Wax mould casting device and method

A technology of wax mold casting and paraffin wax, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of low working efficiency, material discharge, inconvenient wax liquid, etc. variable, loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

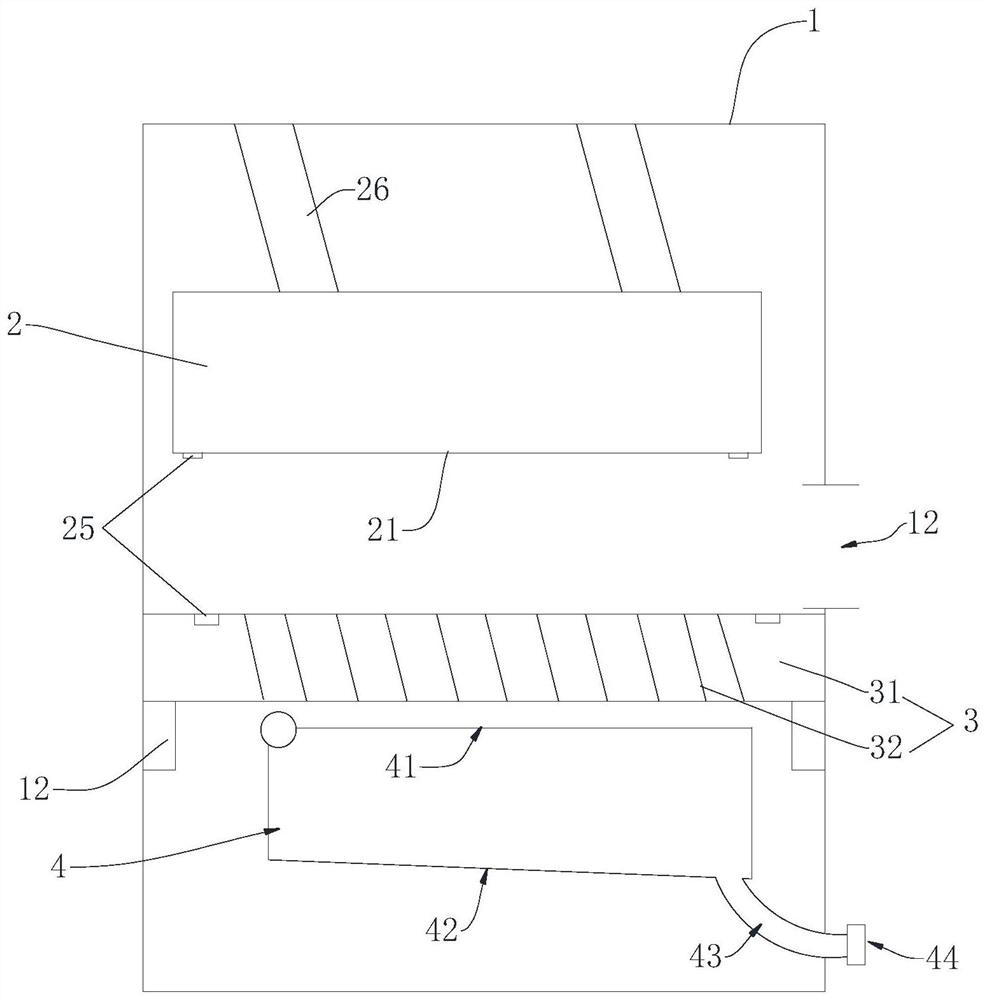

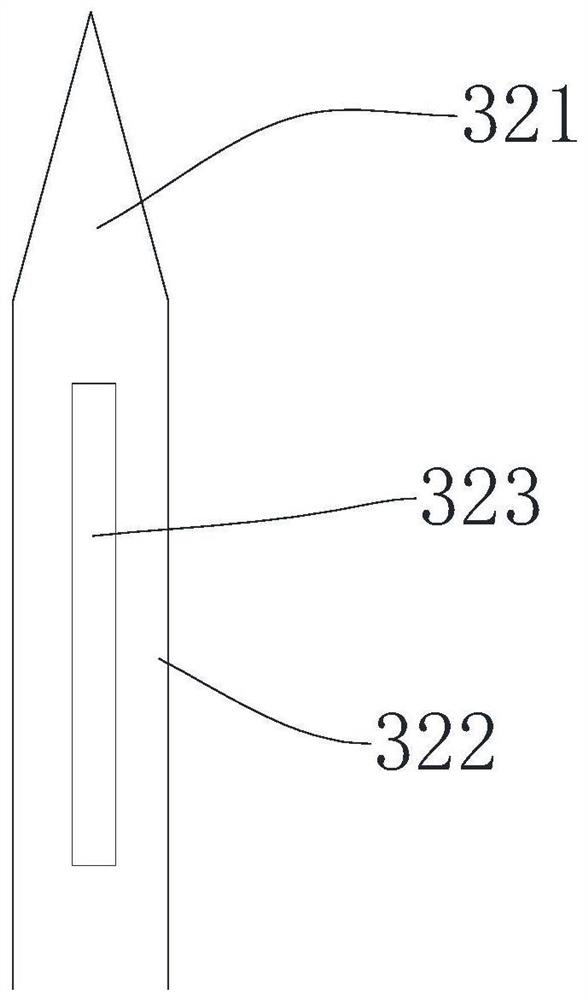

[0040] A wax pattern casting device, comprising: a smelting chamber 1, including a feeding port 11; also comprising: a net knife 3, arranged in the smelting chamber 1, including several blade units 32, the blade units 32 are arranged obliquely, adjacent to each other A dividing gap is formed between the blade units 32; the briquetting assembly 2 is arranged in the melting chamber 1, a clamping space is provided between the briquetting assembly 2 and the net knife 3, and the feeding port 11 Connected to the clamping space, the surface of the pressing block assembly 2 facing the mesh knife 3 is a crushing pressing surface 21, and the pressing block assembly 2 and the mesh knife 3 have a first state in which the relative distance gradually decreases, And the second state where the relative distance between the two remains constant, the moving path of the pressing block assembly 2 and / or the net knife 3 is parallel to the blade unit 32 . Most of the raw materials currently used fo...

