File for soft materials

A soft material and filing technology, which is applied in filing/filing cutters, filing/filing devices, metal sawing equipment, etc., can solve the problems of high-efficiency filing of soft materials, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

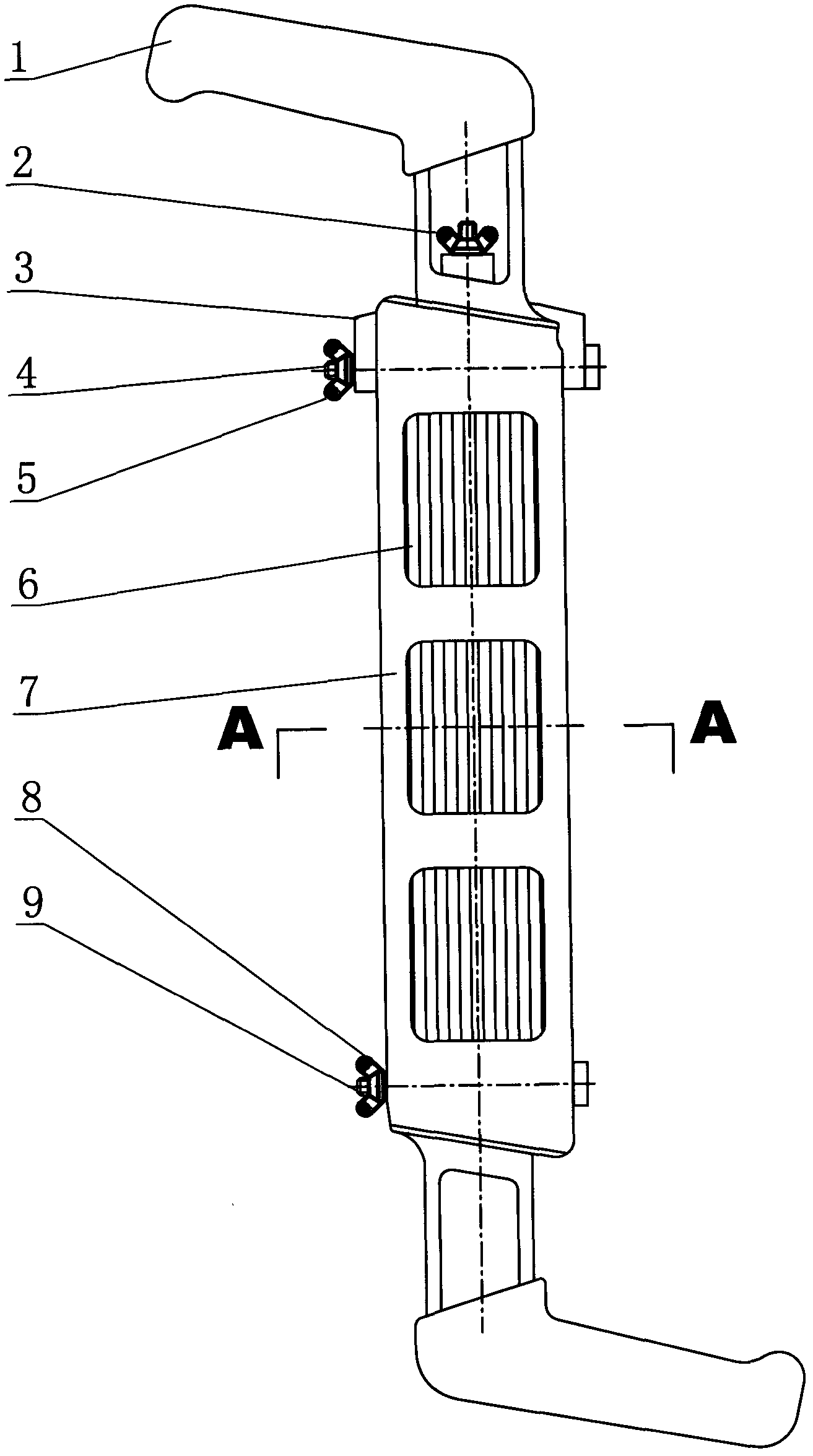

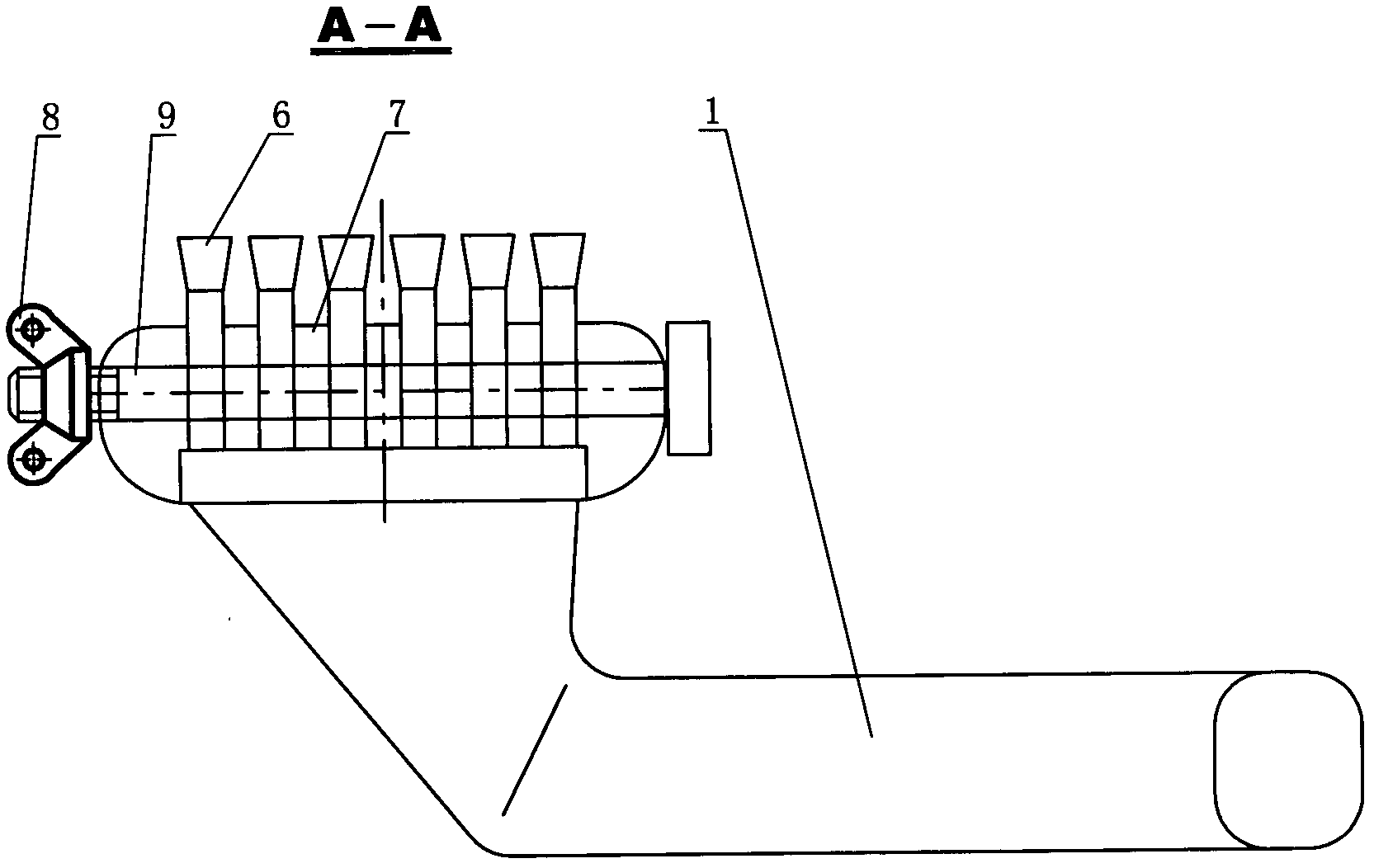

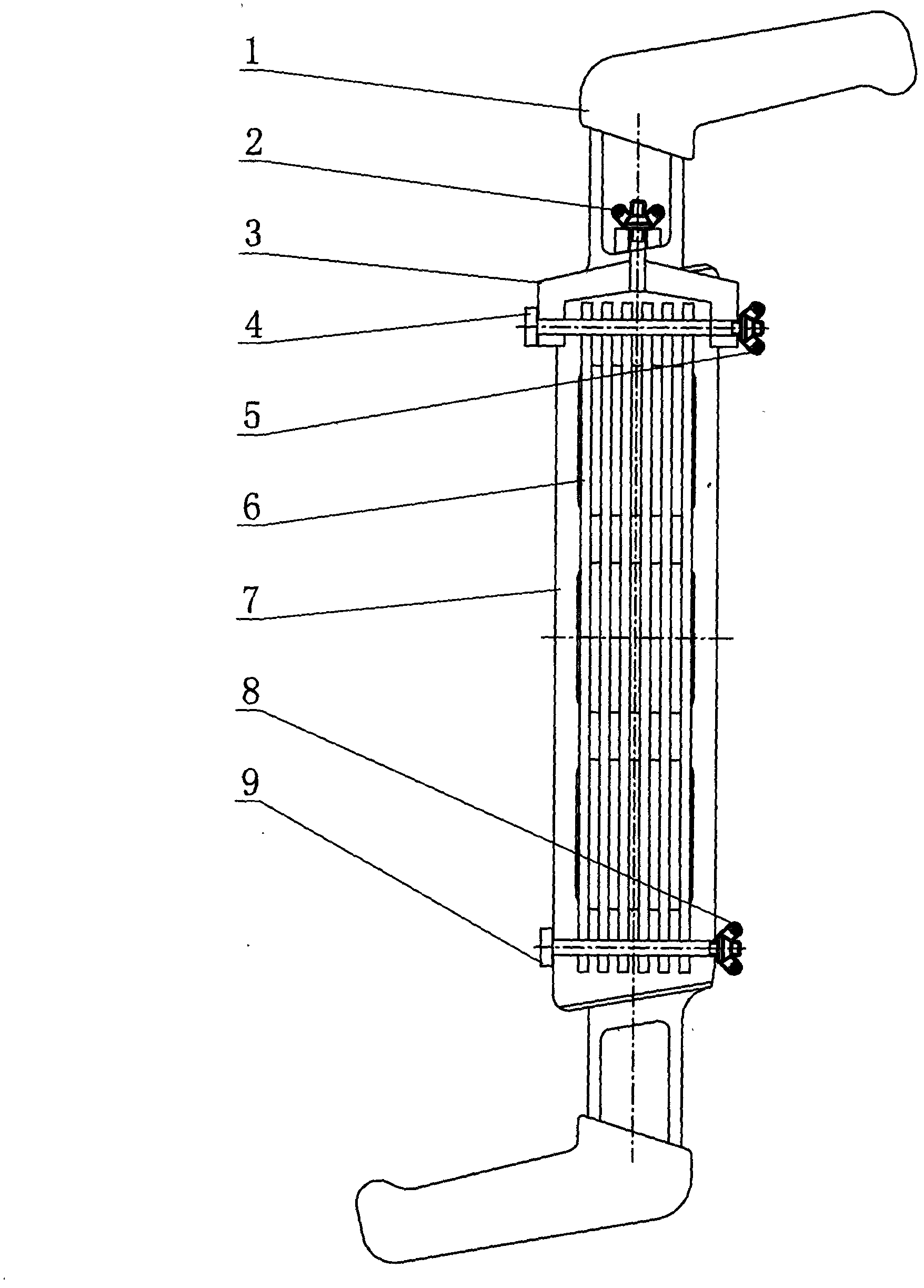

Embodiment Construction

[0023] Saw blade is the most commonly used and most effective tool for sawing workpieces in manual fitter work. It has been widely used since the beginning of woodworking in human history, and then developed to sawing and cutting metal and other materials. Operation. The efficient cutting performance of the saw blade on the material lies in the fact that its sharp saw teeth arranged in rows can smoothly cut into the middle of the material tissue, so the characteristic of the manual saw blade is that it can smoothly cut into the soft material under a small pressure for cutting operations .

[0024] When using a file for manual fitter work to file a plane, it is usually difficult to file soft metal materials such as aluminum and copper, because this type of material is soft and difficult to use with a file The debris from the file is easy to deform and embedded in the dense gap between the teeth of the file. A large amount of debris embedded in the middle of the file will serio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com