Fracturing process for online continuous preparation based on liquid polymer

A liquid polymer and polymer technology, applied in drilling compositions, chemical instruments and methods, production fluids, etc., can solve the problem of reducing the permeability of proppant packing layers, poor reservoir protection, and expired cross-linking fluids. Deterioration and other problems, to achieve the effect of shortening working time, small friction, and protecting oil reservoirs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

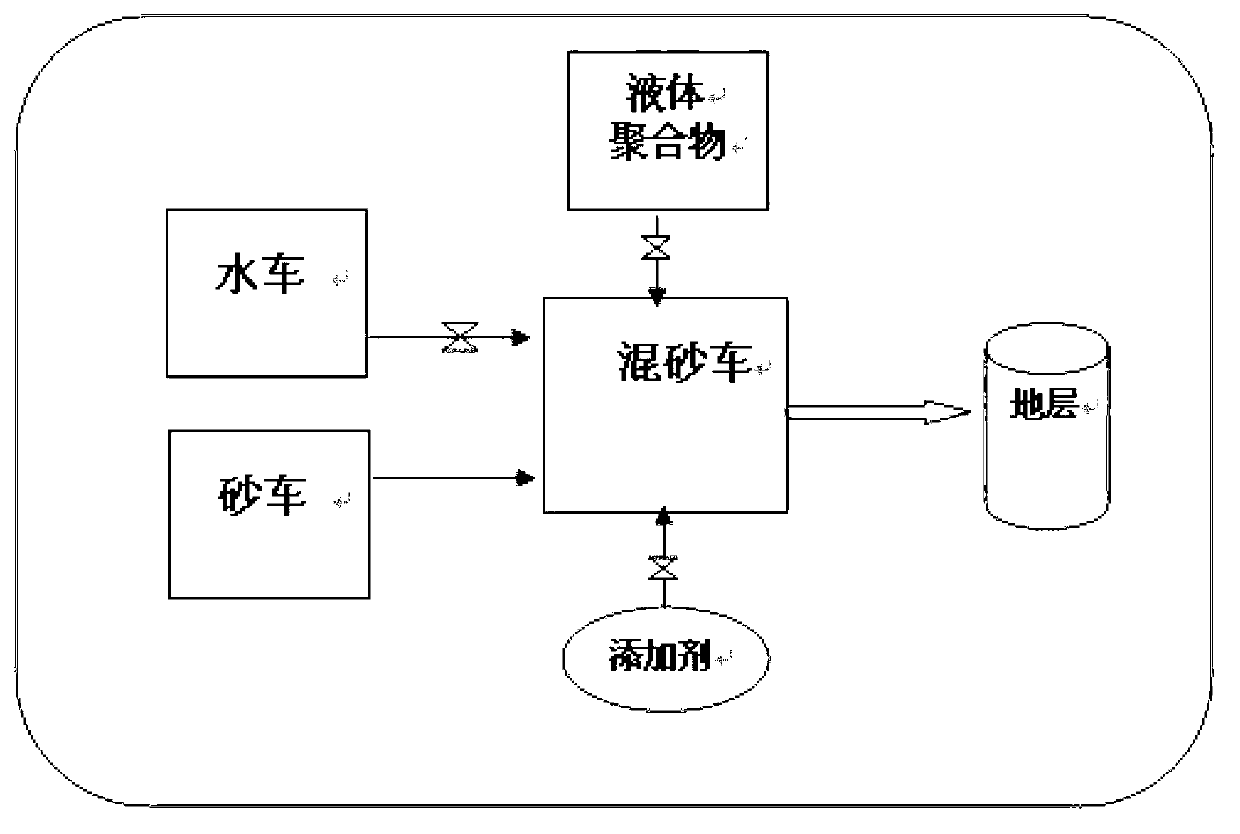

[0040] A fracturing method based on liquid polymer on-line continuous formulation for oil wells, comprising the steps of:

[0041]The polymer used in this example is a polyacrylamide derivative in a synthetic polymer, specifically a chitin graft polymer, which is grafted from chitin and acrylamide, and is a brown emulsion polymer with a molecular weight of 8 million. The solid content is 35%, and the viscosity of the polymer itself is 102mpa.s (ZNN-D6 six-speed viscometer at 170s -1 under test)

[0042] Step 1. Connect the fracturing construction pipeline, test the pressure with clean water, and press open the formation;

[0043] Step 2. Simultaneously use a proportional pump to pump 1 ton (cubic) chitin grafted polymer to the sand mixer, and use the second proportional pump to inject 100 cubic meters of water while the sand mixer is stirring.

[0044] Step 3. Pour 30 cubic meters of proppant at the same time. The proppant is quartz sand with a diameter of 0.425mm. Control t...

Embodiment 2

[0047] A fracturing method based on liquid polymer on-line continuous formulation for oil wells, comprising the steps of:

[0048] The polymer used in this example is a polyacrylamide derivative in a synthetic polymer, specifically a chitin graft polymer, which is grafted from chitin and acrylamide, and is a brown emulsion polymer with a molecular weight of 8 million. The solid content is 35%, and the viscosity of the polymer itself is 102mpa.s (ZNN-D6 six-speed viscometer at 170s -1 under test)

[0049] Step 1. Connect the fracturing construction pipeline, test the pressure with clean water, and press open the formation;

[0050] Step 2. Simultaneously use a proportional pump to pump 1 ton (cubic) of chitin grafted polymer to the sand mixer, and at the same time use the second proportional pump to inject 100 cubic meters of water and 80 kg of additives. The additive is liquid α-olefin Sodium sulfonate,

[0051] Step 3. Pour 30 cubic meters of proppant at the same time. The...

Embodiment 3

[0054] A fracturing method based on liquid polymer on-line continuous formulation for oil wells, comprising the steps of:

[0055] The polymer used in this example is an anionic emulsion polyacrylamide in a synthetic base polymer, a brown emulsion polymer, with a molecular weight of 10 million, a solid content of 35%, and a viscosity of the polymer itself of 99mpa.s (ZNN-D6 six-speed viscometer in the 170s -1 under test)

[0056] Step 1. Connect the fracturing construction pipeline, test the pressure with clean water, and press open the formation;

[0057] Step 2. At the same time, use a proportional pump to pump 1.2 tons (square) of anionic emulsion polyacrylamide to the sand mixer, and use the second proportional pump to inject 100 cubic meters of water while the sand mixer is stirring.

[0058] Step 3. Pour 50 cubic meters of proppant at the same time. The proppant is quartz sand with a diameter of 0.425mm. Control the displacement to ensure that the volume concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com