Whole automobile attitude adjusting mechanism based on stepless adjusting and automobile chassis

A technology for adjusting mechanism and posture, applied to vehicle parts, cantilevers installed on pivots, elastic suspensions, etc., can solve problems such as unfavorable vehicle competitiveness, unfavorable after-sales maintenance, and increased production costs, so as to improve product competition force, reduce manufacturing accuracy and installation requirements, and reduce the effect of manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

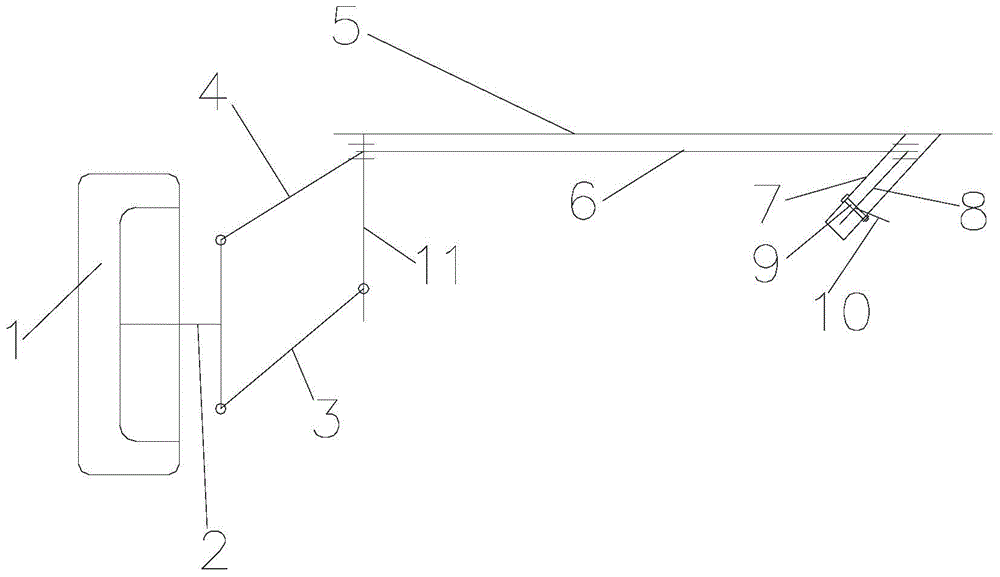

[0024] a kind of like figure 1 Shown automobile chassis of the present invention comprises automobile vehicle frame 5 ( figure 1 Mainly show the longitudinal beam of the automobile frame), the automobile wheel 1, the suspension system and the vehicle attitude adjustment mechanism based on the infinite adjustment of the present invention, the vehicle attitude adjustment mechanism is installed below the automobile frame 5, and the vehicle The attitude adjustment mechanism is connected with the vehicle wheel 1 through the suspension system.

