Upright normal pressure amorphous iron core heat treatment furnace

An amorphous iron core and heat treatment furnace technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of poor product consistency and unsatisfactory uniformity of tank heating temperature, etc., to reduce heat treatment requirements and product magnetic properties. Excellent academic performance and improved product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

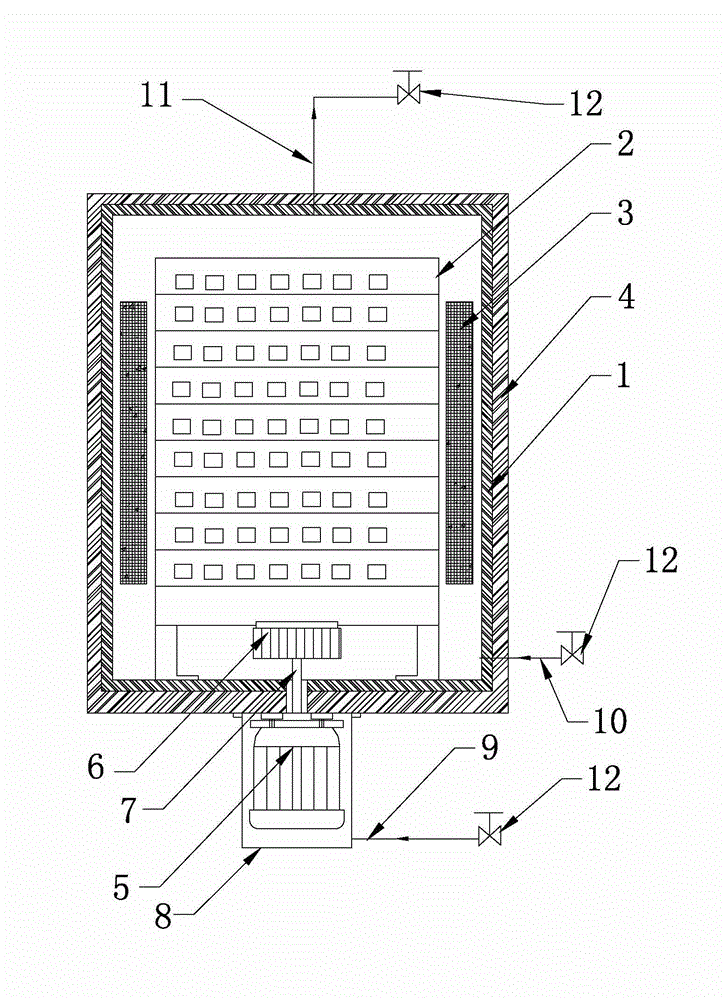

[0009] Such as figure 1 As shown, the vertical cabinet type atmospheric pressure amorphous iron core heat treatment furnace includes a tank body 1, a stacking bracket 2, a heating rod 3 and an insulation layer 4; the insulation layer 4 is arranged on the outside of the tank body 1, and the stacking bracket 2 is arranged on the tank body Inside the body 1; it is characterized in that it also includes a motor 5, a fan 6, a rotating shaft 7, a sealing cover 8, a first air delivery pipe 9, a second air delivery pipe 10 and an exhaust pipe 11; the tank body 1 is a square long tank; a heating rod 3 is set inside the tank body 1; the motor 5 is set outside the insulation layer 4 at the bottom of the tank body 1, the fan 6 is set inside the tank body 1, one end of the rotating shaft 7 is connected to the motor 5, and the other end of the rotating shaft 7 passes through the insulation layer 4 and the tank The body 1 is connected with the fan 6, the sealing cover 8 is arranged on the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com