Double-support pressurizing mechanism

A technology of pressurizing mechanism and double support, which is applied in the field of powder metallurgy products, can solve the problems of single pressurizing mechanism, affecting the quality of product molding, product production cost, and easy damage, and achieves the effect of reducing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

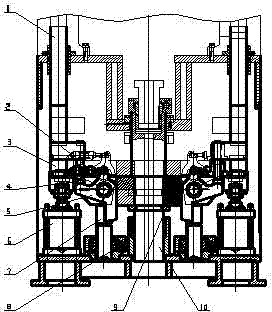

[0008] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0009] In the present invention, after pressurization and secondary pressurization on the product, the fixedly connected female mold and the driving beam 9 move downward for a certain distance, and are supported by the shift fork block 5 on the support adjustment screw 7 of equal height on both sides. . Utilize the shift fork block 5 and the supporting adjusting screw 7 to stop the descending female mold, and the upper punch continues to press down, thereby forming three pressurizations on the product until the pressurization is completed. After the pressurization is completed, under the action of the demoulding cam, the demoulding rod 1 descends to open the shift fork block 5 to disengage it from the supporting adjusting screw 7 to realize the demoulding function and complete the final molding of the product.

[0010] The demoulding rod 1 of the present invention dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com