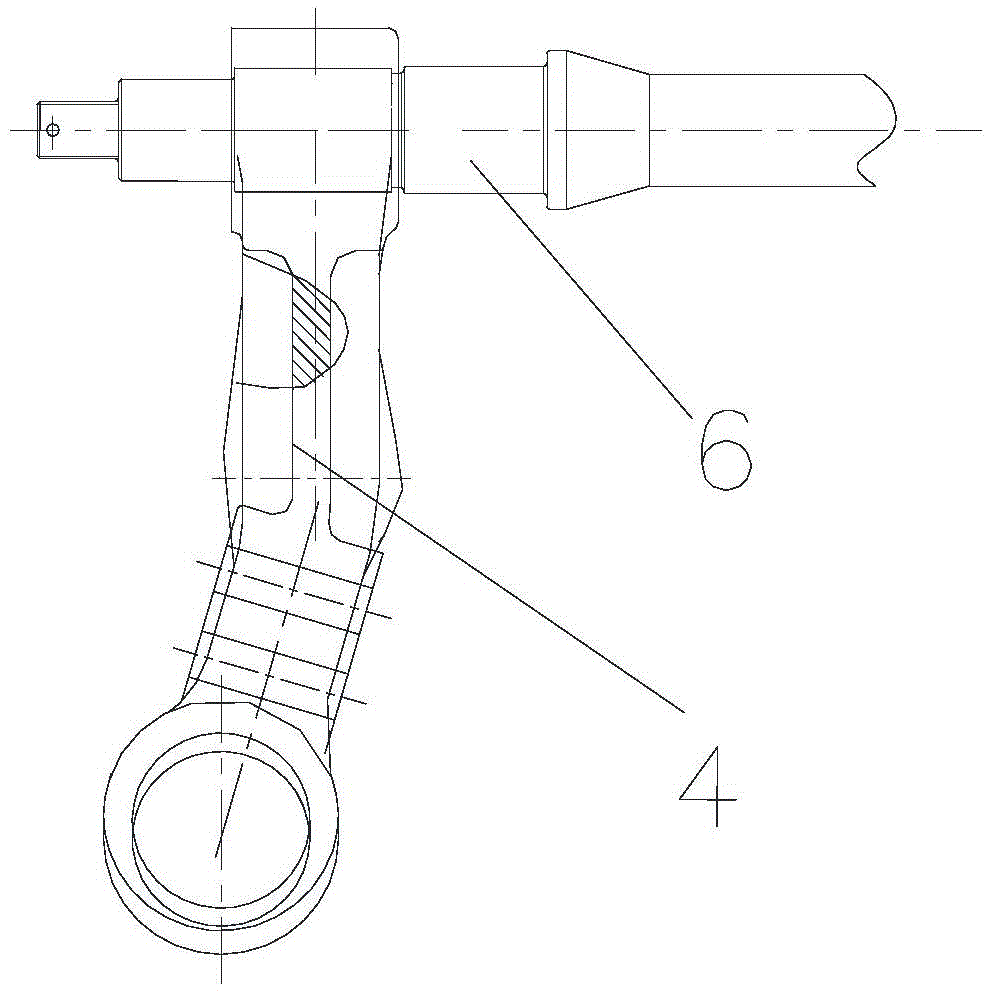

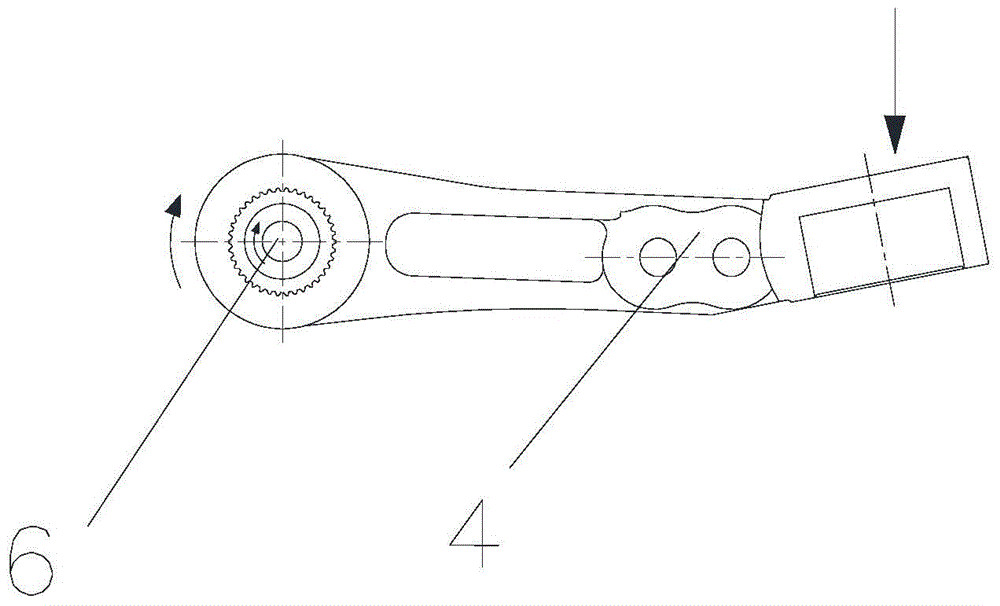

[0025] In the automobile chassis of the present embodiment, the suspension system adopts the double wishbone torsion bar independent suspension system, that is, the whole vehicle attitude adjustment of the present invention is installed on the basis of the double wishbone torsion bar spring independent suspension front axle assembly. mechanism. The double-wishbone torsion bar independent suspension system includes swing arm mechanisms loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com