Garbage grab bucket

A grab and garbage technology, which is applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems affecting the stability and durability of the hydraulic system, inconvenient installation and maintenance, and poor heat dissipation effect, so as to achieve good heat dissipation effect, Easy installation and maintenance, good work durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

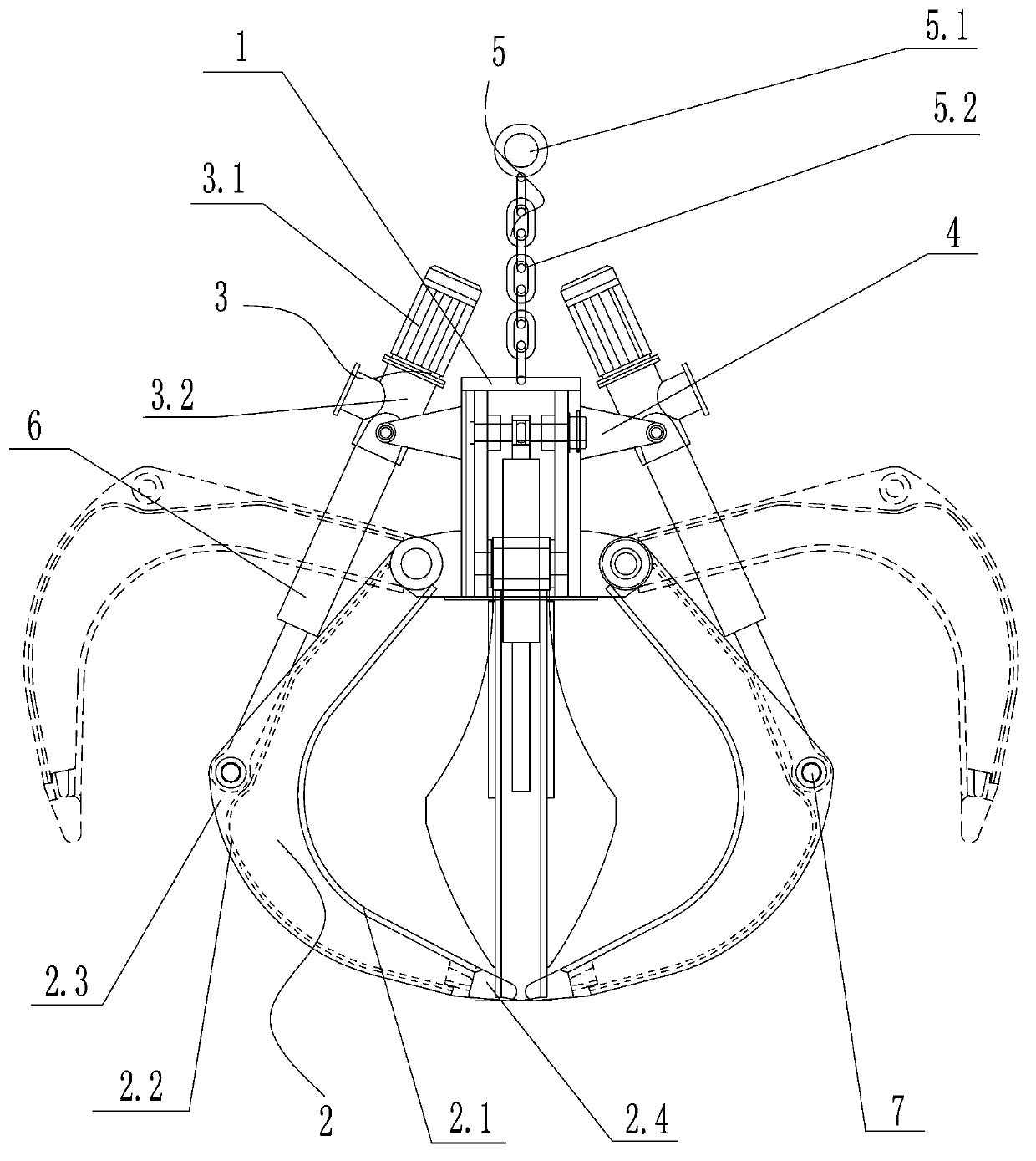

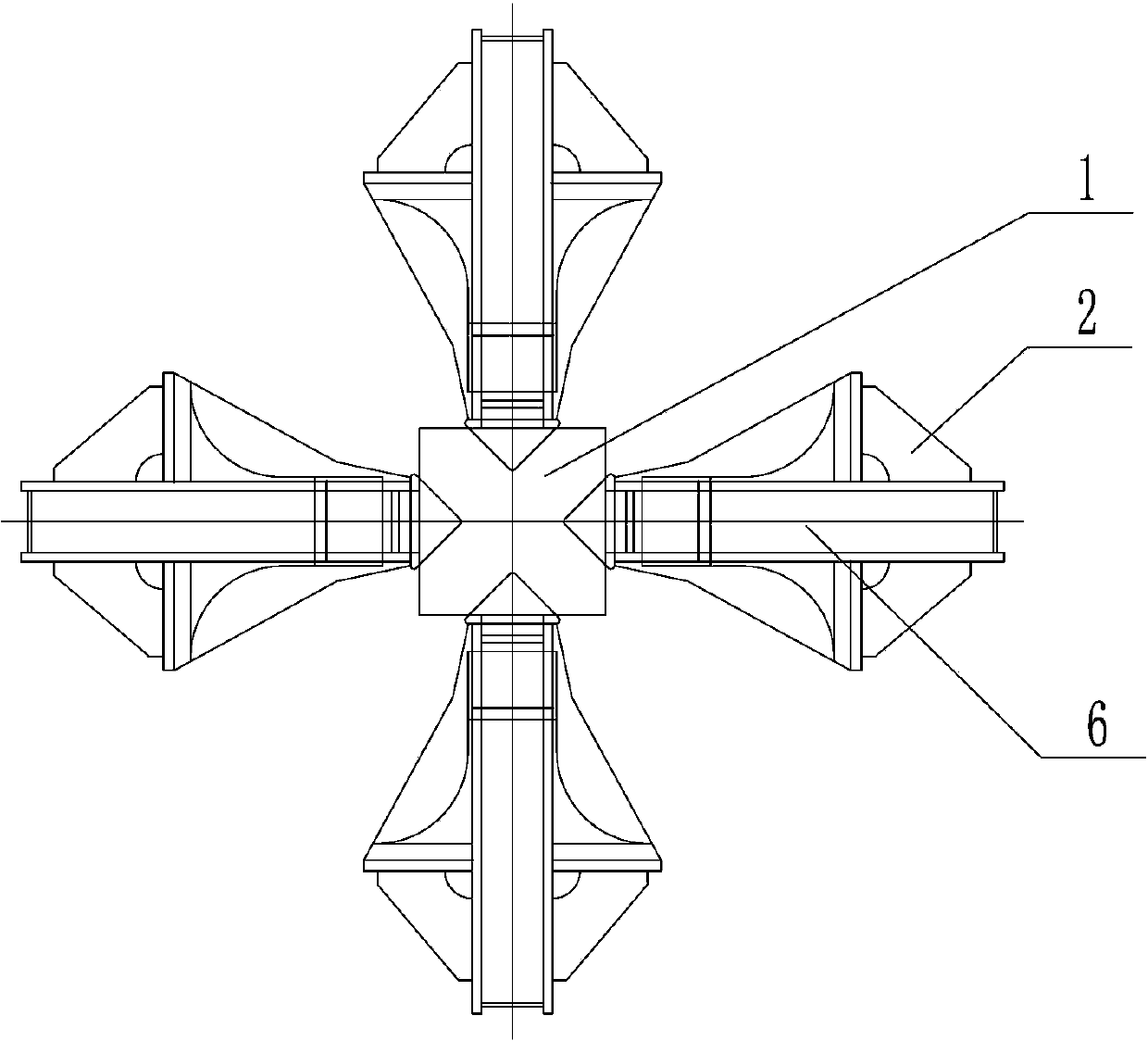

