A plastic waste cutting and processing system

A processing system and plastic waste technology, applied in grain processing, plastic recycling, mechanical material recycling, etc., can solve the problem that the blade cannot cut into plastic bottles and plastic air bags, and achieve the effect of improving cutting efficiency and shredding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

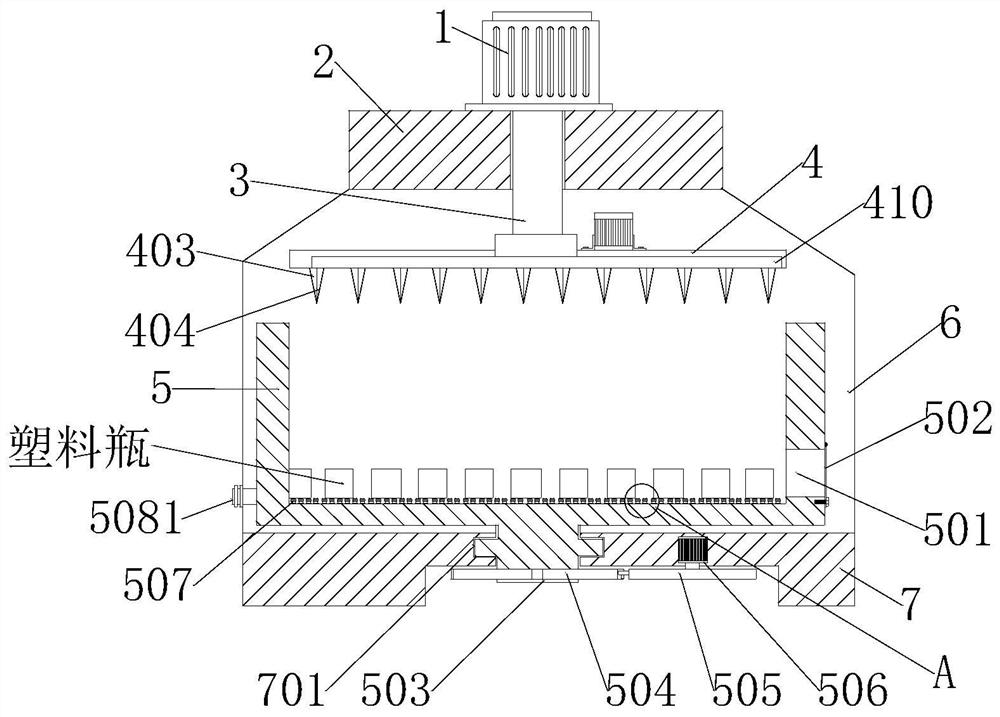

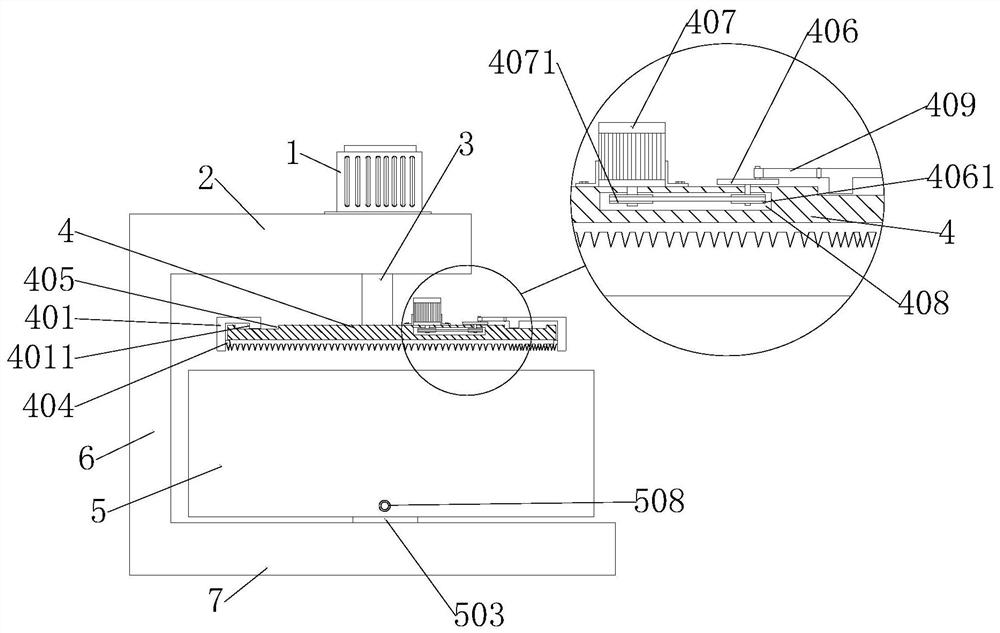

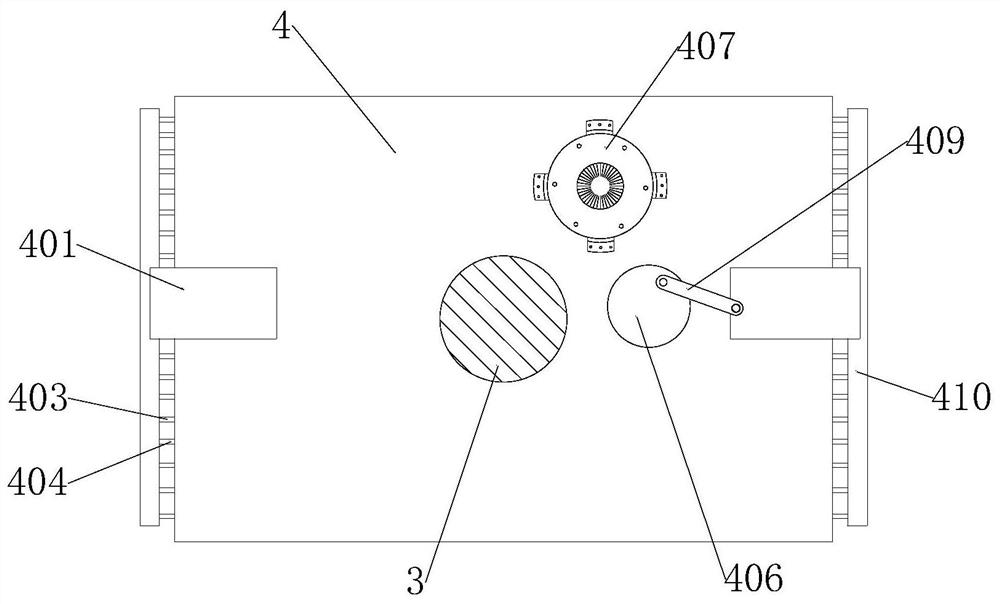

[0037] see Figure 1-7 , is a schematic diagram of the overall structure of a plastic waste slitting and processing system, a plastic waste slitting and processing system, including a base 7, the base 7 is horizontally installed on the ground, and the top of the base 7 is provided with a support plate that is upright and fixed on the top of the base 7 6. The top of the support plate 6 is provided with a horizontal top plate 2, the top of the top plate 2 is installed with a hydraulic cylinder 1, the bottom of the hydraulic cylinder 1 protrudes downwards with a piston rod 3, and the bottom of the piston rod 3 is fixed with a square plate The knife rest 4 of the structure, the knife rest 4 is horizontally fixed on the bottom end of the piston rod 3, and the bottom end of the knife rest 4 is fixed with a plurality of rows of fixed blades 403 equidistantly distributed, and the adjacent two rows of fixed blades 403 are parallel; each row of fixed blades The bottom end of 403 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com