Stacking frame used for touch screens and assembling method thereof

A touch screen and stacking rack technology, applied in tool storage devices, manufacturing tools, etc., can solve the problems of high transportation costs, inconvenient storage, damage to the touch screen, etc., and achieve the effect that it is not easy to fall apart, easy to store, and easy to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

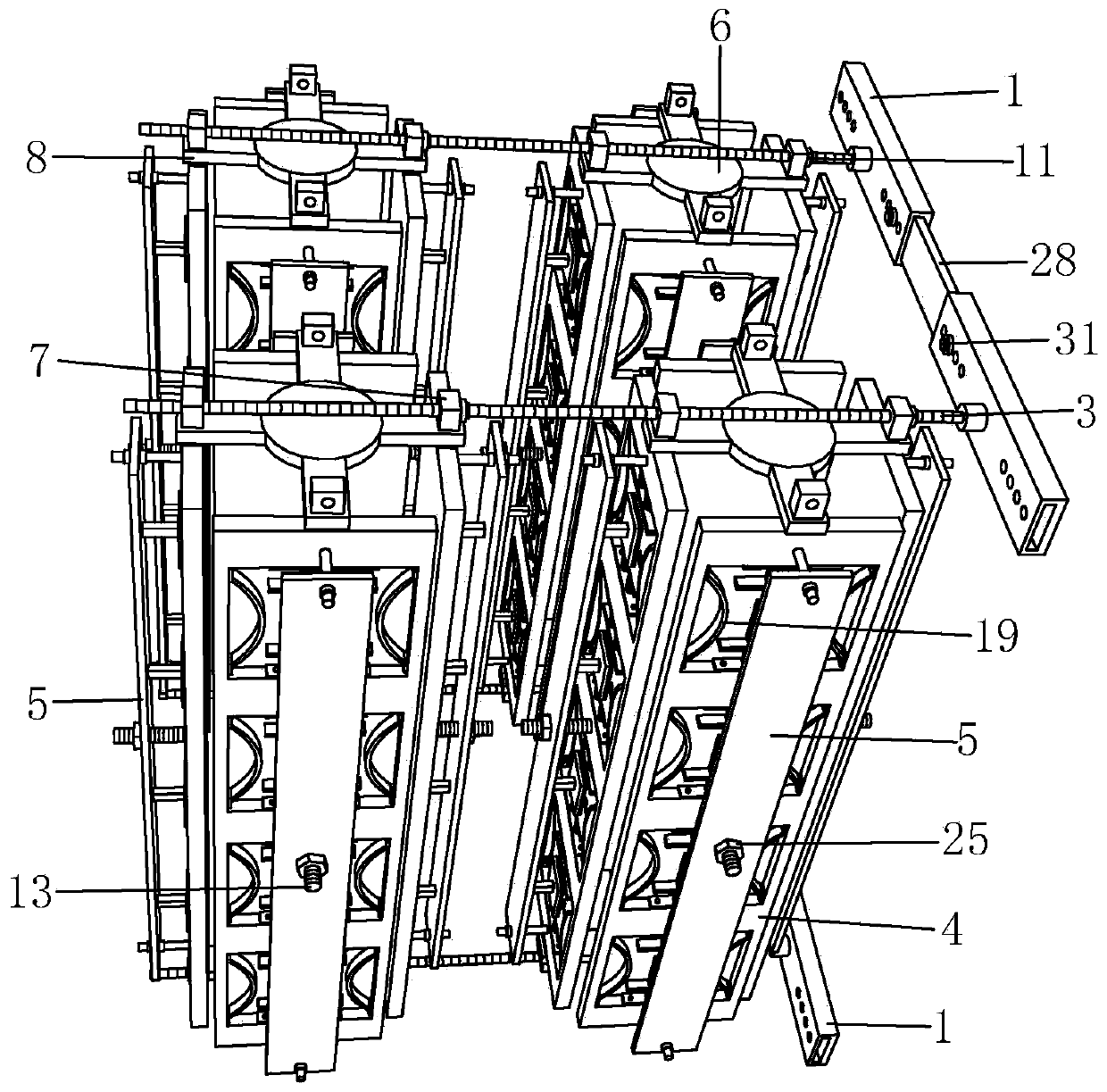

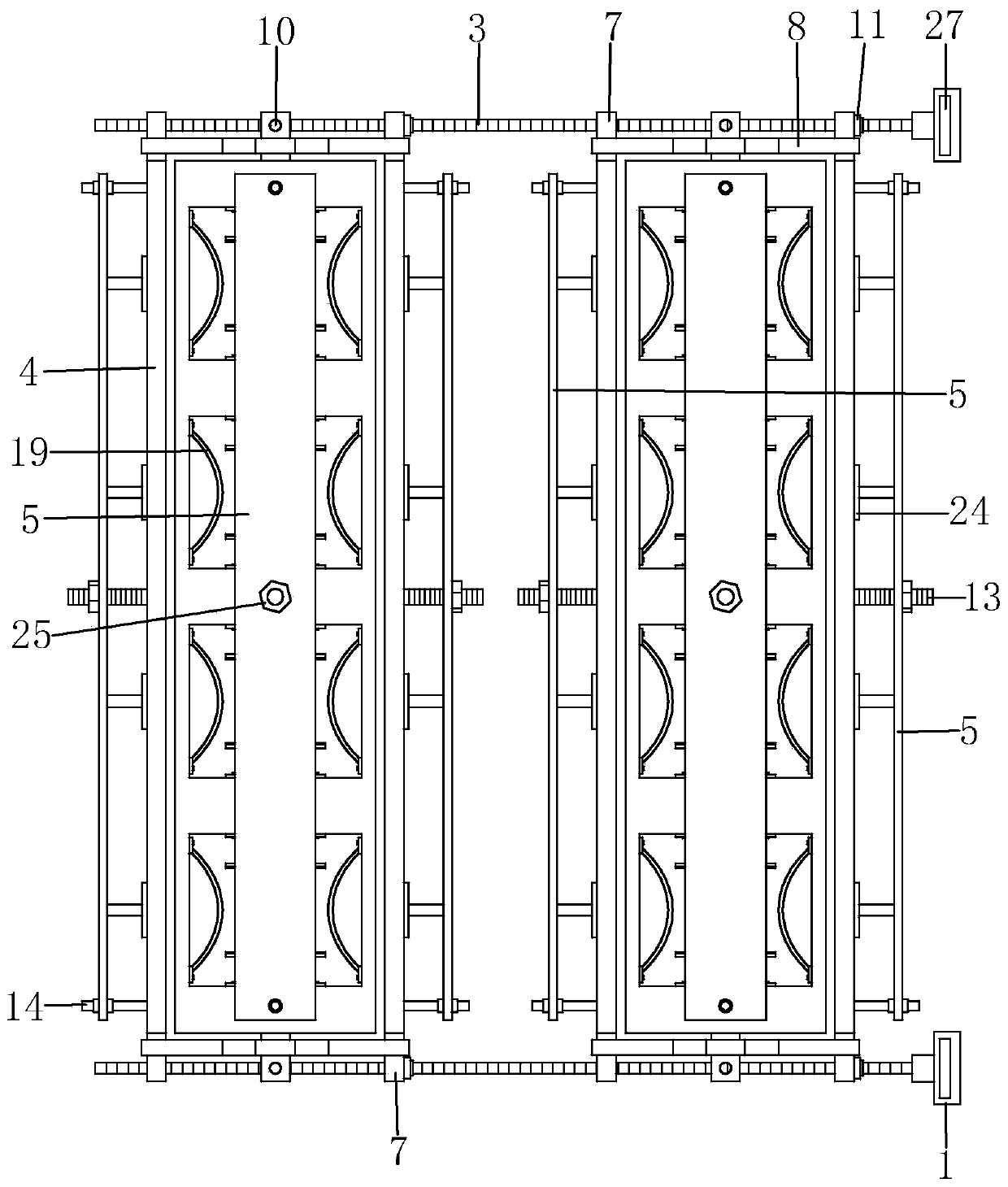

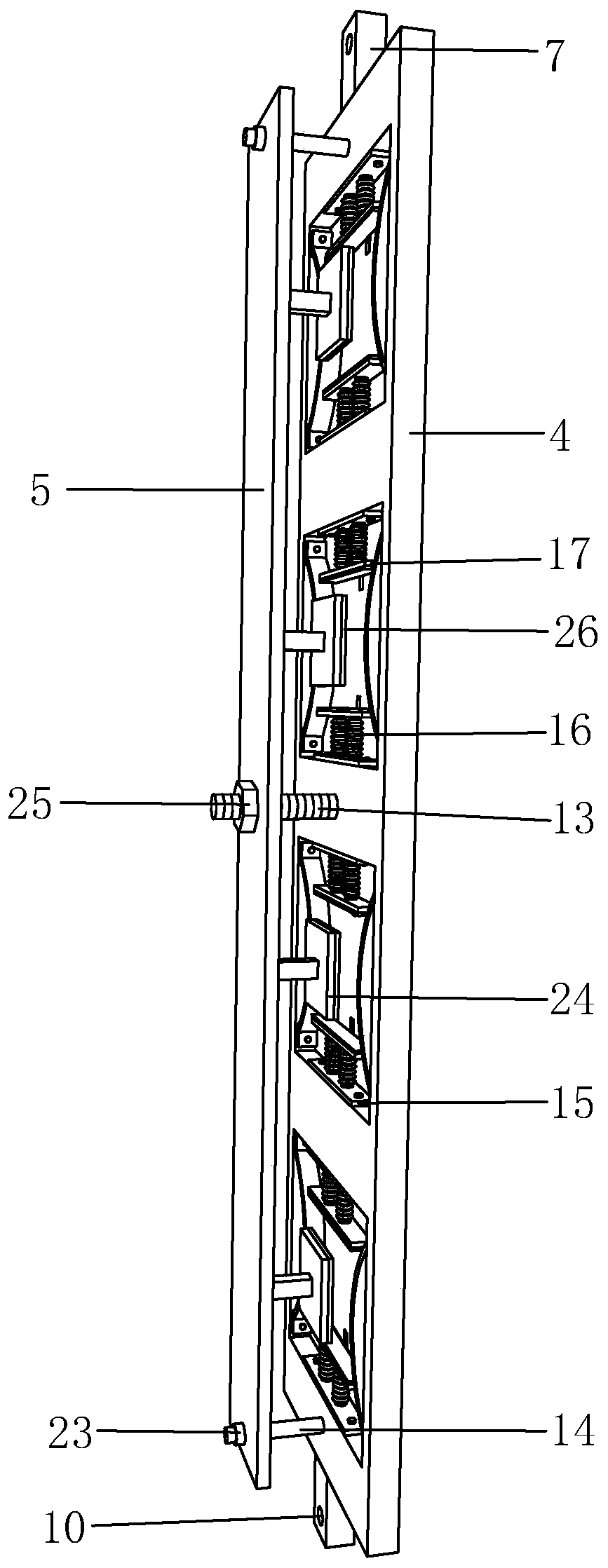

[0039] Such as Figure 1 to Figure 6 As shown, it is a stacking rack for a touch screen according to the present invention, which includes a support base plate 1, a mounting base 2 is provided on the support base plate 1, a support screw 3 is threaded on the mounting base 2, and the support screw 3 is detachable for easy replacement and maintenance. Storage, ready to use, flexible and convenient. Between the supporting screw rods 3, there is a shelf body, the shelf body includes a shelf 4, a spacer plate 5 and a spacer plate 6, the plate 4 is arranged between the spacer plates 6, and both sides of the plate 4 are provided with There are installation convex strips 7, and the limit plate 6 is distributed with fixed rods 8 in the upper direction. The fixed rods 8 are provided with installation through holes 9 that match the installation convex strips 7. Corresponding to the fixed through hole 10, the support screw 3 is connected with a support nut 11, and the support nut 11 supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com