Drill bit wear monitoring method

A drill bit and monitoring point technology, applied in the field of drill bit wear monitoring, can solve the problems of inability to detect small defects, low measurement accuracy, and inability to collect optical signals at the receiving end, so as to improve drilling quality, high measurement accuracy, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

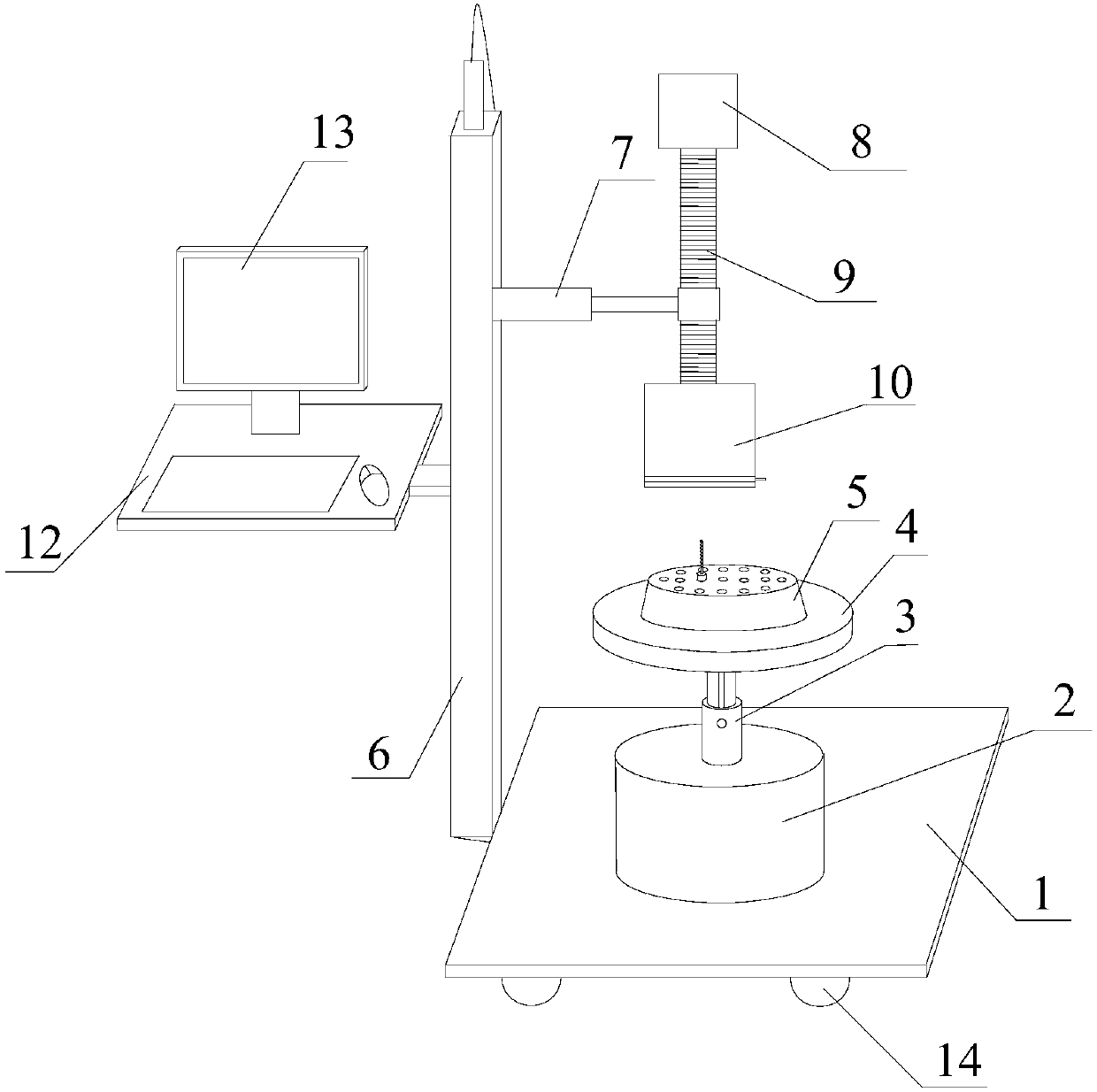

[0027] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

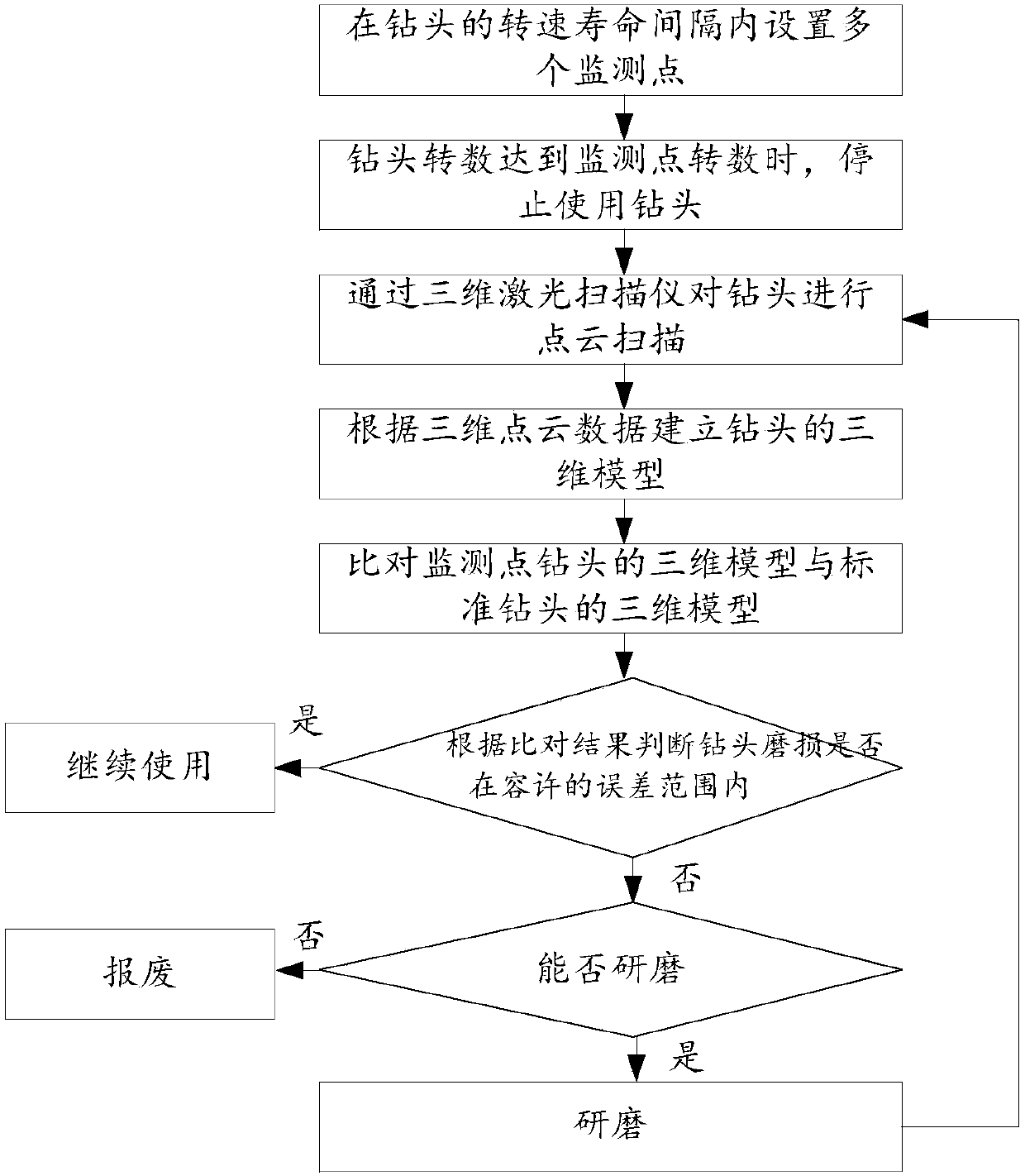

[0028] like figure 1 As shown, a drill bit wear monitoring method provided by an embodiment of the present invention includes the following steps:

[0029] S1. According to the service life of the drill bit provided by the supplier, set multiple monitoring points within the specified drill bit revolution life interval;

[0030] S2. Determine the number of revolutions of the drill bit by the number of revolutions of the motor that drives the drill bit. When the number of revolutions used by the drill bit reaches the number of revolutions at the monitoring point, stop using the drill bit;

[0031] S3. Scan the point cloud of the drill bit at the monitoring point through a three-dimensional laser scanner, and collect the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com