Downhole breaking rock-entering drill of hydraulic slewing drilling machine

A rotary drilling rig and down-the-hole technology, which is applied to drilling equipment, earthwork drilling, and driving devices for drilling in boreholes. Fast response, good anti-rotation effect, fast hole forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

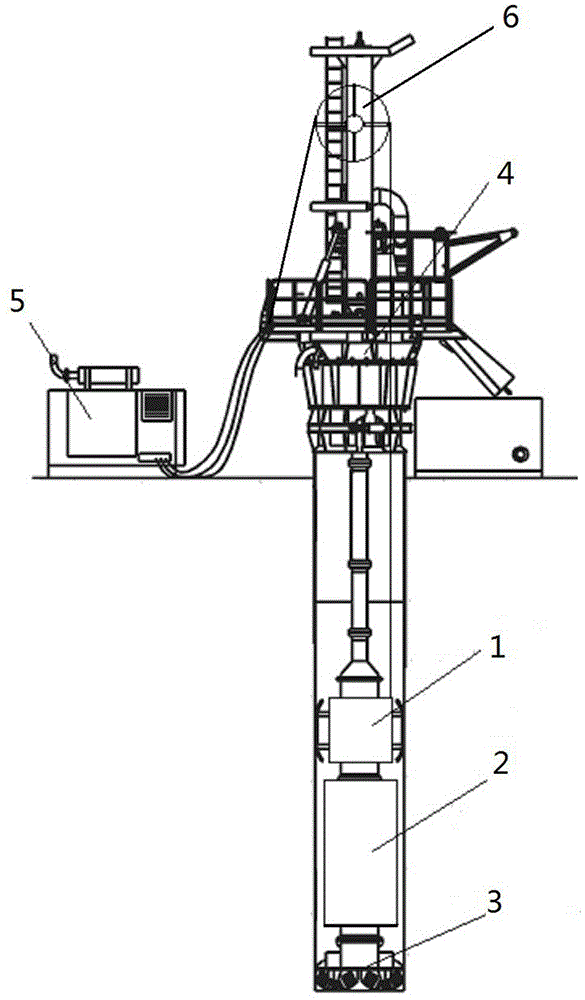

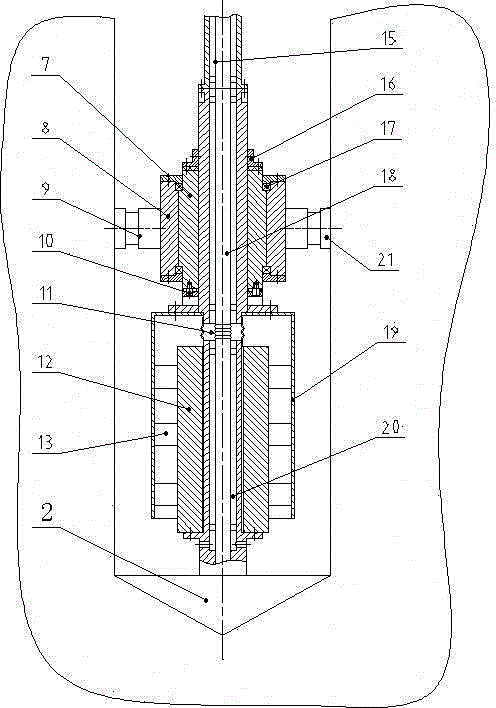

[0013] like figure 1 , 2 As shown, the drill pipe 15 of the rotary drilling rig 4 of the rotary drilling rig of the present invention is equipped with an oil circuit rotary joint assembly 1, and the lower end of the rotary joint assembly 1 is connected with the drill bit 3 through the vibrator 2; Assembly 1 is composed of moving ring 7, static ring 8 and anti-rotation mechanism 9. The rotating joint assembly 1 moving ring 7 is a cylinder with a central through hole, and the moving ring 7 is sleeved on the central shaft 18 through the central through hole; the center The shaft 18 is a transitional drill pipe, the upper end of the central shaft 18 is connected to the drill pipe 15 of the rotary drilling rig through a flange, and the central through hole on the central shaft 18 is connected with the drill slag gas lift channel on the drill pipe 15; the static ring 8 is A cylinder with a central through hole, the static ring 8 is fitted on the outer circumference of the moving ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com