Embodiment 2

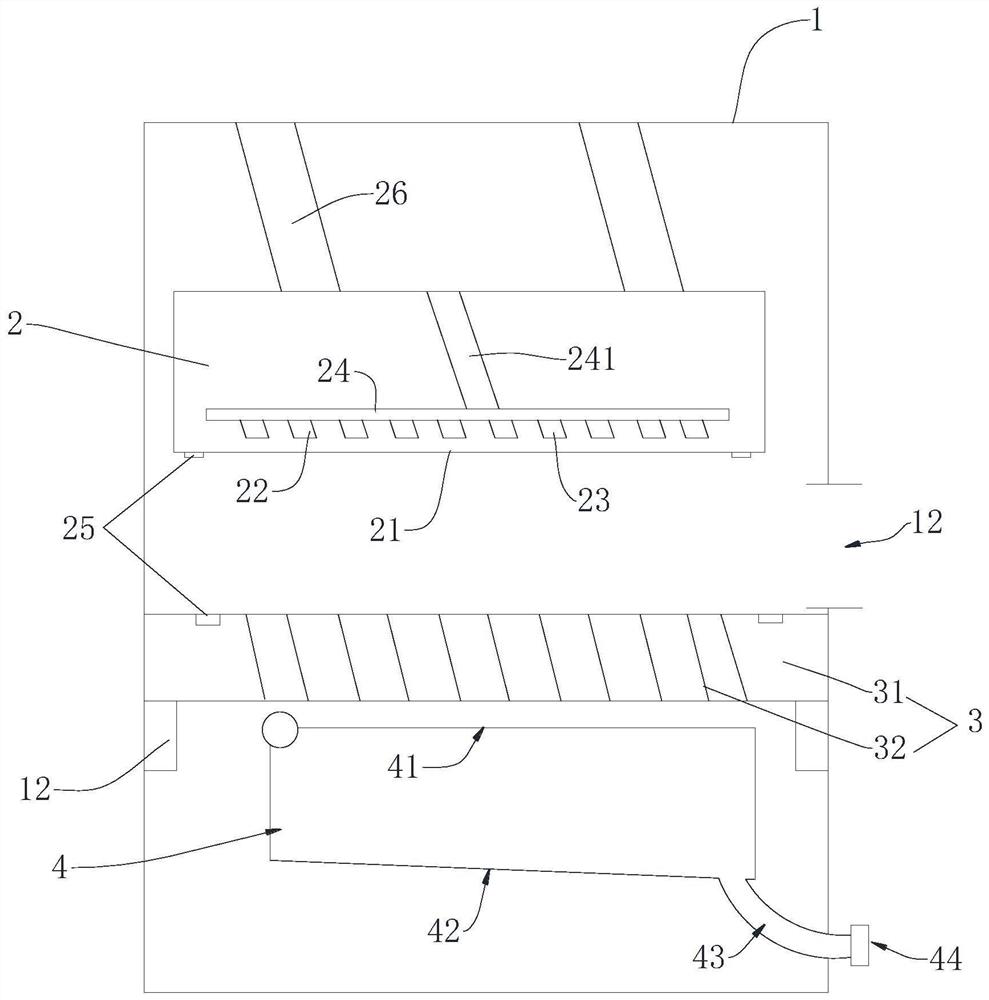

[0049] like image 3 As shown, the difference between this embodiment and Embodiment 1 is that the pressing block assembly 2 also includes:

[0050] The movable unit 22, the movable unit 22 has a first position accommodated in the pressing block assembly 2, and a second position protruding from the pressing block assembly 2 and extending into the grid unit. Utilizing the movable unit 22 embedded in the grid unit can push the paraffin fragments in the grid unit to fall off quickly.

[0051]Wherein, the movable unit 22 is provided with a first heating module 23 , and the movable unit 22 is electrically connected with the pressing block assembly 2 . After the movable unit 22 enters the grid unit, it can also heat the inner wall of the grid unit, so that the paraffin attached to the net knife 3 is melted and flows into the next processing unit.

[0052] In this embodiment, the surface of the pressing block assembly 2 opposite to the frame body 31 is provided with mutually matche...

Embodiment 3

[0055] A wax pattern casting method is characterized in that, comprising:

[0056] Heating tools used to break up paraffin;

[0057] The step of heating the paraffin tool is performed before crushing the paraffin raw material, or the step of heating the paraffin tool is performed simultaneously with the step of crushing the paraffin raw material.

[0058] Further, after the paraffin is crushed, an auxiliary tool is used to assist in heating the tool for crushing the paraffin. Specifically, a plurality of movable units 22 are embedded in the dividing gaps for dividing the paraffin wax plates, and the movable units 22 themselves generate heat for heating and cleaning.

[0059] Further, after the paraffin is crushed, an auxiliary tool is used to dredge the passage where the paraffin fragments fall. The dredging method includes embedding the passage to push the internal residual fragments to move, and / or using a heating tool to extend into the passage for heating.

[0060] The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com