A micro-vortex generating device with airflow auxiliary control

An auxiliary control and generating device technology, applied in transportation and packaging, through generation of vortex, supersonic aircraft, etc., can solve the problems of narrow applicable working conditions, unsatisfactory control effect, and inability to change the design shape, etc., to achieve extended application Working conditions and the effect of simplifying the structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

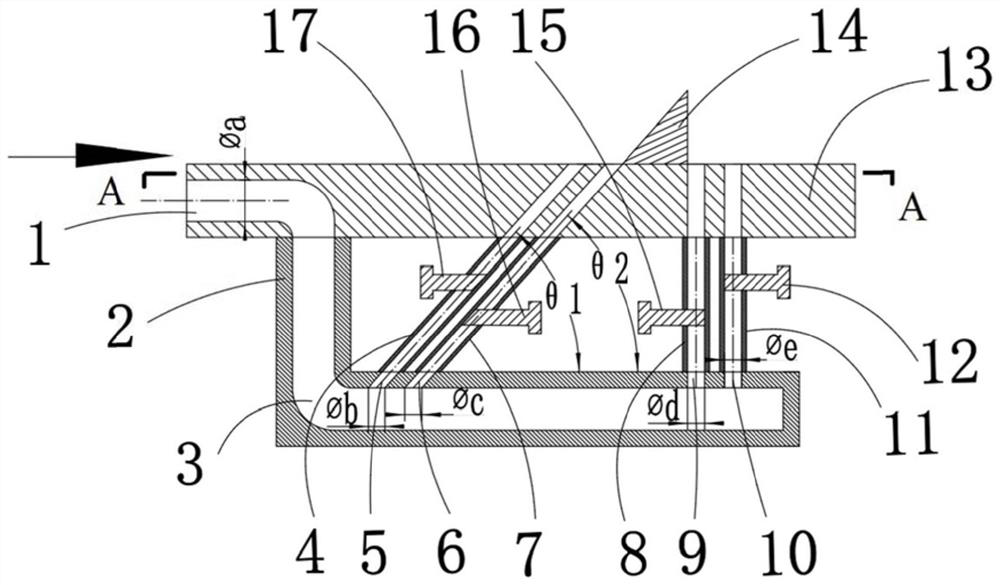

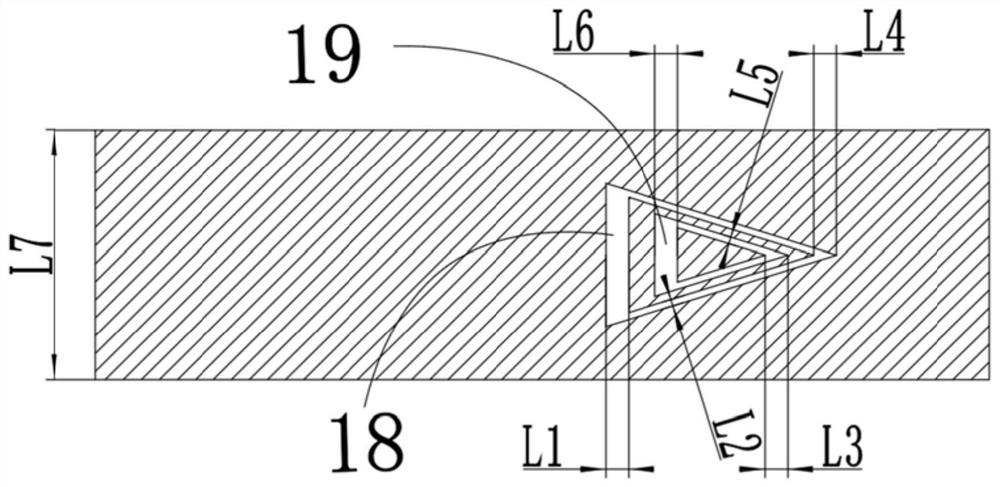

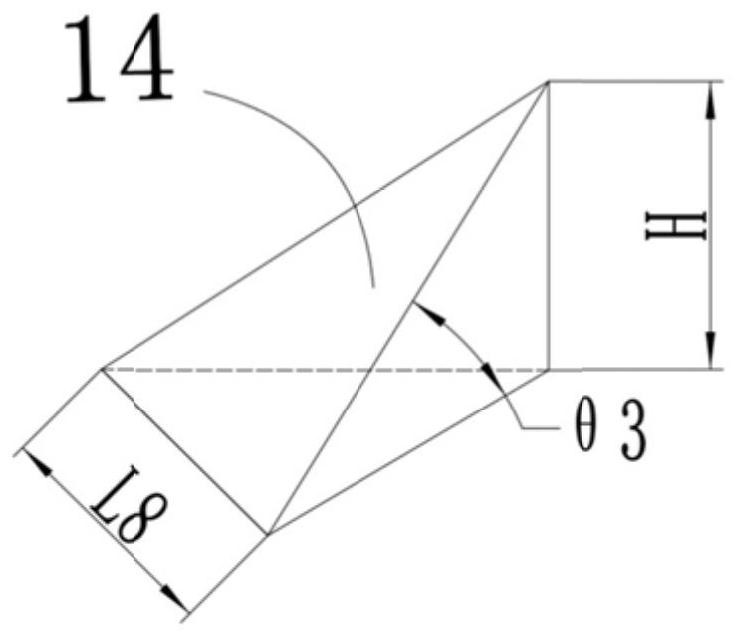

[0022] A micro-vortex generating device with airflow auxiliary control, comprising a high-pressure air supply circuit, an airflow auxiliary control device, a microvortex generator 14, and a supersonic controlled surface 13. An aerodynamic configuration geometrically similar to the micro-vortex generator 14 is formed on the supersonic controlled surface 13, and the aerodynamic configuration is coupled with the micro-vortex generator 14 to enhance the flow control effect.

[0023] Wherein, the high-pressure gas supply circuit includes the gas storage cavity air inlet 1 , the gas storage cavity induction pipe 2 and the gas storage cavity 3 . The auxiliary airflow control device is composed of oblique slot air inlet, oblique slot air guide pipe, solenoid valve and oblique slot. The oblique slot air inlet includes No. Air hole 9, rear air intake hole 10 of the No. 2 oblique seam; the air duct of the oblique seam includes the front air pipe 4 of the No. 2 oblique seam, the front air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com