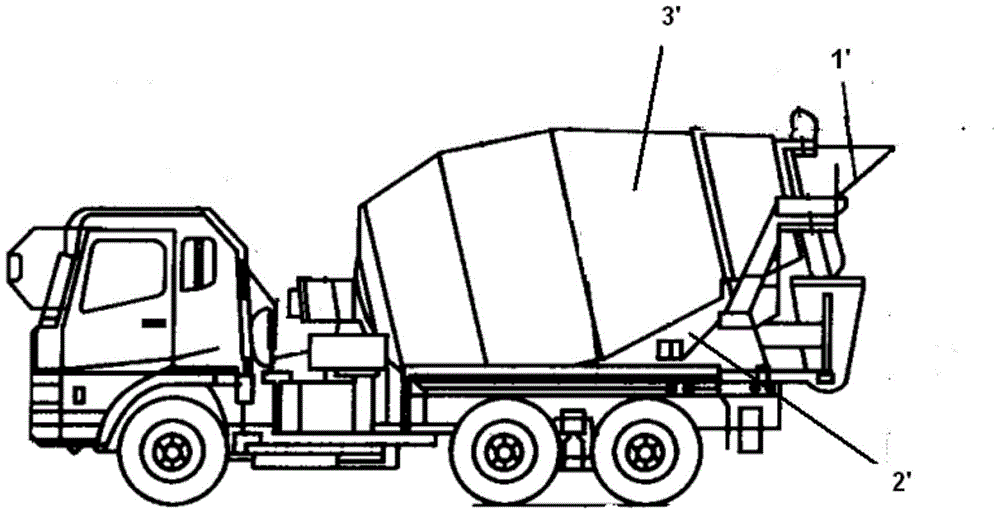

a mixer truck

A technology for mixing transport vehicles and slewing devices, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as cooperative work, limit the scope of use, and reduce the radiation radius of unloading operations. Improve the applicable working conditions and improve the effect of charging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

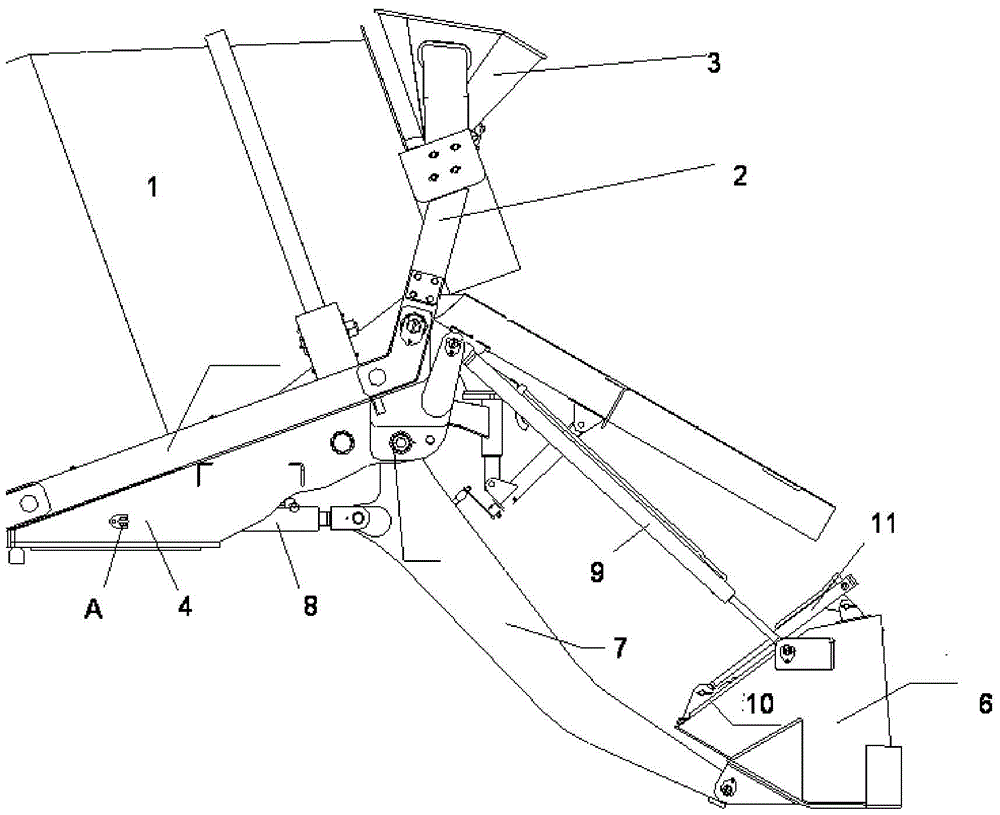

[0038] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

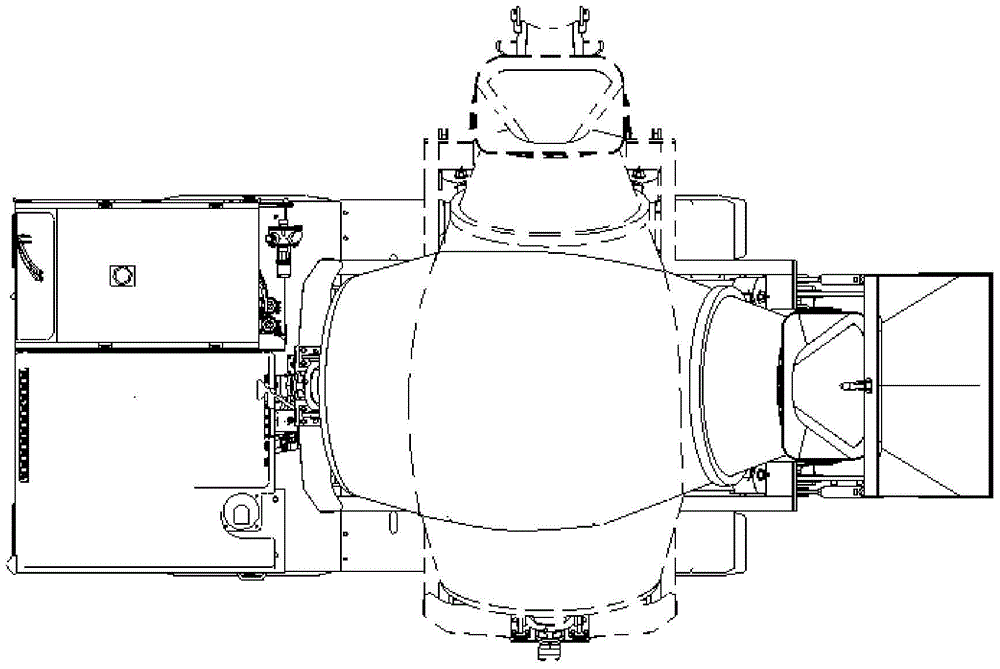

[0039] In a specific embodiment of the present invention, the mixer truck includes a cylinder body 1, a support frame 2 for carrying the cylinder body 1, a feed hopper 3 located at the opening of the cylinder body 1, and further includes:

[0040] Rotary device, the support frame 2 is located on the rotary device, and the rotary device can drive the support frame 2 to rotate; the flip feeding device is hinged to the rotary device for receiving materials and feeding them to the feeding device. Hopper 3 feeding.

[0041] Specifically, such as figure 2 As shown, the turning feeding device of the present embodiment further includes:

[0042] Bucket 6; swing arm 7, one end of which is hinged on the slewing device, and the other end is hinged at the first position of the bucket 6; first oil cylinder 8, one end of which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com