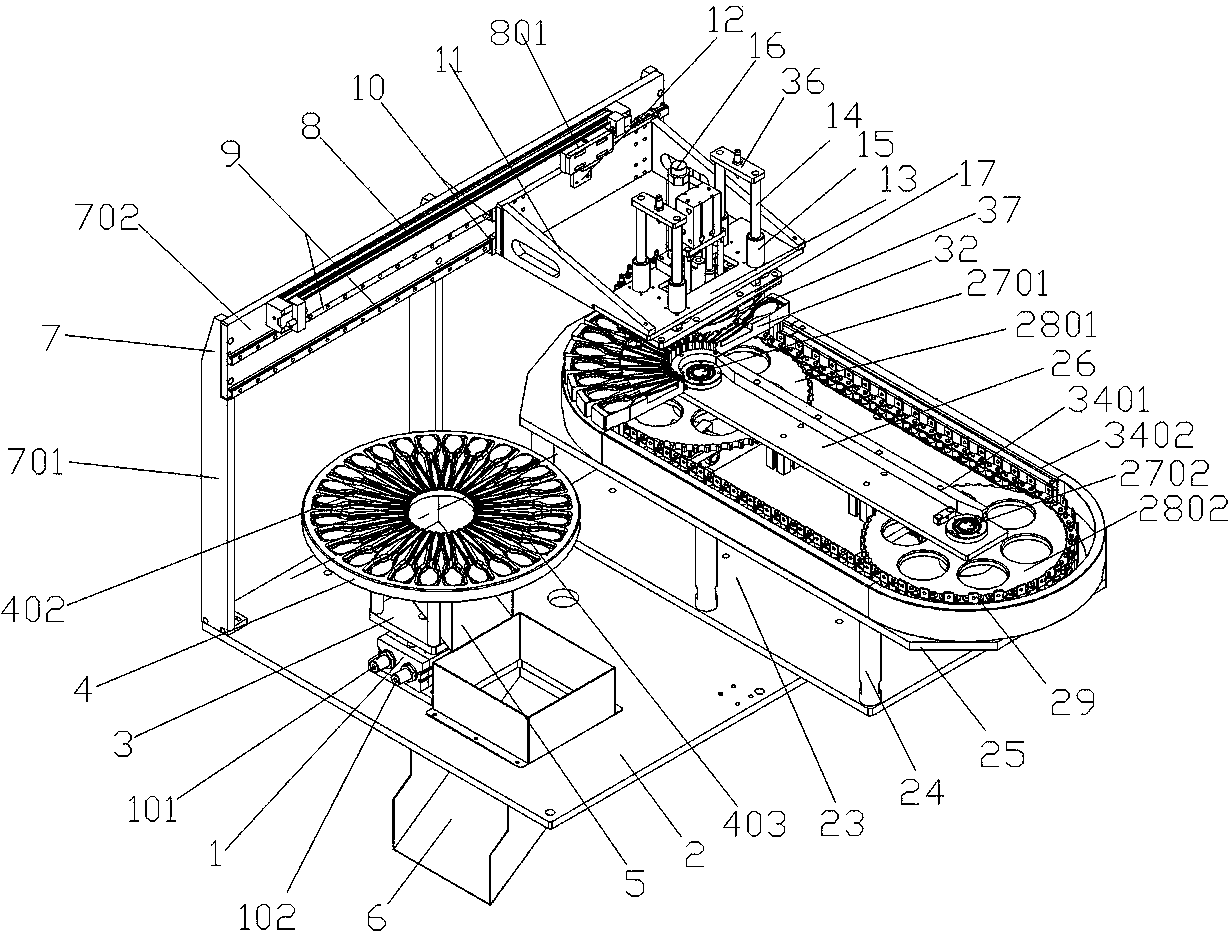

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

[0024] This embodiment is a turntable type material receiving and moving mechanism applied to a feeder for conveying plastic tableware scoops.