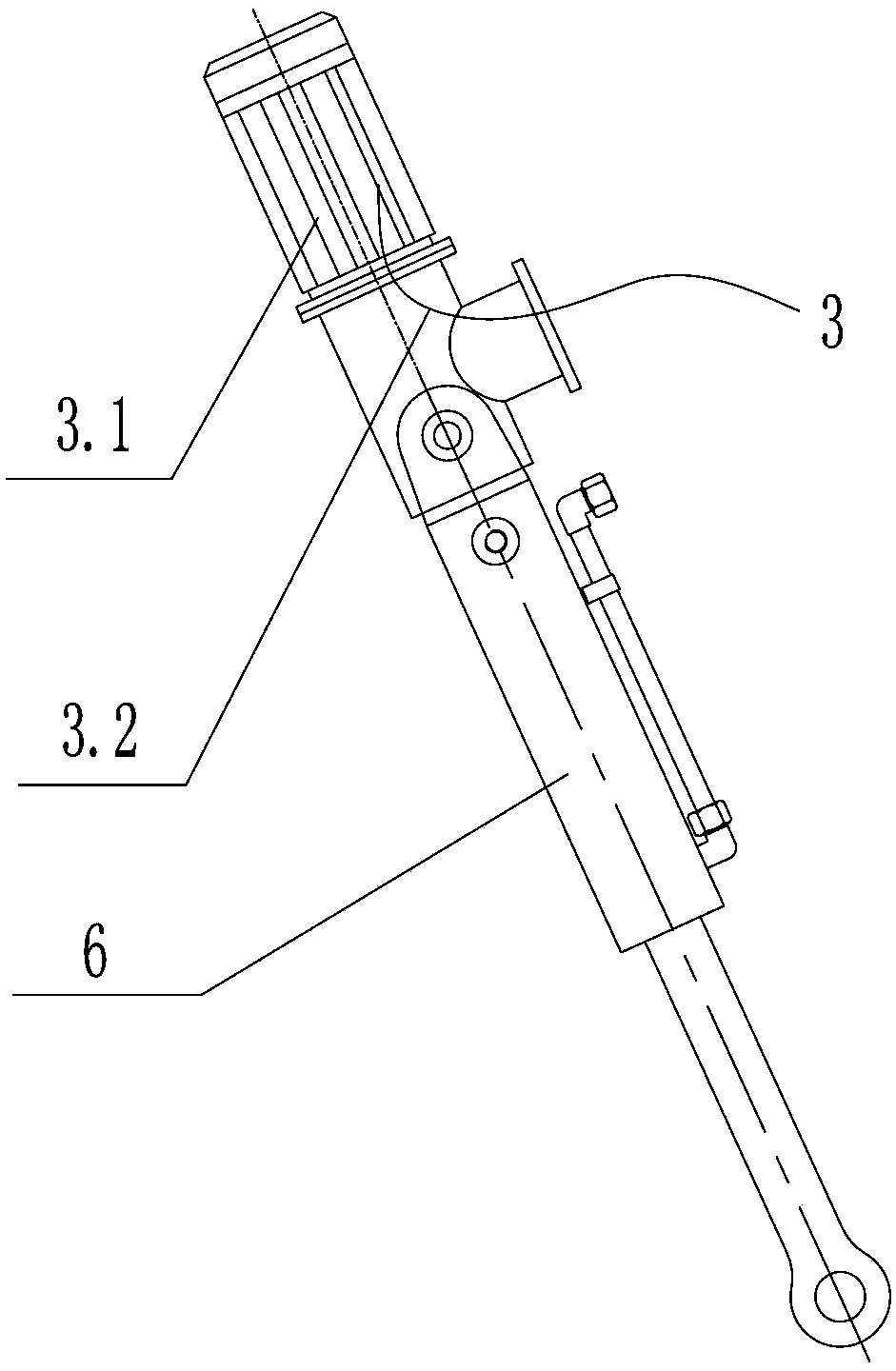

[0019] see figure 1 , figure 2 and image 3 As shown, the garbage grab of the present invention includes a seat body 1, at least two grab flaps 2 whose upper ends are hinged with the seat body 1, a hydraulic cylinder 6 hinged with the free end of the piston rod and the grab flap 2, and a crane or a crane. A fixedly connected hoisting mechanism 5, the hoisting mechanism 5 is fixedly connected with the base body 1, the cylinder end of the hydraulic cylinder 6 is hinged with the base body 1, and it also includes a hydraulic drive mechanism 3 equal in number to the grab flap 2, so The hydraulic drive mechanism 3 is arranged outside the base body 1, and the hydraulic drive mechanism 3 is integrally connected with the cylinder body of the hydraulic cylinder 6 .

[0020] The base body 1 is in the shape of a square column.

[0021] There are four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com