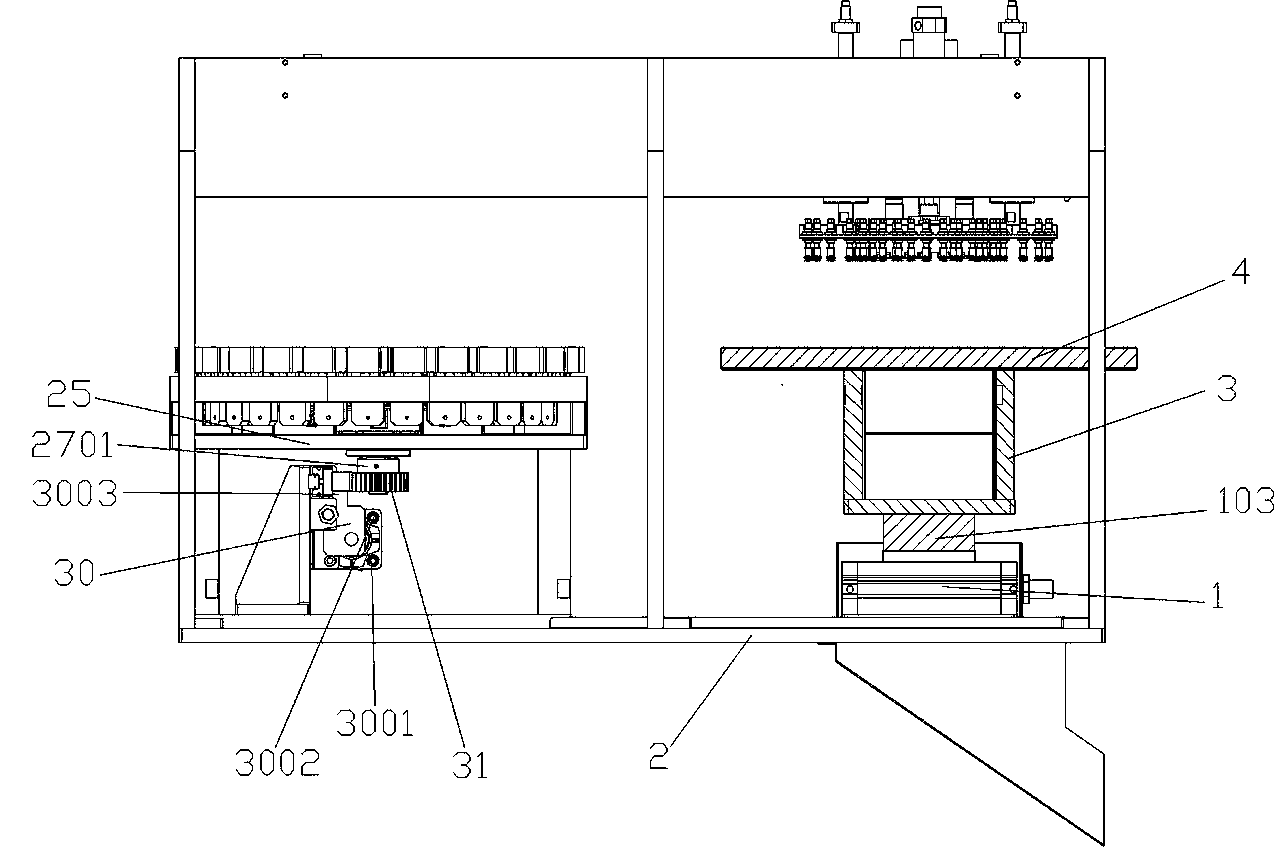

[0025] Such as figure 1 , 2 , 3, and 5, the first rotating part in this embodiment is the first rotary cylinder 1, the second rotating part is the second rotating cylinder 30, the first rotating cylinder 1 is installed on the frame flat plate 2, and the disk support 3 is installed on the top of the first rotary cylinder 1, the bottom surface of the disc support 3 is connected with the first cylinder shaft 103 of the first rotary cylinder 1, the receiving disc 4 is installed on the top of the disc support 3, the receiving disc 4 and The disk support 3 can rotate along with the first cylinder rotating shaft 101 . The center of the receiving disc 4 is a cutter hole 401, and the upper surface of the receiving disc 4 is a concave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com